6061 aluminum t6 vs t651

1251 Views 2024-05-20 08:39:34

6061 aluminum introduction

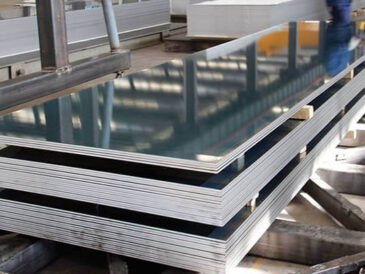

6061 aluminum alloy is a representative product of the 6000 series aluminum alloy. It has good mechanical properties, processing properties, electrical and thermal conductivity properties and a high light weight ratio. It is widely used in aerospace, automobile manufacturing, bicycle parts, shipbuilding, and electronic products. Shell and other fields.

6061 aluminum alloy has multiple states and can be heat treated. The conventional states are O and H states. T represents the heat treatment state, which is different from the F, O, and H states. It is suitable for products that have reached a stable state after (or not) work hardening. The T code is usually followed by one or more Arabic numerals, which is common in heat-treated reinforced materials.

6061 aluminum t6 vs t651

What is the difference between 6061-T6 and T651?

6061 aluminum alloy T6 and T651 are two common heat treatment states. The main difference between them is the cooling rate during heat treatment.

6061-T6

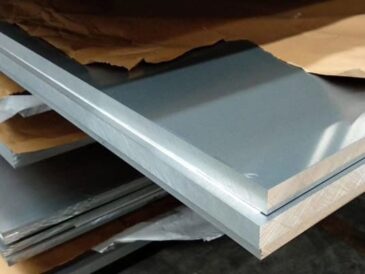

T6: T6 specifically refers to its heat treatment state. It refers to the state of artificial aging after solid solution heat treatment, and is suitable for products that do not undergo cold processing (except for straightening and leveling, and do not affect the mechanical performance limit) after solid solution heat treatment. 6061-T6 is the flagship product in the 6061 aluminum alloy series, also known for its high quality and excellent performance.

6061 T6 aluminum is an aluminum-magnesium-silicon alloy, which is a heat-treatable corrosion-resistant alloy. 6061 aluminum plate has higher strength and corrosion resistance, and better uniformity.

6061-t6 aluminum has high strength, can reach HV above 90 degrees, has good processing effect, and has good oxidation effect.

6061-T651

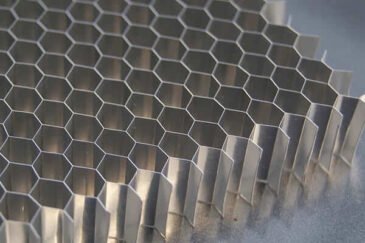

T651: 6061 aluminum alloy is stretched and balanced based on the T6 state. This process is called Stretching Balance Treatment. Its purpose is to make the internal stress distribution of the aluminum alloy more uniform by adjusting it. Therefore, aluminum alloy in T651 state has better mechanical properties and resistance to deformation.

6061-T651 aluminum plate has excellent processing performance, good corrosion resistance, high toughness, easy coloring film after processing, and good oxidation effect.

The tensile strength of 6061 T651 aluminum plate is 310Mpa, the yield strength is 276Mpa, and the hardness is 95HB. Representative uses of 6061 aluminum plates: aviation fixtures, LCD semiconductor equipment components, automated machinery parts, metallurgical fixtures, diode mold frames, automotive parts, model car bases, etc.

Mechanical performance comparison with 6061 aluminum T6 and T651

| Material Properties | T6 | T651 |

| Tensile Strength | 310 MPa | 310 MPa |

| Fatigue Strength | 96 MPa | 95 MPa |

| Yield Strength | 276 MPa | 276 MPa |

| Density | 2.7 g/cc | 2.7 g/cc |

| Weldability | Good | Excellent |

| Machinability | Fair | Excellent |

| Corrosion Resistance | Good | Good |

| Elastic Modulus | 69 GPa | 69 GPa |

| Hardness (Brinell) | 93 | 93 |

| Thermal Expansion Coefficient | 24 µm/m-°C | 24 µm/m-°C |

| Thermal Conductivity | 170 W/m-K | 170 W/m-K |

Among 6061 aluminum alloys with the same composition, the T651 state has higher mechanical properties, deformation resistance and better stability than the T6 state.

How to Choose Between T6 and T651

T6

The T6 temper is suitable for the following requirements:

When a high strength-to-weight ratio is required, the T6 temper provides sufficient hardness and strength, making it suitable for heavy load-bearing applications.

When machining processes for part fabrication are relatively simple and require fewer steps and less processing time, the T6 temper is preferred.

If budget is a crucial factor in the decision-making process, the T6 temper is typically more cost-effective compared to T651.

T651

T651 temper is commonly preferred in the following industries or applications:

When there is a need to enhance the machinability of aluminum alloys, T651 tempering is employed through controlled stretching.

In applications that necessitate high dimensional stability after machining processes, T651 tempering is the recommended process. This tempering process removes internal stresses, resulting in minimal distortions. It’s particularly suitable for industries such as automation and robotics.

The controlled stretching involved in T651 tempering also improves the weldability of the aluminum alloy. Therefore, in cases where superior welding performance is required, T651 tempering is utilized.

More information about 6061 aluminum please visit: https://hw-alu.com/blog/6061-aluminum.html