Aluminum for can pull ring

149 Views 2024-06-06 08:33:54

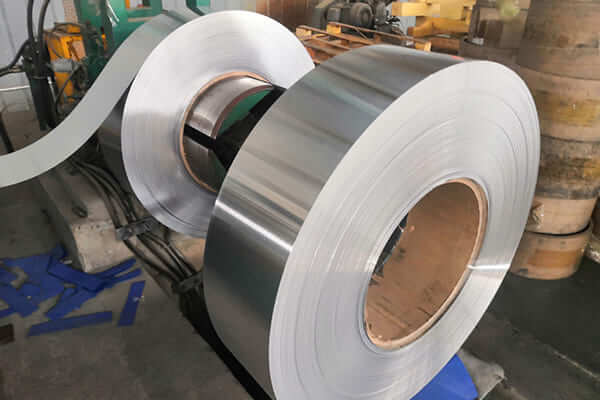

Aluminum for can pull ring

The can pull ring is an important part of the can (or aluminum can), usually located at the top of the can. It is a device for opening the can, and the user can easily open the can by pulling the pull ring and get the beverage or other liquid contents inside.

The material commonly used for the can pull ring is 5182 aluminum alloy. This alloy has good processing performance and strength, and is suitable for the manufacture of cans. The characteristics of 5182 aluminum alloy include good corrosion resistance, certain strength and hardness, and certain plasticity, which can meet the production requirements of can pull rings.

Aluminum for can pull ring

Requirements for the material of can pull rings

The material of can pull rings needs to meet some specific requirements to ensure its performance and function:

- Corrosion resistance: Since cans are often in contact with liquids, the material of the pull ring needs to have good corrosion resistance to avoid corrosion and rust during use.

- Strength and hardness: The pull ring needs to have sufficient strength and hardness so that it is not easy to deform or break during use, ensuring that it can withstand the force of opening the can.

- Plasticity: The material of the pull ring should have a certain plasticity to facilitate processing into the required shape and size, and be able to adapt to the manufacturing process requirements of the can.

- Lightweight: Considering the weight limit of can products, the material of the pull ring should be as light as possible to reduce the overall weight and reduce transportation and use costs.

Mechanical properties of 5182 H19 aluminum alloy

Tensile strength/Mpa: 360-410

Yield strength/Mpa: 310-360

Elongation/%: ≥6

Dimensions and allowable deviations

Thickness (mm): 0.250-0.500

Thickness allowable deviation (mm): ±0.004

Width (mm): 800-1200

Width deviation (mm): ±0.3

Quality requirements for Huawei 5182 aluminum alloy

Surface: No serious bubbles, missing coating, scratches, corrosion, oil spots, peeling, stripes, color difference, spots, roller marks, periodicity, etc. that affect the appearance quality of the product are allowed;

Huawei 5182 aluminum for can pull ring

End face: The end face is neat, the roll is tight and there is no loose layer, the staggered layer is ≤2mm, and the tower shape is ≤5mm;

Flatness: The strip is not allowed to have obvious waves, the wave height within 1 meter does not exceed 3mm, and the waves do not exceed 3/meter;

Side curvature: The side curvature of the product on any 2000mm length should not be greater than 0.5mm;

End warping: For any product cut with a length of 1500mm, the height of the end warping is ≤7mm;

Joints: No joints are allowed.

Realated products:https://hw-alu.com/applications/aluminum-sheet-coil-for-cans.html