Can lid material

141 Views 2024-06-11 08:00:32

Introduction to can lid material

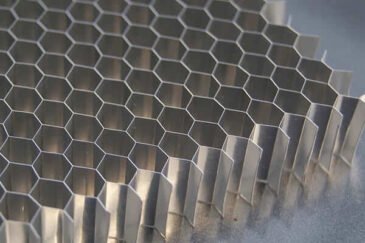

Can lid material is usually made of 5182 aluminum alloy. This material has good formability, strength and sealing, and is suitable for making can lids. In addition, 3104/3004 aluminum alloy is also used as can lid material, especially when good deep drawing performance and thinning stretching are required to achieve lightweight design. The use of these aluminum alloy materials is intended to meet the high standards of can lid materials for processing performance, strength and sealing.

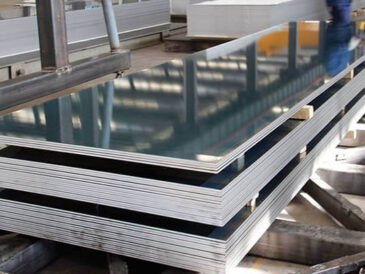

Display of can lids

3004 aluminum alloy is a kind of Al-Mn alloy with higher strength than 3003 aluminum plate, good formability, solubility and corrosion resistance. It is mainly used for parts that require higher strength than 3003 alloy, such as chemical products and storage devices, thin plate processing parts, building baffles, cable ducts, sewer pipes and various lighting parts.

Requirements for can lid materials

Can lids are usually made of metal, usually aluminum. The requirements for can lid materials mainly include the following points:

- Food safety: Can lids must be made of materials that meet food safety standards to ensure that they will not affect the quality and safety of canned food.

- Sealing: The lid must have good sealing performance to ensure that canned food will not be contaminated or oxidized during transportation and storage.

- Corrosion resistance: Can lids need to be able to resist chemicals such as acids and alkalis in food, as well as moisture and oxides in the external environment, to maintain their appearance and performance stability.

- Mechanical properties: Can lids need to have certain mechanical strength and toughness so that they are not easily deformed or damaged during closing and opening.

- Recyclability: Considering the requirements of environmental protection and resource recycling, can lids should generally be recyclable materials and easy to recycle and reuse with the cans themselves.

Introduction to common alloys of can lid materials

3004 aluminum alloy: 3004 aluminum coil is a common material used for can lids. It is mainly composed of aluminum, manganese and a small amount of magnesium, with good formability and corrosion resistance. This alloy is commonly used in the manufacture of can lids because it can provide good mechanical properties and sealing performance.

3104 aluminum alloy: 3104 aluminum alloy is an aluminum alloy commonly used in the manufacture of can lids. It can be used to make early can lids; the tensile strength is greater than or equal to 275MPA, and the elongation can reach 20%; it has good deep drawing performance.

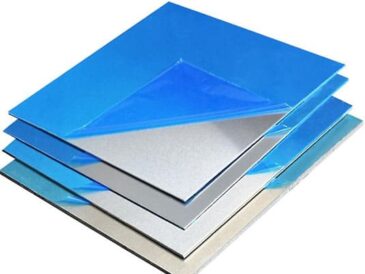

Can lid materials 5182 aluminum coil

5182 aluminum alloy: 5182 aluminum alloy is also a commonly used material for can lids. It is mainly composed of aluminum, magnesium and a small amount of chromium, with high strength and excellent corrosion resistance. 5182 aluminum alloy is usually used in the coating layer of can lids to enhance its corrosion resistance.

Characteristics of can lid materials

- Good formability: Can lids need to be formed, and aluminum alloys have good formability and are easy to manufacture into can lids of various shapes and sizes.

- Excellent sealing: Aluminum alloy can lids can provide good sealing performance, prevent the loss of gas and moisture in food, and maintain the freshness and taste of food.

- Higher strength: The can lid needs to have a certain strength to withstand the extrusion and collision during transportation and storage. Aluminum alloy has appropriate strength to meet this requirement.

- Corrosion resistance: The can lid needs to be able to resist the erosion of chemicals such as acids and alkalis in food, as well as moisture and oxides in the external environment. Aluminum alloy has good corrosion resistance and can maintain the appearance and performance of the can lid.

- Lightweight: Compared with other metal materials, the aluminum alloy can lid has a lower density, making the can lighter as a whole, easier to carry and use.

- Recyclability: Aluminum alloy can lids are recyclable materials, which helps to reduce resource consumption and environmental pollution.

Application of cans

Production process of can lids

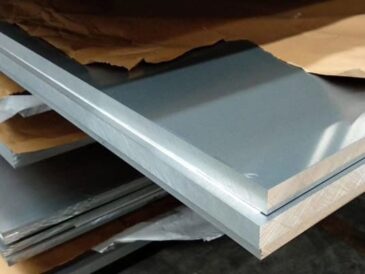

Material preparation: Select suitable aluminum alloy materials and perform pre-processing treatments such as forging and rolling.

Forming: Use a mold to form the aluminum alloy sheet into the shape of the can lid. Deep drawing, stamping and other forming processes can be used.

Surface treatment: The can lid is surface treated, such as cleaning, anodizing, coating, etc., to enhance its corrosion resistance and appearance quality.

Printing and labeling: Print product information, trademarks, safety labels, etc. on the can lid.

Inspection and packaging: Perform quality inspection on the can lid, including size, appearance and performance inspection, and package it after passing the inspection for transportation and use.