The Intersection of Performance and Aesthetics

In the world of modern materials, few products offer the same blend of sleek appearance, durability, and versatility as the white powder coated aluminium sheet.

You see it everywhere: on architectural facades, in clean-room interiors, on high-end signage, and as components in premium appliances.

But what exactly is this material, and what makes it such a superior choice for so many demanding applications?

This is your definitive guide. We will break down the science behind the powder coating process, explore its extensive benefits, compare it directly with other popular finishing methods, and showcase its most common uses.

By the end, you will have a comprehensive understanding of why this material is a go-to solution for architects, engineers, and designers.

White powder coated aluminium sheet

What is a White Powder Coated Aluminium Sheet?

The name itself describes a three-part system, where each component plays a critical role in the final product’s outstanding performance.

First, you have the aluminium sheet. This is the substrate, chosen for its inherent advantages: it is lightweight, inherently corrosion-resistant, and has an excellent strength-to-weight ratio. It’s the perfect canvas.

Next, you have the powder coating. Unlike traditional liquid paint, a powder coating is a dry finishing process.

It involves applying a finely ground powder—a mixture of polymer resins, pigments, curatives, and leveling agents—to the surface of the aluminum.

Finally, the process binds them together. The powder is applied electrostatically and then cured under heat, flowing and forming a “skin.”

The result is a white powder coated aluminium sheet with a finish that is not just painted on, but fused to the surface of the metal, creating a hard, uniform, and incredibly durable layer.

White aluminium sheet display

The Manufacturing Process: From Raw Metal to Flawless Finish

Creating a high-quality powder coated surface is a multi-stage process where precision is key. Skipping or rushing any step can compromise the final quality.

- Pre-treatment (The Critical Foundation):

This is the most important stage. The raw aluminum sheet must be impeccably clean for the powder to adhere properly.

This involves a series of chemical baths to degrease, etch, and deoxidize the surface.

A conversion coating (often chromate or a non-chrome alternative) is then applied to enhance corrosion resistance and promote adhesion. - Powder Application:

The clean, dry sheet moves into a spray booth. An electrostatic spray gun gives the dry powder particles a positive electrical charge.

Since the aluminum sheet is grounded (negatively charged), the charged powder particles are powerfully attracted to it, wrapping evenly around the surface and edges. - Curing:

The coated sheet is then moved into a large curing oven. The heat (typically 180-200°C or 355-390°F) melts the powder, causing it to flow into a smooth, liquid film.

As it cures, a chemical cross-linking reaction occurs, creating the durable, hard finish that is characteristic of powder coating.

This process ensures a consistent, high-quality finish that is far superior to simply spraying liquid paint.

White powder coated aluminium sheet Perforated

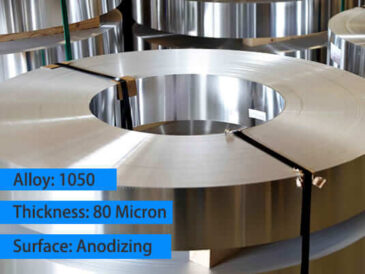

Common Alloys for White Powder Coated Aluminium Sheet

The outstanding performance of a white powder coated aluminium sheet is not solely due to the coating itself.

The choice of the underlying aluminum alloy—the substrate—is equally critical.

The alloy determines the material’s inherent strength, corrosion resistance, formability, and ultimately, its suitability for a specific application.

| Alloy | Nickname / Primary Role | Key Characteristics | Best For… |

| 1100 | The Formability Specialist | Commercially pure, maximum ductility, softest grade. | Intricate decorative parts, nameplates, applications requiring deep drawing or complex forming. |

| 3003 | The General All-Rounder | Excellent formability, good general corrosion resistance. | General architectural panels, signage, truck-trailer roofing, and all-purpose fabrication. |

| 3105 | The Building Product Staple | Similar to 3003 aluminum sheet but often with higher recycled content; excellent value. | Residential siding, rain gutters, mobile home skin, and pre-painted building products. |

| 5005 | The Architectural Finish Grade | Fine grain structure, excellent for high-quality, uniform finishes. | Premium architectural facades and curtain walls where visual consistency is critical. |

| 5052 | The Marine-Grade Champion | Superior corrosion resistance (especially saltwater), higher strength. | Marine components, vehicle bodies, chemical storage, and high-vibration environments. |

| 6061 | The Structural Powerhouse | Heat-treatable, high strength, good weldability. | Load-bearing panels, base plates, platforms, and structural applications needing a durable finish. |

How to Choose the Right Alloy for Your Project

The decision ultimately comes down to balancing three key factors: Environment, Formability, and Strength.

- For harsh environments involving saltwater, chemicals, or constant moisture, 5052 aluminum is the only reliable choice. For general architectural or interior use, 3003 is perfectly sufficient.

- For parts requiring complex bends or deep drawing, 1100 offers the best workability. For standard bends and simple shapes, 3003 provides a better balance with more strength.

- For applications needing higher impact resistance and rigidity, 5052 is the stronger material.

White powder coated aluminium sheet for building

Key Benefits: Why Choose Powder Coating on Aluminum?

Opting for a white powder coated aluminium sheet brings a host of tangible benefits that other materials or finishes struggle to match.

- Exceptional Durability: The cured finish is highly resistant to chipping, scratching, and abrasion. It stands up to daily wear and tear, making it ideal for high-traffic areas and exterior applications.

- Superior Weather and UV Resistance: High-quality polyester powders (the standard for exterior use) are formulated to resist fading and chalking from prolonged sun exposure. This ensures the brilliant white finish remains vibrant for years.

- Enhanced Corrosion Protection: While aluminum is naturally rust-proof, the powder coating provides an impermeable barrier that protects it from environmental pollutants, moisture, and chemicals, significantly extending its service life.

- Aesthetic Uniformity: The electrostatic process ensures a perfectly even coating thickness across the entire sheet, free from the drips, runs, or brush marks associated with liquid paint. You can also specify various gloss levels, from a sleek matte to a high-gloss finish.

- Environmentally Friendly: Powder coating is a green technology. It contains no solvents and releases negligible volatile organic compounds (VOCs) into the atmosphere. Additionally, any overspray powder can be collected and reused, dramatically reducing waste.

Performance Comparison: How Does It Stack Up?

The best way to understand the value of a white powder coated aluminium sheet is to compare it against other common finishes for aluminum.

| Finishing Method | Powder Coating | PVDF (Liquid Paint) | Anodizing |

| Durability & Hardness | Excellent. Highly resistant to scratching and impact. | Good. More flexible, but softer and can scratch easier. | Exceptional. Hardest surface, but can be brittle. |

| UV & Fade Resistance | Good to Excellent (with super-durable powders). | Superior. The industry benchmark for long-term color stability. | Good. But color options are limited and can vary by batch. |

| Appearance | Uniform, smooth finish. Wide range of gloss levels. | Smooth liquid finish. Often has a specific luster. | Metallic, translucent finish. The metal grain is visible. |

| Environmental Impact | Very Low. No VOCs, recyclable overspray. | Higher. Contains solvents (VOCs). | Moderate. Involves heavy acids and high energy use. |

| Cost | Moderate. Excellent performance for the price. | High. A premium finish for high-end projects. | Moderate to High. |

| Best For | Architectural trim, signage, interior panels, machinery. | Monumental architecture, curtain walls, roofing. | Window frames, high-wear surfaces, decorative trim. |

In essence, white powder coated aluminium sheet offers a fantastic balance of performance, aesthetics, and cost, making it the most versatile and widely used option.

PVDF is reserved for projects where 20+ year warranties on color are required, while anodizing is chosen for its unique metallic look and extreme hardness.

Common Applications Across Industries

The versatile properties of this material make it a staple in numerous sectors:

- Architecture and Construction: Used extensively for wall cladding, facade panels, soffits, window and door frames, and roofing trim. Its clean look and durability are perfect for modern building design.

- Signage and Display: The smooth, white surface provides an ideal canvas for vinyl graphics and printing, making it a top choice for corporate signs, wayfinding systems, and retail displays.

- Interior Design: Designers use it for decorative wall panels, kitchen splashbacks, ceiling tiles, and custom furniture, especially in commercial, healthcare, and hospitality settings.

- Transportation: Found as interior panels in buses, trains, and marine vessels, where it offers a durable, lightweight, and easy-to-clean surface.

Signage used White powder coated aluminium sheet

Conclusion

Ultimately, a white powder coated aluminium sheet is more than just a painted piece of metal.

It is a highly engineered product that provides a long-lasting, attractive, and sustainable solution for countless applications.

It successfully combines the lightweight and corrosion-resistant nature of aluminum with a tough, protective, and beautiful finish.

For projects that demand a clean aesthetic, robust performance, and excellent value, it remains the undisputed champion.

It is a testament to how modern material science can deliver a product that is both beautiful and built to last.

Casting production process and its introduction

The purpose of melting and casting is to produce alloys with satisfactory composition and high purity of melt, so as to create favorable conditions for casting alloys of various shapes.

Melting and casting process steps: batching --- feeding --- melting --- stirring after melting, slag removal --- pre-analysis sampling --- adding alloy to adjust the composition, stirring --- refining --- static Setting——Guide furnace casting.

Hot rolling production process and its introduction

- 1. Hot rolling generally refers to rolling above the metal recrystallization temperature;

- 2. During the hot rolling process, the metal has both hardening and softening processes. Due to the influence of deformation speed, as long as the recovery and recrystallization process is too late, there will be a certain work hardening;

- 3. The recrystallization of the metal after hot rolling is incomplete, that is, the coexistence of recrystallized structure and deformed structure;

- 4. Hot rolling can improve the processing performance of metals and alloys, reduce or eliminate casting defects.

- 1. The casting and rolling temperature is generally between 680°C and 700°C. The lower the better, the stable casting and rolling line usually stops once a month or more to re-stand. During the production process, it is necessary to strictly control the liquid level of the front tank to prevent low liquid level;

- 2. Lubrication uses C powder with incomplete combustion of gas for lubrication, which is also one of the reasons for the dirty surface of casting and rolling materials;

- 3. The production speed is generally between 1.5m/min-2.5m/min;

- 4. The surface quality of products produced by casting and rolling is generally relatively low, and generally cannot meet products with special physical and chemical performance requirements.

- 1. Cold rolling refers to the rolling production method below the recrystallization temperature;

- 2. There will be no dynamic recrystallization during the rolling process, and the temperature will rise to the recovery temperature at most, and the cold rolling will appear in a work hardening state, and the work hardening rate will be large;

- 3. The cold-rolled sheet and strip have high dimensional accuracy, good surface quality, uniform structure and performance, and products in various states can be obtained with heat treatment;

- 4. Cold rolling can roll out thin strips, but at the same time, it has the disadvantages of high energy consumption for deformation and many processing passes.

- 1. Finishing is a processing method to make the cold-rolled sheet meet the customer's requirements, or to facilitate the subsequent processing of the product;

- 2. The finishing equipment can correct the defects produced in the hot rolling and cold rolling production process, such as cracked edge, oily, poor plate shape, residual stress, etc. It needs to ensure that no other defects are brought into the production process;

- 3. There are various finishing equipments, mainly including cross-cutting, slitting, stretching and straightening, annealing furnace, slitter, etc.

Casting and rolling process

Casting and rolling process: liquid metal, front box (liquid level control), casting and rolling machine (lubrication system, cooling water), shearing machine, coiling machine.

Cold rolling production process

Introduction to finishing production process

Aluminum alloy has the characteristics of low density, good mechanical properties, good processing performance, non-toxic, easy to recycle, excellent electrical conductivity, heat transfer and corrosion resistance, so it has a wide range of applications.

Aerospace: used to make aircraft skins, fuselage frames, girders, rotors, propellers, fuel tanks, wall panels and landing gear struts, as well as rocket forging rings, spacecraft wall panels, etc.

Aluminum alloy used for aerospace

Transportation: used for car body structure materials of automobiles, subway vehicles, railway passenger cars, high-speed passenger cars, doors and windows, shelves, automotive engine parts, air conditioners, radiators, body panels, wheels and ship materials.

Traffic application

Packaging: All-aluminum pop cans are mainly used as metal packaging materials in the form of thin plates and foils, and are made into cans, lids, bottles, barrels, and packaging foils. Widely used in the packaging of beverages, food, cosmetics, medicines, cigarettes, industrial products, medicines, etc.

Packaging application

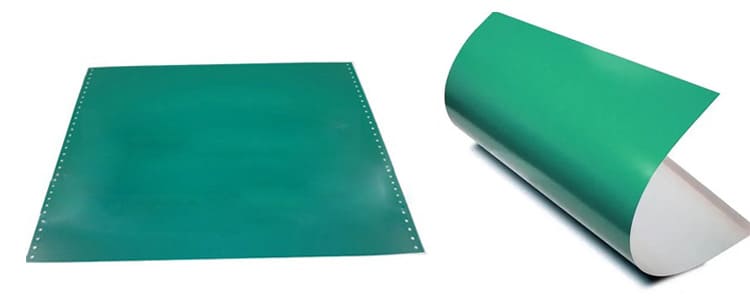

Printing: Mainly used to make PS plates, aluminum-based PS plates are a new type of material in the printing industry, used for automatic plate making and printing.

PS printing

Architectural decoration: aluminum alloy is widely used in building structures, doors and windows, suspended ceilings, decorative surfaces, etc. due to its good corrosion resistance, sufficient strength, excellent process performance and welding performance.

Aluminum alloy construction application

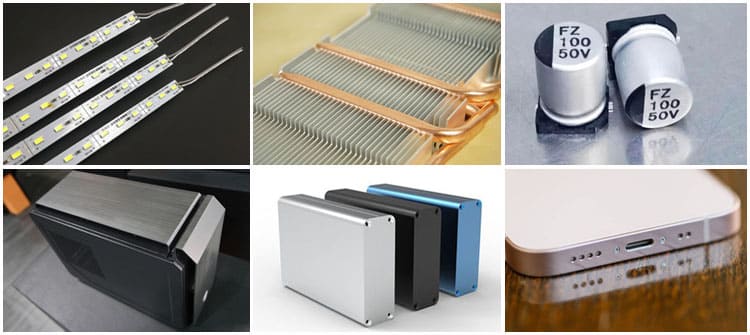

Electronic products: computers, mobile phones, refrigerator shells, radiators, etc.

Electronic product application

Kitchen supplies: aluminum pots, aluminum basins, rice cooker liners, household aluminum foil, etc.

Kitchen application

Packaging Of Aluminum Sheet/Coil

Every detail of packaging is where we pursue perfect service. Our packaging process as a whole is as follows:

Lamination: clear film, blue film, micro-mucosal, high-mucosal, laser cutting film (2 brands, Novacell and Polyphem);

Protection: paper corner protectors, anti-pressure pads;

drying: desiccant;

Tray: fumigated harmless wooden tray, reusable iron tray;

Packing: Tic-tac-toe steel belt, or PVC packing belt;

Material Quality: Completely free from defects such as white rust, oil spots, rolling marks, edge damage, bends, dents, holes, break lines, scratches, etc., no coil set.

Port: Qingdao or other ports in China.

Lead time: 15-45 days.

Aluminum sheet/plate packaging process

Aluminum coil packaging process

F: Are you a manufacturer or a trader?

Q: We are a manufacturer, our factory is at No.3 Weier Road, Industrial Zone, Gongyi, Henan, China.

F: What is the MOQ for ordering the product?

Q: Our MOQ is 5 tons, and some special products will have a minimum order quantity of 1 or 2 tons.

F: How long is your lead time?

Q: Generally our lead time is about 30 days.

F: Do your products have quality assurance?

Q: Yes, if there is a quality problem with our products, we will compensate the customer until they are satisfied.

Related Products

Latest Blogs

Trusted 3003 Aluminium Checker Plate Sheet Suppliers Worldwide

Find reliable 3003 Aluminium Checker Plate Sheet Suppliers offering certified quality, competitive pricing, custom sizes, and fast global delivery for your projects.

6061 T6 vs 7075 Aluminum: Strength, Weight & Best Uses

Compare 6061 T6 vs 7075 aluminum easily. Discover differences in strength, weight, and applications to choose the best for your projects.

Industrialization and Application of Honeycomb Aluminum Foil

This blog explores the industrialization of honeycomb aluminum foil, focusing on the 3003 alloy production process. It covers hot rolling, continuous casting, and the continuous casting-rolling method, highlighting the benefits of process optimization in improving mechanical properties, reducing energy consumption, and lowering production costs.