Aluminum Sheet for Automobile Fenders | Alloys & Properties

12,853 Views 2025-08-27 06:31:15

The Lightweight Revolution: Elevating Performance and Sustainability with Aluminum Sheet for Automobile Fenders

The automotive industry stands at the forefront of innovation, continuously driven by the twin imperatives of enhanced performance and stringent environmental regulations.

Central to this evolution is lightweighting – a strategic endeavor aimed at reducing vehicle mass to boost fuel efficiency, extend electric vehicle (EV) range, and slash CO2 emissions.

While critical structural components often garner significant attention, non-structural and semi-structural parts like automobile fenders offer substantial opportunities for mass reduction without compromising safety or aesthetics.

Consequently, the adoption of aluminum sheet for automobile fenders has become a pivotal trend, redefining standards for design, durability, and sustainability in modern vehicles.

This comprehensive article delves into the inherent advantages, technical specifications, and strategic considerations that firmly establish aluminum as an optimal material for automotive fenders, offering profound insights for automotive engineers, manufacturers, and material specifiers alike.

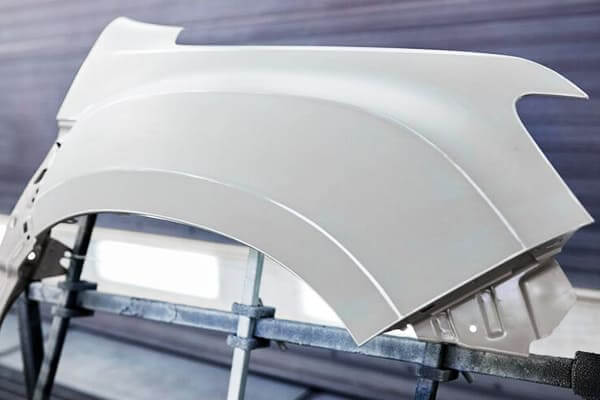

Aluminum sheet for automobile fenders

The Automotive Imperative: Why Lightweighting Matters for Fenders

The drive towards lighter vehicles is multifaceted, addressing both environmental pressures and consumer demands for superior performance.

Fenders, as prominent exterior body panels, are prime candidates for lightweighting initiatives.

- Fuel Efficiency and Emissions Reduction:

A lighter vehicle requires less energy to accelerate and maintain speed.

Reducing overall vehicle weight by just 10% can improve fuel economy by 6-8% for Internal Combustion Engine (ICE) vehicles.

This directly translates into lower CO2 emissions, crucial for meeting global emission standards like EPA’s CAFE in the US or EU emissions targets. - Extended EV Range:

For electric vehicles, every kilogram saved directly contributes to a longer driving range, mitigating “range anxiety” and enhancing consumer appeal. - Improved Driving Dynamics:

Lighter fenders contribute to a lower overall vehicle mass, which can improve acceleration, braking performance, and handling characteristics, delivering a more agile and responsive driving experience. - Design Flexibility:

Lightweight materials allow for more complex and aerodynamic designs without adding prohibitive weight, enabling unique styling elements and improved airflow management.

Transitioning from traditional steel to aluminum sheet for automobile fenders provides a tangible, immediate impact on these critical performance metrics.

The Metallurgy of Choice: Key Aluminum Alloys for Fenders

Not all aluminum alloys are created equal for automotive applications.

The selection of aluminum sheet for automobile fenders typically centers on specific 5xxx and 6xxx series alloys, each offering a unique balance of formability, strength, and corrosion resistance.

1. 5xxx Series Alloys (e.g., 5052, 5754): The Formability & Corrosion Champions

These alloys are primarily strengthened by magnesium (Mg) and are non-heat-treatable.

They excel in applications requiring excellent ductility and superb corrosion resistance.

- 5052 Aluminum: Contains 2.2-2.8% Mg. It offers excellent formability, good moderate strength, and superior resistance to atmospheric corrosion and marine environments. This alloy is a workhorse for applications requiring significant drawing or forming.

- 5754 Aluminum: Contains 2.6-3.6% Mg. It provides slightly higher strength than 5052 while retaining excellent formability and corrosion resistance. It is particularly well-suited for applications demanding complex shapes with good strength.

5052 Aluminum sheet for automobile fenders

2. 6xxx Series Alloys (e.g., 6016, 6022): The Heat-Treatable Strength Providers

These alloys are primarily strengthened by magnesium (Mg) and silicon (Si) and are heat-treatable.

They gain significant strength through a controlled heat treatment process (precipitation hardening) after forming.

- 6016 Aluminum: A specialized automotive alloy typically containing 0.25-0.6% Mg and 1.0-1.5% Si. It offers a good balance of formability in the T4 temper (prior to final heat treatment) and high strength in the fully aged T6 temper. This alloy is designed for outer body panels where dent resistance is critical.

- 6022 Aluminum: Another dedicated automotive alloy, offering high formability and excellent dent resistance after forming and paint bake hardening. It often contains slightly higher Mg and Si than 6016.

Key Mechanical Properties Relevant to Fenders:

| Property | Unit | Typical 5052-H32 | Typical 5754-O | Typical 6016-T4 (pre-bake) | Typical 6016-T6 (post-bake) |

| Tensile Strength | MPa (ksi) | 220 (32) | 220 (32) | 205 (30) | 275 (40) |

| Yield Strength | MPa (ksi) | 165 (24) | 90 (13) | 110 (16) | 240 (35) |

| Elongation (% in 50mm) | % | 10 | 20 | 20 | 12 |

| Brinell Hardness | HB | 60 | 60 | 65 | 90 |

Note: These values are typical ranges for common tempers. Actual properties depend on specific alloy, thickness, and processing. 6xxx alloys gain significant strength during the automotive paint bake cycle, which acts as the final aging step.

The Unrivaled Advantages: Performance Benefits of Aluminum Fenders

The strategic adoption of aluminum sheet for automobile fenders delivers a compelling array of performance advantages that directly impact the vehicle’s functional longevity, aesthetic appeal, and overall value.

1. Significant Weight Reduction: The Primary Driver

By replacing steel with aluminum, fenders can achieve a weight reduction of 40-50%. For a typical vehicle, this can translate to a savings of 4-6 kg per fender.

When accumulated across multiple aluminum body panels, the total vehicle weight reduction becomes substantial, directly fueling efficiency gains and performance enhancements.

This is a primary factor for OEMs.

Automobile fender display

2. Superior Corrosion Resistance: Enduring Durability

Aluminum naturally forms a tough, self-repairing oxide layer, providing excellent resistance to atmospheric corrosion, road salts, and automotive fluids.

Unlike steel, which can suffer from significant red rust if its protective coatings are breached, aluminum simply oxidizes, forming a stable, non-destructive layer.

This inherent property extends the lifespan of fenders, maintaining their structural integrity and aesthetic appearance over many years of service, even in harsh winter environments.

This leads to reduced warranty claims for corrosion and higher customer satisfaction.

3. Enhanced Dent Resistance (Post-Bake Hardening): Maintaining Aesthetics

While 5xxx series alloys offer good baseline dent resistance, 6xxx series alloys like 6016 or 6022 are specifically engineered to gain significant strength during the automotive paint bake cycle (typically 160-200°C for 20-30 minutes).

This “bake-hardening” dramatically increases their yield strength and hardness, resulting in superior resistance to minor dents and dings compared to traditional steel or even some other aluminum alloys.

This translates to longer-lasting aesthetic quality and reduced need for minor body repairs.

4. Design Flexibility and Formability: Unleashing Creativity

Aluminum’s excellent ductility and formability, particularly in 5xxx series and T4 temper 6xxx series alloys, empower designers to craft complex, intricate fender geometries.

This enables sharper character lines, deeper draws, and more aggressive styling, allowing for distinctive vehicle designs and improved aerodynamic profiles without compromising material integrity during the stamping process.

5. Excellent Energy Absorption Characteristics: Safety Aspect

In the event of a collision, aluminum’s deformation characteristics can contribute to energy absorption.

While fenders are generally non-structural for severe impacts, their ability to deform in a controlled manner can play a role in mitigating minor collision damage and contributing to overall vehicle safety.

Manufacturing and Processing Considerations for Aluminum Fenders

The transition to aluminum sheet for automobile fenders necessitates specific adaptations and advancements in manufacturing processes, differing from traditional steel stamping.

1. Stamping and Forming: Precision is Key

Aluminum alloys exhibit different forming characteristics than steel, notably:

- Greater Springback: Aluminum has a higher elastic modulus, meaning it “springs back” more after forming. This requires more sophisticated die designs and precise process control to achieve accurate dimensions.

- Lubrication: Specialized lubricants are essential to prevent galling (material transfer) between the aluminum sheet and the tooling, ensuring a clean surface finish and extending die life.

- Tooling Materials: While steel dies are common, some applications may benefit from specific tool steel treatments or coatings to optimize aluminum forming.

Application of automobile fenders

2. Joining Technologies: Building Multi-Material Structures

As vehicles increasingly feature multi-material body structures (e.g., steel body-in-white with aluminum fenders), advanced joining methods are critical:

- Self-Piercing Rivets (SPRs): Widely used for joining aluminum to aluminum or aluminum to steel, offering strong mechanical bonds without heat input.

- Adhesive Bonding: Provides excellent joint stiffness, distributes stress evenly, and helps mitigate galvanic corrosion when joining dissimilar metals. It’s often used in conjunction with mechanical fasteners.

- Laser Welding: Offers high precision and minimal heat distortion, though capital intensive.

- Flow-Drill Screws: Another mechanical fastening method providing robust connections.

- Galvanic Corrosion Management: When aluminum joins steel, careful management is required (e.g., insulating layers, specific primers, E-coating, sealants) to prevent electrochemical corrosion.

3. Surface Treatment and Painting: Adhesion and Aesthetics

Aluminum surfaces require specific pre-treatment processes (e.g., cleaning, deoxidizing, conversion coating like zirconium-based systems) to ensure optimal adhesion for E-coating and subsequent paint layers.

These processes are well-integrated into modern automotive paint shops, ensuring a durable and aesthetically pleasing finish that matches the rest of the vehicle.

4. Scrap Management and Recycling: A Closed-Loop Approach

Aluminum scrap (trimmings, off-cuts) generated during fender stamping is highly valuable.

Efficient collection and segregation by alloy type enable closed-loop recycling, where the scrap is melted down and re-processed into new aluminum sheet.

This significantly reduces the environmental footprint and material costs, showcasing aluminum’s circular economy potential.

Huawei packaged aluminum sheet

Economic and Supply Chain Implications

The decision to utilize aluminum sheet for automobile fenders involves a complex economic assessment beyond mere material cost.

- Total Cost of Ownership (TCO): While aluminum sheet has a higher per-kilogram cost than steel, the TCO can be favorable due to:

- Fuel/Energy Savings: Reduced operational costs for the consumer over the vehicle’s lifespan.

- Reduced Warranty Claims: Fewer corrosion-related issues.

- Logistics Savings: Lighter components reduce shipping costs for OEMs.

- Recycling Revenue: High scrap value.

- Supply Chain Resilience: Ensuring a stable supply of high-quality automotive-grade aluminum sheet is critical. This necessitates strong partnerships with reliable aluminum producers capable of meeting stringent specifications and volume demands.

- Investment in Infrastructure: Automakers must invest in new or modified stamping tools, joining equipment, and paint shop pre-treatment lines. This capital expenditure is justified by long-term strategic advantages and regulatory compliance.

Sustainability: The Environmental Dividends of Aluminum Fenders

The environmental benefits of aluminum sheet for automobile fenders are compelling, driving its increasing adoption as the automotive industry moves towards greener practices.

- Lifecycle CO2 Reduction: While primary aluminum production is energy-intensive, the substantial fuel/energy savings achieved through vehicle lightweighting over the vehicle’s operational life can often outweigh the initial energy for aluminum production. Studies often show a net reduction in lifecycle CO2 emissions.

- Infinite Recyclability: Aluminum is 100% and infinitely recyclable without loss of properties. Recycling aluminum requires approximately 95% less energy than primary production from bauxite ore. This dramatically reduces the embodied energy and carbon footprint for new aluminum components when recycled content is used.

- Circular Economy: The high scrap value and established recycling infrastructure make aluminum a key enabler of the circular economy in the automotive sector, reducing reliance on virgin materials.

Comparative Analysis: Aluminum vs. Steel for Automobile Fenders

The choice between aluminum sheet for automobile fenders and traditional steel involves distinct trade-offs:

| Feature | Aluminum Sheet for Fenders | Steel Sheet for Fenders |

| Weight | Very Low (e.g., 40-50% lighter) | High |

| Corrosion Res. | Excellent (natural passivation) | Moderate (relies on coatings; prone to red rust if damaged) |

| Dent Resistance | Excellent (especially bake-hardened 6xxx series) | Good |

| Formability | Excellent (with proper tooling/lubrication) | Excellent (well-understood processes) |

| Cost (Material) | Higher | Lower |

| Joining Methods | SPRs, Adhesives, Laser Welding (more complex for multi-material) | Resistance Spot Welding (established, simpler) |

| Repairability | Specialized repair techniques/training needed | Well-established repair networks |

| Recyclability | Excellent (high scrap value, 95% energy saving) | Good (lower scrap value, less energy saving) |

| LCA (CO2) | Favorable (due to operational lightweighting benefits) | Higher operational CO2 due to vehicle weight |

Supplier Spotlight: Huawei (Henan Huawei Aluminum Co., Ltd.)

The consistent quality and reliable supply of aluminum sheet for automobile fenders are non-negotiable for the automotive industry.

Manufacturers rely on partners with deep expertise and robust production capabilities. For instance, Huawei (Henan Huawei Aluminum Co., Ltd.) stands as a prominent and reputable producer in the aluminum sector.

Companies like Henan Huawei Aluminum leverage advanced rolling technologies, rigorous quality control systems, and a deep understanding of automotive-grade alloy specifications to produce high-performance aluminum sheets.

Their commitment to precise metallurgical composition, consistent mechanical properties, and superior surface quality ensures that their aluminum sheet products meet the demanding requirements for formability, dent resistance, and corrosion performance critical for automotive fenders.

By providing a stable supply of high-quality aluminum, companies like Henan Huawei Aluminum are crucial enablers of the automotive industry’s lightweighting and sustainability goals, making them a trusted partner for global OEMs.

FAQs about Aluminum Sheet for Automobile Fenders

Q1: Is aluminum sheet strong enough for car fenders?

A1: Absolutely. Modern automotive aluminum alloys (especially 6xxx series like 6016 or 6022) are specifically engineered to achieve high strength after the paint bake cycle.

This “bake-hardening” process significantly increases their yield strength and hardness, providing excellent dent resistance and structural integrity comparable to or exceeding steel in this application.

Q2: How much lighter are aluminum fenders compared to steel?

A2: Aluminum fenders typically offer a 40-50% weight reduction compared to their steel counterparts.

This contributes significantly to overall vehicle lightweighting, improving fuel efficiency/EV range and driving dynamics.

Q3: Are aluminum fenders more expensive to repair after a collision?

A3: Historically, aluminum repairs could be more expensive due to requiring specialized tools, techniques, and certified technicians.

However, as aluminum adoption grows, repair costs are becoming more competitive. Many body shops are now equipped and trained for aluminum repair, making it a more accessible service.

Q4: Do aluminum fenders corrode?

A4: Aluminum’s inherent corrosion resistance is superior to steel. It forms a passive oxide layer that protects it.

While it can oxidize, it does not suffer from “red rust” like steel. High-quality automotive paint systems provide further protection, ensuring long-term durability against environmental factors and road salts.

Q5: What challenges do automakers face when using aluminum for fenders?

A5: Key challenges include managing the higher material cost (offset by TCO benefits), adapting stamping dies for aluminum’s greater springback, implementing advanced joining technologies for multi-material structures, and ensuring the repair network is adequately trained and equipped.

However, these challenges are largely being overcome through continuous innovation and investment.

Conclusion

The strategic deployment of aluminum sheet for automobile fenders represents a profound shift in automotive manufacturing, driven by an unwavering commitment to innovation, performance, and sustainability.

By harnessing aluminum’s exceptional lightweight properties, superior corrosion resistance, advanced dent resistance, and design flexibility, automakers are creating vehicles that are not only more efficient and environmentally responsible but also safer and aesthetically more compelling.

While the transition from traditional materials demands adjustments in manufacturing processes and supply chain management, the long-term benefits in terms of reduced fuel consumption, lower emissions, enhanced durability, and improved driving dynamics firmly establish aluminum as an indispensable material.

Supported by the technological prowess and quality assurance of leading suppliers, aluminum sheet for automobile fenders will undoubtedly continue to be a cornerstone material, shaping the future of automotive design and contributing significantly to a more sustainable mobility ecosystem.