Marine Grade 5052-H32 Aluminum Sheet – Lightweight & Strength

12,171 Views 2025-09-04 05:53:00

The marine environment, with its relentless assault of saltwater, extreme weather, and constant motion, represents one of the most challenging frontiers for material science.

In this demanding arena, the selection of the right materials is not merely a preference but a critical determinant of a vessel’s lifespan, safety, and operational efficiency.

Among the advanced metallic solutions that excel under such unforgiving conditions, Marine Grade 5052-H32 Aluminum Sheet stands out as a preeminent choice, offering an unparalleled synergy of robust corrosion resistance, strength, and workability.

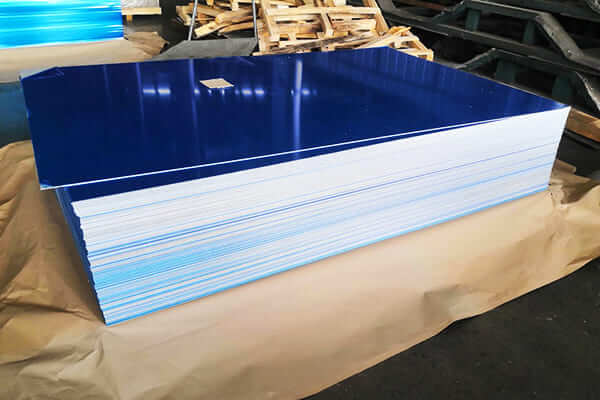

Marine Grade 5052-H32 Aluminum Sheet

This comprehensive article delves into the precise composition, the defining H32 temper, and the pivotal properties that collectively position 5052-H32 as an indispensable material for naval architects, boat builders, and offshore engineers, providing profound insights into its enduring legacy and future applications.

The Marine Imperative: Why Aluminum Excels in Saltwater

Historically, steel dominated marine construction. However, its susceptibility to corrosion in saltwater necessitates extensive painting, cathodic protection, and ongoing maintenance.

Aluminum, with its intrinsic properties, emerged as a transformative alternative for marine applications:

- Exceptional Corrosion Resistance: Aluminum naturally forms a passive, self-healing oxide layer, providing a formidable barrier against saltwater and atmospheric corrosion, unlike steel which suffers from red rust.

- Outstanding Strength-to-Weight Ratio: Aluminum is roughly one-third the density of steel (approx. 2.7 g/cm³ vs. 7.85 g/cm³). This lightness allows for faster vessels, increased payload capacity, or reduced fuel consumption.

- Good Weldability: Allows for the fabrication of complex, watertight structures.

- Non-Magnetic: An advantage for vessels carrying sensitive navigation equipment or operating near magnetic anomaly detection systems.

While many aluminum alloys offer these benefits, specific “marine grade” alloys, like 5052, are meticulously engineered to maximize performance in this harsh environment.

Shipbuilding used Marine Grade 5052-H32 Aluminum Sheet

Unpacking the Alloy: 5052 Composition and the H32 Temper

The superior performance of Marine Grade 5052-H32 Aluminum Sheet begins with its meticulously balanced chemical composition and culminates in its precise mechanical conditioning through the H32 temper.

Chemical Composition and Element Effects of 5052 Aluminum Alloy

5052 is a member of the 5xxx series of aluminum alloys, characterized by magnesium (Mg) as its primary alloying element.

| Element | Percentage (%) | Effects |

|---|---|---|

| Aluminum (Al) | 95.7 – 97.7 | Provides basic structure, enhances lightweight properties, forms a protective oxide layer, and improves corrosion resistance. |

| Magnesium (Mg) | 2.2 – 2.8 | Increases strength and corrosion resistance, improves workability and weldability. |

| Chromium (Cr) | 0.15 – 0.35 | Enhances corrosion resistance and strength, improves overall structural integrity. |

| Manganese (Mn) | 0.10 max | Increases strength and toughness, improves corrosion resistance, and refines grain structure. |

| Copper (Cu) | 0.10 max | Increases strength and hardness, but excessive amounts may reduce corrosion resistance. |

| Silicon (Si) | 0.25 max | Improves fluidity, lowers melting point, and enhances casting performance in small amounts. |

| Iron (Fe) | 0.40 max | Typically an undesirable impurity; high content may affect corrosion resistance and mechanical properties. |

| Zinc (Zn) | 0.10 max | Increases strength, but excessive amounts may increase corrosion susceptibility. |

| Titanium (Ti) | 0.15 max | Refines grain structure during processing, improving strength and toughness. |

The Defining H32 Temper: A Balance of Strength and Formability:

The “H32” designation is a specific temper that defines the mechanical conditioning of 5052 aluminum, providing a critical balance for marine fabrication.

- Strain Hardened (H):

This indicates that the alloy has been strengthened through cold working (e.g., rolling).

Unlike heat-treatable alloys (like 6xxx series), 5052’s strength is primarily derived from this mechanical process. - Strain Hardened to Quarter Hard (3):

The “3” indicates that the material has been strain hardened to a quarter of its maximum potential work hardening, providing a moderate increase in strength. - Stabilized (2):

The “2” signifies that the material has then undergone a low-temperature heat treatment, which slightly reduces strength but stabilizes its mechanical properties.

This stabilization process prevents age softening and improves ductility, enhancing long-term performance and ensuring more predictable behavior during fabrication and service.

This precise H32 temper renders Marine Grade 5052-H32 Aluminum Sheet highly suitable for applications requiring good strength and formability, with stable properties that are less prone to changes over time or during subsequent fabrication (e.g., bending or moderate forming).

Defining Properties of Marine Grade 5052-H32 Aluminum Sheet

The judicious application of the H32 temper, combined with its optimized elemental composition, bestows Marine Grade 5052-H32 Aluminum Sheet with a highly desirable suite of mechanical and chemical properties, making it a stellar choice for the marine sector.

1. Superior Corrosion Resistance: The Ultimate Barrier Against Saltwater

This is the preeminent property that defines 5052-H32 as a marine-grade alloy.

Its high magnesium content and dense oxide layer provide exceptional resistance to general corrosion, pitting, and crevice corrosion in saltwater and marine atmospheres.

Unlike steel, which can rapidly degrade if protective coatings fail, 5052-H32 maintains its structural integrity and aesthetic appearance over decades in harsh environments.

Laboratory salt spray tests (e.g., ASTM B117) consistently show 5052-H32 outperforming many other alloys in saline conditions, exhibiting minimal weight loss or surface degradation.

2. Moderate Strength-to-Weight Ratio: Structural Efficiency

Marine Grade 5052-H32 Aluminum Sheet offers a commendable balance of strength and lightness.

- Typical Tensile Strength: Approximately 220 MPa (32,000 psi).

- Typical Yield Strength: Approximately 165 MPa (24,000 psi).

This allows naval architects to design lightweight structures that possess sufficient rigidity and load-bearing capacity for boat hulls, decks, and superstructures, contributing to improved vessel performance without compromising safety.

3. Excellent Weldability: Seamless Fabrication

5052-H32 exhibits excellent weldability with conventional fusion welding methods like Gas Metal Arc Welding (GMAW/MIG) and Gas Tungsten Arc Welding (GTAW/TIG).

- Filler Metals: Common choices include 5356 or 5183 filler wires, which provide good strength and corrosion resistance in the weld zone, ensuring the integrity of the fabricated structure.

- Maintained Properties: Welds typically retain a high percentage of the base metal’s strength and corrosion resistance, a critical factor for complex marine assemblies.

4. Good Formability: Shaping Complex Structures

Despite its strength, Marine Grade 5052-H32 Aluminum Sheet retains good formability.

This characteristic allows for easy bending, forming, and shaping into the complex curves and contours required for boat hulls, deck structures, and various marine components without cracking or excessive springback.

This enhances design flexibility and streamlines fabrication processes.

5. Good Fatigue Resistance: Enduring Dynamic Loads

Marine vessels are constantly subjected to dynamic loads from waves, vibrations, and structural movements.

5052-H32 demonstrates good fatigue resistance, allowing it to withstand these continuous cyclic stresses over prolonged periods, ensuring the long-term structural integrity of the vessel.

Marine Grade 5052-H32 Aluminum Sheet application

Like most aluminum alloys, 5052-H32 is non-magnetic. This is a significant advantage in marine applications, as it prevents interference with sensitive magnetic compasses, sonar systems, and other navigation or communication equipment, ensuring reliable operation.

Mechanical Properties: Marine Grade 5052-H32 Aluminum Sheet

The table below presents typical mechanical properties for 5052-H32 aluminum sheet, providing essential data for engineering design and material specification in marine applications.

| Property | Unit | Typical Value for 5052-H32 |

| Tensile Strength | MPa (ksi) | 220 (32) |

| Yield Strength | MPa (ksi) | 165 (24) |

| Elongation (% in 50mm) | % | 10 |

| Shear Strength | MPa (ksi) | 135 (20) |

| Fatigue Limit | MPa (ksi) | 125 (18) |

| Brinell Hardness | HB | 60 |

| Density | g/cm³ | 2.68 |

Note: These values are typical minimums or ranges from industry standards (e.g., ASTM B209).

Actual properties can vary slightly based on specific product form, thickness, and precise manufacturing conditions.

Always consult certified Material Test Reports (MTRs) for critical applications.

Diverse Applications of Marine Grade 5052-H32 Aluminum Sheet

The exceptional and balanced suite of Marine Grade 5052-H32 Aluminum Sheet properties makes it an indispensable material across a broad spectrum of marine and offshore applications.

- Small to Medium-Sized Boat Hulls:

Highly favored for recreational boats, fishing vessels, workboats, and patrol boats (up to approximately 20-30 meters in length).

Its corrosion resistance means no rust, no painting below the waterline, and significantly reduced maintenance. - Large Vessel Superstructures:

For larger ships and yachts, 5052-H32 is commonly used for upper decks, cabins, masts, and other superstructure components, leveraging its lightweight to lower the vessel’s center of gravity, thereby enhancing stability and reducing fuel consumption. - Marine Tanks:

Utilized for fuel tanks, freshwater tanks, and wastewater tanks on various vessels due to its excellent corrosion resistance to contained fluids and the marine environment. - Docks, Piers, and Gangways:

Its durability and resistance to saltwater make it an ideal material for constructing permanent or floating marine infrastructure that requires minimal maintenance. - Marine Equipment and Components:

Applied in various components like access hatches, bulkheads, storage lockers, and equipment housings that require robust construction and corrosion resistance. - Offshore and Coastal Structures:

Used for components in offshore platforms, aquaculture cages, and other coastal installations where long-term integrity in harsh saltwater conditions is paramount.

5052 aluminum sheet for Marine Equipment

Comparative Analysis: 5052-H32 vs. Other Marine Alloys

Understanding where Marine Grade 5052-H32 Aluminum Sheet stands relative to other common marine alloys is crucial for informed material selection.

1. Vs. 5083-H116/H321 Aluminum:

- Strength: 5083 is significantly stronger than 5052 (e.g., 5083-H321 has a typical yield strength of 215 MPa vs. 165 MPa for 5052-H32).

- Corrosion Resistance: Both offer excellent corrosion resistance. 5083 is often chosen for even more aggressive marine environments or very thick sections due to its slightly higher magnesium content and specialized tempers (H116/H321) designed for enhanced exfoliation resistance in marine applications.

- Cryogenic Performance: 5083 has superior cryogenic toughness, making it the preferred choice for LNG tanks.

- Verdict: Choose 5052-H32 for good strength, excellent corrosion resistance, and good formability, particularly for general-purpose marine construction and lighter structures. Choose 5083 for higher strength requirements, more extreme corrosive conditions, larger vessels, or cryogenic applications.

2. Vs. 6061-T6 Aluminum:

- Strength: 6061-T6 is generally stronger than 5052-H32 (yield strength 276 MPa vs. 165 MPa).

- Weldability: 5052-H32 is generally considered to have better weldability for marine structures, with welds retaining more original strength. Welding 6061-T6 can significantly degrade its T6 temper in the heat-affected zone, often requiring post-weld heat treatment, which is impractical for large marine structures.

- Corrosion Resistance: Both offer good corrosion resistance, but 5052 is often preferred for direct saltwater immersion due to its Al-Mg composition.

- Verdict: Choose 5052-H32 for welded marine structures where corrosion resistance and ease of fabrication are paramount. Choose 6061-T6 for bolted or riveted marine components or for components requiring higher strength where post-weld heat treatment is feasible.

3. Vs. Marine Steel (e.g., AH36):

- Weight: Aluminum offers a ~65% weight reduction over steel for equivalent strength.

- Corrosion Resistance: Aluminum is inherently corrosion-resistant; marine steel requires rigorous painting, coating, and cathodic protection schemes, which demand ongoing maintenance.

- Cost: Initial material cost for aluminum is higher, but lifecycle costs can be lower due to reduced maintenance, painting, and fuel consumption.

- Verdict: Choose aluminum for lightweighting, reduced maintenance, and long-term corrosion performance. Choose steel for ultra-large vessels or applications requiring very high stiffness and absolute resistance to abrasion.

Fabrication and Maintenance Considerations

Working with Marine Grade 5052-H32 Aluminum Sheet demands specific fabrication expertise and adherence to best practices to maximize its inherent advantages.

- Welding: Thorough surface preparation (degreasing, wire brushing) is critical. Use recommended filler metals (e.g., 5356) and employ appropriate welding parameters to minimize distortion and achieve sound, strong welds.

- Forming: While formable, adherence to minimum bend radii for the specific thickness is crucial to prevent cracking.

- Galvanic Corrosion Prevention: When 5052-H32 is joined to dissimilar metals (e.g., steel fasteners, bronze fittings), proper insulation (e.g., neoprene gaskets, non-conductive washers, marine-grade sealants) is essential to prevent galvanic corrosion.

- Surface Finishing: While its natural corrosion resistance is excellent, painting or anodizing can provide additional aesthetic appeal and a further layer of protection, particularly in areas prone to abrasion.

- Maintenance: Aluminum boats and structures require significantly less maintenance than steel. Routine cleaning and inspection are usually sufficient.

Quality Assurance & Supplier Spotlight (Huawei)

The uncompromising demands of the marine industry necessitate the highest standards of quality assurance for Marine Grade 5052-H32 Aluminum Sheet.

From raw material sourcing to final inspection, a robust QA system is non-negotiable. Manufacturers rely on certified Material Test Reports (MTRs) to confirm chemical composition and mechanical properties, ensuring the material meets rigorous ASTM or other international standards.

For marine fabricators and shipbuilders, partnering with a technically proficient and quality-driven aluminum supplier is indispensable.

Huawei packaged 5052 aluminum sheet

Huawei (Henan Huawei Aluminum Co., Ltd.), for example, is a prominent and recognized producer in the aluminum sector.

Companies like Henan Huawei Aluminum leverage state-of-the-art rolling mills, advanced metallurgical controls, and stringent quality assurance processes to manufacture a comprehensive range of high-performance aluminum plate, including Marine Grade 5052-H32 Aluminum Sheet.

Their commitment to precise alloying, consistent mechanical properties, superior surface quality, and adherence to relevant industry standards (e.g., ASTM, as well as internal marine-specific criteria) ensures that their materials meet the rigorous demands of marine environments.

By providing a reliable supply of high-quality aluminum, companies like Henan Huawei Aluminum serve as trusted partners for boat builders, marine equipment manufacturers, and offshore infrastructure projects globally.

Frequently Asked Questions (FAQs) about Marine Grade 5052-H32 Aluminum Sheet

Q1: What makes 5052-H32 “marine grade”?

A1: Its high magnesium content (2.2-2.8%) provides exceptional resistance to corrosion, especially in saltwater and marine atmospheres. The H32 temper offers a stable balance of strength and formability, ideal for marine fabrication.

Q2: Will 5052-H32 rust in saltwater?

A2: No. Unlike steel, 5052-H32 does not “rust” (form red iron oxide). It forms a tough, self-repairing passive oxide layer that protects it from corrosion. This makes it highly durable in saltwater without significant degradation.

Q3: Is 5052-H32 suitable for welding boat hulls?

A3: Yes, 5052-H32 has excellent weldability, making it very suitable for welding boat hulls and superstructures. Common filler metals like 5356 or 5183 are used to maintain weld strength and corrosion resistance.

Q4: How does 5052-H32 compare to 5083-H116 for marine use?

A4: 5083-H116 offers higher strength and slightly better resistance to very aggressive corrosive conditions, making it preferred for larger vessels, high-stress components, or extreme environments. 5052-H32 provides excellent performance for general marine construction, smaller boats, and lighter structures at a typically lower cost.

Q5: What maintenance does an aluminum boat made with 5052-H32 require?

A5: Aluminum boats require significantly less maintenance than steel boats. They don’t need painting below the waterline (for corrosion protection), though anti-fouling paint may be applied to prevent marine growth. Routine cleaning and inspection for any damage are generally sufficient.

Conclusion

The strategic deployment of Marine Grade 5052-H32 Aluminum Sheet represents a definitive commitment to durability, efficiency, and sustainability in the marine sector.

Its unparalleled resistance to saltwater corrosion, combined with an optimal strength-to-weight ratio, excellent weldability, and good formability, positions it as an indispensable material for a vast array of marine and offshore applications.

From enabling faster, more fuel-efficient recreational boats to providing robust superstructures for larger vessels, 5052-H32 consistently delivers reliable performance, minimizing maintenance and extending operational lifespans.

Supported by rigorous quality assurance and the advanced manufacturing capabilities of leading suppliers, Marine Grade 5052-H32 Aluminum Sheet will undoubtedly continue to be a cornerstone material, navigating the elements with enduring excellence and shaping the future of marine engineering.