3003 alüminyum levha vs 1060 Alüminyum levha

188 Görüntüleme 2024-05-21 09:49:37

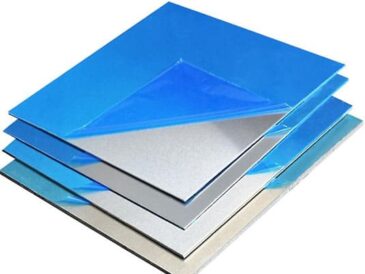

3003 alüminyum levha ve 1060 alüminyum levhanın her ikisi de yaygın alüminyum levhalardır. Bazı kullanım senaryolarında birbirlerinin yerini alabilirler, ancak kimyasal bileşimlerinde büyük sapmalar var, mekanik özellikler ve fiyat. Öyleyse, alüminyum levha sipariş etmeden önce kullanım senaryolarınızı anlamanız gerekir. Ve arasındaki fark 3003 alüminyum levha ve 1060 Alüminyum levha.

3003 alüminyum levha tanıtımı

3003 Alüminyum levha en yaygın alaşımlı alüminyum levhalardan biridir. temsili bir üründür. 3000 seri (Al-Mn) aliminyum tabak. Yaygın olarak kullanılan pas önleyici bir alüminyumdur. Bu alaşımın gücü yüksek değil (endüstriyel saf alüminyumdan biraz daha yüksek).

Isıl işlemle güçlendirilemez, bu nedenle mekanik özelliklerini geliştirmek için soğuk çalışma yöntemleri kullanılır: tavlanmış durumda yüksek plastisiteye sahiptir, yarı soğuk iş sertleşmesi sırasında iyi esneklik, Soğuk iş sertleşmesi sırasında düşük plastisite, iyi korozyon direnci, iyi kaynaklanabilirlik, ve kesilebilir. Zayıf performans.

3003 alüminyum levha paketlenmiş

Esas olarak yüksek plastisite ve iyi kaynaklanabilirlik gerektiren ve sıvı veya gaz ortamlarda çalışan düşük yüklü parçalar için kullanılır., yakıt depoları gibi, benzin veya yağlama yağı kanalları, derin çekmeyle yapılmış çeşitli sıvı kapları ve diğer küçük yüklü parçalar: Perçin yapımında tel kullanılır.

Kimyasal bileşim

Kimyasal bileşim açısından, ana unsurları 3003 alüminyum levha alüminyum içerir (Al) ve manganez (Mn), alüminyum içeriğinin daha fazla olduğu 98% ve manganez içeriği arasında 1-1.5%. 3003 alüminyum levha ayrıca az miktarda bakır içerir (cu) ve diğer safsızlık unsurları. Bu alaşım elementlerinin içeriği ve oranı sertliğin belirlenmesinde önemli rol oynamaktadır., kuvvet, korozyon direnci ve diğer özellikleri 3003 alüminyum levhalar.

Mekanik standartlar

Mekanik standartlar, malzeme performansının ölçülmesinde önemli bir gösterge ve kalitenin değerlendirilmesinde önemli bir temeldir. 3003 alüminyum levhalar. Mekanik standartlar açısından, sertlik, kuvvet, süneklik ve korozyon direnci 3003 alüminyum plakaların tümü temel göstergelerdir.

sertliği 3003 alüminyum levha esas olarak çekme mukavemetine ve akma mukavemetine yansır. Uluslararası standartlara göre, çekme mukavemeti 3003 alüminyum levha 110-205MPa arasındadır ve akma dayanımı 40-150MPa arasındadır.. Bu şunu gösteriyor 3003 Alüminyum levhanın belirli bir dereceye kadar belirli bir sertliği ve mukavemeti vardır ve farklı alanların ihtiyaçlarını karşılayabilir.

Süneklik 3003 alüminyum levha da önemli mekanik standartlarından biridir. Uzama oranı 3003 alüminyum levha genellikle yukarıdadır 10%, bu da iyi bir sac şekillendirme performansına sahip olduğu ve çeşitli damgalama ve şekillendirme işlemlerine uygun olduğu anlamına gelir.

Korozyon direnci 3003 Alüminyum levha aynı zamanda mekanik standartlarındaki önemli göstergelerden biridir.. Manganez ve diğer alaşım elementlerini içerdiğinden, 3003 Alüminyum levhalar iyi korozyon direncine sahip olup nemli ve korozif ortamlarda hasar görmeden uzun süre kullanılabilir..

Giriş 1060 Alüminyum levha

1060 alüminyum levha ve şerit, kapsamak 99.6% alüminyum, saf alüminyum levha da denir. Alüminyum levha ve şerit ailesinde yaygın olarak kullanılan bir seridir.. Bu seri alüminyum plakaların avantajları: en çok kullanılan seri, üretim süreci nispeten basittir, teknoloji nispeten olgun, ve fiyatının diğer üst düzey alaşımlı alüminyum levhalara kıyasla büyük bir avantajı var. İyi uzama ve çekme mukavemetine sahiptir, ve geleneksel işleme gereksinimlerini tam olarak karşılayabilir (damgalama, germe) ve yüksek şekillendirilebilirlik.

1060 Alüminyum levha yüksek plastisiteye sahip endüstriyel saf alüminyumdur, korozyon direnci, Elektriksel iletkenlik ve termal iletkenlik, ama düşük güç, ısıl işlemle güçlendirilemez, ve işlenebilirliği zayıftır; gaz kaynaklı olabilir, hidrojen atomu kaynaklı ve temas kaynaklı, ama sert lehimlemek kolay değil; Çeşitli basınç işlemlerine dayanması kolay, germe ve bükme.

3003 alüminyum levha vs 1060 Alüminyum levha

1060 Alüminyum levha, yüksek mukavemet gerektirmeyen ürünlerde yaygın olarak kullanılmaktadır.. Tabelalarda yaygın olarak kullanılan ürünler, reklam panoları, bina dış dekorasyonu, otobüs gövdeleri, yüksek bina ve fabrika duvar dekorasyonları, mutfak lavaboları, lamba sahipleri, fan kanatları, elektronik parçalar, kimyasal aletler, ince levha işleme parçaları, derin çekme veya bükme içbükey parçaları. Şekilli mutfak eşyaları, kaynaklı parçalar, ısı eşanjörleri, saat yüzeyleri ve diskler, isim levhaları, mutfak eşyaları, dekorasyonlar, yansıtıcı ekipman, vesaire.

3003 alüminyum levha vs 1060 Alüminyum levha

Alaşım farklılıkları

| Al(%) | Ve (%) | cu (%) | Mg(%) | Zn (%) | Mn(%) | İle ilgili(%) | V (%) | Fe(%) |

| 99.60 | 0.25 | 0.05 | 0.03 | 0.05 | 0.03 | 0.03 | 0.05 | 0.35 |

| 96.8-99.0 | 0.60 | 0.05-0.20 | 0-0.05 | 0.10 | 1.00-1.50 | – | – | 0.70 |

Mekanik özelliklerdeki farklılıklar

| Alaşım | Gerilme direnci | Akma dayanımı |

| 1060 | 110-136 | ≥35 |

| 3003 | 120-160 | ≥85 |

Kullanımdaki farklılıklar

O zamandan beri 1060 alüminyum levha iyi elektrik iletkenliğine sahiptir, genellikle elektronik cihazlarda kullanılır, piller, kapasitörler ve diğer alanlar. Daha yüksek mukavemeti ve korozyon direnci nedeniyle, 3003 alüminyum levha gövde panellerinin imalatına uygundur, yakıt tankları, yüksek mukavemet gereksinimleri olan gemiler ve diğer alanlar.

1060 alüminyum levha uygulaması

- Elektronik ürünler: elektronik bileşenlerin üretiminde kullanılır, elektrik muhafazaları, LED ısı emiciler, vesaire., iyi elektriksel ve termal iletkenlik özelliklerinden yararlanarak.

- Yapı malzemeleri: dekoratif paneller yapmak için kullanılır, perde duvarları, çatı malzemeleri, vesaire., iyi korozyon direnci ve estetik ile.

- Reklam tabelaları: tabela ve reklam panoları yapımında kullanılır, iyi şekillendirilebilirliği ve yüzey işleme yetenekleri sayesinde.

- Ev aletleri: mutfak lavaboları gibi, abajurlar, fan kanatları, vesaire., işlenme kolaylığı ve korozyon direncinden yararlanarak.

- Kimyasal ekipman: kimyasal stabilitesinden yararlanmak için kimyasal ekipmanın belirli parçalarının yapımında kullanılır.

uygulamaları 1060 Alüminyum levha

3003 alüminyum levha uygulaması

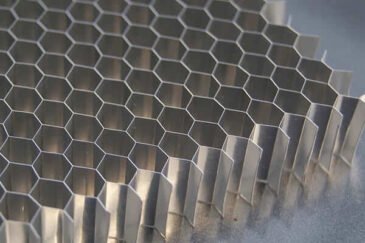

- Kimyasal ekipman ve kaplar: İlaç ve gıda endüstrilerinde, 3003 alüminyum plakalar kap ve ambalaj malzemeleri yapımında kullanılır. Çünkü kimyasal maddelerle reaksiyona girmeyeceklerdir., Ürünlerin güvenliğini ve kalitesini sağlarlar.

- havacılık: Hafifliğinden yararlanılıyor, korozyona dayanıklı ve aşırı koşullara dayanma yeteneği, 3003 alüminyum levhalar havacılık bileşenleri ve ekipmanlarının üretiminde kullanılır, uçak performansının ve yakıt verimliliğinin iyileştirilmesine yardımcı olmak.

- otomobil üretimi: Araba gibi araçlarda, trenler, tramvaylar, vesaire., 3003 Gövde paneli olarak alüminyum levhalar kullanılıyor, bölme panelleri, çatı panelleri, vesaire. ağırlığı azaltmak ve yakıt ekonomisini iyileştirmek için.

- elektronik alan: elektronik ürün muhafazalarında kullanılır, radyatörler, vesaire., elektronik bileşenleri korumak için iletken özelliklerini ve ısı dağıtma yeteneklerini kullanıyor.

- Yapı malzemeleri: Dış cephe kaplaması yapımında kullanılır, çatı panelleri, tavanlar, vesaire., hem dekoratif malzeme olarak hem de hafifliğinden ve hava koşullarına dayanıklılığından yararlanmak için.

- Toplu taşıma: Arabalarla sınırlı değil, aynı zamanda trenlerin gövde parçaları da, tramvaylar, vesaire. hafif tasarım elde etmek için.