Fuel tank aluminum sheet

17,162 Погляди 2024-04-02 03:29:57

Introduction of Fuel tank aluminum sheet

With the promotion of lightweight automobiles, aluminum alloy materials are increasingly used in automobiles. Aluminum alloy materials are gradually used in body structures, doors, паливні резервуари, тощо. to reduce body weight.

Aluminum alloy materials have the characteristics of low density, high lightness, and strong corrosion resistance, and are very suitable for use in automobile fuel tanks.

Fuel tank aluminum sheet also has certain requirements for the tensile strength, подовження, and corrosion resistance of aluminum alloys.

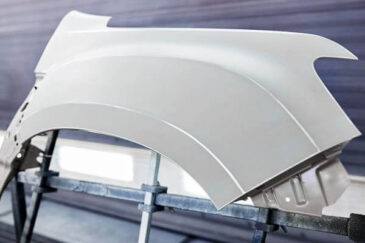

Fuel tank aluminum sheet

Fuel tank aluminum sheet generally uses 5000 Алюмінієвий сплав серії (5005 алюмінієва пластина, 5052 алюмінієва пластина, 5083 алюмінієва пластина, 5754 алюмінієва пластина). Сила 5000 series alloy is higher than that of 1000 серія та 3000 Алюмінієвий сплав серії. It is a medium-high strength alloy with high strength, high formability and high corrosion resistance. It has high surface treatment and good welding performance, so it is widely used in automobile fuel tanks.

Fuel tank aluminum sheet common alloys

Aluminum plate alloys commonly used in automobile fuel tanks mainly include but are not limited to 5052 і 5083 Алюмінієві сплави серії. details as follows:

5052 aluminum alloy plate

5052 aluminum plate is a medium-high strength non-heat-treated strengthened aluminum alloy containing magnesium and a small amount of chromium. It has good formability and weldability, as well as high tensile strength and fatigue strength.

This alloy has excellent corrosion resistance and weather resistance, and is especially suitable for making parts that require corrosion resistance and certain strength requirements, such as automobile fuel tanks. It can effectively prevent fuel from corroding the fuel tank and ensure safety and stability under long-term use.

5083 aluminum alloy plate

5083 aluminum plate is also a high magnesium alloy with excellent corrosion resistance, especially to seawater and marine environments.

Its strength and corrosion resistance are higher than those of the 5052 серія. While maintaining good weldability and processability, it is suitable for occasions with higher hardness and corrosion resistance requirements. It is also widely used in automobile fuel tanks and other pressure vessels. In production.

Fuel tank aluminum sheet chemical composition comparison

| Сплав | І | Феод | Куточок | Мн | Мг | Cr | Zn | На | Al | Інший |

|---|---|---|---|---|---|---|---|---|---|---|

| 5005 | 0.30 | 0.70 | 0.20 | 0.20 | 0.50-1.10 | 0.10 | 0.25 | 0.15 | 余量 | 0.05 (кожен) 0.15 (загальний) |

| 5052 | 0.25 | 0.40 | 0.10 | 0.10 | 2.20-2.80 | 0.15-0.35 | 0.10 | 0.10 | 余量 | 0.05 (кожен) 0.15 (загальний) |

| 5083 | 0.40 | 0.40 | 0.10 | 0.40-1.0 | 4.0-4.9 | 0.05-0.25 | 0.25 | 0.15 | 余量 | 0.05 (кожен) 0.15 (загальний) |

| 5754 | 0.40 | 0.40 | 0.10 | 0.50 | 2.6-3.6 | 0.30 | 0.20 | 0.15 | 余量 | 0.05 (кожен) 0.15 (загальний) |

The magnesium content in 5083 aluminum plate is significantly higher than that of 5052 алюмінієва пластина, which makes 5083 have higher strength and better corrosion resistance, making it more suitable for applications that require higher corrosion resistance, such as ships, хімічне обладнання, and high-pressure vessels.

5052 алюмінієва листова пластина has high strength, especially fatigue strength. In addition to magnesium, the alloy also contains small amounts of manganese, хром, beryllium, titanium and other elements. Серед них, chromium and manganese have similar effects, which can improve the ability of aluminum plates to resist stress corrosion cracking and the strength of the base metal and welds, and reduce the tendency of welding cracks. When encountering severe impact, cracks are not easy to occur, ensuring the safety of the vehicle.

5052 aluminum sheet for fuel tank

На додаток, aluminum alloy is not easy to burn and has obvious explosion-proof effect. The aluminum alloy fuel tank market has broad prospects and is an inevitable trend in the future.

5052 aluminum plate is often used in automobile fuel tanks, ship hulls, aircraft parts and some complex-shaped stamping parts due to its good formability and weldability.

Specifications of Fuel tank aluminum sheet

| Сплави | 5005,5052,5083,5454,5754 |

| Товщина | 1.95-2.5мм |

| Ширина | 700-2600мм |

| Вдача | О, H24, H32, H34, тощо. |

| Performance advantages | good molding and processing performance, Корозійна стійкість |

Advantages of using fuel tank aluminum sheets

Using aluminum sheets for fuel tanks offers several advantages:

- 1. **Lightweight**: Aluminum is lightweight, which can reduce the overall weight of the fuel tank, leading to improved fuel efficiency.

- 2. **Corrosion Resistance**: Aluminum has natural corrosion resistance, which helps protect the fuel tank from rust and other forms of corrosion, extending its lifespan.

- 3. **Strength**: Fuel tank aluminum sheets offer good strength-to-weight ratio, providing durability and structural integrity to the fuel tank.

- 4. **Formability**: Aluminum sheets can be easily formed into various shapes, allowing for the design of complex fuel tank shapes and sizes.

- 5. **Recyclability**: Алюміній підлягає вторинній переробці, making it an environmentally friendly choice for fuel tanks.

- 6. **Heat Conductivity**: Aluminum has good heat conductivity, which can help dissipate heat from the fuel, reducing the risk of overheating.

- 7. **Aesthetic Appeal**: Fuel tank aluminum sheets can be finished in various ways, providing a visually appealing surface for the fuel tank.

Other uses of fuel tank aluminum plates

5083 aluminum sheet is widely used in the manufacturing of fuel truckers. Its main element is magnesium, which has good welding performance, corrosion resistance and processing performance, і середня сила.

5182 aluminum plate is used for the latest high-magnesium alloy tanker which was born for the European road dangerous goods transportation agreement in recent years. Its tensile strength and elongation are relatively high. The excellent quality of 5182 alloy plate improves the safety of aluminum alloy tankers.

5454 алюмінієва листова пластина is suitable for aluminum-magnesium alloy tankers used under high temperature conditions, with strong corrosion resistance.

Cost considerations and ROI of using fuel tank aluminum sheets

The price of aluminum alloy materials is higher than that of steel, and steel is better than aluminum in terms of price.

Однак, the density of fuel tank aluminum sheets is lower. For plates of the same weight and thickness, the number of aluminum plates is higher than that of steel plates. Отже, for the same 1 ton of aluminum plates and steel plates, aluminum plates can make more automobile fuel tanks.

The corrosion resistance of fuel tank aluminum sheet is much higher than that of steel, and its service life is extended.

Due to the low density of the fuel tank aluminum sheet, the overall weight of the vehicle body is reduced, which plays a great role in improving the fuel economy of the car.

Підсумовувати, although the price of fuel tank aluminum sheet is higher than that of steel plate, overall the cost performance of fuel tank aluminum sheet is higher than that of steel.

Market situation of fuel tank aluminum sheets

With the development of various new materials, the rust prevention problem of iron fuel tanks has become a major problem in the quality of fuel tanks. Especially in today’s environmental efforts. Fuel tanks made of fuel tank aluminum sheets are far superior to carbon steel and plastic in terms of corrosion resistance, impact resistance, service life and recycling value.

У 1980, Europe produced the first aluminum alloy fuel tank. By 2004, 400,000 aluminum fuel tanks were produced in Europe, with the number of pillars reaching 1,100 liters.

The truck fuel tanks produced by Mercedes-Benz and MAN have 100% used fuel tank aluminum sheets. The advantage is that they are light in weight, only 40% of the steel fuel tanks of the same volume. They do not require paint, the production process is environmentally friendly, the service life is long, and they can achieve 10 years of anti-corrosion. The material is more than twice that of a steel fuel tank with the same structure, and the material is recyclable. After the aluminum alloy fuel tank is scrapped, the material recycling rate is more than 85%.

Truck fuel tank

Aluminum alloy fuel tanks can not only meet strength requirements, but also have great advantages over new materials such as iron in terms of corrosion resistance. It has also become the first choice for large buses and heavy trucks with high fuel consumption and high fuel quality requirements.

Aluminum alloy fuel tanks have accounted for more than 80% of heavy trucks, buses and multi-purpose vehicles. They are currently occupying the booming fuel tank market and are also the leading direction in the development of fuel tank accessories.

Car door aluminum plate knowledge please visit: Car door aluminum plate