Aluminum foil vs tin foil

1296 Views 2024-04-23 07:57:45

Aluminum foil vs tin foil

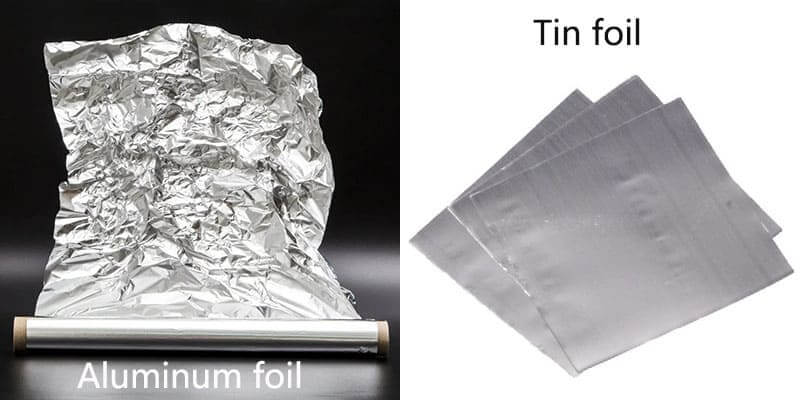

Aluminum foil and tin foil are two common metal sheet materials. They are similar in appearance, both have a silver-white metallic luster, and are often used in daily life to wrap food, perform baking or grilling and other cooking operations. Although they are used interchangeably for some purposes, there are significant differences between them.

Aluminum foil vs tin foil

Definition of aluminum foil vs tin foil

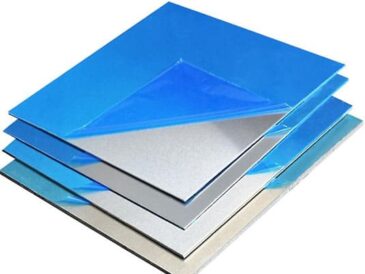

Aluminum foil: Aluminum foil is made of pure aluminum or aluminum alloy. The thickness is generally between 0.006-0.2mm. It is similar to paper, soft and malleable, ensuring sunshade, no falling, no light transmission, no pollution, and the price Cheap.

Tin foil: Tin foil is an alloy of tin and aluminum, which is also obtained by rolling. The color of tin foil is silvery white, and the ashes are golden yellow after burning. It conducts electricity and heat very well. It can also be made into a lampshade to increase the brightness of the lamp. The insulation of tin foil is very good, and the tin foil has good finish and heat reflectivity.

Aluminum foil vs tin foil in Performance and applications

Materials and ingredients

Aluminum foil: Mainly made of pure aluminum or aluminum alloy through rolling process, does not contain other metal elements, and the thickness is usually less than 0.025mm.

Tin Foil: Made of pure tin or tin-aluminum alloy and may contain tin and other alloy components. Traditionally, real tin foil is a pure tin product, but now the so-called “tinfoil” on the market often refers to aluminum products.

Melting point and heat resistance

Aluminum foil: has a higher melting point of 660°C, suitable for high-temperature cooking such as barbecue, and can withstand higher heat without melting easily.

Tin foil: The melting point is lower, only 231.89°C, which means that under high-temperature cooking conditions, tin foil is more likely to melt and is not suitable for direct use on barbecues or high-temperature baking.

Physical properties

Aluminum foil: It has good ductility and toughness, is easy to shape, is relatively stiff and not easy to break when cutting.

Tin foil: Although it has good gloss, it has poor ductility, is brittle, and easily breaks when pulled.

Corrosion resistance

Aluminum foil: It easily reacts with oxygen in a humid environment to form a dense aluminum oxide protective layer. This oxide film has certain corrosion resistance, but it may still be further corroded in an acidic or alkaline environment.

Tin foil: Tin itself has good corrosion resistance, is not easy to oxidize and discolor, and is more stable especially in dry environments.

Safety and health

Aluminum foil: It is safe as a food contact material, but long-term ingestion of large amounts of aluminum may pose potential health risks. Although aluminum migration from aluminum foil is extremely low during normal use, it is wise to avoid prolonged high temperature exposure to acidic foods or baking in direct contact with foods.

Tin foil: Pure tin is non-toxic and has sterilization, purification, and preservation effects. It was historically used to prevent the formation of toxic patina on the surface of copperware. However, the description of “tinfoil” mentions that it contains aluminum, and if this is the case, the health risks associated with aluminum should be considered. In addition, the statement that eating aluminum foil may cause Alzheimer’s disease lacks scientific basis and has not been found in authoritative information.

Price and Application

Aluminum foil: Due to abundant aluminum resources and low processing costs, aluminum foil is relatively affordable and widely used in various food packaging, baking, barbecue, electromagnetic shielding and other fields.

Tin foil: As a precious metal, pure tin foil is more expensive and is mainly used in specific occasions such as high-end product packaging and traditional handicraft production. “Tin foil” on the modern market actually refers to aluminum products, which are relatively low-priced. However, if they really contain 50% lead, there may be safety hazards and should be selected with caution.

Summarize

Since the content of aluminum in nature is higher than that of tin, and with the development of aluminum purification and processing technology, the price of aluminum and aluminum alloys is much lower than that of tin. Therefore, aluminum foil paper is more widely used than tin foil. If you ignore Price and cost factors mean that the applications of the two can be substituted for each other to a certain extent.