What are the common quality problems of aluminum plates?

1159 Views 2024-04-08 10:00:57

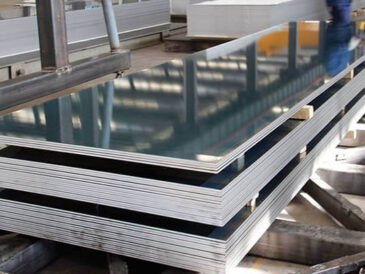

Brief introduction to the quality of aluminum plates

In the production process of aluminum plates and strips, it is very easy to have product quality problems due to incorrect operation of machinery, equipment or staff. Or during the transportation of aluminum plates, surface oxidation or scratches are also prone to problems.

A summary of common product quality issues in the aluminum industry is shown below. I hope this can provide you with some help when purchasing aluminum plates. Huawei Aluminum specializes in the production and sales of aluminum plates/rolls, aluminum foil and other materials. If you have any needs, please contact us.

Common quality problems of aluminum plates

Oil stains are very common in product quality problems: Oil stains refer to excessive amounts of oil on the surface of the aluminum tip after cold rolling, and carry unnecessary oil in addition to the rolling oil film, which are visible to the human eye during the production and inspection processes.

The surface layer is oily. This kind of oil is mainly caused by the roll neck or the upper and lower sides of the hot continuous rolling entrance and exit, splashing, dripping on the surface of the box and the abnormality of the hot continuous rolling roller cleaning device, oil leakage of the hot continuous rolling thickness measuring head, etc., and is usually relatively large. The dirty ingredients are complex.

Oil stained aluminum plate

This type of oil stain will cause greater damage to the surface of the alloy aluminum plate:

First of all, most alloy aluminum sheet plate products are used as decorative or packaging products and must have a clean surface; secondly, whether they are thin or thick, bubbles will easily form after quenching because too much residual oil will affect the use. Oil stains are an important indicator to evaluate the quality of aluminum and platinum.

Solution: Rigorous inspection of production equipment before production. Once too much oil stains are found in the equipment, they should be cleaned immediately, the cause should be found, and the surface of the equipment should be cleaned and processed. If the goods that cannot be cleaned are damaged, oil-stained goods are strictly prohibited from being put into the warehouse and put into the sales market.

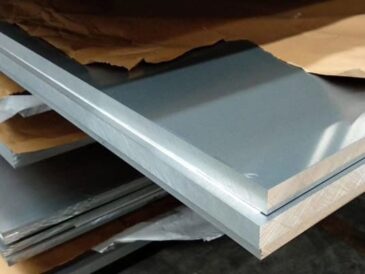

Scratches are a familiar customer of product quality problems: Scratches, scratches and gouges are intermittent or continuous scars on the surface of aluminum alloy plates. It usually occurs when a sharp object comes into contact with the surface of the foil and then slides relative to it.

Main reasons: The surface of hot-rolled strip steel and guide rollers has sharp defects or is stained with hard dirt; the guide rollers and guide paths of cutting, rolling, and splitting machinery have sharp defects or withered dirt. Scratches: Bundles (or groups) on the surface of the box caused by relative sliding or misalignment after the edge of the object touches the surface or surface.

Bruises:

Reason: During processing, transportation or stacking, the friction between different objects causes scars on the surface of the aluminum plate to appear in clusters or groups.

What are the common quality problems of aluminum plates?

Unsatisfactory mechanical properties:

Reasons: incorrect execution of the heat treatment process or equipment failure, such as poor air circulation; improper operation during quenching, excessive loading or substandard salt bath temperature, insufficient holding time or inappropriate outlet temperature; inaccurate laboratory test methods or standards ; The specimen specifications and shape do not meet the requirements, or the surface of the specimen is damaged.