The development history of aluminum and aluminum alloys

1257 Views 2024-04-12 08:23:00

Source of aluminum

Aluminum is named after the Latin word “alumen”, which means “bitter earth” or “alum”. The name was first proposed by Swedish chemist Jons Jakob Berzelius around 1825 to describe the properties of this metal oxide. Later, when Hans Christian Ersted successfully extracted the metal aluminum, he suggested naming the newly discovered metal “aluminium”, a name that was widely accepted in Britain and other countries.

Aluminum ore

However, in the United States, people preferred to call it “aluminum”, and this spelling eventually became widely used in the United States and Canada and became the international standard. Therefore, today we usually call it “aluminum” in English.

The development history of aluminum and aluminum alloys

In 1746, German scientist Porter used alum to prepare alumina.

In 1807, the British master and apprentice David failed to electrolyze molten alumina to obtain metallic aluminum.

In 1809, David named the envisioned metal Alumium, which was later changed to Aluminum.

In 1825, Danish scientist Osler used potassium to reduce aluminum oxide to obtain a small amount of metallic aluminum.

Alum

In 1854, French scientist Deville used sodium to reduce NaALCL4 complex salt, and built a factory to produce some aluminum helmets, tableware and toys, which were expensive and equivalent to gold.

In 1886, American inventor Charles Martin Hall and French engineer Paul-Louis Taubet independently invented a method for electrolytic extraction of pure aluminum at almost the same time, called the “Hall-Tauppet process”. This greatly reduces the production cost of aluminum and makes aluminum a widely used metal.

In 1888, the first electrolytic aluminum plant was established in Pittsburgh, USA, and aluminum production entered a new stage.

The invention of the Bayer process to produce alumina from bauxite in 1888 and the advancement of direct current electrolysis technology laid the foundation for the development of aluminum production on an industrial scale.

By the end of the 19th century, the production cost of aluminum began to decline significantly, and aluminum itself had become a common and commonly used metal.

In the early 20th century, in addition to daily necessities, aluminum was mainly used in the transportation industry.

In 1901, aluminum plates were used to manufacture automobile bodies.

In 1903, Alcoa supplied aluminum parts to the Wright brothers to build small airplanes. Automobile engines began to use aluminum alloy castings, and the shipbuilding industry also began to use aluminum alloy thick plates, profiles and castings. With the increase in aluminum production and the advancement of science and technology, aluminum has been used in other industrial sectors (such as medical equipment, aluminum printing plates and steelmaking). The use of deoxidizers, packaging containers, etc.) is also becoming more and more widespread, which has greatly stimulated the development of the aluminum industry.

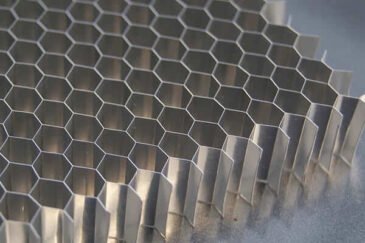

German A. Wilm invented duralumin alloy (Al-Cu-Mg alloy) in 1906, which tripled the strength of aluminum and was widely used in aircraft manufacturing and other arms industries during World War I. Since then, aluminum alloys with different compositions and heat treatment states, such as Al-Mn, Al-Mg, Al-Mg-Si, Al-Cu-Mg, Al-Zn-Ma, etc. have been developed. These alloys have different characteristics and functions, greatly The use of aluminum has been expanded, and the application of aluminum in industrial sectors such as construction, automobiles, railways, ships and aircraft manufacturing has been rapidly developed.

The development history of aluminum and aluminum alloys

During the Second World War, the aluminum industry achieved rapid growth under the strong stimulation of the military industry. In 1943, the total output of primary aluminum soared to 2 million tons. After the war, due to the sharp drop in military demand, the total output of primary aluminum dropped to 1 million tons in 1945. However, as major aluminum companies actively developed new civilian products, the application of aluminum materials was gradually extended to instrumentation, electronic and electrical transportation, Various fields such as daily hardware and food packaging have increased the demand for aluminum year by year. In 1956, world aluminum production surpassed copper, ranking first among nonferrous metals.

By the early 1980s, the world’s primary aluminum production had exceeded 16 million tons, and secondary aluminum consumption reached 4.5 million tons. The production scale and production technology level of the aluminum industry had reached a very high level.

With the continuous advancement of science and technology, the application fields of aluminum continue to expand and innovate. For example, aluminum alloys are widely used in the aerospace industry, as well as in electrolytic capacitors, solar panels and electric vehicles.

Overall, aluminum has experienced a transformation from a rare metal to a wide range of applications over the past two centuries. Its cost reduction and performance improvement have made it an important material that plays an important role in modern industry and life. effect.

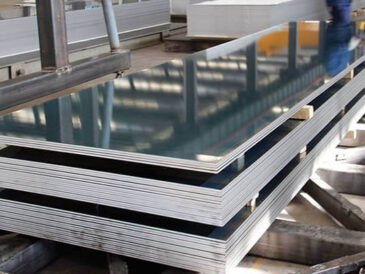

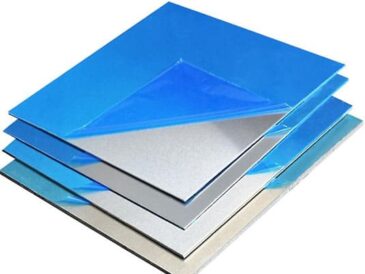

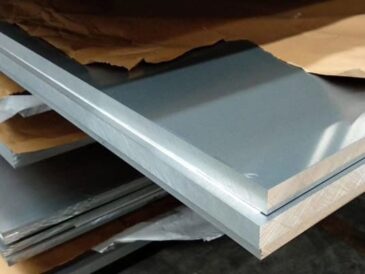

Aluminum alloy products we can provide

As a supplier of high-quality aluminum products in China, Huawei Aluminum has long-term supply of aluminum plates/rolls, aluminum strips, aluminum foil, aluminum wafers and other products with excellent prices and complete service system.

Aluminum foil

If you have any needs, please contact:

Email: [email protected]

Whatsapp: +86 18137782032