7075 t651 aluminum material properties

1311 Views 2024-04-20 06:54:44

What is 7075 t651 aluminum?

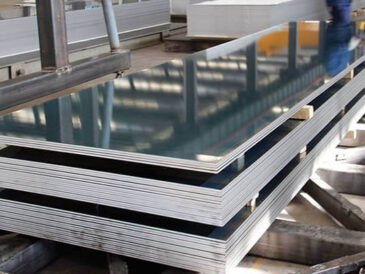

7075 aluminum alloy is a high-strength aluminum alloy. It belongs to the Al-Zn-Mg-Cu alloy series and is a representative product of the 7000 series aluminum alloy. It is widely used in high-end manufacturing, especially aviation and aviation, because of its excellent mechanical properties. defense industry.

7075 t651 aluminum material properties

7075 aluminum alloy is one of the aluminum alloys that can be heat treated. T651 is one of the heat treatment states of 7075 aluminum alloy.

T6: This is a heat treatment process, including two steps: solution treatment and artificial aging. First, the material is heated to a high enough temperature to fully dissolve the internal alloy elements in the aluminum matrix to form a single-phase solid solution, and then rapidly cooled (usually using water cooling) to make it supersaturated solid solution, and then artificially aged at room temperature. Precipitation hardening occurs inside the metal, thereby greatly improving the strength and hardness of the material.

T651: This represents a special refinement process known as ultra-deep drawing. After completing the T6 heat treatment, the 7075 aluminum alloy material undergoes at least 1% pre-stretching deformation. This process can further improve the mechanical properties of the material, especially the fatigue strength, and can reduce or eliminate the internal stress caused by heat treatment, reducing Small material dimensional changes, improved dimensional stability.

7075 t651 aluminum material properties

7075 aluminum alloy is a commonly used high-strength aluminum alloy that is often used to make parts that require high strength in aerospace and high-performance applications. T651 is a heat-treated state of 7075 alloy with good mechanical properties and tensile strength.

The following are the characteristics of 7075 T651 aluminum:

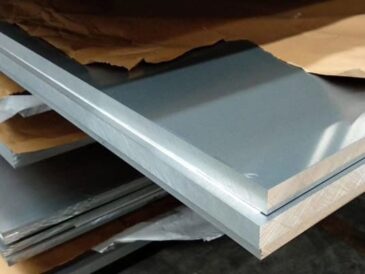

- High strength: 7075 alloy has high tensile strength in the T651 temper, typically exceeding 500 MPa.

- Excellent corrosion resistance: 7075 alloy has good corrosion resistance, especially good resistance to oxidizing media and chloride corrosion.

- Good processability: Despite its excellent strength, 7075 alloy still has good processability and can be processed by cutting, forming and welding.

- Higher Cost: Due to its high strength and excellent properties, 7075 alloy is generally more expensive than general aluminum alloys.

- Lightweight Design: Due to the lightweight properties of aluminum, 7075 alloy is used in lightweight designs in aerospace and other fields to improve efficiency and performance.

7075 t651 aluminum physical properties

Mechanical properties:

- Tensile strength (UTS): A typical value is around 572 MPa, which indicates the maximum stress a material can withstand when stretched.

- Yield strength (YS): Typical value is about 503 MPa, indicating the stress level when the material begins to undergo plastic deformation.

- Elongation (EL): Approximately between 11% and 15%, reflecting the extent to which a material can withstand tensile deformation before breaking.

Thermal performance:

- Coefficient of thermal expansion (CTE): approximately 23.6 μm/m·K (or 68×10⁻⁶ m³·K⁻¹), indicating the slight expansion amount per unit length of the material as the temperature increases by 1 degree Celsius.

- Melting point range: usually between 475 and 635°C.

Electrical properties:

- Electrical conductivity (20°C): approximately 33% IACS (International Annealed Copper Standard), which reflects the conductive properties of the material.

- Resistivity (20℃): The specific value is not given, but it can be calculated based on the conductivity.

Other properties:

- Density: approximately 2.8 g/cm³, which is the general density range of aluminum alloys, and the specific values may vary.

- Hardness: 7075 T651 aluminum alloy has a high hardness after T651 heat treatment, usually around HB130.

7075 t651 aluminum applications

7075 t651 aluminum application

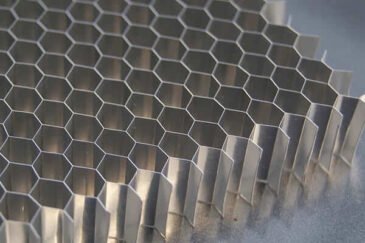

- Aerospace: 7075 T651 aluminum alloy is commonly used in aircraft structures, such as wings, fuselages and landing gear components. Its high strength and light weight help reduce aircraft weight and improve fuel efficiency.

- Automobile industry: In automobile manufacturing, 7075 T651 aluminum alloy is usually used to manufacture parts for racing cars, high-performance cars and motorcycles, such as wheels, suspension systems and frames, etc., to improve vehicle performance and save fuel.

- Sports equipment: Due to the high strength and lightweight properties of 7075 T651 aluminum alloy, it is often used to manufacture sports equipment such as hiking poles, bicycle parts, and arrow shafts to improve its durability and performance.

- Military and defense: 7075 T651 aluminum alloy is also widely used in the military and defense fields, used to manufacture weapons, armored vehicles and ships, etc., to meet the demand for high strength and lightweight.

- Industrial machinery: 7075 T651 aluminum alloy is often used to manufacture structural components of industrial machinery and equipment, such as pressure vessels, pump bodies and valves, etc., playing an important role in improving equipment performance and reducing maintenance costs.