8021 Aluminum Foil introduction

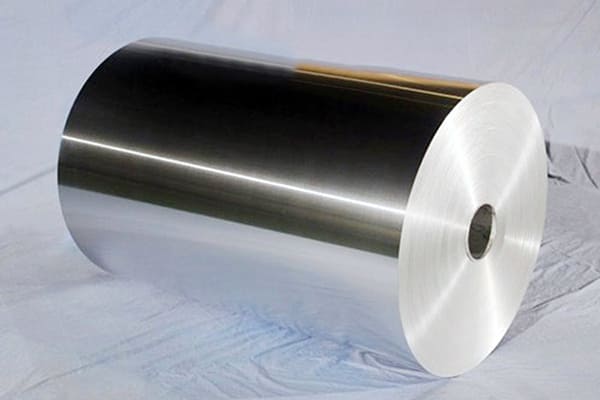

8021 aluminum foil is one of the superior products of Huawei Aluminum. The thickness range of production is 0.006mm-0.2mm, and the width can be controlled at 100-1600mm according to customer requirements. 8021 aluminum foil is the main product of food packaging and battery soft packaging aluminum foil.

8021 aluminum foil has excellent moisture-proof performance, light-shielding and extremely high barrier ability. Non-toxic and tasteless, safe and hygienic. Aluminum foil after compounding, printing and gluing is widely used as packaging material.

8021 Aluminum Foil Introduction

8079 aluminum foil has high strength, good elongation and stretchability. 8079 aluminum foil not only has the advantages of moisture-proof, air-tight, shading, abrasion-resistant, fragrant, non-toxic and tasteless, but also because of its elegant silver-white luster, it is easy to process beautiful patterns and patterns of various colors, so it is easier favored by people. 8079 aluminum foil is widely used in food packaging, pharmaceutical packaging, battery soft packs and other fields.

8021 Aluminum Foil Chemical Composition

| Si | Cu | Mg | Zn | Mn | Cr | Fe | Ti | Other | Other total | Al |

| ≤ 0.5-0.9 | ≤ 0.1 | ≤ 0.05 | ≤ 0.1 | ≤ 0.2 | ≤ 0.05 | ≤ 0.6-1.0 | ≤ 0.08 | ≤ 0.05 | ≤ 0.15 | remainder |

Specifications and applications of 8021 aluminum foil

| Product | Type | Temper | Thickness(mm) | Width(mm) |

| 8021 battery case foil | polished,bare | O/HX2 HX4 | 0.036-0.055 | 200-1600 |

| 8021 Packaging Foil | O H22/H24 | 0.016-0.2 | 150-1600 | |

| 8021 Medicinal foil | H14/H18 | 0.018-0.2 | 200-1600 |

Advantages of Huawei 8021 Aluminum Foil

- (1) The surface is clean and hygienic, and no bacteria or microorganisms can grow on the surface.

- (2) 8021-O aluminum foil is a non-toxic packaging material, which can be in direct contact with food without any danger to human health.

- (3) 8021-O aluminum foil is a tasteless and odorless packaging material, which will not cause any peculiar smell to the packaged food.

- (4) No matter at high temperature or low temperature, the 8021-O aluminum foil will not have the phenomenon of grease penetration.

- (5) 8021-O aluminum foil has high hardness and high tensile strength, but its tear strength is small, so it is easy to tear.

- (6) 8021-O aluminum foil is an opaque packaging material, so it is a good packaging material for products exposed to sunlight, such as margarine.

- (7) 8021-O aluminum foil has good plasticity, so it can be used to package products of various shapes. Containers of various shapes can also be made arbitrarily.

8021 aluminum foil has excellent moisture-proof performance, light-shielding and extremely high barrier ability.

Non-toxic and tasteless, safe and hygienic. Aluminum foil after compounding, printing and gluing is widely used as packaging material.

8021 aluminum foil is the main product of food packaging and battery soft package aluminum foil.

The Difference Between 8011 Aluminum Foil And 8021 Aluminum Foil

1. 8011 aluminum foil contains Mn and Mg elements, but 8021 aluminum foil does not contain these two elements, so the strength and corrosion resistance of 8011 aluminum foil are higher than that of 8021 aluminum foil;

2. Aluminum foil 8011 has high strength, but the corresponding elongation and puncture resistance under the same state are lower than 8021 aluminum foil. 8021 aluminum foil and 8079 aluminum foil are mostly used for blister aluminum and tropical aluminum that require higher performance and elongation;

3. The use of aluminum foil 8011 is more extensive, and can be used in many fields such as pharmaceutical packaging, food packaging, lunch box materials, tape foil, cable foil, milk cap material, bottle cap material, etc., while 8021 aluminum foil is relatively expensive and is mostly used for requirements Relatively high lithium battery soft package aluminum plastic film and blister drug packaging.

8011 Aluminum Foil

Typical Application Of 8021 Aluminum Foil

8021 aluminum foil has excellent moisture-proof performance, light-shielding and extremely high barrier ability. Non-toxic and tasteless, safe and hygienic. Aluminum foil after compounding, printing and gluing is widely used as packaging material.

8021-O Aluminum Foil Meets The Standard Of Pharmaceutical Foil

The application of pharmaceutical aluminum foil is very extensive and mature. The main uses of pharmaceutical foil are blister packaging of pharmaceutical capsules, tablets, etc., as well as bag packaging of powder granules and water. Due to its direct contact with edible medicines, the country has very strict requirements on the appearance and performance of medicine foils.

There are two common medicinal foils on the market, 8011 aluminum foil and 8021 aluminum foil. The thickness of 8011 alloy is generally below 0.05mm, and the thickness of 8021 alloy is above 0.05mm. Today we will discuss about 8021-O pharmaceutical aluminum foil.

8021 Aluminum Foil for Pharmaceutical Foil

8021 aluminum foil is one of the key products of Huawei Aluminum. The thickness range of production is 0.018mm-0.2mm, and the width can be controlled at 100-1650mm according to customer requirements.

The surface of the 8021-O pharmaceutical aluminum foil produced by Huawei should be clean, smooth, and evenly coated, without dense, continuous, and periodic pinholes, and the content of heavy metals should not exceed 0.25 parts per million. And ensure that ventilation, moisture-proof, dust-proof, sun-proof, mildew-proof, anti-corrosion candle gas and liquid are paid attention to during storage. The distance between the packing box and the ground and wall is about 100mm, which is very in line with the production and storage standards of medicinal aluminum foil.

8021-O Requirements For Pharmaceutical Packaging Aluminum Foil

Pharmaceutical packaging should follow the following principles:

- (1) Prevent changes in drug quality

- (2) Ease of use

- (3) Be able to provide explanatory information such as drug characteristics and usage matters

The Characteristics Of Aluminum Foil In Pharmaceutical Packaging Are As Follows

(1) Protection function: ① Moisture-proof ② Light-shielding ③ Air-shielding

(2) Use performance: ①Easy to tear; ②Hard aluminum foil, easy to take out the medicine

(3) Information expression: the surface of aluminum foil can be printed or engraved, and has the ability to carry text and pattern information

8021 Food Packaging Aluminum Foil

8021 aluminum foil is one of the raw materials used in aluminum food packaging industry. 8021 aluminum foil has the characteristics of cleanliness and sanitation. In addition, the surface of aluminum foil has a shiny effect. It can be made into integrated packaging materials with many other packaging materials. Moreover, the surface printing effect of 8021 aluminum foil is better than other materials. Therefore, 8021 aluminum foil is widely used in the field of food packaging.

As one of the 8 series aluminum foils, 8021 aluminum foil is the most commonly used alloy product for food packaging aluminum foil, which is inseparable from its good alloy properties. The surface of 8021 aluminum foil is extremely clean and hygienic. No bacteria or microorganisms can grow on the surface. It is a non-toxic packaging material that can be in direct contact with food without any danger to human health.

8021 Food Packaging Aluminum Foil

8021 aluminum foil is an opaque packaging material. It is a good packaging material for products that need to avoid sunlight. For example, aluminum foil packaging is commonly used for margarine packaging. In terms of processing, 8021 aluminum foil has good plasticity and can be processed into products of various shapes, and can also be arbitrarily formed into containers of various shapes.

In food packaging, 8021 aluminum foil is mainly used for cooking and holding food in the kitchen, or for making some materials that can be easily cleaned, and can wrap food on both sides. It is usually wrapped with the bright side of the finished product to improve the heat conduction effect; it is very common to process 8021 aluminum foil into packaging materials, such as aluminum foil trays for food. Although some aluminum foil packaging is disposable tableware, the ingredient is aluminum, which is more harmful to nature. Some foods (such as: sweet potatoes, enoki mushrooms, etc.) must be wrapped in aluminum foil to avoid burning; use aluminum foil to cook seafood, enoki mushrooms, etc., to preserve the flavor.

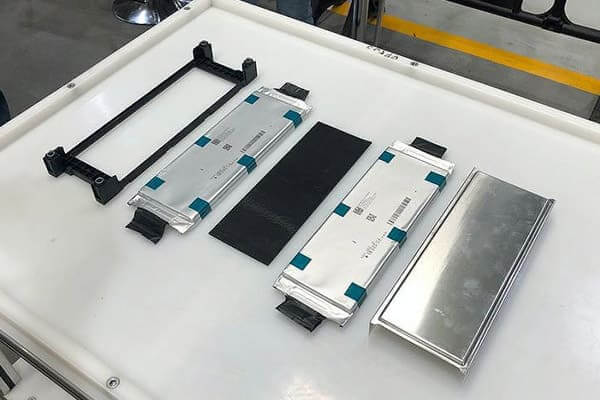

8021 Aluminum Foil For Lithium Battery Soft Package

The packaging material used in soft-pack lithium batteries is aluminum-plastic composite film, referred to as aluminum-plastic film. What is the aluminum-plastic film? The aluminum-plastic film is composed of five layers: the outer nylon layer, the adhesive, the middle layer of aluminum foil, the adhesive, and the inner heat-sealing layer.

The main purpose of the Al layer material in the middle is to prevent the infiltration of moisture in the air. When moisture penetrates into the battery cell, it will react with the electrolyte to generate HF and form a side reaction to generate a large amount of gas, causing the lithium battery to bulge, which is one of the important hidden dangers of the lithium battery. The Al layer has a certain strength and can prevent damage to the cell by external force.

The advantages of soft pack batteries in terms of energy density, cycle life and safety make their penetration rate in the field of consumer electronics close to 70%, and their market share in the field of power batteries is less than 13%. In the car-dominated market, more power battery companies will join the production of pouch batteries in the future.

8021 Aluminum Foil For Lithium Battery Soft Package

The aluminum layer of the lithium battery soft-packed aluminum-plastic film uses 8021 aluminum foil. The main products of the 8021 aluminum-plastic film soft-packed battery aluminum foil are 8021 aluminum alloy coils. The 8021 aluminum foil produced by Huawei has a clean, smooth and oil-free surface. Good adhesion and lamination performance, not easy to fall off and delaminate; at the same time, the product has excellent stamping and puncture resistance. After testing, the elongation of Huawei 8021 aluminum foil can reach 13%-18%, cupping The highest can reach 7.3mm. It is one of the few aluminum foil substrate manufacturers in China that can fully meet the processing requirements of aluminum-plastic film for lithium batteries.

Advantages Of 8021 Aluminum Foil For Soft Pack Lithium Battery

- 1. The quality is lighter. Soft-pack batteries are 40% lighter than steel-cased cylindrical lithium batteries of the same capacity, and 20% lighter than aluminum-cased prismatic lithium batteries. The product is lighter and thinner, which can reduce the weight of the vehicle and provide longer cruising range to meet lightweight requirements. direction of development.

- 2. Higher security. The pouch battery is packaged in aluminum-plastic film. When a short-circuit accident occurs, it will generally explode and burst, which is relatively safe and suitable for assembly of passenger cars.

- 3. Longer service life. The internal resistance of the soft-pack lithium battery is small, which can greatly reduce the self-consumption of the battery. In addition, the cycle life of the soft-pack lithium battery is longer.

Other Aluminum Alloys Application In Power Batteries

| Typical Alloy | Material status | Thickness (mm) | Width(mm) | Length(mm) | Typical product |

|---|---|---|---|---|---|

| 5182 battery cover sheet | O | 1.0 | Customized | C | Battery cover material |

| 5083 separator material (battery side panel) | O | 1.0—2.0 | Customized | C | Separator material (battery side plate) |

| 3003 power battery shell material | O | 1.0—3.0 | Customized | C | Power battery shell material |

| 3003 mobile phone battery shell material | H14 | 0.6 | Customized | C | Mobile phone battery shell material |

| Typical Alloy | Material status | Thickness (mm) | Width(mm) | Length(mm) | Typical product |

|---|---|---|---|---|---|

| 3003 battery water cooling sheet | O/H14 | 1.0-3.0 | Customized | C | Materials for battery water cooling plate |

| 5083 separator material (battery side panel) | O | 1.0—2.0 | Customized | C | Separator material (battery side plate) |

| 3003 power battery shell material | O | 0.6—3.0 | Customized | C | Power battery shell material |

| 6061 power battery tray | O | 1.0-12 | Customized | C | Tray material for power battery |

Advantages Of Our Equipment

1. Foil rolling: introduce international equipment, improve the quality of aluminum foil, and increase the rate of finished products

10 foil rolling mills with an annual output of more than 50,000 tons.

The use of ANDRITZ shape rolls guarantees a good shape. The Honeywell thickness gauge is used to ensure the control of the outlet thickness.

2. Mechanical: excellent air barrier performance, temperature resistance

The equipment and instruments ensure the printing effect and mechanical properties of the food packaging foil, and improve the product’s air insulation performance and temperature resistance.

Aluminum Foil Jumbo Roll

3. 30 tons of annealing furnace: natural gas annealing, fast heating, good effect

Furnace body equipment includes box type furnace body, air circulation system, diversion device, purge and exhaust system, bayonet type heater, furnace door, furnace door lifting mechanism and pressing device, cooling water system, etc. The maximum working temperature of the furnace is 650°C, the temperature difference is ≤±5°C, and the metal annealing temperature is 120~580°C. At the end of the heat preservation, the metal temperature difference is ≤±3°C, which enhances the product quality and improves the product process level.

Our Packing Materials And Shipping

In addition to basic packaging materials such as desiccant, moisture-proof film, kraft paper, wooden tray, wooden board, and steel strip, battery foil must also be padded with sponge strips to prevent the bottom of the roll from being scratched. Moreover, the battery foil is thin and easy to damage, so it needs to be boxed and packaged in the end to prevent water, rain, and bumps.

Packing And Shipping

The same desiccant is added to the battery foil products sent to different regions (for example, some places are rainy and some are dry and hot), because the company uses the highest standard desiccant.

We have a reliable and long-term cooperative freight forwarder to ensure that the goods are delivered to the port on time.

Casting production process and its introduction

The purpose of melting and casting is to produce alloys with satisfactory composition and high purity of melt, so as to create favorable conditions for casting alloys of various shapes.

Melting and casting process steps: batching --- feeding --- melting --- stirring after melting, slag removal --- pre-analysis sampling --- adding alloy to adjust the composition, stirring --- refining --- static Setting——Guide furnace casting.

Hot rolling production process and its introduction

- 1. Hot rolling generally refers to rolling above the metal recrystallization temperature;

- 2. During the hot rolling process, the metal has both hardening and softening processes. Due to the influence of deformation speed, as long as the recovery and recrystallization process is too late, there will be a certain work hardening;

- 3. The recrystallization of the metal after hot rolling is incomplete, that is, the coexistence of recrystallized structure and deformed structure;

- 4. Hot rolling can improve the processing performance of metals and alloys, reduce or eliminate casting defects.

- 1. The casting and rolling temperature is generally between 680°C and 700°C. The lower the better, the stable casting and rolling line usually stops once a month or more to re-stand. During the production process, it is necessary to strictly control the liquid level of the front tank to prevent low liquid level;

- 2. Lubrication uses C powder with incomplete combustion of gas for lubrication, which is also one of the reasons for the dirty surface of casting and rolling materials;

- 3. The production speed is generally between 1.5m/min-2.5m/min;

- 4. The surface quality of products produced by casting and rolling is generally relatively low, and generally cannot meet products with special physical and chemical performance requirements.

- 1. Cold rolling refers to the rolling production method below the recrystallization temperature;

- 2. There will be no dynamic recrystallization during the rolling process, and the temperature will rise to the recovery temperature at most, and the cold rolling will appear in a work hardening state, and the work hardening rate will be large;

- 3. The cold-rolled sheet and strip have high dimensional accuracy, good surface quality, uniform structure and performance, and products in various states can be obtained with heat treatment;

- 4. Cold rolling can roll out thin strips, but at the same time, it has the disadvantages of high energy consumption for deformation and many processing passes.

- 1. Finishing is a processing method to make the cold-rolled sheet meet the customer's requirements, or to facilitate the subsequent processing of the product;

- 2. The finishing equipment can correct the defects produced in the hot rolling and cold rolling production process, such as cracked edge, oily, poor plate shape, residual stress, etc. It needs to ensure that no other defects are brought into the production process;

- 3. There are various finishing equipments, mainly including cross-cutting, slitting, stretching and straightening, annealing furnace, slitter, etc.

Casting and rolling process

Casting and rolling process: liquid metal, front box (liquid level control), casting and rolling machine (lubrication system, cooling water), shearing machine, coiling machine.

Cold rolling production process

Introduction to finishing production process

Aluminum alloy has the characteristics of low density, good mechanical properties, good processing performance, non-toxic, easy to recycle, excellent electrical conductivity, heat transfer and corrosion resistance, so it has a wide range of applications.

Aerospace: used to make aircraft skins, fuselage frames, girders, rotors, propellers, fuel tanks, wall panels and landing gear struts, as well as rocket forging rings, spacecraft wall panels, etc.

Aluminum alloy used for aerospace

Transportation: used for car body structure materials of automobiles, subway vehicles, railway passenger cars, high-speed passenger cars, doors and windows, shelves, automotive engine parts, air conditioners, radiators, body panels, wheels and ship materials.

Traffic application

Packaging: All-aluminum pop cans are mainly used as metal packaging materials in the form of thin plates and foils, and are made into cans, lids, bottles, barrels, and packaging foils. Widely used in the packaging of beverages, food, cosmetics, medicines, cigarettes, industrial products, medicines, etc.

Packaging application

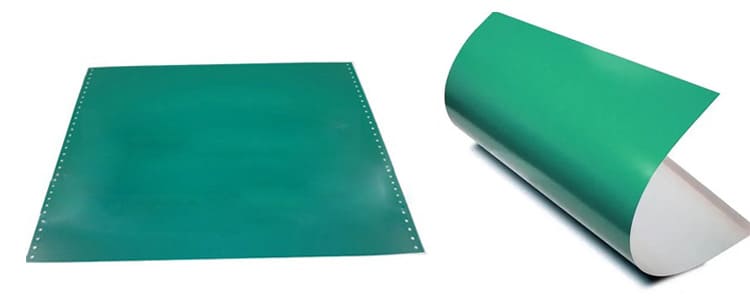

Printing: Mainly used to make PS plates, aluminum-based PS plates are a new type of material in the printing industry, used for automatic plate making and printing.

PS printing

Architectural decoration: aluminum alloy is widely used in building structures, doors and windows, suspended ceilings, decorative surfaces, etc. due to its good corrosion resistance, sufficient strength, excellent process performance and welding performance.

Aluminum alloy construction application

Electronic products: computers, mobile phones, refrigerator shells, radiators, etc.

Electronic product application

Kitchen supplies: aluminum pots, aluminum basins, rice cooker liners, household aluminum foil, etc.

Kitchen application

Packaging Of Aluminum Sheet/Coil

Every detail of packaging is where we pursue perfect service. Our packaging process as a whole is as follows:

Lamination: clear film, blue film, micro-mucosal, high-mucosal, laser cutting film (2 brands, Novacell and Polyphem);

Protection: paper corner protectors, anti-pressure pads;

drying: desiccant;

Tray: fumigated harmless wooden tray, reusable iron tray;

Packing: Tic-tac-toe steel belt, or PVC packing belt;

Material Quality: Completely free from defects such as white rust, oil spots, rolling marks, edge damage, bends, dents, holes, break lines, scratches, etc., no coil set.

Port: Qingdao or other ports in China.

Lead time: 15-45 days.

Aluminum sheet/plate packaging process

Aluminum coil packaging process

F: Are you a manufacturer or a trader?

Q: We are a manufacturer, our factory is at No.3 Weier Road, Industrial Zone, Gongyi, Henan, China.

F: What is the MOQ for ordering the product?

Q: Our MOQ is 5 tons, and some special products will have a minimum order quantity of 1 or 2 tons.

F: How long is your lead time?

Q: Generally our lead time is about 30 days.

F: Do your products have quality assurance?

Q: Yes, if there is a quality problem with our products, we will compensate the customer until they are satisfied.

Related Products

Latest Blogs

6061 vs 7075 aluminum

"6061" and "7075" are two common aluminum alloy grades, which are widely used in many industrial fields, especially in aviation, aerospace, transportation and structural manufacturing.

Aluminum Foil Used in Air Fryers

Aluminum foil is widely used in daily life, mainly due to its light weight, good ductility, moderate price, and excellent heat conduction and light-shielding properties.

Reasons why the surface of honeycomb aluminum foil cannot be bonded with the adhesive

Aluminum honeycomb panels have good performance in use. They have good strength and good impact resistance. They can be well designed in use. Therefore, they are widely used at present.

Introduction hardness of 1000-8000 series aluminum alloys

1000-8000 series basically covers all aluminum alloy series products. Different series of products have different performance and hardness.