What Is 4×8 Aluminum Sheet?

4×8 aluminum sheet is a common size of aluminum sheet plate, 4 feet wide and 8 feet long, it is considered a standard size aluminum plate, often called 4×8 aluminum sheet;

4×8 aluminum sheet plate is deeply loved by consumers because of its convenient size for production and transportation, as well as for use after purchase;

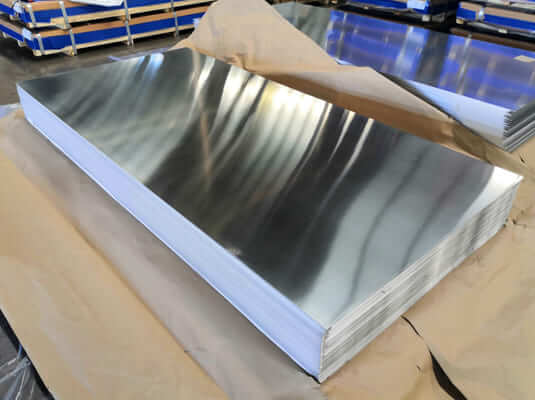

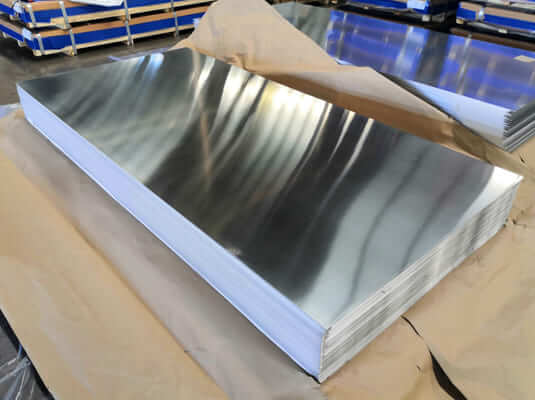

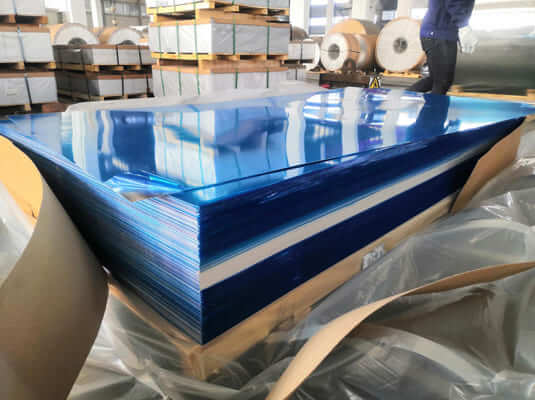

4×8 aluminum sheet plate

4×8 aluminum sheet is widely used, often used in construction, automobile manufacturing, truck box, bus skin, hull skin, Anti-slip ramps and stairs, etc.

Dimension Conversion Of 4×8 Aluminum Sheet Plate

4×8 foot is an imperial unit, and converting it to SI units is:

1 foot(′) = 12 inch(”) = 304.8 mm

4 feet = 1219.2 mm ≈ 1219 mm

8 foot = 2438.4 mm ≈ 2438 mm

In the production of 4×8 aluminum plate, some customers will also set the length and width as 1220x2440mm for convenience, that is, the size of 4×8 aluminum plate can also be roughly considered as 1220x2440mm.

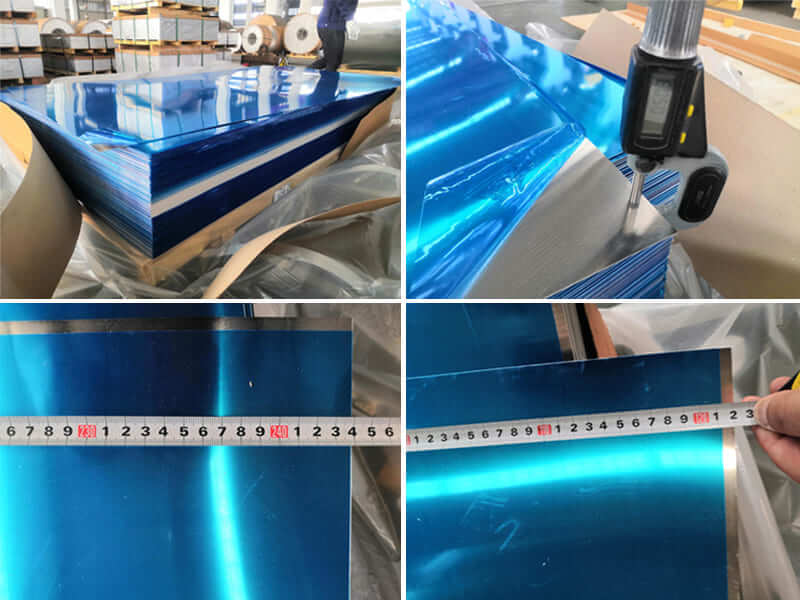

4×8 aluminum sheet measurement

Other Names Of 4′ x 8′ Aluminum Sheet

| aluminum sheeting 4×8 | 4×8 sheet of aluminum | aluminum sheet 4×8 | sheet aluminum 4×8 |

| sheets of aluminum 4×8 | aluminum 4×8 sheet | 4*8 foot aluminum sheet | 4×8 foot aluminum sheet |

| 4′ x 8′ aluminum sheet | 4ft x 8ft aluminum sheet | 4 x 8 foot aluminum sheet | 48 x 96 aluminum sheet |

| 48 x 96 inch aluminum sheet | 48″ x 96″ aluminum sheet | 1219mm × 2438mm aluminum sheet | 1220 x 2440mm aluminum sheet |

What Is Similar To 4×8 Aluminum Sheet

Similar to 4×8 aluminum sheets, other common aluminum sheet sizes are:

- 4×4 aluminum sheet

- 4×8 aluminum sheet

- 4×10 aluminum sheet

- 4×12 aluminum sheet

- 5×10 aluminum sheet

- 5×12 aluminum sheet

- 6×12 aluminum sheet

The above size is the common size of aluminum sheet plate. Huawei Aluminum supports customized aluminum plate size. The width range is 100mm-2600mm, and the length is not limited. It can be produced in the form of coil.

How To Produce 4×8 Aluminum Sheet

The production process of 4×8 aluminum sheet plate is basically the same as that of regular size aluminum plate. The following is the detailed production process of aluminum plate:

Casting

(1) Ingredients: Calculate the addition amount of various alloy components according to the specific alloy grades to be produced, and reasonably match various raw materials.

(2) Smelting: Add the prepared raw materials into the smelting furnace according to the process requirements and heat them to 950°C-1200°C for melting, and effectively remove the impurities and gas in the melt by means of degassing and slag removal refining.

Melting And Casting

The melting point of aluminum is around 660°C

(3) Casting: The smelted aluminum liquid is in a certain casting process, including casting, extrusion and fish on-line, including: oxidation, electrophoretic coating, fluorocarbon spraying, powder coating, grain wood transfer, etc.) three processes.

Aluminum Slab

Rolling

The cast aluminum plate also needs to be processed to obtain better material properties. This process is rolling, also called calendering.

Rolling can be considered as the following two types:

Cold Rolling

Cold rolling refers to the process of compressing and deforming metal billets by rolling force at room temperature to improve their strength, hardness and dimensional accuracy, and to achieve thinning, homogenization and smoothing of metal materials.

Cold rolling can not only realize the thinning of metal materials, but also improve the precision, strength, hardness and surface finish of materials, which is a very important method in metal processing.

Rolling Machine

Cold rolling is processed at room temperature and will not cause thermal effects on metal materials, so precise control of materials can be achieved.

Hot Rolling

Hot rolling is the process of compressing, bending and forming metal sheets or strips at high temperatures to finally obtain metal products with the desired shape and properties.

In the hot rolling process, metal sheet heated to certain temperature, usually above the recrystallization temperature. Then fed into rolling mill where they are rolled several times at high temperatures, gradually forming them into the desired shape and thickness.

During the rolling process, the temperature of the metal sheet or strip is usually kept above 800°C.

The hot rolling process has many advantages, such as high production efficiency, low cost, and high material utilization rate. Therefore, it is widely used in the field of metal processing.

Rolled aluminum and aluminum alloy materials are available in coil form.

Stretching And Straightening

After the 4×8 aluminum sheet is rolled, it still needs further processing to improve its strength and plasticity. Stretching is required here, and the rolled aluminum sheet is put into a stretching machine for processing.

Stretching And Straightening

During the stretching process, attention should be paid to key points such as stretching speed, temperature, and stretching degree to ensure that the mechanical properties of the 4×8 aluminum sheet plate meet the requirements.

Cutting And Surface Treatment

After finishing the anodizing and coating treatment, the aluminum plate needs to be cut and surface treated. Cutting can adopt methods such as laser cutting, water jet cutting or mechanical cutting according to needs.

The cut aluminum plate needs surface treatment to eliminate the burrs and sharp angles left by cutting, and improve the safety and aesthetics of the aluminum plate.

Cutting And Surface Treatment

Surface Treatment Process

Polishing

Polishing treatment refers to polishing the surface of the aluminum plate to a mirror state by mechanical means, which can enhance the decorative effect and reflective performance of the aluminum plate.

Anodizing

Anodizing is the most commonly used method in surface treatment of aluminum sheets. In this method, an aluminum plate is used as an anode, and an oxide film is formed on the surface of the aluminum plate by electrolysis, and the film has high hardness and good corrosion resistance.

Coating Treatment

Powder coating

Powder coating is an advanced and efficient coating process. Its basic principle is to spray plastic powder on the surface of the workpiece and heat it to melt to form a uniform coating.

Coating Treatment Of 4×8 Aluminum Sheet

Powder coating has the following advantages: dense coating, corrosion resistance, wear resistance, rich color and long-lasting color, suitable for coating various metals, plastics, wood and other materials.

Roller Coating

Roller coating is a more traditional method of coating application. It uses a roller to spread the paint evenly on the surface of the workpiece.

The advantage of roller coating is that the construction is simple, fast, and the cost is low, and it is suitable for the coating of large area walls. However, compared with powder spraying, the coating quality of roller coating may not be as good as the former, and the color is not rich enough.

When choosing powder spraying and roller coating, it is necessary to make a trade-off according to specific application scenarios and requirements.

Inspect The Package

After cutting and surface treatment, the final quality inspection of the aluminum sheet is required. Quality inspection includes checking the size, thickness, surface quality and other aspects of the aluminum plate.

Packaging And Shipping

Aluminum sheets that meet the requirements will be packaged and shipped to customers. The main processes of packaging are:

- Sydney paper split aluminum plate

- Moisture-proof film coating

- Carton package

- Packing bandage

- Wooden pallet

The packaged 4×8 aluminum sheets will be shipped to Shanghai or Qingdao port, and sent to the country where the customer is located.

Different Series Of 4×8 Aluminum Sheets

The series of 4×8 aluminum sheets include 1000 series pure aluminum sheets 1000 series aluminum sheet, 3000 series aluminum sheet, 5000 series aluminum sheets, 6000 series aluminum sheets, 7000 series aluminum sheets, and 8000 series aluminum sheets.

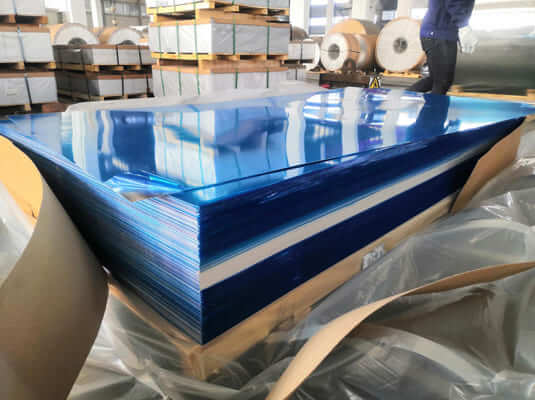

1mm 4×8 aluminum sheet with blue film

The most common aluminum sheet series are 3000 series aluminum sheets, 5000 series aluminum plates and 6000 series aluminum plates.

Common Alloys

- 1050 Aluminum Sheet Plate

- 1060 Pure Aluminum Sheet

- 1100 Aluminum Sheet

- 3003 Aluminum Sheet Plate

- 3004 Aluminum Sheett

- 3104 Aluminum Sheet

- 3105 alloy aluminum sheet

- 5005 alloy aluminum sheet

- 5052 aluminum sheet

- 5454 aluminum sheet

- 5754 alloy aluminum sheet plate

- 6061 aluminum sheet plate

- 6082 aluminum sheet

- 7075 aluminum plate

Thickness Of 4ft x 8ft Aluminum Sheet (Gauge-Inch-MM)

| Alloy | Sheet/Plate | Gauge | Thickness(inch) | Thickness(mm) |

|---|---|---|---|---|

| 1000 series 3000 series 5000 series 6000 series 7000 series |

4×8 aluminum plate | 1 Gauge | 0.289 | 7.348 |

| 2 Gauge | 0.276 | 6.543 | ||

| 4×8 aluminum sheet | 3 Gauge | 0.229 | 5.826 | |

| 4 Gauge | 0.204 | 5.189 | ||

| 5 Gauge | 0.182 | 4.620 | ||

| 6 Gauge | 0.162 | 4.115 | ||

| 7 Gauge | 0.144 | 3.665 | ||

| 8 Gauge | 0.129 | 3.264 | ||

| 9 Gauge | 0.114 | 2.906 | ||

| 10 Gauge | 0.102 | 2.588 | ||

| 11 Gauge | 0.091 | 2.304 | ||

| 12 Gauge | 0.081 | 2.052 | ||

| 13 Gauge | 0.072 | 1.829 | ||

| 14 Gauge | 0.064 | 1.628 | ||

| 15 Gauge | 0.057 | 1.450 | ||

| 16 Gauge | 0.051 | 1.290 | ||

| 17 Gauge | 0.045 | 1.151 | ||

| 18 Gauge | 0.040 | 1.024 | ||

| 19 Gauge | 0.036 | 0.912 | ||

| 20 Gauge | 0.032 | 0.813 | ||

| 21 Gauge | 0.029 | 0.724 | ||

| 22 Gauge | 0.025 | 0.643 | ||

| 23 Gauge | 0.023 | 0.574 | ||

| 24 Gauge | 0.020 | 0.511 |

4×8 Aluminum Sheet Of 1/8 Inch Weight

The formula for calculating the weight of the aluminum sheet is:

weight = volume x density

Notice:

The density of the aluminum sheet is 2.7g/cm³

Foot (ft) 1 foot = 12 inches = 30.48cm = 304.8mm.

Inch (in) 1 inch=2.54cm==25.4mm.

4×8 Aluminum Sheet Of 1/8 Inch Volume

volume = length x width x thickness

4 feet = 1219 mm ≈ 122cm

8 feet = 2438 mm ≈ 244cm

1/8 Inch = 3.175 mm = 0.3175cm

Inserting the formula yields:

Volume = 122cm x 244cm x 0.3175cm ≈ 9451cm³

Weight

4×8 aluminum sheet of 1/8 inch weight is

Weight = 9451cm³ x 2.7g/cm³ = 25517.7g ≈ 2.55kg

What Can We Supply About 4×8 Aluminum Sheet

- Anodized 4×8 aluminum sheet

- Powder coated 4×8 aluminum sheets

- 4×8 perforated aluminum plate

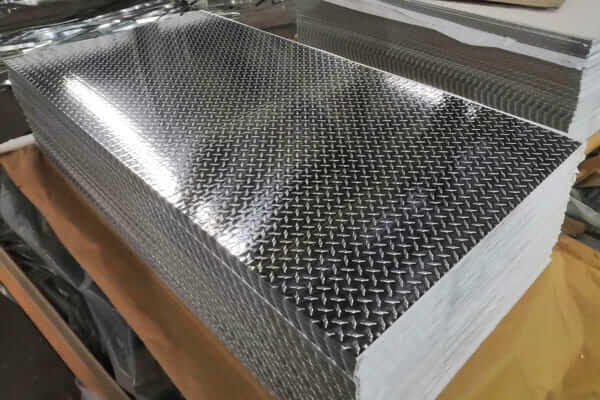

- 4×8 embossed aluminum sheet

- 4×8 brushed aluminum sheet

- 4×8 colored aluminum sheet

- 4×8 aluminum checker plate

- 4×8 sheet aluminum diamond plate

- black aluminum diamond plate 4×8 sheet

4×8 sheet aluminum diamond plate

4′ x 8′ Aluminum Sheet Typical Usage

4×8 aluminum sheet is a standard size aluminum sheet that is very versatile. Due to aluminum’s light weight, corrosion resistance, and ease of processing, 4×8 aluminum panels have an important role in many industries and applications.

Here are some typical uses:

Construction and architectural decoration: 4×8 aluminum panels are used in building exterior walls, roofs, facade panels, ceilings, window frames, doors and other parts. They can be coated, anodized or colored as required for enhanced decorative effect and weather resistance.

4×8 aluminum sheet for building

Transportation: 4×8 aluminum panels are used to make truck beds, trailers, container trucks and ships. Aluminum’s lightweight properties help reduce overall vehicle weight and improve fuel efficiency.

Boat use aluminum sheet

Aerospace: In aerospace, 4×8 aluminum sheets are used to make aircraft fuselages, wings, interior trim, and other structural components. Aluminum’s high strength and light weight contribute to improved flight performance.

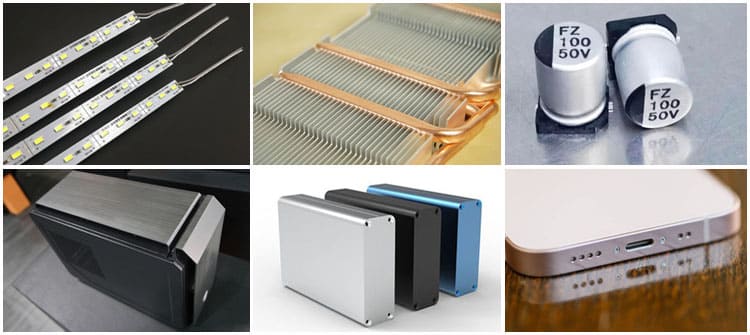

Electronics: 4×8 aluminum sheets are used in the electronics industry to make components such as computer cases, electronic device casings, and heat sinks to provide effective heat dissipation.

Traffic Signs: Traffic signs, road signs, and signs are often made from 4×8 aluminum sheets because they are weather and corrosion resistant for outdoor use.

Interior decoration: Aluminum panels can be used for interior decoration, such as wall panels, suspended ceilings, stair railings and furniture.

Machinery manufacturing industry: 4×8 aluminum sheets can be used in various manufacturing industries, such as manufacturing molds, fixtures, machine equipment parts, etc.

Food & Beverage Packaging: Due to the corrosion resistance and food safety of aluminum, 4×8 aluminum sheets are also widely used in food cans, beverage cans, and other food packaging.

Determinants Of 4×8 Aluminum Sheet Plate Price

- 1. Aluminum raw material price

- 2. RMB to USD/EUR exchange rate

- 3. Processing cost of aluminum sheet plate production

- 4. Packaging and transportation costs

Paying attention to the price of the above four factors can calculate the approximate price of imported aluminum sheets from China.

4×8 Aluminum Sheet Manufacturer Near Me

As an important base of the global manufacturing industry, China has many excellent aluminum sheet manufacturers.

China’s 4×8 aluminum sheet manufacturer stands out and becomes a leader in the industry with its excellent quality, professional production technology and considerate service.

4×8 foot aluminum sheet packaged

As an aluminum plate manufacturer with profound historical background, Huawei Aluminum always adheres to the business philosophy of taking quality as the foundation and customer as the center.

Since our establishment, we have been committed to improving production technology and product quality to meet the ever-changing market demand. At present, our products are exported to 72 countries around the world.

Countries We Export To

| Continents | countries |

|---|---|

| Asia | Vietnam, Thailand, Korea, Indonesia, United Arab Emirates, India, Malaysia,Bangladesh, Saudi Arabia, Uzbekistan, Philippines,China Taiwan, Egypt, Singapore, Pakistan, Israel, Qatar, Jordan, Iran, China Hong Kong, Oman, Iraq, Brunei, Algeria, etc. |

| South America | Mexico, Colombia, Peru, Brazil, Ecuador, Argentina, Bolivia, etc. |

| Europe | Turkey, France, Italy, U.K., Poland, Hungary, Norway, Belgium, Czech, Romania, Ukraine, Russia, Germany, Netherlands, etc. |

| North America | Dominican, El Salvador, U.S., Canada, etc. |

| Africa | Ghana, Nigeria, South Africa, Tunisia, Djibouti, Kenya, Morocco, Ethiopia, Gabon, Tanzania, Mozambique, etc. |

| Oceania | Australia, New Zealand, etc. |

Casting production process and its introduction

The purpose of melting and casting is to produce alloys with satisfactory composition and high purity of melt, so as to create favorable conditions for casting alloys of various shapes.

Melting and casting process steps: batching --- feeding --- melting --- stirring after melting, slag removal --- pre-analysis sampling --- adding alloy to adjust the composition, stirring --- refining --- static Setting——Guide furnace casting.

Hot rolling production process and its introduction

- 1. Hot rolling generally refers to rolling above the metal recrystallization temperature;

- 2. During the hot rolling process, the metal has both hardening and softening processes. Due to the influence of deformation speed, as long as the recovery and recrystallization process is too late, there will be a certain work hardening;

- 3. The recrystallization of the metal after hot rolling is incomplete, that is, the coexistence of recrystallized structure and deformed structure;

- 4. Hot rolling can improve the processing performance of metals and alloys, reduce or eliminate casting defects.

- 1. The casting and rolling temperature is generally between 680°C and 700°C. The lower the better, the stable casting and rolling line usually stops once a month or more to re-stand. During the production process, it is necessary to strictly control the liquid level of the front tank to prevent low liquid level;

- 2. Lubrication uses C powder with incomplete combustion of gas for lubrication, which is also one of the reasons for the dirty surface of casting and rolling materials;

- 3. The production speed is generally between 1.5m/min-2.5m/min;

- 4. The surface quality of products produced by casting and rolling is generally relatively low, and generally cannot meet products with special physical and chemical performance requirements.

- 1. Cold rolling refers to the rolling production method below the recrystallization temperature;

- 2. There will be no dynamic recrystallization during the rolling process, and the temperature will rise to the recovery temperature at most, and the cold rolling will appear in a work hardening state, and the work hardening rate will be large;

- 3. The cold-rolled sheet and strip have high dimensional accuracy, good surface quality, uniform structure and performance, and products in various states can be obtained with heat treatment;

- 4. Cold rolling can roll out thin strips, but at the same time, it has the disadvantages of high energy consumption for deformation and many processing passes.

- 1. Finishing is a processing method to make the cold-rolled sheet meet the customer's requirements, or to facilitate the subsequent processing of the product;

- 2. The finishing equipment can correct the defects produced in the hot rolling and cold rolling production process, such as cracked edge, oily, poor plate shape, residual stress, etc. It needs to ensure that no other defects are brought into the production process;

- 3. There are various finishing equipments, mainly including cross-cutting, slitting, stretching and straightening, annealing furnace, slitter, etc.

Casting and rolling process

Casting and rolling process: liquid metal, front box (liquid level control), casting and rolling machine (lubrication system, cooling water), shearing machine, coiling machine.

Cold rolling production process

Introduction to finishing production process

Aluminum alloy has the characteristics of low density, good mechanical properties, good processing performance, non-toxic, easy to recycle, excellent electrical conductivity, heat transfer and corrosion resistance, so it has a wide range of applications.

Aerospace: used to make aircraft skins, fuselage frames, girders, rotors, propellers, fuel tanks, wall panels and landing gear struts, as well as rocket forging rings, spacecraft wall panels, etc.

Aluminum alloy used for aerospace

Transportation: used for car body structure materials of automobiles, subway vehicles, railway passenger cars, high-speed passenger cars, doors and windows, shelves, automotive engine parts, air conditioners, radiators, body panels, wheels and ship materials.

Traffic application

Packaging: All-aluminum pop cans are mainly used as metal packaging materials in the form of thin plates and foils, and are made into cans, lids, bottles, barrels, and packaging foils. Widely used in the packaging of beverages, food, cosmetics, medicines, cigarettes, industrial products, medicines, etc.

Packaging application

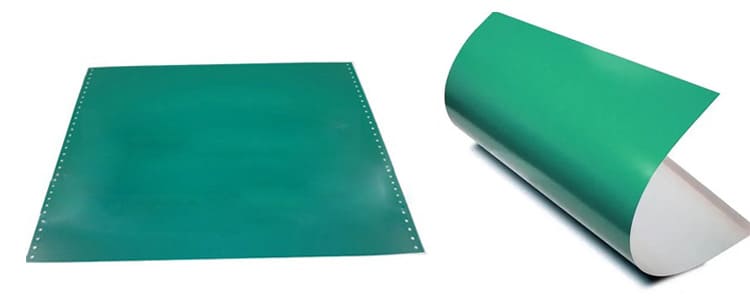

Printing: Mainly used to make PS plates, aluminum-based PS plates are a new type of material in the printing industry, used for automatic plate making and printing.

PS printing

Architectural decoration: aluminum alloy is widely used in building structures, doors and windows, suspended ceilings, decorative surfaces, etc. due to its good corrosion resistance, sufficient strength, excellent process performance and welding performance.

Aluminum alloy construction application

Electronic products: computers, mobile phones, refrigerator shells, radiators, etc.

Electronic product application

Kitchen supplies: aluminum pots, aluminum basins, rice cooker liners, household aluminum foil, etc.

Kitchen application

Packaging Of Aluminum Sheet/Coil

Every detail of packaging is where we pursue perfect service. Our packaging process as a whole is as follows:

Lamination: clear film, blue film, micro-mucosal, high-mucosal, laser cutting film (2 brands, Novacell and Polyphem);

Protection: paper corner protectors, anti-pressure pads;

drying: desiccant;

Tray: fumigated harmless wooden tray, reusable iron tray;

Packing: Tic-tac-toe steel belt, or PVC packing belt;

Material Quality: Completely free from defects such as white rust, oil spots, rolling marks, edge damage, bends, dents, holes, break lines, scratches, etc., no coil set.

Port: Qingdao or other ports in China.

Lead time: 15-45 days.

Aluminum sheet/plate packaging process

Aluminum coil packaging process

F: Are you a manufacturer or a trader?

Q: We are a manufacturer, our factory is at No.3 Weier Road, Industrial Zone, Gongyi, Henan, China.

F: What is the MOQ for ordering the product?

Q: Our MOQ is 5 tons, and some special products will have a minimum order quantity of 1 or 2 tons.

F: How long is your lead time?

Q: Generally our lead time is about 30 days.

F: Do your products have quality assurance?

Q: Yes, if there is a quality problem with our products, we will compensate the customer until they are satisfied.

Related Products

Latest Blogs

Aluminum foil vs tin foil

Aluminum foil and tin foil are two common metal sheet materials. They are similar in appearance, both have a silver-white metallic luster, and are often used in daily life to wrap food, perform baking or grilling and other cooking operations.

7075 t651 aluminum material properties

7075 aluminum alloy is a high-strength aluminum alloy. It belongs to the Al-Zn-Mg-Cu alloy series and is a representative product of the 7000 series aluminum alloy.

Physical and Chemical Properties of Aluminum and aluminum alloys

Although aluminum and aluminum alloys both use aluminum as the main synthetic element, they have great differences in certain physical and chemical properties.

The development history of aluminum and aluminum alloys

Aluminum is named after the Latin word "alumen", which means "bitter earth" or "alum". The name was first proposed by Swedish chemist Jons Jakob Berzelius around 1825 to describe the properties of this metal oxide.