In the sophisticated world of flexible packaging and advanced industrial materials, no single material can perfectly address every requirement. The demand for solutions that combine the best attributes of polymers and metals has led to the widespread adoption of multi-layer composites. Among these, LDPE composite aluminum foil stands out as an exceptionally versatile and high-performance material, leveraging the unparalleled barrier properties of aluminum with the flexibility, sealability, and chemical resistance of Low-Density Polyethylene (LDPE).

This engineered laminate underpins countless products, safeguarding freshness, ensuring hygiene, and providing crucial protection across diverse sectors, from food and pharmaceuticals to construction and electronics.

This comprehensive article delves into the precise composition, defining properties, and intricate manufacturing processes that collectively position LDPE composite aluminum foil as an indispensable choice for modern packaging and industrial solutions, offering profound insights for packaging engineers, material scientists, and procurement specialists.

1. The Composite Imperative: Why Combining Materials Unlocks Superior Performance

The concept of composite materials revolves around combining two or more distinct materials to create a new material with properties superior to its individual components.

In flexible packaging and industrial barriers, this is particularly true.

- Aluminum Foil’s Strength: Aluminum foil is an absolute barrier to moisture, oxygen, light, and aroma, and boasts excellent thermal conductivity/reflectivity. However, it is mechanically fragile (prone to tearing/pinholing when thin) and not heat-sealable on its own.

- LDPE’s Strength: Low-Density Polyethylene (LDPE) is a flexible, tough, chemically resistant, and highly heat-sealable polymer. However, it is permeable to gases, moisture, and light, making it a poor standalone barrier.

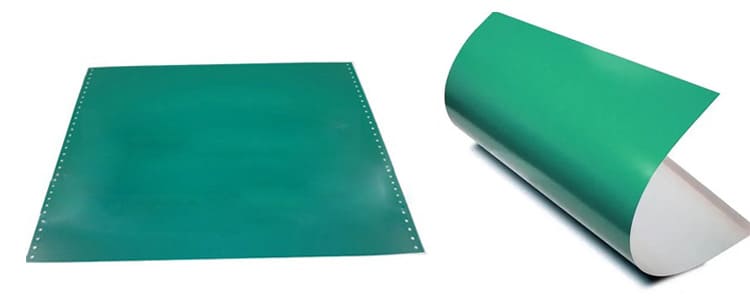

LDPE Composite Aluminum Foil

The synergy of LDPE composite aluminum foil directly addresses the limitations of each component, creating a laminate that provides:

- Unrivaled Barrier Properties: From aluminum.

- Mechanical Strength & Flexibility: From LDPE, preventing foil tearing.

- Heat Sealability: From LDPE, allowing the package to be sealed.

- Chemical Resistance: From LDPE, protecting the aluminum layer.

This layered excellence defines the utility of this specialized composite.

2. Unpacking the Composite: Understanding LDPE and Aluminum Foil

The exceptional performance of LDPE composite aluminum foil stems from the precise interaction of its two primary components.

A. Aluminum Foil: The Absolute Barrier Core

Aluminum foil forms the crucial core of the composite, providing the unparalleled barrier properties that are indispensable for sensitive applications.

Material Composition

Aluminum foil used in these composites is typically derived from high-purity aluminum alloys, carefully selected for their optimal ductility, strength at thin gauges, and ability to be rolled with a low pinhole count. The most common alloys include:

| Alloy | Primary Alloying Elements | Key Property Advantage | Typical Application in Composites (as foil layer) |

| 1050 | Min 99.5% Al | High purity, excellent ductility & chemical inertness | General food packaging, capacitor foil |

| 1200 | Min 99.0% Al | Good ductility, slightly stronger than 1050 | Lids, general flexible packaging |

| 8011 | Fe (0.6-1.0%), Si (0.5-0.9%) | Enhanced strength & puncture resistance, low pinholes | Food, pharma, industrial flexible packaging |

| 8079 | Fe (0.8-1.3%), Si (0.05-0.30%) | Superior strength, very low pinholes, excellent formability at thin gauge | Pharma (e.g., Cold Form Foil), high-barrier food packaging |

| 8021 | Fe (0.8-1.4%), Si (0.05-0.15%) | High strength, excellent pinhole performance | Pharma (e.g., Cold Form Foil), demanding industrial barriers |

Thickness

The thickness of the aluminum foil layer within the composite is a critical design parameter, usually ranging from 6 to 50 micrometers (µm).

Thicker foil generally offers a more robust barrier, greater mechanical resistance to damage, and contributes more to the overall stiffness of the laminate.

Huawei 8079 aluminum foil jumbo roll

Key Properties

- Absolute Barrier: This is the core function. Aluminum foil is virtually 100% impermeable to gases (oxygen), moisture (water vapor), light (UV/visible/IR), and aroma. This comprehensive barrier is unmatched by any single plastic film.

- Thermal Properties: Exhibits high thermal conductivity (rapid heat transfer) and excellent reflectivity (bounces radiant heat), contributing to thermal management of the packaged product.

- Formability: Highly malleable and flexible, providing “dead-fold” characteristics, allowing the composite to conform to various shapes and hold its form.

The choice of alloy and thickness is meticulously matched to the end-use application’s barrier demands, mechanical stresses, and processing requirements.

The table below outlines common aluminum foil alloys used for flexible packaging composites and their typical roles.

B. LDPE (Low-Density Polyethylene): The Flexible, Sealable, Protective Layer

- Material: Low-Density Polyethylene is a thermoplastic polymer characterized by its branched molecular structure, which results in lower density and greater flexibility compared to High-Density Polyethylene (HDPE).

- Thickness: LDPE layers in the composite typically range from 10 to 100 micrometers (µm), adjusted for desired seal strength, thickness, and protective properties.

- Key Properties:

- Excellent Heat Sealability: Melts under heat and pressure to form strong, reliable, hermetic seals, crucial for packaging.

- Flexibility & Toughness: Provides puncture and tear resistance, protecting the delicate aluminum foil layer.

- Chemical Resistance: Resistant to many acids, bases, alcohols, and oils.

- Moisture Barrier (Good for Plastic): While not as absolute as foil, LDPE offers a good moisture barrier for a plastic.

- Cost-Effectiveness: Relatively inexpensive and easy to process.

C. The Bonding Mechanism: Lamination

The aluminum foil and LDPE layers are typically bonded together using an adhesive (e.g., a two-component polyurethane-based adhesive) or through extrusion lamination, where molten LDPE is directly extruded onto the foil, forming a strong, continuous bond.

This multi-layer structure can involve one or more layers of LDPE, sometimes on both sides of the foil (e.g., Foil/LDPE or PET/Foil/LDPE/LDPE).

3. Defining Properties: The Multilayered Power of LDPE Composite Aluminum Foil

The synergy between the robust aluminum foil and the versatile LDPE layers bestows LDPE composite aluminum foil with a highly desirable suite of properties critical for high-performance applications.

Pharmaceutical used LDPE Composite Aluminum Foil

3.1 Unparalleled Barrier Properties: Comprehensive Protection

This is the composite’s crowning achievement.

- Absolute Oxygen Barrier (OTR): Effectively zero (< 0.005 cm³/(m²·day·atm)). This prevents oxygen-induced degradation, rancidity, and flavor loss for sensitive products.

- Absolute Water Vapor Barrier (WVTR): Effectively zero (< 0.005 g/(m²·day)). This eliminates moisture ingress or egress, crucial for maintaining product texture, chemical stability, and preventing caking.

- Complete Light Barrier: The aluminum foil provides full opacity, blocking all visible, UV, and infrared light, protecting light-sensitive contents from photodegradation.

- Absolute Aroma Barrier: Prevents the loss of volatile flavor compounds and blocks external odors, preserving the intended sensory experience.

3.2 Excellent Heat Sealability: Hermetic Integrity

- Impact: The LDPE layer provides the critical heat-sealable surface. It melts under heat and pressure, forming strong, reliable, hermetic seals, essential for creating leak-proof pouches, bags, and closures for liquid, semi-liquid, or gas-sensitive products.

3.3 Enhanced Mechanical Strength & Flexibility: Durability in Handling

- Protection: The LDPE layers provide crucial mechanical support, significantly improving the puncture, tear, and abrasion resistance of the delicate aluminum foil core. This allows the composite to withstand the rigors of manufacturing, filling, transportation, and consumer handling without compromising barrier integrity.

- Flexibility: The overall laminate remains highly flexible, allowing it to conform to product shapes and packaging machinery.

3.4 Chemical Resistance: Versatility for Diverse Contents

- Impact: The LDPE layer’s chemical resistance protects the aluminum foil from direct contact with aggressive contents (e.g., certain foods, chemicals) that might otherwise cause corrosion. This extends the applicability of the composite to a wider range of products.

3.5 Thermal Management & Reflectivity: Temperature Stability

- Impact: The aluminum foil’s high thermal reflectivity (up to 98% radiant heat) helps mitigate temperature fluctuations within the package, contributing to maintaining product temperature (hot or cold). Its thermal conductivity can also aid in rapid heating/cooling of contents in certain applications.

3.6 Food Safety and Non-Toxicity: Consumer Trust

- Impact: All components (aluminum foil, LDPE, and adhesives) are food-grade and non-toxic, making LDPE composite aluminum foil safe for direct contact with food, pharmaceuticals, and other sensitive products.

4. Mechanical Properties Table: Components of LDPE Composite Aluminum Foil

The table below presents typical mechanical properties for the individual components of LDPE composite aluminum foil (in their respective forms), illustrating their contributions.

| Property | Unit | Aluminum Foil (e.g., 8011-O) | LDPE (Typical Film) |

| Tensile Strength | MPa (ksi) | 100 – 145 (15 – 21) | 10 – 25 (1.5 – 3.5) |

| Yield Strength | MPa (ksi) | 40 – 90 (6 – 13) | 8 – 15 (1 – 2) |

| Elongation (% in 50mm) | % | 20 – 30 | 400 – 800 |

| Tear Strength | g/mil | Moderate (can tear if thin) | High (very tough) |

| Thermal Conductivity | W/m·K | ~160 | ~0.3 – 0.4 |

| Density | g/cm³ | 2.71 | 0.91 – 0.94 |

| Melting Point | °C (°F) | ~660 (1220) | ~110 – 120 (230 – 250) |

Note: Values are typical ranges. The final properties of the composite are synergistic, combining the best aspects of each layer.

5. Diverse Applications: Where LDPE Composite Aluminum Foil Excels

The unique blend of properties makes LDPE composite aluminum foil an indispensable material across a wide array of critical applications.

5.1 Food Packaging: Ensuring Freshness and Shelf Life

- Usage: Pouches and bags for coffee, dry soups, snacks, sauces, condiments, and retort pouches for ready meals. Lids for dairy products and prepared foods. Inner liners for cartons (e.g., juice boxes, milk cartons).

- Impact: The absolute barrier properties dramatically extend shelf life, prevent spoilage, and maintain the flavor, aroma, and nutritional value of perishable goods, especially crucial for global distribution and convenience foods.

LDPE Composite Aluminum Foil for food packaging

5.2 Pharmaceutical Packaging: Drug Stability and Patient Safety

- Usage: Sachets and pouches for powders, granules, liquids, or individual tablets. Child-resistant and senior-friendly packaging designs. Used as a component in blister pack laminates.

- Impact: Provides an uncompromised barrier against moisture, oxygen, and light, protecting sensitive APIs from degradation and ensuring drug efficacy and patient safety.

5.3 Medical Device Packaging: Sterility and Integrity

- Usage: Sterile barrier systems for medical devices (e.g., catheters, implants, surgical kits) requiring protection from moisture and environmental contaminants.

- Impact: Ensures devices maintain sterility until point of use, critical for patient safety in healthcare settings.

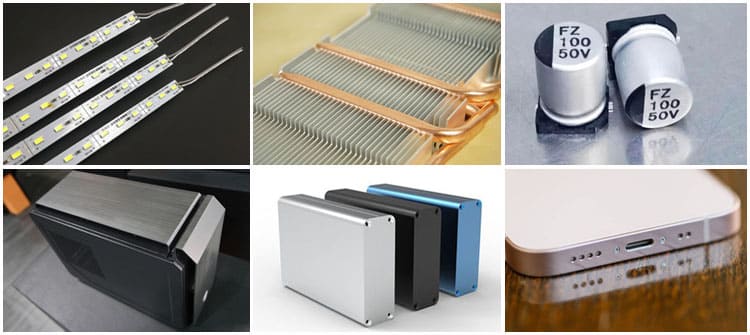

5.4 Electronics Packaging: Protection from Environment & ESD

- Usage: Barrier bags for sensitive electronic components (e.g., PCBs, semiconductors) to protect against moisture, electrostatic discharge (ESD), and corrosion during shipping and storage.

- Impact: Prevents costly damage to high-value electronic components, ensuring reliability and performance.

5.5 Construction & HVAC: Thermal and Vapor Barriers

- Usage: As a facing on insulation materials (e.g., mineral wool, fiberglass) for ductwork, pipes, and building envelopes. Vapor retarders in wall and roof assemblies.

- Impact: Provides an excellent vapor/moisture barrier, preventing condensation and protecting insulation from degradation, thereby enhancing energy efficiency and preventing mold growth.

5.6 Industrial and Chemical Packaging: Hazardous Materials & Sensitive Products

- Usage: Liners for drums and containers, bags for chemical powders, specialty adhesives, and moisture-sensitive industrial materials.

- Impact: Offers robust protection against chemical interaction, moisture ingress, and environmental degradation, crucial for safety and product integrity.

6. Economic and Sustainability Aspects

The use of LDPE composite aluminum foil offers compelling economic and sustainability advantages.

- Cost-Effectiveness (Lifecycle): While initial material cost is higher than some single-layer plastics, the superior product protection, extended shelf life, and prevention of spoilage/recalls lead to significant lifecycle cost savings for manufacturers and consumers.

- Reduced Product Waste: By providing an absolute barrier, it dramatically reduces product spoilage and waste (especially food waste), which often has a much larger environmental footprint than the packaging itself.

- Lightweighting: The composite is highly efficient in its use of materials, minimizing packaging weight and thereby reducing transportation costs and associated carbon emissions.

- Recyclability Challenges: While both aluminum and LDPE are individually recyclable, the multi-material nature of the composite (layers are difficult to separate) presents challenges for conventional recycling streams. Currently, specialized recycling facilities or advanced de-lamination technologies are needed for efficient recovery, though industry efforts are ongoing to improve this.

7. Quality Assurance & Supplier Context (Henan Huawei Aluminum)

The uncompromising demands of various industries necessitate the highest standards of quality assurance for LDPE composite aluminum foil.

From the production of the aluminum foil and LDPE film to their lamination and final product, a robust QA system is non-negotiable.

- Material Certification: Ensuring all components (aluminum foil alloy, LDPE resin, adhesives) meet international standards (e.g., ASTM, FDA, EFSA) for chemical composition, mechanical properties, and food/pharma-grade compliance.

- Barrier Performance Testing: Rigorous testing for Oxygen Transmission Rate (OTR), Water Vapor Transmission Rate (WVTR), and light transmission on the final laminate to confirm absolute barrier properties.

- Bond Strength Testing: Verification of the adhesive bond strength between layers to prevent delamination during processing or use (e.g., peel strength tests).

- Pinhole Control: Rigorous inspection of the aluminum foil layer for an ultra-low pinhole count, crucial for maintaining barrier integrity.

- Heat Seal Integrity: Testing to ensure strong, hermetic, and consistent heat seals are formed.

For manufacturers of packaging, industrial components, and high-tech solutions, sourcing from technically proficient and quality-driven aluminum foil and composite material suppliers is indispensable.

packaging of aluminum foil

Huawei (Henan Huawei Aluminum Co., Ltd.), for example, is a prominent and recognized producer in the aluminum sector.

While Huawei Technologies, the electronics and telecommunications giant, is globally renowned for its advanced devices and sophisticated technological infrastructure (including smart buildings, energy solutions, and industrial automation), its extensive global manufacturing operations and complex supply chains consistently rely on foundational industrial materials from such specialized suppliers.

For instance, in manufacturing facilities that produce appliances, or components where thermal management, structural integrity, or safe material contact is critical, high-quality aluminum materials are indispensable.

Companies like Henan Huawei Aluminum leverage state-of-the-art rolling mills, advanced metallurgical controls, and stringent quality assurance processes to manufacture a comprehensive range of high-performance aluminum foils, including those specifically engineered for applications like LDPE composite aluminum foil.

Their commitment to precise alloying, consistent mechanical properties, superior surface quality, and adherence to relevant industry standards ensures that their materials meet the rigorous demands of various industrial and consumer applications globally, supporting the quality ecosystem of advanced manufacturing and sustainable development.

8. FAQs about LDPE Composite Aluminum Foil

Addressing common inquiries helps clarify the intricacies of LDPE composite aluminum foil for practical application.

Q1: What are the main benefits of combining LDPE with aluminum foil?

A1: The combination provides an absolute barrier to oxygen, moisture, light, and aroma (from the foil), combined with excellent heat sealability, mechanical strength (puncture/tear resistance), and flexibility (from the LDPE). This creates a versatile, high-performance protective material.

Q2: Is LDPE composite aluminum foil safe for food and pharmaceutical contact?

A2: Yes, when produced to food-grade and pharmaceutical-grade standards, all components (aluminum foil, LDPE, and adhesives) are non-toxic, chemically inert, and safe for direct contact with sensitive products, meeting stringent international regulatory approvals.

Q3: Is this material suitable for very hot or cold temperatures?

A3: Yes. The aluminum foil component allows it to handle both high temperatures (e.g., for retort pouches up to 121°C) and very low temperatures (e.g., for frozen foods). LDPE maintains flexibility at low temperatures and provides heat sealability.

Q4: Can LDPE composite aluminum foil be recycled?

A4: Recycling multi-material laminates (aluminum foil bonded to plastic layers) is currently challenging for conventional recycling streams due to the difficulty of separating the layers.

While both aluminum and LDPE are individually recyclable, specialized facilities or advanced de-lamination technologies are needed for efficient recovery.

Industry efforts are ongoing to improve this.

Q5: What is the primary role of the LDPE layer in the composite?

A5: The LDPE layer primarily provides the heat-sealable surface that allows the package to be closed.

It also adds significant mechanical strength, flexibility, and puncture resistance, protecting the delicate aluminum foil barrier layer from damage.

9. Conclusion

The strategic deployment of LDPE composite aluminum foil represents a foundational pillar of modern packaging and advanced industrial solutions.

This meticulously engineered material, through the synergistic combination of aluminum foil’s absolute barrier properties and LDPE’s flexibility, heat sealability, and mechanical strength, delivers unparalleled protection.

From safeguarding the freshness and integrity of food and pharmaceutical products to protecting sensitive electronics and enhancing the energy efficiency of HVAC systems, LDPE composite aluminum foil consistently provides reliable performance and drives innovation.

Despite challenges in recyclability, its critical functional benefits remain indispensable. Supported by rigorous quality assurance and the advanced manufacturing capabilities of leading suppliers, LDPE composite aluminum foil will undoubtedly continue to be an essential material, shaping the future of packaging and contributing significantly to more secure and sustainable industrial practices worldwide.

Casting production process and its introduction

The purpose of melting and casting is to produce alloys with satisfactory composition and high purity of melt, so as to create favorable conditions for casting alloys of various shapes.

Melting and casting process steps: batching --- feeding --- melting --- stirring after melting, slag removal --- pre-analysis sampling --- adding alloy to adjust the composition, stirring --- refining --- static Setting——Guide furnace casting.

Hot rolling production process and its introduction

- 1. Hot rolling generally refers to rolling above the metal recrystallization temperature;

- 2. During the hot rolling process, the metal has both hardening and softening processes. Due to the influence of deformation speed, as long as the recovery and recrystallization process is too late, there will be a certain work hardening;

- 3. The recrystallization of the metal after hot rolling is incomplete, that is, the coexistence of recrystallized structure and deformed structure;

- 4. Hot rolling can improve the processing performance of metals and alloys, reduce or eliminate casting defects.

- 1. The casting and rolling temperature is generally between 680°C and 700°C. The lower the better, the stable casting and rolling line usually stops once a month or more to re-stand. During the production process, it is necessary to strictly control the liquid level of the front tank to prevent low liquid level;

- 2. Lubrication uses C powder with incomplete combustion of gas for lubrication, which is also one of the reasons for the dirty surface of casting and rolling materials;

- 3. The production speed is generally between 1.5m/min-2.5m/min;

- 4. The surface quality of products produced by casting and rolling is generally relatively low, and generally cannot meet products with special physical and chemical performance requirements.

- 1. Cold rolling refers to the rolling production method below the recrystallization temperature;

- 2. There will be no dynamic recrystallization during the rolling process, and the temperature will rise to the recovery temperature at most, and the cold rolling will appear in a work hardening state, and the work hardening rate will be large;

- 3. The cold-rolled sheet and strip have high dimensional accuracy, good surface quality, uniform structure and performance, and products in various states can be obtained with heat treatment;

- 4. Cold rolling can roll out thin strips, but at the same time, it has the disadvantages of high energy consumption for deformation and many processing passes.

- 1. Finishing is a processing method to make the cold-rolled sheet meet the customer's requirements, or to facilitate the subsequent processing of the product;

- 2. The finishing equipment can correct the defects produced in the hot rolling and cold rolling production process, such as cracked edge, oily, poor plate shape, residual stress, etc. It needs to ensure that no other defects are brought into the production process;

- 3. There are various finishing equipments, mainly including cross-cutting, slitting, stretching and straightening, annealing furnace, slitter, etc.

Casting and rolling process

Casting and rolling process: liquid metal, front box (liquid level control), casting and rolling machine (lubrication system, cooling water), shearing machine, coiling machine.

Cold rolling production process

Introduction to finishing production process

Aluminum alloy has the characteristics of low density, good mechanical properties, good processing performance, non-toxic, easy to recycle, excellent electrical conductivity, heat transfer and corrosion resistance, so it has a wide range of applications.

Aerospace: used to make aircraft skins, fuselage frames, girders, rotors, propellers, fuel tanks, wall panels and landing gear struts, as well as rocket forging rings, spacecraft wall panels, etc.

Aluminum alloy used for aerospace

Transportation: used for car body structure materials of automobiles, subway vehicles, railway passenger cars, high-speed passenger cars, doors and windows, shelves, automotive engine parts, air conditioners, radiators, body panels, wheels and ship materials.

Traffic application

Packaging: All-aluminum pop cans are mainly used as metal packaging materials in the form of thin plates and foils, and are made into cans, lids, bottles, barrels, and packaging foils. Widely used in the packaging of beverages, food, cosmetics, medicines, cigarettes, industrial products, medicines, etc.

Packaging application

Printing: Mainly used to make PS plates, aluminum-based PS plates are a new type of material in the printing industry, used for automatic plate making and printing.

PS printing

Architectural decoration: aluminum alloy is widely used in building structures, doors and windows, suspended ceilings, decorative surfaces, etc. due to its good corrosion resistance, sufficient strength, excellent process performance and welding performance.

Aluminum alloy construction application

Electronic products: computers, mobile phones, refrigerator shells, radiators, etc.

Electronic product application

Kitchen supplies: aluminum pots, aluminum basins, rice cooker liners, household aluminum foil, etc.

Kitchen application

Packaging Of Aluminum Sheet/Coil

Every detail of packaging is where we pursue perfect service. Our packaging process as a whole is as follows:

Lamination: clear film, blue film, micro-mucosal, high-mucosal, laser cutting film (2 brands, Novacell and Polyphem);

Protection: paper corner protectors, anti-pressure pads;

drying: desiccant;

Tray: fumigated harmless wooden tray, reusable iron tray;

Packing: Tic-tac-toe steel belt, or PVC packing belt;

Material Quality: Completely free from defects such as white rust, oil spots, rolling marks, edge damage, bends, dents, holes, break lines, scratches, etc., no coil set.

Port: Qingdao or other ports in China.

Lead time: 15-45 days.

Aluminum sheet/plate packaging process

Aluminum coil packaging process

F: Are you a manufacturer or a trader?

Q: We are a manufacturer, our factory is at No.3 Weier Road, Industrial Zone, Gongyi, Henan, China.

F: What is the MOQ for ordering the product?

Q: Our MOQ is 5 tons, and some special products will have a minimum order quantity of 1 or 2 tons.

F: How long is your lead time?

Q: Generally our lead time is about 30 days.

F: Do your products have quality assurance?

Q: Yes, if there is a quality problem with our products, we will compensate the customer until they are satisfied.

Related Products

Latest Blogs

Ultra-high reflectivity aluminum mirror sheet

Ultra-high reflectivity aluminum mirror sheet with 95–98% visible reflectance, low scatter (TIS <1%), and specification advice for BRDF, spectral curves and coatings.

Trusted 3003 Aluminium Checker Plate Sheet Suppliers Worldwide

Find reliable 3003 Aluminium Checker Plate Sheet Suppliers offering certified quality, competitive pricing, custom sizes, and fast global delivery for your projects.

6061 T6 vs 7075 Aluminum: Strength, Weight & Best Uses

Compare 6061 T6 vs 7075 aluminum easily. Discover differences in strength, weight, and applications to choose the best for your projects.

Industrialization and Application of Honeycomb Aluminum Foil

This blog explores the industrialization of honeycomb aluminum foil, focusing on the 3003 alloy production process. It covers hot rolling, continuous casting, and the continuous casting-rolling method, highlighting the benefits of process optimization in improving mechanical properties, reducing energy consumption, and lowering production costs.