Introduction hardness of 1000-8000 series aluminum alloys

1109 Views 2024-06-03 09:42:27

Introduction hardness of 1000-8000 series aluminum alloys

1000-8000 series basically covers all aluminum alloy series products. Different series of products have different performance and hardness. Customers can choose products according to their own needs. For the use of aluminum alloys, some are useful for molds, some are useful for shell equipment accessories, some are used to make automotive accessories, and some choose to make alloy hardness accessories, etc. However, many people may not know the hardness difference between different series of alloy aluminum plates. So today we will summarize and introduce the hardness of 1000-8000 series aluminum alloys.

Introduction hardness of 1000-8000 series aluminum alloys

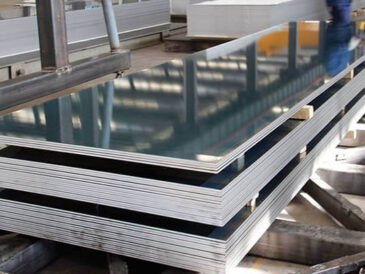

Introduction hardness of 1000 aluminum alloys

1000 series aluminum plates belong to the series with the highest aluminum content in the entire aluminum plate series. The basic aluminum content is maintained at more than 99.00%. It is known that the 1000 series aluminum plate is relatively simple in technology, and the price is basically the lowest in the entire series. The hardness of 1000 series alloy aluminum plates is naturally the lowest in the entire series. Ordinary plates are more suitable for stamping or decoration purposes.

Introduction hardness of 2000 aluminum alloys

2000 aluminum alloys is the product with the highest hardness in the entire series. The advantage of 2000 series is its high hardness, especially in the use of stamping parts. 2000 series is generally used as a choice for parts. For example, 2A16/2A06 are the leading products of 2000 series, and this is also used in car wheels. Another is 2024 aluminum alloy, which is called aviation aluminum due to its high hardness.

Introduction hardness of 3000 aluminum alloys

3000 series aluminum plate is basically a rust-proof aluminum plate, and its hardness is 20% higher than that of 1000 aluminum alloys. Because manganese is the main added element in 3000 series aluminum plates, which basically accounts for about 1-1.5%. Due to the addition of manganese, the hardness of 3000 series aluminum alloys is improved. Of course, the price of aluminum alloys is also increased to a certain extent. The price of 3000 series aluminum alloys is slightly higher than that of 1000 series aluminum alloys.

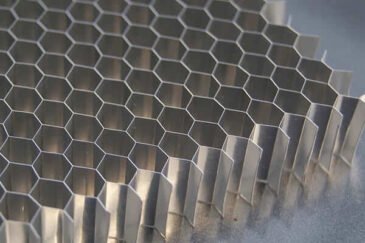

Introduction hardness of 4000 aluminum alloys

The 4000 series is generally a series with a high proportion of silicon, and the silicon content can basically reach 4.5% to 6.0%. However, 4000 series products are used less, and most of them are used for products with low melting point and good corrosion resistance. Because the advantages of 4000 aluminum alloys are heat resistance, wear resistance and corrosion resistance.

Introduction hardness of 5000 aluminum alloys

5000 series aluminum alloys are hot-rolled aluminum plates, similar to conventional 1000 series and 3000 series aluminum plates. Generally, aluminum-magnesium alloy is the main material, with a magnesium content of 3-5%. As a common aluminum plate in our lives, the 5000 series is widely used in various fields due to its low density, high elongation and high tensile strength. In addition, the 5000 aluminum alloys has moderate hardness and mature technology.

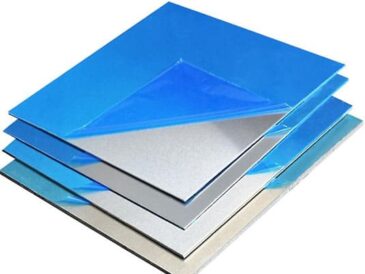

Introduction hardness of 6000 aluminum alloys

The 6000 series aluminum plate is an aluminum plate strip that integrates all the best features. It basically integrates the features of 4000 series and 5000 series products. The 6000 series aluminum alloy has high hardness, corrosion resistance and forging resistance. In particular, it has good oxidation effect and high aesthetics.

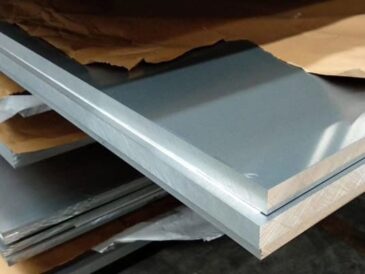

Introduction hardness of 7000 aluminum alloys

The 7000 series aluminum plate is an aviation series aluminum plate. The main added element is zinc, which is second only to the 2000 aluminum alloys. At the same time, the 7000 series aluminum plate contains aluminum, magnesium, zinc and copper. It does not deform after processing and has advantages such as high hardness and high strength.

Introduction hardness of 8000 aluminum alloys

8000 aluminum alloys belongs to other series, so the hardness of 8000 aluminum alloys is generally not included in this comparison. Because 8000 aluminum alloys is mainly used for bottle caps or aluminum foil.

Here is a general introduction hardness of 1000-8000 series aluminum alloys. It can be seen that 2000 series aluminum alloy is the hardest, followed by 7000 aluminum alloys. However, 1000 series aluminum plate is basically the hardest. The aluminum industry is still booming, and we look forward to having harder and more stable alloy aluminum plate products that can allow aluminum alloys to enter all aspects of our lives.