Container aluminum foil

1227 Views 2024-01-29 07:15:26

What is container aluminum foil?

Container aluminum foil refers to thin aluminum metal foil used to make disposable or reusable lunch boxes, containers and packaging materials. This kind of aluminum foil is usually made of higher purity aluminum alloy through continuous rolling processing.

Container aluminum foil has excellent barrier properties (preventing the penetration of oxygen and moisture), high temperature and low temperature resistance, and no harmful substances are precipitated during the heating process, so it is especially suitable for the food packaging industry.

3004 container aluminum foil

Aluminum foil containers are widely used in catering takeout, airline catering, home cooking (such as baking, barbecue) and other fields due to their lightweight, hygienic, good thermal insulation effect, environmental protection and recyclability.

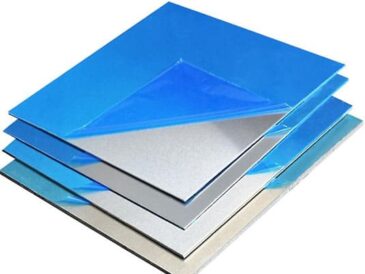

According to different usage needs, aluminum foil containers can be designed in various shapes and sizes, and can be a single layer of aluminum foil or a multi-layer structure made of other materials to meet the functional requirements of different food packaging.

Alloys of container aluminum foil

Aluminum foil for containers usually uses several specific aluminum alloys. These alloys are widely used to make disposable or recyclable meals due to their excellent processing properties, corrosion resistance, hygienic safety and suitability for food contact. box. The following are several commonly used aluminum foil alloys:

8011 aluminum foil for lunch box

- 8011 aluminum foil: This alloy is more common in container materials. It has good moisture resistance, sealing and formability, is not easy to crack during the stamping process, has high surface quality, and is suitable for the food packaging industry.

- 8006: 8006 aluminum foil has application advantages in fields such as airline lunch boxes due to its high elongation and cupping value. Its tensile strength is relatively high and it can ensure good flatness and cleanliness. It is suitable for manufacturing with higher requirements. High quality container products.

- 3003: 3004 and 3003 (3004 is mentioned here, but usually 3003 is also commonly used in containers). Both alloys are suitable for making container materials. Their mechanical properties are moderate, and they have good corrosion resistance and formability. In particular, 3003 alloy is commonly used in the food packaging industry, such as making container foils, food packaging foils, etc.

- 5052: Although the main features of 5052 aluminum foil are high strength and corrosion resistance, it is usually used in the aerospace field and products requiring high strength requirements. However, under certain conditions, it can also be used in the production of high-quality lunch boxes to ensure wrinkle-free and wrinkle-free containers. Pinholes and good anti-rust effect.

Different types of aluminum foil are selected based on specific container uses, cost considerations, and product performance requirements. Among them, 8011 and 3003 may be relatively cost-effective choices, while 8006 and 5052 may be more suitable for high-end or special requirements application scenarios.

Specifications of container aluminum foil

| Series | Alloy | Temper | Surface | Thickness | Width |

| 3000 | 3003/3004 | F,O,H14,H16,H18,

H19,H22,H24,H26, H28 |

plain foil coated aluminum foil |

0.006mm~0.20mm | 100mm-1700mm |

| 5000 | 5052 | ||||

| 8000 | 8006/8011/8021 |

The thickness of container aluminum foil is generally between 0.006mm and 0.20mm. It can be divided into wrinkled and wrinkle-free, and can also be divided into disposable and reusable.

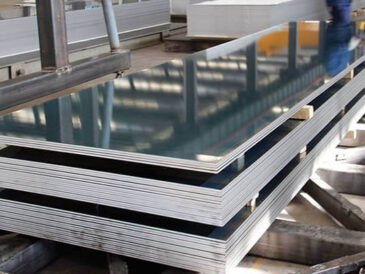

aluminum foil container

Container aluminum foil is actually made of 3000 series or 8000 series aluminum ingots as raw materials, which are cold-rolled or hot-rolled into aluminum foil mother rolls with uniform thickness, smooth surface, no pinholes, no dust particles, and no odor.

Aluminum foil containers are widely used in aviation food, home cooking and large chain cake shops. Main uses: food cooking, baking, freezing, preservation, etc.

Container aluminum foil is usually made of 8011, 8006 aluminum alloy or 3003, 3004 aluminum alloy, and there are two types: plain foil and coated foil.

Advantages of container aluminum foil

- Product is light in weight

- Comply with national food grade hygiene standards

- Recyclable

- Pollution-free renewable resources

- Fully preserve food moisture and heat

- Can be heated directly in the microwave

Performance characteristics container aluminum foil

Barrier performance Aluminum foil for containers has good barrier properties and can effectively block air, water vapor and odors, ensuring the freshness and taste of food. At the same time, aluminum foil also has functions such as moisture-proof, mildew-proof and rust-proof, which can extend the shelf life of food.

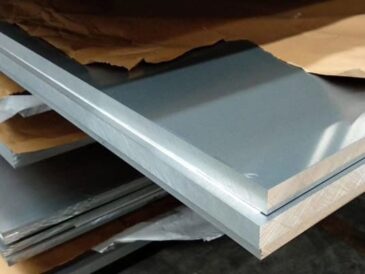

Container aluminum foil packaged

Processing performance Aluminum foil for containers has good processing performance and can meet the needs of various processing techniques. For example, aluminum foil can be punched, bent, welded and other processes to facilitate the production of containers of various shapes and structures. In addition, aluminum foil can also be compounded with other materials to improve the overall performance of the packaging.

Safety performance Aluminum foil for containers is a non-toxic, odorless metal material that will not contaminate or cause odor to food. At the same time, aluminum foil can still maintain good stability and safety in extreme environments such as high temperature and low temperature, and will not release harmful substances.

What are the advantages of using 3004 container aluminum foil?

- 1. 3004 aluminum foil has high hardness, good load-bearing, and better stamping effect than 3003 aluminum foil.

- 2. The production of 3004 aluminum foil material uses a high-temperature annealing and disinfection process to prevent bacteria and microorganisms from growing on its surface.

- 3. The aluminum foil lunch box material has strong barrier properties. After sealing, it can protect the original flavor of the food and extend the shelf life of the food.

- 4. It can be recycled and reused efficiently, protecting the environment and saving resources.

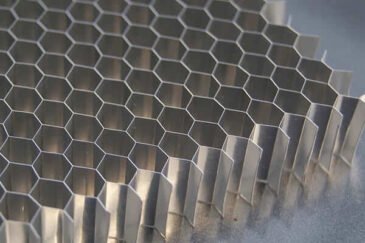

What is a thickened aluminum foil container?

Thickened aluminum foil containers are different from traditional aluminum foil boxes and are increasingly favored by the takeout market.

Thickened aluminum foil containers are also called wrinkle-free aluminum foil containers, scientifically known as aviation containers, commonly known as golden aluminum foil containers, and golden aluminum foil take-out packaging boxes. It adopts multi-layer aluminum ingot drawing technology and is stamped in one step. It has the characteristics of high strength, no heavy metal residue, and can be environmentally friendly and recycled;

Thickened aluminum foil container

How to use thickened aluminum foil lunch boxes

As take-out packaging boxes and pre-made vegetable packaging boxes, they generally need to be sealed with corresponding sealing machines.

The sealing film is also made of aluminum foil, which can effectively ensure the overall beauty and strength requirements of the lunch box. Of course, if some meals do not contain soup, or for the convenience of displaying the contents of the dishes, matching plastic lids can also be used for sealing.

Advantages of thickened aluminum foil lunch boxes

The golden aluminum foil lunch box has beautiful material and is convenient for box type customization and printing.

At the same time, it has excellent heat preservation function, which can effectively protect the color and taste of dishes. Solve the problem of reduced food quality caused by plastic lunch boxes in many restaurants;

The sealing feature is also a major feature of golden aluminum foil lunch boxes that is different from traditional lunch boxes such as plastic lunch boxes, traditional aluminum foil lunch boxes, paper lunch boxes, etc. Sealing can effectively prevent leakage

The golden aluminum foil lunch box can be heated by open flame, electric ceramic stove, oven, microwave, etc.;