PVDF Coated Aluminum Coil: The Gold Standard for Architectural Durability

Walk through any modern city, and you are surrounded by architectural marvels—gleaming skyscrapers, vibrant stadiums, and sleek commercial buildings.

What you are often admiring is the remarkable finish of PVDF coated aluminum coil.

This advanced material is the secret behind some of the world’s most durable and visually stunning building facades.

But what exactly is it? And why has it become the gold standard for projects where longevity and aesthetic appeal are non-negotiable?

This guide will delve deep into the world of PVDF coated aluminum coil, explaining its composition, its unparalleled benefits, and how it stacks up against other options.

By the end, you will understand why choosing this material is an investment in lasting quality.

Pvdf Coated Aluminum Coil

Deconstructing the Term: PVDF + Coating + Aluminum Coil

PVDF: The Heart of the Coating

PVDF stands for Polyvinylidene Fluoride. This is a high-performance fluoropolymer, a type of specialty plastic that is exceptionally stable and robust.

Its power lies in its chemical structure, specifically the strong fluorine-carbon (F-C) bond.

This bond is one of the strongest in chemistry, making it incredibly resistant to being broken down by environmental stressors.

Consequently, a PVDF coating provides a formidable shield against UV radiation, acid rain, pollution, and extreme temperatures.

It doesn’t just protect the metal; it preserves itself, ensuring colors remain vibrant and the surface remains intact for decades.

The Coil Coating Process: A Perfect Bond

The PVDF resin is applied to the aluminum in a highly controlled, continuous process known as coil coating.

Before any paint is applied, the aluminum coil undergoes a rigorous multi-step cleaning and pretreatment phase. This is crucial for ensuring maximum adhesion.

Next, a layer of primer is applied and cured. Following this, the PVDF topcoat, which contains the color pigments, is precisely applied and baked in an oven.

This process creates a uniform, flexible, and incredibly durable finish that is chemically bonded to the metal surface.

Pvdf Coated Aluminum Coil Packaging

Aluminum Coil: The Ideal Substrate

Aluminum is the perfect partner for a PVDF coating. It is inherently lightweight, which reduces the structural load on buildings and makes it easier to transport and install.

Furthermore, aluminum naturally forms a protective oxide layer, giving it excellent corrosion resistance on its own.

When combined with a PVDF coating, you get a multi-layered defense system against environmental degradation.

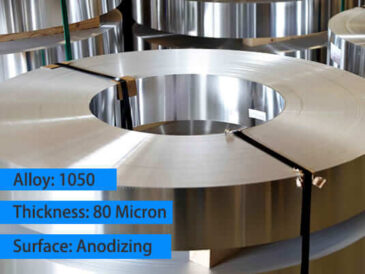

Choosing the Right Foundation: Common Alloys for PVDF Coated Aluminum Coil

The incredible performance of a PVDF coated aluminum coil comes from a partnership between the coating and the metal beneath it.

The aluminum alloy, or substrate, provides the structural foundation.

Selecting the right alloy is crucial, as it dictates the material’s strength, flexibility, and suitability for specific environments.

Below is a detailed comparison of the most common alloys used for PVDF coating.

3003 Pvdf Coated Aluminum Coil

This table will help you understand their unique strengths and identify the perfect match for your project’s needs.

| Alloy Series | Key Characteristics & Strengths | Ideal Applications | Why Choose This Alloy? |

| A3003 | The Industry Standard & All-Rounder • Excellent Formability • Very Good Corrosion Resistance • Moderate Strength |

• General architectural cladding & facades • Standard metal roofing & siding • Rainware (gutters, downspouts) • Interior decorative panels |

For Balanced Performance and Cost.

This is the most versatile and cost-effective choice for a vast range of standard applications where extreme strength is not the primary concern. |

| A3004 / A3105 | The Stronger Performer • Higher Strength & Rigidity than A3003 • Good Formability • Very Good Corrosion Resistance |

• High-performance roofing systems with long spans • Industrial siding that must withstand higher wind loads • Aluminum Composite Panels (ACP) requiring extra stiffness |

When You Need More Structural Strength.

Choose this when your project demands greater rigidity to handle environmental stresses like wind, or when you need to cover wider areas with less support. |

| A5005 | The Aesthetic & Architectural Choice • Superior Surface Finish Quality • Excellent Corrosion Resistance • Good Formability • Provides excellent base for anodizing |

• High-end, premium architectural projects • Facades where coated panels are adjacent to anodized aluminum extrusions (e.g., window frames) • Projects demanding the highest visual consistency |

For a Perfect Visual Match.

This is the premier choice when visual harmony is critical, especially for ensuring a consistent appearance between PVDF coated surfaces and anodized aluminum parts. |

| A5052 | The Durability & Marine-Grade Champion • Excellent Strength & Toughness • Outstanding Corrosion Resistance, especially in saltwater • Good Formability |

• Coastal buildings and marine applications • Industrial facilities with chemical exposure • Transportation industry (trailers, vehicle bodies) • High-traffic areas requiring impact resistance |

For Maximum Protection in Harsh Environments.

Select this alloy when your project faces extreme conditions like salt spray, industrial pollutants, or physical wear and tear. It offers the best long-term durability. |

The Unmistakable Advantages of PVDF Coated Aluminum Coil

Choosing a PVDF coated aluminum coil brings a host of powerful benefits that justify its position as a premium building material.

1. Unmatched Weathering and UV Resistance

This is the material’s signature strength. While other coatings fade, chalk, or peel under constant sun exposure, PVDF stands firm.

Its ability to resist UV degradation means the building’s facade will look fresh and vibrant for 20 years or more, even in the harshest climates like coastal regions or high-altitude locations.

2. Exceptional Color and Gloss Retention

The stability of the PVDF resin ensures that color pigments are locked in and protected.

This results in outstanding color fastness. For architects and brand owners, this means the building’s intended color scheme will remain true over its lifespan, maintaining the original design intent and corporate identity.

Pvdf Coated Aluminum Coil With Different Colors

3. Superior Chemical and Pollution Resistance

Urban and industrial environments are filled with airborne pollutants and chemicals that can stain and corrode building materials.

The inert nature of the PVDF coating makes it highly resistant to acids, alkalis, salt spray, and other corrosive agents, ensuring the surface remains clean and undamaged.

4. Extremely Low Maintenance

The surface of a PVDF coating is dense and non-porous. This gives it a natural resistance to dirt accumulation.

In many cases, normal rainfall is sufficient to wash the surface clean, significantly reducing the long-term costs and efforts associated with building maintenance.

5. Excellent Flexibility and Formability

Despite its incredible toughness, the coating is highly flexible. The PVDF coated aluminum coil can be bent, roll-formed, stamped, and cut without the paint cracking or peeling.

This gives designers immense freedom to create complex curves, sharp angles, and intricate shapes for modern architectural elements.

PVDF vs. The Alternatives: A Clear Comparison

To fully appreciate its value, it’s essential to see how PVDF stacks up against other common coil coating options, such as Polyester (PE) and Silicone Modified Polyester (SMP).

| Feature | PVDF Coating | SMP Coating | PE Coating |

| Durability & Lifespan | Exceptional (20+ years) | Good (10-15 years) | Standard (5-8 years) |

| UV Resistance | Excellent | Good | Fair |

| Color & Gloss Retention | Excellent | Good | Moderate |

| Chalk & Fade Resistance | Excellent | Good | Fair to Poor |

| Chemical Resistance | Excellent | Moderate | Low |

| Cost | Premium | Moderate | Economical |

| Typical Warranty | 20-30 Years | 10-15 Years | 5-10 Years |

| Best Application | High-end architecture, monumental projects, harsh environments | Commercial buildings, industrial roofing, mid-range projects | Interior decoration, temporary structures, low-budget projects |

As the table shows, while PE is a cost-effective choice for less demanding applications, and SMP offers a good middle-ground, PVDF is in a class of its own for long-term performance.

For any project where durability, color stability, and a premium finish are paramount, PVDF is the only logical choice.

Key Applications: Building the Future with Performance and Style

The exceptional characteristics of PVDF coated aluminum coil are not just theoretical advantages; they translate directly into superior performance in the real world.

This is why it has become the material of choice for ambitious, long-lasting, and high-visibility projects.

Let’s explore its most vital applications in greater detail to understand its impact.

Architectural Wall Cladding and Facades

This is the premier application where PVDF coatings truly demonstrate their value.

A building’s facade is its public face—it defines its aesthetic, communicates its purpose, and protects it from the elements.

- Monumental Projects:

Think of landmark skyscrapers, international airports, futuristic stadiums, and sprawling hospitals.

For these structures, failure is not an option. Architects specify PVDF coated aluminum coil because its 20+ year lifespan ensures the original design vision endures.

Its outstanding resistance to UV radiation, urban pollution, and acid rain prevents the facade from becoming a faded, chalky shadow of its former self. - Maintaining Property Value:

A pristine, vibrant facade directly contributes to a building’s perceived and actual value.

By resisting stains and degradation, the PVDF finish keeps the property looking new and well-maintained, safeguarding the owner’s investment for decades.

Pvdf Coated Aluminum Coil for Building

High-Performance Metal Roofing Systems

A roof is a building’s first line of defense against the weather.

It must be tough, water-tight, and durable. PVDF coatings elevate metal roofing to a new level of performance and design.

- Long-Term Weather Protection:

From the intense sun of a desert climate to the corrosive salt spray of a coastal town, a PVDF-coated roof provides unwavering protection.

Its color retention means a vibrant red or deep blue roof will remain just as striking in year 15 as it was on day one. - Energy Efficiency (“Cool Roofs”):

PVDF coatings can be formulated with special infrared-reflective pigments.

These “cool roof” finishes reflect solar energy, significantly reducing the heat absorbed by the building.

This leads to lower air conditioning costs, reduced energy consumption, and a smaller carbon footprint—a tangible financial and environmental benefit.

The flexibility of the PVDF coated aluminum coil also allows for the creation of sophisticated standing-seam profiles that offer superior weather-tightness.

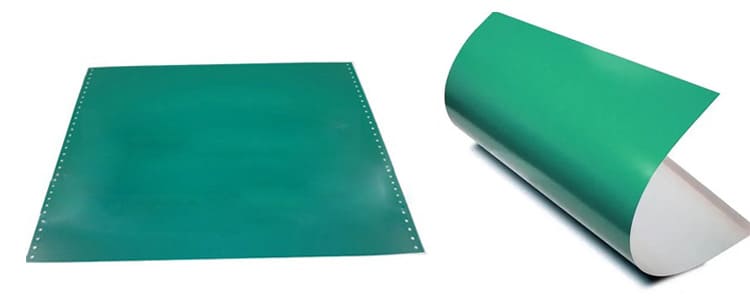

Aluminum Composite Panels (ACP/MCM)

Modern architecture often features sleek, flat, and monolithic surfaces.

This is frequently achieved using Aluminum Composite Panels (ACP) or Metal Composite Materials (MCM), which consist of two aluminum sheets bonded to a solid core.

- The Premium Finish:

The PVDF coated aluminum coil serves as the outer skin of these panels.

The aluminum coil coating process ensures perfect color uniformity and flatness, which is essential for creating a flawless, high-end appearance. - Design Freedom:

The remarkable flexibility of the PVDF coating is critical here.

Fabricators can bend, fold, and curve the composite panels into complex shapes and cassettes without any risk of the paint cracking or peeling at the edges.

This allows architects to realize creative and dynamic facade designs that would be impossible with more brittle materials.

Roofing sheet

Corporate Signage and Brand Identity

For any major brand, consistency is everything.

The colors on a storefront, gas station canopy, or corporate headquarters sign are a vital part of their identity.

- Protecting Brand Integrity:

Brands like McDonald’s, BP, or Citibank invest millions in their specific brand colors.

They choose PVDF coatings to ensure that “McDonald’s Red” or “BP Green” remains uniform and vibrant across thousands of locations worldwide, regardless of the local climate. - Durability and Low Maintenance:

A faded, dirty sign sends a negative message.

The fade resistance and self-cleaning properties of PVDF ensure that brand signage stays crisp and professional-looking for years, protecting the brand’s image with minimal maintenance.

Essential Architectural Components

Beyond the main facade, PVDF is crucial for the smaller details that complete a building’s design and function.

- Canopies, Awnings, Soffits, and Fascias:

These elements are highly exposed to the elements, including direct sun and water runoff from the roof.

PVDF’s superior durability ensures these accent pieces won’t become weak points in the building’s aesthetic, maintaining color harmony with the primary facade over the long term.

Conclusion

In conclusion, a PVDF coated aluminum coil is more than just a raw material; it is an advanced building solution.

It delivers on the promise of longevity, beauty, and performance.

By choosing PVDF, you are not just selecting a color or a finish—you are investing in peace of mind, knowing that your architectural vision will be protected and preserved against the tests of time and nature.

For any landmark project, it is the definitive choice for a legacy of quality.

FAQs About PVDF Coated Aluminum Coil

To help you make the most informed decision, we have compiled answers to some of the most common questions about PVDF coated aluminum coil.

This section provides clear, practical insights into its use, maintenance, and specifications.

1. Is PVDF coating significantly more expensive than other coatings?

Yes, the initial investment for a PVDE coated aluminum coil is higher than for materials with Polyester (PE) or SMP coatings. However, it’s crucial to consider the total lifecycle cost.

PVDF’s exceptional durability means it will not need to be repainted or replaced for 20 years or more.

When you factor in the savings from drastically reduced maintenance, cleaning, and replacement costs, PVDF often proves to be the more economical choice in the long run for high-value projects. It is an investment in longevity and preserved property value.

2. What is the difference between 70% PVDF and other formulations?

When you see a specification for 70% PVDF, it refers to the percentage of PVDF resin within the solid part of the paint formula (the binder).

This 70/30 ratio (70% PVDF resin, 30% acrylic resin) is the industry’s gold standard for architectural coatings.

This specific formulation, used in premium products like those based on Kynar 500® or Hylar 5000® resins, provides the optimal balance for achieving maximum resistance to weathering, chalking, and fading.

Coatings with less than 70% PVDF will not deliver the same long-term performance and durability. Always insist on a 70% PVDF formulation for critical exterior applications.

3. Can you repaint a surface with a PVDF coating?

While it is possible, repainting a PVDF surface is a specialized task.

The very properties that make the coating so durable—its chemical inertness and smooth, non-porous surface—also make it difficult for new paint to adhere properly.

A successful repaint requires meticulous surface preparation, including thorough cleaning and the application of a special adhesion-promoting primer designed for fluoropolymer surfaces.

We always recommend consulting with a professional coating specialist to ensure the job is done correctly and the new finish will last.

4. How should I clean a PVDF coated aluminum surface?

Gentle cleaning is the key to maintaining a PVDF surface. The coating’s excellent resistance to dirt means aggressive methods are unnecessary.

For routine cleaning:

- Start by rinsing the surface with clean water to remove loose dust and dirt.

- If needed, use a soft cloth or sponge with a solution of water and a mild, non-abrasive detergent (like standard dish soap).

- Thoroughly rinse with clean water afterward to remove any soap residue.

- Crucially, never use abrasive cleaners, harsh chemical solvents, or rough scouring pads, as these can permanently damage the finish.

5. Is Kynar 500® the same thing as PVDF?

This is a common point of confusion. Think of it like this: PVDF is the generic chemical name for the resin (Polyvinylidene Fluoride), while Kynar 500® is a premium, globally recognized brand name for a 70% PVDF resin manufactured by Arkema.

When a specifier requests a coating with Kynar 500®, they are asking for the high-performance standard that guarantees top-tier weather resistance and color retention.

So, while not all PVDF coatings are Kynar 500®, all Kynar 500®-based coatings are the highest quality PVDF.

6. Is PVDF coating environmentally friendly?

The primary environmental advantage of a PVDF coated aluminum coil lies in its exceptional durability and longevity.

Because the coating lasts for decades without needing replacement, it significantly reduces the consumption of resources and energy associated with manufacturing, transporting, and installing replacement materials.

This long-service life is a key pillar of sustainable building practices.

Furthermore, the aluminum substrate is 100% recyclable, and the modern coil coating process is a highly efficient, closed-loop system designed to minimize waste and capture volatile organic compounds (VOCs).

Casting production process and its introduction

The purpose of melting and casting is to produce alloys with satisfactory composition and high purity of melt, so as to create favorable conditions for casting alloys of various shapes.

Melting and casting process steps: batching --- feeding --- melting --- stirring after melting, slag removal --- pre-analysis sampling --- adding alloy to adjust the composition, stirring --- refining --- static Setting——Guide furnace casting.

Hot rolling production process and its introduction

- 1. Hot rolling generally refers to rolling above the metal recrystallization temperature;

- 2. During the hot rolling process, the metal has both hardening and softening processes. Due to the influence of deformation speed, as long as the recovery and recrystallization process is too late, there will be a certain work hardening;

- 3. The recrystallization of the metal after hot rolling is incomplete, that is, the coexistence of recrystallized structure and deformed structure;

- 4. Hot rolling can improve the processing performance of metals and alloys, reduce or eliminate casting defects.

- 1. The casting and rolling temperature is generally between 680°C and 700°C. The lower the better, the stable casting and rolling line usually stops once a month or more to re-stand. During the production process, it is necessary to strictly control the liquid level of the front tank to prevent low liquid level;

- 2. Lubrication uses C powder with incomplete combustion of gas for lubrication, which is also one of the reasons for the dirty surface of casting and rolling materials;

- 3. The production speed is generally between 1.5m/min-2.5m/min;

- 4. The surface quality of products produced by casting and rolling is generally relatively low, and generally cannot meet products with special physical and chemical performance requirements.

- 1. Cold rolling refers to the rolling production method below the recrystallization temperature;

- 2. There will be no dynamic recrystallization during the rolling process, and the temperature will rise to the recovery temperature at most, and the cold rolling will appear in a work hardening state, and the work hardening rate will be large;

- 3. The cold-rolled sheet and strip have high dimensional accuracy, good surface quality, uniform structure and performance, and products in various states can be obtained with heat treatment;

- 4. Cold rolling can roll out thin strips, but at the same time, it has the disadvantages of high energy consumption for deformation and many processing passes.

- 1. Finishing is a processing method to make the cold-rolled sheet meet the customer's requirements, or to facilitate the subsequent processing of the product;

- 2. The finishing equipment can correct the defects produced in the hot rolling and cold rolling production process, such as cracked edge, oily, poor plate shape, residual stress, etc. It needs to ensure that no other defects are brought into the production process;

- 3. There are various finishing equipments, mainly including cross-cutting, slitting, stretching and straightening, annealing furnace, slitter, etc.

Casting and rolling process

Casting and rolling process: liquid metal, front box (liquid level control), casting and rolling machine (lubrication system, cooling water), shearing machine, coiling machine.

Cold rolling production process

Introduction to finishing production process

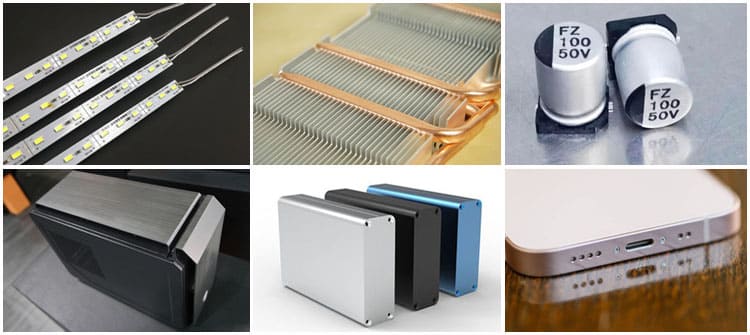

Aluminum alloy has the characteristics of low density, good mechanical properties, good processing performance, non-toxic, easy to recycle, excellent electrical conductivity, heat transfer and corrosion resistance, so it has a wide range of applications.

Aerospace: used to make aircraft skins, fuselage frames, girders, rotors, propellers, fuel tanks, wall panels and landing gear struts, as well as rocket forging rings, spacecraft wall panels, etc.

Aluminum alloy used for aerospace

Transportation: used for car body structure materials of automobiles, subway vehicles, railway passenger cars, high-speed passenger cars, doors and windows, shelves, automotive engine parts, air conditioners, radiators, body panels, wheels and ship materials.

Traffic application

Packaging: All-aluminum pop cans are mainly used as metal packaging materials in the form of thin plates and foils, and are made into cans, lids, bottles, barrels, and packaging foils. Widely used in the packaging of beverages, food, cosmetics, medicines, cigarettes, industrial products, medicines, etc.

Packaging application

Printing: Mainly used to make PS plates, aluminum-based PS plates are a new type of material in the printing industry, used for automatic plate making and printing.

PS printing

Architectural decoration: aluminum alloy is widely used in building structures, doors and windows, suspended ceilings, decorative surfaces, etc. due to its good corrosion resistance, sufficient strength, excellent process performance and welding performance.

Aluminum alloy construction application

Electronic products: computers, mobile phones, refrigerator shells, radiators, etc.

Electronic product application

Kitchen supplies: aluminum pots, aluminum basins, rice cooker liners, household aluminum foil, etc.

Kitchen application

Packaging Of Aluminum Sheet/Coil

Every detail of packaging is where we pursue perfect service. Our packaging process as a whole is as follows:

Lamination: clear film, blue film, micro-mucosal, high-mucosal, laser cutting film (2 brands, Novacell and Polyphem);

Protection: paper corner protectors, anti-pressure pads;

drying: desiccant;

Tray: fumigated harmless wooden tray, reusable iron tray;

Packing: Tic-tac-toe steel belt, or PVC packing belt;

Material Quality: Completely free from defects such as white rust, oil spots, rolling marks, edge damage, bends, dents, holes, break lines, scratches, etc., no coil set.

Port: Qingdao or other ports in China.

Lead time: 15-45 days.

Aluminum sheet/plate packaging process

Aluminum coil packaging process

F: Are you a manufacturer or a trader?

Q: We are a manufacturer, our factory is at No.3 Weier Road, Industrial Zone, Gongyi, Henan, China.

F: What is the MOQ for ordering the product?

Q: Our MOQ is 5 tons, and some special products will have a minimum order quantity of 1 or 2 tons.

F: How long is your lead time?

Q: Generally our lead time is about 30 days.

F: Do your products have quality assurance?

Q: Yes, if there is a quality problem with our products, we will compensate the customer until they are satisfied.

Related Products

Latest Blogs

Trusted 3003 Aluminium Checker Plate Sheet Suppliers Worldwide

Find reliable 3003 Aluminium Checker Plate Sheet Suppliers offering certified quality, competitive pricing, custom sizes, and fast global delivery for your projects.

6061 T6 vs 7075 Aluminum: Strength, Weight & Best Uses

Compare 6061 T6 vs 7075 aluminum easily. Discover differences in strength, weight, and applications to choose the best for your projects.

Industrialization and Application of Honeycomb Aluminum Foil

This blog explores the industrialization of honeycomb aluminum foil, focusing on the 3003 alloy production process. It covers hot rolling, continuous casting, and the continuous casting-rolling method, highlighting the benefits of process optimization in improving mechanical properties, reducing energy consumption, and lowering production costs.