Can body materials

191 Views 2024-06-07 09:02:06

Can body materials

The can body materials is a lightweight and environmentally friendly packaging material, usually used to fill beverages, beer and other liquid foods.

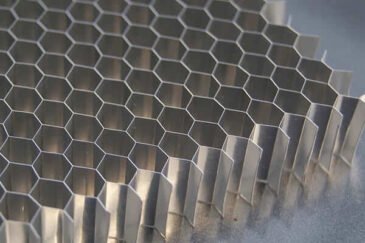

There are three main components of a can, namely the can body, can lid, and pull ring. Although these three structures are all made of aluminum alloy, there are some differences in the raw materials used to make them.

Aluminum for can body

We have previously talked about the can pull ring material – 5182 aluminum alloy. Today we will explain the can body materials in detail.

Requirements for can body materials

There are some requirements for can body materials, mainly including the following points:

Food safety: The material must comply with the relevant regulations and standards for food contact materials to ensure that it will not cause contamination to the food or beverage in the can.

Corrosion resistance: The can body materials needs to have good corrosion resistance and be able to resist the erosion of acidic or alkaline liquids to ensure the integrity of the can body and the safety of the product.

Structural strength: The material must have sufficient structural strength to withstand the extrusion and impact force during transportation, storage and use, and maintain the shape and sealing of the can body.

Processability: The can body materials needs to have good processability, and can be made into the shape of the can body through molding, stamping and other processes, and maintain the stability of size and shape.

Lightweight: Lightweight materials such as aluminum are often selected to ensure that the overall weight of the can is light and easy to carry and transport.

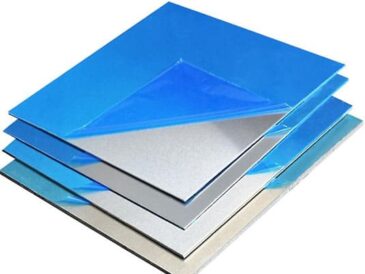

Can body materials

Common materials for can bodies

The common materials for can bodies are mainly aluminum alloys. Specifically, the can body and bottom are usually made of 3004 aluminum alloy. This material is widely used because of its light weight, high strength and good recyclability.

Alloy: 3004

Thickness: 0.2-0.6mm

Temper: O

Advantages of 3004 aluminum alloy can body materials

3004 aluminum alloy is a food-grade aluminum alloy, non-toxic and tasteless, and has no adverse effects on food and human body;

3004 aluminum alloy has good formability, weldability and corrosion resistance;

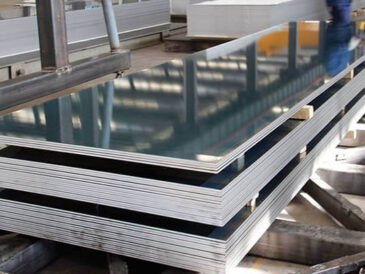

3004 aluminum coil for can body

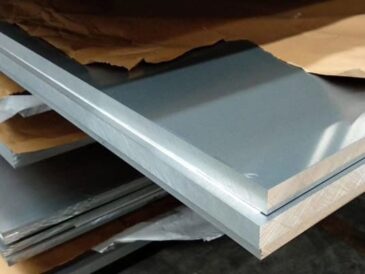

Good forming processing characteristics, high corrosion resistance, good weldability and conductivity, and higher strength than 3003 aluminum plate;

3004 aluminum alloy has a smooth surface, good plasticity and pressure resistance;

Good recyclability, aluminum alloy material is a recyclable and environmentally friendly material;