Quick Understanding Of 3105 Aluminiumsplate

3105 aluminum sheet is essentially a 98% aluminum alloy with a small amount of manganese added for strength, making it more than alloys 1100 og 3003 aluminiumsplate.

3105 aluminum alloy cannot be strengthened by heat treatment, har god korrosjonsbestandighet, good plasticity and processing performance, and has good gas welding and arc welding performance.

3105 Display av aluminiumsplater

Typical applications for 3105 aluminum sheet include metal products that require higher strength than 1000 serie aluminiumslegeringer, residential siding, mobile homes, and sign making.

Chemical Composition Of 3105 Aluminiumsplate

| Elementer | Og | Fe | Cu | Mn | Mg | Cr | Zn | Av | Andre | Al |

| Innhold (maks) | 0.6 | 0.70 | 0.30 | 0.3.-0.80 | 0.20-0.80 | 0.20 | 0.40 | 0.10 | 0.15 | remain |

3105 aluminum is a 3000 serie aluminiumslegering: the main alloy addition is manganese, which improves the strength of the alloy.

0.3% copper is added to 3105 aluminiumslegering, so the conductivity is good, and the conductivity can reach 41%;

Mechanical Properties With Different Temper

Requirements for strain hardened H14 temper (½ hard)

as specified in ASTM B209 and ASME SB209

| Materiale | Temperament | Strekkstyrke (N/mm²) | Yield Styrke (N/mm²) | Elongation on 50mm | |||

| 0.5 mm | 0.8mm | 1.3mm | 2.6mm | ||||

| 3105 Aluminiumsplate | 0 | 110-155 | – | 16 | 18 | 20 | 20 |

| 3105 Aluminiumsplate | H12 | 130-175 | 115 | 2 | 3 | 4 | 5 |

| 3105 Aluminiumsplate | H14 | 160-205 | 145 | 2 | 2 | 3 | 4 |

| 3105 Aluminiumsplate | H16 | 185-230 | 170 | 1 | 1 | 2 | 3 |

| 3105 Aluminiumsplate | H18 | 215 min | 190 | 1 | 1 | 1 | 2 |

3105 aluminum sheet has high plasticity in the annealing state, in the semi cold hardened, the plasticity is still better, it has low plasticity, god korrosjonsbestandighet, good weld-ability and poor cutting properties in cold hardening state.

3105 Aluminum Sheet Physical Properties

| Eiendom | Data |

| Calomel Potential | -750 mV |

| Tetthet | 175 Ib/ft3′ |

| Electrical Conductity | 44 % IACS |

| Elektrisk resistivitet | 1.504 μQ-in |

| Melting Onset (Solidus) | 1180 °F (638 ℃) |

| Spesifikk varmekapasitet | 0.214 BTU/Ib-oF |

| Termisk ledningsevne | 98 BTU/ft Hr oF |

| Thermnal Difusivity | 721 ft/s |

| CTE (68-212F) | 13.1 pin/in-9F |

3105 Aluminum Plate Advantages

- 1. Good conductivity, adding 0.3% copper element, the conductivity can reach 41%;

- 2. Deep drawing ability. The deep drawing performance of 3105 aluminum alloy plate in O state is better than that in H26 state, and the deep drawing performance of 3105 aluminum alloy plate before low temperature treatment is better than that after 24h treatment.

- 3. De 3105 aluminum sheet has high plasticity in the annealed state, good plasticity in semi-cold work hardening, and low plasticity in cold work hardening.

- 4. The excellent weldability of 3105 aluminum plate is suitable for all existing welding techniques, among which arc welding is the best method.

- 5. Other features. God korrosjonsbestandighet, good anodic oxidation performance, poor machinability, osv.

advantages of 3105 aluminiumsplate

Due to its good anti-corrosion performance, this series of aluminum plates are often used in humid environments such as air conditioners, refrigerators, and the bottom of cars.

Typical characteristics of 3105 aluminium

| Principal Design Features | This is an essentially 98% pure aluminum alloy with minor additions for strength. It is not hardenable by heat treatment. Korrosjonsbestandighet,formability and welding characteristics are excellent. |

| Bearbeidbarhet | Machinability of AL 3105 is fair. Oil lubricants should be used for all machining operations. Machinability of the alloy when in the harder (H) tempers is improved over machining in the annealed (O) condition. |

| Forming | The forming characteristics of the alloy are very good by all conventional processes regardless of temper. Bend radii should be in the one thickness to 2 t range for annealed, H12, H14 and H16 tempers. The H18 temper requires bend radii of2 to 7 t, depending upon thickness of the material. |

| Welding | Weldability of this alloy is excellent by all commercial techniques. Arc welding is preferred for the best results. |

| Heat Treatment | A non-heat treatable alloy. |

| Hot Working | The hot working range (as for forging) is 205°C to 372°C. In that range the alloy is easily hot worked. |

| Cold Working | The cold working characteristics of AL 3105 are very good, even in the harder cold worked tempers. Bend radi for sheet up to 1/16″ thick vary from 1/2 to one t for all tempers. |

| Gløding | Annealing from a cold worked condition may be accomplished at 345°C followed by air cooling. |

| Aging | Not applicable to this alloy. |

| Hardening | Hardens as a result of cold working only. |

| Typical Applications | Aluminium 3105 is most commonly used where a painted finish is desired.Typical applications include general sheet metal work requiring greater strength than is provided by 1000 serie aluminiumslegeringer, residential siding, room partition, baffle, mobile homes, rain carrying goods and sign making. |

| Package | Packed in waterproof Kraft, fastened by steel straps on wood pallets, suitable for handling, loading and unloading from the trunks or containers, suitable for export ocean forwarding. |

| Handling | Prevent the goods hurting the people who are moving, loading, unloading, especially pay attention to the rlling and dropping for the coils. |

| Lagring | Stored in indoor area on plain floor, free away from moisture, vann, snow, animal oils and dye wastes, avoid storing with acid or basic chemical goods. |

Data Sources: 3105 aluminium

Sizas Huawei Aluminum Supply Of 3105 aluminum Sheet

Huawei Aluminium har vært engasjert i produksjon og salg av aluminiumsprodukter for 22 år. It has rich experience in the production and export of aluminum sheets. We provide customized 3105 aluminiumsplater. The following are common sizes:

- 4×8 aluminum sheet plate

- 4×10 aluminiumsplate

- 5×10 aluminiumsplate

- 1000 x 1500 mm aluminiumsplate

- 1500 x 2000mm aluminum sheet

- 1500 x 3000mm aluminum sheet

- 2000 x 3000mm aluminum sheet

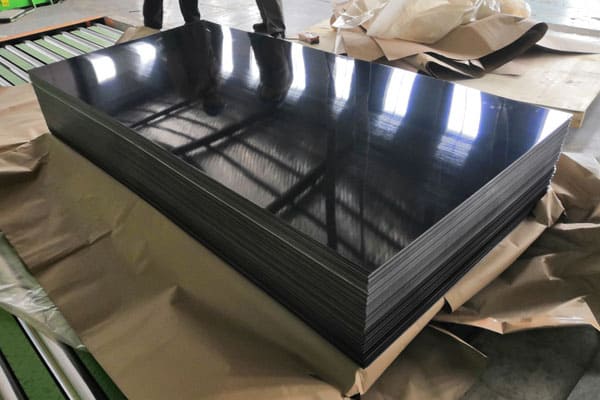

Different types of 3105 aluminiumsplater

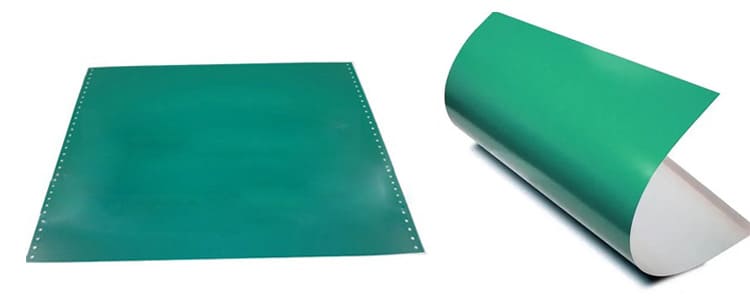

3105 anodisert aluminiumsplate: This aluminum sheet is anodized to form an oxide layer, which improves its surface hardness and wear resistance. Anodized aluminum sheets are usually used in electronic equipment casings, decorative parts and other occasions that require surface protection and aesthetics.

traffic sign

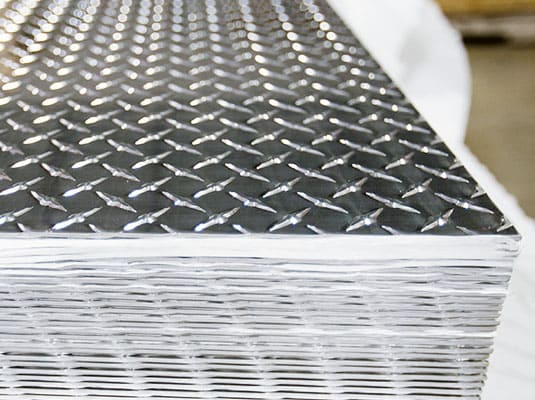

3105 embossed aluminum sheet: Embossed aluminum sheet undergoes special processing technology to make its surface present different patterns, textures or patterns. This not only increases the aesthetics of the aluminum sheet, but also increases the skid resistance of its surface, so it is often used in stair treads, floors and other places that require anti-skid functions.

- Diamond aluminum sheet of 3105

- 1 bar 3105 aluminiumsplate

- 3 bar 3105 aluminiumsplate

- 5 bar 3105 aluminiumsplate

3105 color-coated aluminum sheet: 3105 aluminum sheet has been coated, and different colors and coating types can be selected to meet different decoration and protection needs. Common prepainted colors are:

- Svart

- White

- Orange

- Champagne

- Charcoal

- Rød

- Silver

- Brandywine

- Emerald Green

- Indigo Blue

- Pewter

- Penske Yellow

- Burgundy

- Brite One Side

Svart 3105 aluminiumsplate

3105 perforated aluminum plate: 3105 perforated aluminum plate is a product made by processing 3105 aluminum alloy plate through punching process. Punching is a processing method in which sheet metal is punched through a die to form a specific hole pattern.

3105 brushed aluminum plate: 3105 aluminum sheet plate is an aluminum alloy plate that has been processed by wire drawing. Wire drawing is a processing method that forms uniform textures and lines on the metal surface by mechanical means, thus giving the metal surface a unique appearance and texture.

Application Of 3105 Aluminiumsplate

3105 aluminum sheet has good tensile strength and corrosion resistance, so it is often used in room partitions, baffles, mobile room panels, color-coated aluminum substrates, skodder, and lamp head materials. Gutters and downspouts, sheet formed parts, bottle caps, stoppers, transportation and more.

3105 aluminum roofing sheet production

3105 Takplate av aluminium

3105 aluminum sheet is very advantageous for aluminum roofing sheet because of its high strength to weight ratio.

Reduce the weight of the roof while meeting the strength needs of the shingle.

Not only that, the strong corrosion resistance of 3105 aluminum sheet also improves the service life of aluminum roofing sheet.

3105 Diamond Aluminum Sheet

Diamond aluminum sheets, also known as diamond plate or tread plate, are aluminum sheets with a raised diamond pattern on their surface. This pattern provides a textured and slip-resistant surface, making diamond aluminum sheets suitable for various applications. Here are some common applications of diamond aluminum sheets:

Diamantplate av 3105 Aluminium

Flooring: Diamond aluminum sheets are often used as flooring material in places where slip resistance is crucial, such as industrial facilities, ramps, stair treads, and walkways. The raised diamond pattern provides traction, reducing the risk of accidents.

Transport: These sheets are commonly used for flooring and walls in vehicles like trucks, trailers, and buses. The textured surface prevents cargo or equipment from shifting during transportation and helps maintain safe footing for workers inside the vehicles.

Decorative Elements: The distinct diamond pattern of these sheets can add an industrial or rugged aesthetic to interiors and exteriors of buildings, kjøretøy, and other structures. They are used for decorative wall panels, wainscoting, backsplashes, and more.

3105 aluminum sheet for car

Toolboxes and Storage: Diamond aluminum sheets are often used for constructing toolboxes, storage cabinets, and chests. The pattern adds strength to the structure while also enhancing the appearance.

Trailers and Loading Ramps: Diamond aluminum sheets are commonly used on trailer floors, especially for trailers that carry heavy equipment or vehicles. They also find application in constructing loading ramps for easy loading and unloading.

Marine Applications: The corrosion-resistant properties of aluminum make diamond sheets suitable for marine applications, including boat decks, dokker, and other waterfront structures.

Produksjonsprosessen for støping og introduksjonen av den

Hensikten med smelting og støping er å produsere legeringer med tilfredsstillende sammensetning og høy renhet av smelten, for å skape gunstige forhold for støping av legeringer av forskjellige former.

Smelte- og støpeprosesstrinn: batching --- fôring --- smelting --- omrøring etter smelting, slaggfjerning --- prøvetaking før analyse --- legge til legering for å justere sammensetningen, røring --- raffinering --- statisk innstilling——Guide ovnsstøping.

Varmvalsende produksjonsprosess og dens introduksjon

- 1. Varmvalsing refererer generelt til valsing over metallrekrystalliseringstemperaturen;

- 2. Under varmvalsingsprosessen, metallet har både herde- og mykningsprosesser. På grunn av påvirkningen av deformasjonshastigheten, så lenge gjenopprettings- og rekrystalliseringsprosessen er for sent, det blir en viss arbeidsherding;

- 3. Omkrystalliseringen av metallet etter varmvalsing er ufullstendig, det vil si, sameksistensen av rekrystallisert struktur og deformert struktur;

- 4. Varmvalsing kan forbedre prosessytelsen til metaller og legeringer, redusere eller eliminere støpefeil.

- 1. Støpe- og valsetemperaturen er vanligvis mellom 680°C og 700°C. Jo lavere jo bedre, den stabile støpe- og rullelinjen stopper vanligvis en gang i måneden eller mer for å stå igjen. Under produksjonsprosessen, det er nødvendig å strengt kontrollere væskenivået i fronttanken for å forhindre lavt væskenivå;

- 2. Smøring bruker C-pulver med ufullstendig forbrenning av gass til smøring, som også er en av grunnene til den skitne overflaten til støpe- og valsematerialer;

- 3. Produksjonshastigheten er vanligvis mellom 1,5 m/min-2,5 m/min;

- 4. Overflatekvaliteten på produkter produsert ved støping og valsing er generelt relativt lav, og kan generelt ikke oppfylle produkter med spesielle fysiske og kjemiske ytelseskrav.

- 1. Kaldvalsing refererer til rullende produksjonsmetode under rekrystalliseringstemperaturen;

- 2. Det vil ikke være noen dynamisk rekrystallisering under valseprosessen, og temperaturen vil stige til gjenvinningstemperaturen på det meste, og kaldvalsingen vil fremstå i en arbeidsherdende tilstand, og arbeidsherdehastigheten vil være stor;

- 3. Det kaldvalsede arket og båndet har høy dimensjonsnøyaktighet, god overflatekvalitet, enhetlig struktur og ytelse, og produkter i forskjellige tilstander kan oppnås med varmebehandling;

- 4. Kaldrulling kan rulle ut tynne strimler, men samtidig, den har ulempene med høyt energiforbruk for deformasjon og mange behandlingspass.

- 1. Etterbehandling er en bearbeidingsmetode for å få det kaldvalsede arket til å møte kundens krav, eller for å lette den etterfølgende behandlingen av produktet;

- 2. Etterbehandlingsutstyret kan rette opp defektene som er produsert i produksjonsprosessen for varm- og kaldvalsing, som sprukket kant, fet, dårlig plateform, gjenværende stress, osv. Den må sørge for at ingen andre defekter kommer inn i produksjonsprosessen;

- 3. Det finnes ulike etterbehandlingsutstyr, hovedsakelig inkludert tverrskjæring, spalting, strekking og retting, glødeovn, skli, osv.

Støpe- og valseprosess

Støpe- og valseprosess: flytende metall, frontboks (væskenivåkontroll), støpe- og valsemaskin (smøresystem, kjølevann), klippemaskin, kveilmaskin.

Kaldvalsende produksjonsprosess

Introduksjon til etterbehandling av produksjonsprosessen

Aluminiumslegering har egenskapene til lav tetthet, gode mekaniske egenskaper, god behandlingsytelse, ikke-giftig, lett å resirkulere, utmerket elektrisk ledningsevne, varmeoverføring og korrosjonsbestandighet, så den har et bredt spekter av bruksområder.

Luftfart: brukes til å lage flyskinn, flykroppsrammer, dragere, rotorer, propeller, drivstofftanker, veggpaneler og landingsstellstag, samt rakettsmieringer, romfartøyets veggpaneler, osv.

Aluminiumslegering brukt til romfart

Transport: brukes til karosserimaterialer til biler, t-banekjøretøyer, jernbane personbiler, høyhastighets personbiler, dører og vinduer, hyller, deler til bilmotorer, klimaanlegg, radiatorer, kroppspaneler, hjul og skipsmateriell.

Trafikksøknad

Emballasje: Popbokser i aluminium brukes hovedsakelig som metallemballasjematerialer i form av tynne plater og folier, og lages til bokser, lokk, flasker, fat, og emballasjefolier. Mye brukt i emballasje av drikkevarer, mat, kosmetikk, medisiner, sigaretter, industrielle produkter, medisiner, osv.

Emballasjeapplikasjon

Printing: Brukes hovedsakelig til å lage PS-plater, aluminiumsbaserte PS-plater er en ny type materiale i trykkeribransjen, brukes til automatisk platefremstilling og utskrift.

PS utskrift

Arkitektonisk dekorasjon: aluminiumslegering er mye brukt i bygningskonstruksjoner, dører og vinduer, undertak, dekorative overflater, osv. på grunn av sin gode korrosjonsbestandighet, tilstrekkelig styrke, utmerket prosessytelse og sveiseytelse.

Konstruksjonsapplikasjon i aluminiumslegering

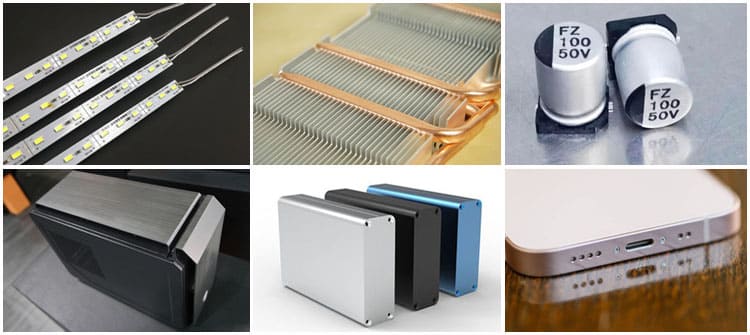

Elektroniske produkter: datamaskiner, mobiltelefoner, kjøleskapsskall, radiatorer, osv.

Elektronisk produktapplikasjon

Kjøkkenutstyr: aluminiums gryter, kummer i aluminium, riskokerforinger, husholdnings aluminiumsfolie, osv.

Kjøkkenapplikasjon

Emballasje av aluminiumsplate/coil

Hver detalj av emballasjen er der vi streber etter perfekt service. Vår pakkeprosess som helhet er som følger:

Laminering: klar film, blå film, mikro-slimhinnen, høy slimhinne, laserskjærende film (2 merkevarer, Novacell og Polyfem);

Beskyttelse: papirhjørnebeskyttere, anti-trykk pads;

tørking: tørkemiddel;

Brett: fumigert ufarlig trebrett, gjenbrukbart jernbrett;

Pakking: Tic-tac-toe stålbelte, eller PVC-pakkebelte;

Materialkvalitet: Helt fri for defekter som hvitrust, oljeflekker, rullende merker, kantskade, bøyer, bulker, hull, bryte linjer, riper, osv., ingen spole satt.

Havn: Qingdao eller andre havner i Kina.

Ledetid: 15-45 dager.

Emballasjeprosess for aluminiumsplater/plater

Emballasjeprosess for aluminiumsspole

F: Er du produsent eller handelsmann?

Q: Vi er en produsent, fabrikken vår er på No.3 Weier Road, Industrisone, Gongyi, Henan, Kina.

F: Hva er MOQ for å bestille produktet?

Q: Vår MOQ er 5 tonn, og noen spesialprodukter vil ha et minimumsbestillingsantall på 1 eller 2 tonn.

F: Hvor lang er ledetiden din?

Q: Vanligvis er ledetiden vår ca 30 dager.

F: Har produktene dine kvalitetssikring?

Q: Ja, hvis det er et kvalitetsproblem med produktene våre, vi vil kompensere kunden til de er fornøyd.

Relaterte produkter

Siste blogger

8011 Aluminiumsfolie 90 Mikrofon for luftkanal | Sterk & Fleksibel

Premium 8011 aluminiumsfolie 90 mikrofon for luftkanalsystemer – gir utmerket fleksibilitet, fuktmotstand, og termisk isolasjonsytelse.

Pinholes på PTP aluminiumsfolie | Årsaker, Testing & Spesifikasjoner

Forstå hvordan pinholes på PTP aluminiumsfolie, deres innvirkning på fukt-/oksygenbarrieren, og testmetodene & akseptgrenser som holder blemmer i spesifikasjonene.

Er aluminiumsfolie giftig? | Sikkerhetsfakta du trenger å vite

Lurer på er aluminiumsfolie giftig? Vi avliver vanlige myter og gir vitenskapelig støttede fakta om sikkerheten for matlaging og matoppbevaring.