1. Introduction

Industrial aluminum foil is a high-value engineered material, distinct from household foil in both performance requirements and manufacturing standards.

With thicknesses typically ranging from 6 μm to 200 μm, industrial aluminum foil plays a critical role in packaging, electronics, energy systems, thermal management, and advanced manufacturing.

Driven by trends such as lightweighting, electrification, high-barrier packaging, and sustainability, global demand for industrial aluminum foil continues to grow steadily.

According to industry data, the global aluminum foil market exceeded USD 30 billion in recent years, with industrial-grade foil accounting for a significant and fast-growing share.

Industrial Aluminum Foil Introduction

2. Redefining Foil: The Essential Difference Between Industrial and Household Aluminum Foil

To understand industrial aluminum foil, one must first distinguish it from the familiar household foil.

Although both originate from aluminum, they differ vastly in performance, specifications, and application.

Household Aluminum Foil

- Alloy: Typically 8011 in the ‘H34’ (annealed) temper.

- Thickness: Generally ranges from 10 to 25 micrometers (µm).

- Core Requirements: Food safety, good barrier properties (moisture, light, aroma), and ease of forming (“dead-fold” characteristic).

Industrial Aluminum Foil

- Alloys: A much broader range, including the 1xxx series (e.g., 1235, 1060), 3xxx series (e.g., 3003), and 8xxx series (e.g., 8011, 8079), selected based on specific applications.

- Thickness: An extremely wide range, from ultra-thin 6 µm (for capacitors) to several hundred micrometers (for container foil).

- Core Requirements: Beyond barrier properties, the focus is on specific industrial performance metrics such as electrical conductivity, thermal conductivity, mechanical strength, corrosion resistance, and weldability.

End of 1235 aluminum foil jumbo roll

3. Market Size and Quantified Growth

According to the latest market research reports, the global aluminum foil market size reached approximately USD 29 billion to 31 billion in 2024.

Driven by the explosive growth in emerging application fields, the market is projected to expand at a Compound Annual Growth Rate (CAGR) of 5.1% to 6.5%, potentially exceeding USD 45 billion by 2033.

| Key Market Indicators | Global Aluminum Foil Market (2024) | Forecasted CAGR (2025-2033) | China’s Aluminum Foil Output (2022) |

|---|---|---|---|

| Value | Approx. USD 29-31 Billion | 5.1% – 6.5% | 5.02 Million Tons |

| Main Drivers | New Energy Vehicles (NEVs), Energy Storage, High-end Electronics Manufacturing | Lithium Batteries, Electronic Products, Pharmaceutical Packaging | Packaging and Lithium Battery Sectors |

Insight:

The Asia-Pacific region, particularly China, is the core growth engine of the global aluminum foil market.

China’s aluminum foil output grew from 3.83 million tons in 2018 to 5.02 million tons in 2022, achieving a high CAGR of 7.00%.

This rapid growth is primarily attributed to its massive production capacity and technological investment in the lithium battery and high-end flexible packaging sectors.

4. Key Alloys and Performance of Industrial Aluminum Foil

Different industrial applications place distinct demands on foil performance, which dictates the diversity in alloy selection.

4.1 1xxx Series Aluminum Alloys (e.g., 1235, 1060): Champions of Purity and Conductivity

- Chemical Composition: Extremely high aluminum content (1235 ≥99.35% Al, 1060 ≥99.6% Al) with minimal impurities.

- Core Advantages:

- Excellent Electrical Conductivity: Can reach 60-62% IACS, making it an ideal choice for the electronics industry.

- Superb Thermal Conductivity: A thermal conductivity as high as ~230 W/m·K makes it outstanding for thermal management.

- Superior Formability and Corrosion Resistance: High purity results in a soft texture and easy processing.

- Typical Applications:

- Capacitor Foil: Used as the anode foil in electrolytic capacitors, its high purity ensures excellent electrochemical performance.

- Battery Foil: Serves as the cathode current collector in lithium-ion batteries.

- Transformer Winding Foil: Replaces copper wire to achieve lightweight transformers.

4.2 3xxx Series Aluminum Alloys (e.g., 3003): The Perfect Balance of Strength, Formability, and Corrosion Resistance

- Chemical Composition: The primary alloying element is manganese (Mn, 1.0-1.5%).

- Core Advantages:

- Moderate Strength: Approximately 20% stronger than 1xxx series alloys while retaining good formability.

- Excellent Corrosion Resistance: Inherits aluminum’s superior properties, with manganese further enhancing its resistance.

- Good Weldability.

- Typical Applications:

- Honeycomb Core Foil: Used to manufacture lightweight, high-strength aluminum honeycomb panels for architectural curtain walls and rail transportation.

- Brazing Composite Foil: Serves as the core material or fins for heat exchangers like radiators and intercoolers.

- Food Container Foil: Strong enough to hold food, and safe and non-toxic.

4.3 8xxx Series Aluminum Alloys (e.g., 8011, 8079, 8021): The Versatile All-Rounders Engineered for Foil

- Chemical Composition: The main alloying elements are iron (Fe) and silicon (Si).

- Core Advantages:

- Excellent Overall Performance: The 8xxx series was specifically developed for foil production, achieving an optimal balance between strength, ductility, corrosion resistance, and stamping performance.

- Fewer Pinholes: When rolled to ultra-thin gauges, 8xxx series alloys can achieve a lower pinhole rate, which is critical for packaging foils.

- Typical Applications:

- Pharmaceutical Packaging Foil (PTP): 8011, 8021, and 8079 aluminum foil are the mainstays of pharmaceutical packaging, providing an absolute barrier.

- Flexible Food Packaging: Used in composite packaging bags to protect food from light, oxygen, and moisture.

- Tape Foil: Serves as the base material for aluminum foil tape, used for sealing HVAC ducts and for electromagnetic shielding.

8021 Aluminum Foil Pharmaceutical Packaging

5. Manufacturing Processes of Industrial Aluminum Foil

5.1 Raw Material Preparation and Slab Casting

The process begins with primary aluminum ingots or recycled aluminum, which are melted and alloyed according to target specifications (commonly 1xxx, 3xxx, or 8xxx series).

Key process controls include:

- Chemical composition accuracy (typically ±0.02–0.05%)

- Hydrogen content control to prevent porosity

- Grain refiner additions to improve rolling behavior

Molten aluminum is then cast into slabs, usually 500–600 mm thick, using continuous or semi-continuous casting systems.

5.2 Hot Rolling

Hot rolling reduces the cast slab thickness to approximately 2–6 mm.

- Rolling temperatures: 450–500°C

- Primary objectives:

- Break down the cast structure

- Improve grain uniformity

- Prepare the material for cold rolling

Hot rolling establishes the base microstructure that will influence foil flatness and mechanical stability in later stages.

5.3 Cold Rolling and Gauge Reduction

Cold rolling is the most critical step in aluminum foil manufacturing.

- Material passes through multiple rolling stands

- Thickness is progressively reduced from millimeters to microns

- Rolling oil is used for lubrication and surface quality

For foils thinner than 25 μm, double rolling is applied, where two foil layers are rolled together to prevent tearing.

Modern rolling mills achieve thickness tolerances within ±1–2%, which is critical for applications such as batteries and pharmaceuticals.

Huawei Aluminum Foil Production Workshop

5.4 Annealing and Temper Control

Annealing adjusts mechanical properties and removes residual stresses.

- Typical annealing temperature: 300–400°C

- Atmosphere control prevents oxidation

- Oil residues are burned off to ensure surface cleanliness

Annealing determines the final temper:

- O temper for maximum softness and formability

- H18/H19 for high strength and rigidity

- H22/H24 for balanced performance

5.5 Surface Treatment and Finishing

Depending on application requirements, aluminum foil may undergo additional treatments:

- Degreasing and cleaning for food and pharmaceutical use

- Embossing to improve stiffness or aesthetics

- Coating or laminating with polymers, paper, or other foils

- Hydrophilic Coating: Applied to fins of Air Conditioning (HVAC) heat exchangers, it allows condensed water to spread evenly, improving heat exchange efficiency and preventing corrosion from stagnant water droplets.

- Corrosion-Resistant Coating: Used in building insulation and marine environments to provide extra protection and extend service life.

- Conductive Coating: Applied to battery current collectors to reduce interface resistance and enhance battery performance.

Color-coated aluminum foil

6. Mechanical and Physical Performance

The performance of industrial aluminum foil is determined not only by its chemical composition but also by its thickness, temper, rolling history, and surface condition.

Mechanical and physical properties directly influence formability, durability, barrier effectiveness, and functional reliability across different industrial applications.

6.1 Mechanical Properties

Because aluminum foil is extremely thin, its mechanical behavior differs from that of thicker aluminum sheets or plates.

As thickness decreases, strength increases while elongation generally decreases, a phenomenon driven by work hardening during rolling.

Typical Mechanical Property Ranges

| Property | Typical Range | Influencing Factors |

|---|---|---|

| Tensile strength | 60–160 MPa | Alloy type, temper, thickness |

| Yield strength | 35–120 MPa | Cold reduction level |

| Elongation | 1.5–20% | Annealing state, grain size |

| Tear resistance | Medium to high | Thickness, rolling direction |

Key Insight:

Foils in O temper prioritize ductility and formability, while H18/H19 tempers provide higher strength and stiffness, essential for high-speed packaging lines and capacitor winding.

6.2 Thickness Effect on Mechanical Performance

Thickness is one of the most critical variables in foil behavior.

- Below 20 μm, aluminum foil becomes increasingly sensitive to:

- Pinholes

- Tearing

- Edge defects

- Above 40 μm, foil exhibits:

- Improved puncture resistance

- Higher dimensional stability

- Better suitability for forming and insulation

| Thickness Range | Mechanical Behavior | Typical Applications |

|---|---|---|

| 6–9 μm | Very fragile, high precision required | Pharma blister, battery foil |

| 10–30 μm | Balanced strength and flexibility | Food packaging, laminates |

| 40–200 μm | High stiffness and durability | Industrial insulation, forming |

Huawei Aluminum foil thickness measurement

6.3 Physical Properties

Aluminum foil retains the intrinsic physical advantages of aluminum, even at very low thickness.

Key Physical Property Data

| Property | Typical Value |

|---|---|

| Density | ~2.70 g/cm³ |

| Thermal conductivity | 130–235 W/m·K |

| Electrical conductivity | ~35–60% IACS |

| Reflectivity (radiant heat) | Up to 95% |

| Magnetic behavior | Non-magnetic |

Practical Implication:

High thermal reflectivity makes aluminum foil highly effective in thermal insulation and radiant heat barriers, particularly in HVAC and building applications.

6.4 Barrier Performance

One of the most valuable attributes of industrial aluminum foil is its near-perfect barrier capability.

- Blocks 100% of light

- Prevents transmission of:

- Oxygen

- Moisture

- Aroma

- Microorganisms

Even at thicknesses as low as 6–7 μm, intact aluminum foil provides superior barrier performance compared to polymer films many times thicker.

6.5 Electrical and Functional Performance

In electronics and energy applications, aluminum foil serves functional roles beyond containment.

- Capacitor foil: Requires high purity, controlled surface roughness

- Battery foil: Demands tight thickness tolerance (≤±1%) and surface cleanliness

- EMI/RFI shielding: Relies on conductivity and continuity

Small deviations in surface quality or thickness can significantly impact electrical performance, highlighting the importance of manufacturing precision.

7. Key Application Areas of Industrial Aluminum Foil: Where Each Alloy Shines

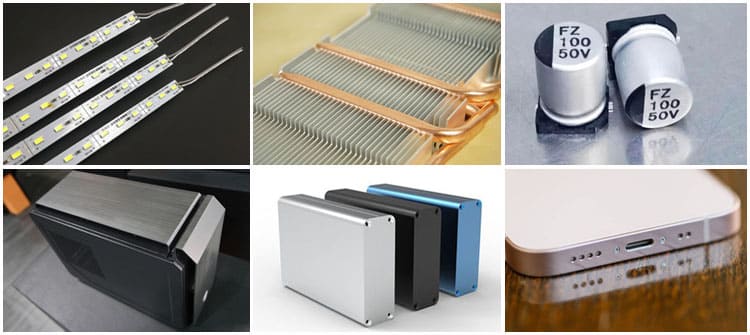

7.1 Power and Electronics Industry: The Lightweight Conductor and Guardian

- Applications:

- Capacitor Anode Foil: Utilizes the ability of the aluminum foil surface to form a dense oxide film, which is then etched and formed to greatly increase the surface area, thus manufacturing miniaturized, high-capacity electrolytic capacitors.

- Lithium Battery Cathode Current Collector: 1060 or 1235 aluminum foil serves as the carrier for the cathode material. Its high electrical conductivity, low contact resistance, and lightweight properties help to increase the energy density and cycle performance of the battery.

- Electromagnetic Shielding (EMI/RFI): Aluminum foil has excellent shielding effectiveness against electromagnetic waves and is widely used in cables, electronic device enclosures, and server rooms to prevent signal interference.

- Value: In this field, the electrical conductivity and lightweight nature of aluminum foil are its core values.

Industrial Aluminum Foil for HVAC

7.2 Construction and HVAC Industry: The Energy-Saving and Durable Barrier

- Applications:

- Insulated Sandwich Panels: As the surface layer for insulation cores like polyurethane (PUR) or rock wool, it utilizes its up to 97% thermal reflectivity as a radiant heat barrier and acts as a vapor barrier to protect the core from moisture.

- Flexible Ducts: Aluminum foil is laminated with materials like PET and PVC to form lightweight, corrosion-resistant, and easy-to-install air conditioning ducts.

- Aluminum Foil Tape: 8011 aluminum foil is the primary material for sealing HVAC duct joints, ensuring the system’s airtightness and thermal efficiency.

- Value: Thermal reflectivity and vapor barrier properties are the core values of aluminum foil in the building and energy conservation sector.

7.3 Transportation: The Driver of Lightweighting and Thermal Management

- Applications:

- Automotive Heat Exchangers: 3003 or other brazing composite aluminum foils are key materials for manufacturing automotive radiators, condensers, evaporators, and intercoolers, with their high thermal conductivity ensuring efficient heat exchange.

- Automotive Heat Shields: Stamped aluminum foil parts are used to block heat transfer from the engine and exhaust system to the cabin and sensitive components.

- Aluminum Honeycomb Core: Honeycomb cores made from 3003 aluminum foil are used to produce lightweight, high-strength interior panels and flooring for rail vehicles and ships.

- Value: High thermal conductivity and lightweight properties are the core advantages of aluminum foil in the transportation sector.

Industrial Aluminum Foil for Heat Exchangers

7.4 High-Performance Packaging: The Absolute Guardian

- Applications:

- Aseptic Packaging: In composite packaging like Tetra Pak, an extremely thin layer of aluminum foil (usually only 6-7µm) provides an absolute barrier to light, oxygen, and microorganisms, enabling products like milk and juice to have a shelf life of several months at room temperature.

- Pharmaceutical Packaging: 8011, 8021, or 8079 aluminum foils are used to make PTP (blister) packs and cold-form aluminum, providing the ultimate protection for drugs.

- Retort Pouches: Used for flexible packaging of high-temperature retorted foods, requiring aluminum foil with good heat resistance and barrier properties.

- Value: In this field, the absolute barrier property of aluminum foil is its irreplaceable core value.

8. The Importance of Quality Assurance and Supplier Selection (Henan Huawei Aluminum)

The performance of Industrial Aluminum Foil directly affects the quality and reliability of the final product. Therefore, its quality control must be extremely stringent.

- Chemical Composition Control: The content of alloying elements must be precisely controlled to ensure the final mechanical and physical properties.

- Thickness and Shape: High-precision thickness gauges and shape meters are used to ensure uniform thickness and a flat shape across the entire coil, which is crucial for subsequent high-speed processing.

- Surface Quality: The foil surface must be clean, free of oil stains, scratches, and bright spots. For packaging foil, the surface wetting tension is also required to meet standards (usually >32 dynes) to ensure strong printing and lamination.

- Pinhole Count: This is a key indicator of barrier performance. High-quality industrial foil, especially for packaging, has extremely strict requirements for the number and size of pinholes.

For manufacturers worldwide, choosing an aluminum foil supplier with strong technical capabilities and strict quality control is essential.

Henan Huawei Aluminum Co., Ltd, a well-known aluminum product manufacturer in the industry, is such a partner.

It is important to clarify that this “Huawei” refers to Henan Huawei Aluminum, a company specializing in the R&D and production of aluminum, and is a different, independent entity from the renowned consumer electronics and communication technology giant, Huawei Technologies.

9. Standards, Testing, and Compliance

9.1 Major International Standards for Industrial Aluminum Foil

Industrial aluminum foil is governed by multiple national and international standards that define chemical composition, mechanical properties, dimensional tolerances, and surface quality.

| Standard Organization | Standard | Scope |

|---|---|---|

| ASTM (USA) | ASTM B479 | Aluminum foil for general industrial use |

| ISO | ISO 6361 | Wrought aluminum and aluminum alloys |

| EN (EU) | EN 546 | Tolerances for aluminum foil |

| GB (China) | GB/T 3198 | Aluminum and aluminum alloy foil |

| JIS (Japan) | JIS H4160 | Aluminum and aluminum alloy foils |

9.2 Industry-Specific Regulatory Requirements

Beyond general material standards, many applications impose sector-specific regulations:

- Food packaging

- FDA (21 CFR) compliance in the U.S.

- EU Regulation (EC) No. 1935/2004

- Pharmaceutical packaging

- GMP requirements

- Low pinhole density and cleanliness standards

- Electronics and batteries

- Tight thickness tolerance (often ≤±1%)

- Surface contamination control

9.3 Testing Methods and Quality Verification

Testing is essential to confirm that aluminum foil meets both standard and customer-specific requirements.

Common Testing Items

| Test Item | Purpose |

|---|---|

| Tensile test | Verify mechanical strength |

| Pinhole test | Ensure barrier integrity |

| Thickness gauge | Confirm dimensional accuracy |

| Surface inspection | Detect defects and contamination |

10. Conclusion

Industrial Aluminum Foil, with its lightweight, high thermal conductivity, high electrical conductivity, excellent barrier properties, and superior corrosion resistance, plays a crucial role in modern industry.

From supporting the electronic components of the digital economy and ensuring the comfort of cities through HVAC systems to safeguarding the safety of food and drugs with packaging solutions, every application of industrial aluminum foil reflects the ingenuity of material science.

Through the precise application of different alloys like the 1xxx, 3xxx, and 8xxx series, manufacturers can provide customized solutions for a variety of extreme and precision conditions.

As a producer committed to providing high-quality metal products, Henan Huawei Aluminum Co., Ltd will continue to leverage its professional knowledge and advanced technology to provide excellent Industrial Aluminum Foil products to global customers, jointly promoting technological progress and sustainable development.

FAQs

Q1: Can industrial and household aluminum foil be used interchangeably?

A1: No. Industrial aluminum foil is designed for specific properties (like conductivity or specific strength), may not be certified for food-grade use, and its mechanical properties (like hardness) are not suitable for kitchen use. Conversely, household foil cannot meet the strict requirements of industrial applications for strength, temperature resistance, or electrical properties.

Q2: Does the “shiny” vs. “dull” side of industrial aluminum foil matter in use?

A2: In terms of industrial aluminum foil performance, especially for thermal conductivity and barrier properties, the difference between the shiny and dull sides is negligible. This difference is a natural result of the “pack rolling” process. However, in applications requiring high reflectivity (like insulation boards), the shiny side is usually oriented towards the heat source.

Q3: Why is aluminum foil used for the cathode of lithium batteries, while copper foil is used for the anode?

A3: At high potentials, aluminum reacts with the electrolyte to form a dense AlF₃ passivation film, protecting the current collector from corrosion, whereas copper would oxidize. At low potentials (anode), aluminum would alloy with lithium, destroying the structure, while copper does not. Therefore, aluminum foil is the ideal cathode current collector, and copper foil is the ideal anode current collector.

Q4: Is industrial aluminum foil a sustainable material?

A4: Yes. Aluminum is a 100% infinitely recyclable material, and the recycling process requires only about 5% of the energy needed for primary aluminum production. Scrap from industrial production and end-of-life aluminum foil products have high recycling value, making it a model for a circular economy.

Casting production process and its introduction

The purpose of melting and casting is to produce alloys with satisfactory composition and high purity of melt, so as to create favorable conditions for casting alloys of various shapes.

Melting and casting process steps: batching --- feeding --- melting --- stirring after melting, slag removal --- pre-analysis sampling --- adding alloy to adjust the composition, stirring --- refining --- static Setting——Guide furnace casting.

Hot rolling production process and its introduction

- 1. Hot rolling generally refers to rolling above the metal recrystallization temperature;

- 2. During the hot rolling process, the metal has both hardening and softening processes. Due to the influence of deformation speed, as long as the recovery and recrystallization process is too late, there will be a certain work hardening;

- 3. The recrystallization of the metal after hot rolling is incomplete, that is, the coexistence of recrystallized structure and deformed structure;

- 4. Hot rolling can improve the processing performance of metals and alloys, reduce or eliminate casting defects.

- 1. The casting and rolling temperature is generally between 680°C and 700°C. The lower the better, the stable casting and rolling line usually stops once a month or more to re-stand. During the production process, it is necessary to strictly control the liquid level of the front tank to prevent low liquid level;

- 2. Lubrication uses C powder with incomplete combustion of gas for lubrication, which is also one of the reasons for the dirty surface of casting and rolling materials;

- 3. The production speed is generally between 1.5m/min-2.5m/min;

- 4. The surface quality of products produced by casting and rolling is generally relatively low, and generally cannot meet products with special physical and chemical performance requirements.

- 1. Cold rolling refers to the rolling production method below the recrystallization temperature;

- 2. There will be no dynamic recrystallization during the rolling process, and the temperature will rise to the recovery temperature at most, and the cold rolling will appear in a work hardening state, and the work hardening rate will be large;

- 3. The cold-rolled sheet and strip have high dimensional accuracy, good surface quality, uniform structure and performance, and products in various states can be obtained with heat treatment;

- 4. Cold rolling can roll out thin strips, but at the same time, it has the disadvantages of high energy consumption for deformation and many processing passes.

- 1. Finishing is a processing method to make the cold-rolled sheet meet the customer's requirements, or to facilitate the subsequent processing of the product;

- 2. The finishing equipment can correct the defects produced in the hot rolling and cold rolling production process, such as cracked edge, oily, poor plate shape, residual stress, etc. It needs to ensure that no other defects are brought into the production process;

- 3. There are various finishing equipments, mainly including cross-cutting, slitting, stretching and straightening, annealing furnace, slitter, etc.

Casting and rolling process

Casting and rolling process: liquid metal, front box (liquid level control), casting and rolling machine (lubrication system, cooling water), shearing machine, coiling machine.

Cold rolling production process

Introduction to finishing production process

Aluminum alloy has the characteristics of low density, good mechanical properties, good processing performance, non-toxic, easy to recycle, excellent electrical conductivity, heat transfer and corrosion resistance, so it has a wide range of applications.

Aerospace: used to make aircraft skins, fuselage frames, girders, rotors, propellers, fuel tanks, wall panels and landing gear struts, as well as rocket forging rings, spacecraft wall panels, etc.

Aluminum alloy used for aerospace

Transportation: used for car body structure materials of automobiles, subway vehicles, railway passenger cars, high-speed passenger cars, doors and windows, shelves, automotive engine parts, air conditioners, radiators, body panels, wheels and ship materials.

Traffic application

Packaging: All-aluminum pop cans are mainly used as metal packaging materials in the form of thin plates and foils, and are made into cans, lids, bottles, barrels, and packaging foils. Widely used in the packaging of beverages, food, cosmetics, medicines, cigarettes, industrial products, medicines, etc.

Packaging application

Printing: Mainly used to make PS plates, aluminum-based PS plates are a new type of material in the printing industry, used for automatic plate making and printing.

PS printing

Architectural decoration: aluminum alloy is widely used in building structures, doors and windows, suspended ceilings, decorative surfaces, etc. due to its good corrosion resistance, sufficient strength, excellent process performance and welding performance.

Aluminum alloy construction application

Electronic products: computers, mobile phones, refrigerator shells, radiators, etc.

Electronic product application

Kitchen supplies: aluminum pots, aluminum basins, rice cooker liners, household aluminum foil, etc.

Kitchen application

Packaging Of Aluminum Sheet/Coil

Every detail of packaging is where we pursue perfect service. Our packaging process as a whole is as follows:

Lamination: clear film, blue film, micro-mucosal, high-mucosal, laser cutting film (2 brands, Novacell and Polyphem);

Protection: paper corner protectors, anti-pressure pads;

drying: desiccant;

Tray: fumigated harmless wooden tray, reusable iron tray;

Packing: Tic-tac-toe steel belt, or PVC packing belt;

Material Quality: Completely free from defects such as white rust, oil spots, rolling marks, edge damage, bends, dents, holes, break lines, scratches, etc., no coil set.

Port: Qingdao or other ports in China.

Lead time: 15-45 days.

Aluminum sheet/plate packaging process

Aluminum coil packaging process

F: Are you a manufacturer or a trader?

Q: We are a manufacturer, our factory is at No.3 Weier Road, Industrial Zone, Gongyi, Henan, China.

F: What is the MOQ for ordering the product?

Q: Our MOQ is 5 tons, and some special products will have a minimum order quantity of 1 or 2 tons.

F: How long is your lead time?

Q: Generally our lead time is about 30 days.

F: Do your products have quality assurance?

Q: Yes, if there is a quality problem with our products, we will compensate the customer until they are satisfied.

Related Products

Latest Blogs

Ultra-high reflectivity aluminum mirror sheet

Ultra-high reflectivity aluminum mirror sheet with 95–98% visible reflectance, low scatter (TIS <1%), and specification advice for BRDF, spectral curves and coatings.

Trusted 3003 Aluminium Checker Plate Sheet Suppliers Worldwide

Find reliable 3003 Aluminium Checker Plate Sheet Suppliers offering certified quality, competitive pricing, custom sizes, and fast global delivery for your projects.

6061 T6 vs 7075 Aluminum: Strength, Weight & Best Uses

Compare 6061 T6 vs 7075 aluminum easily. Discover differences in strength, weight, and applications to choose the best for your projects.

Industrialization and Application of Honeycomb Aluminum Foil

This blog explores the industrialization of honeycomb aluminum foil, focusing on the 3003 alloy production process. It covers hot rolling, continuous casting, and the continuous casting-rolling method, highlighting the benefits of process optimization in improving mechanical properties, reducing energy consumption, and lowering production costs.