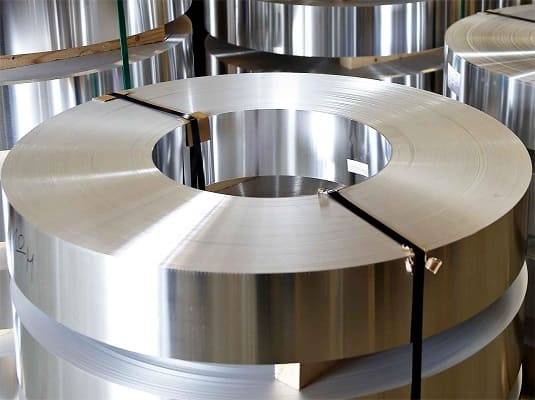

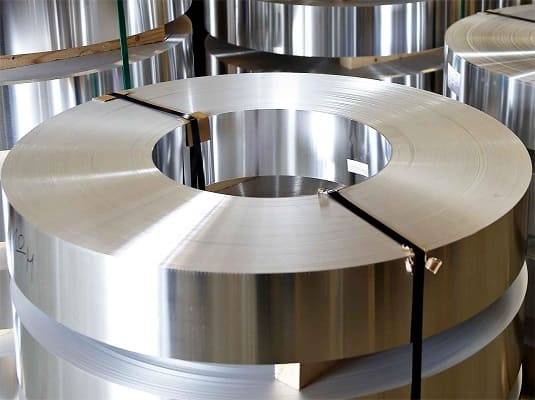

6061 aluminum strip product

6061 aluminum strip is a commonly used aluminum strip material with excellent mechanical properties and corrosion resistance. Akunum strip 6061 belongs to the Al-Mg-Si alloy and contains a moderate amount of copper element, so its strength is higher than that of 6063 alloy. It also has good formability, weldability and easy processing characteristics.

6061 aluminium srtip

Chemical composition of 6061 aluminum strip

The chemical composition of 6061 aluminum strip mainly includes aluminum, magnesium, silicon and a small amount of copper, manganese, zinc and other elements. The content and proportion of these elements determine the mechanical properties and corrosion resistance of 6061 aluminum strip.

| Al strip 6061 element content(%) | |||||||||

| Alloy | Cu | Mn | Mg | Zn | Cr | Ti | Si | Fe | Al |

| 6061 | 0.15~0.4 | 0.15 | 0.8~1.2 | 0.25 | 0.04~0.35 | 0.15 | 0.4~0.8 | 0.7 | Balance |

What can 6061 aluminum strip be used for?

6061 aluminum strip is a widely used aluminum model among the 6000 series aluminum alloys and is used in many aspects.

6061 aluminum strip is used in the aerospace field: 6061 aluminum strip has the characteristics of light weight, high strength and corrosion resistance, so it is widely used in the aerospace field. It can be used to manufacture aircraft wings, fuselages, propellers and other components, as well as spacecraft structural parts and shells.

6061 aluminum strip is used in the automobile manufacturing industry: With the development of the automobile industry, lightweighting has become an important trend in automobile manufacturing. The light weight and high strength of 6061 aluminum strip make it one of the ideal materials for the automotive manufacturing industry. It can be used to manufacture car bodies, doors, hoods and other components.

aluminum strip for aircraft wings

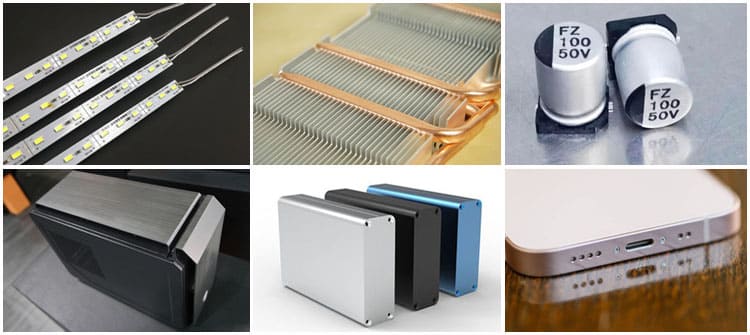

6061 aluminum strip Electronic products: 6061 aluminum strip has good electrical and thermal conductivity and can be used to manufacture components such as housings, heat sinks and connectors for electronic equipment. It can effectively dissipate heat and ensure the normal operation of electronic equipment.

Aluminum strip 6061 is used for building decoration: 6061 aluminum strip has beautiful appearance and strong corrosion resistance, so it is used in wall panels, ceilings, stair handrails and other components of buildings. 6061 can not only provide good decorative effects, but also improve the durability and safety of buildings.

Aluminum strip for pipes and containers: Because 6061 aluminum strip has good corrosion resistance and sealing properties, it has important applications in manufacturing pipes and containers. It can be used to manufacture pipelines for transporting liquids and gases, as well as containers for storing liquids and gases, such as oil tanks, gas bottles, etc.

6061 aluminum strip for containers

6061 aluminum strip performance parameters

6061 aluminum is a versatile alloy that offers good strength, corrosion resistance and workability. Has better performance parameters. :

Tensile Strength

The tensile strength of 6061 aluminum strip is typically around 45,000 psi (310 MPa) or higher, depending on tempering (heat treatment).

Yield Strength

The yield strength of 6061 aluminum is approximately 40,000 psi (275 MPa)

Elongation

The elongation at break of 6061 aluminum strip is generally about 8% to 12%, indicating its ability to deform before breaking.

Hardness

The hardness of 6061 aluminum depends on the tempering state. For example, in the T6 temper, the Brinell hardness is typically around 95.

6061 aluminum strip product

Density

The density of 6061 aluminum is approximately 0.098 pounds per cubic inch (2.70 g/cm³).

Thermal conductivity

The thermal conductivity of 6061 aluminum is approximately 170 W/mK.

Corrosion resistance

6061 aluminum has good corrosion resistance, especially under atmospheric conditions. However, it may be susceptible to corrosion in certain environments, and protective coatings or treatments may be applied to increase resistance.

Machinability

6061 aluminum has good machinability, especially under heat treatment conditions. It can be cut, drilled and shaped easily.

Solderability

6061 aluminum is generally considered weldable, but precautions should be taken to avoid hot cracking. It is recommended to use filler alloys with sufficient silicon content.

Casting production process and its introduction

The purpose of melting and casting is to produce alloys with satisfactory composition and high purity of melt, so as to create favorable conditions for casting alloys of various shapes.

Melting and casting process steps: batching --- feeding --- melting --- stirring after melting, slag removal --- pre-analysis sampling --- adding alloy to adjust the composition, stirring --- refining --- static Setting——Guide furnace casting.

Hot rolling production process and its introduction

- 1. Hot rolling generally refers to rolling above the metal recrystallization temperature;

- 2. During the hot rolling process, the metal has both hardening and softening processes. Due to the influence of deformation speed, as long as the recovery and recrystallization process is too late, there will be a certain work hardening;

- 3. The recrystallization of the metal after hot rolling is incomplete, that is, the coexistence of recrystallized structure and deformed structure;

- 4. Hot rolling can improve the processing performance of metals and alloys, reduce or eliminate casting defects.

- 1. The casting and rolling temperature is generally between 680°C and 700°C. The lower the better, the stable casting and rolling line usually stops once a month or more to re-stand. During the production process, it is necessary to strictly control the liquid level of the front tank to prevent low liquid level;

- 2. Lubrication uses C powder with incomplete combustion of gas for lubrication, which is also one of the reasons for the dirty surface of casting and rolling materials;

- 3. The production speed is generally between 1.5m/min-2.5m/min;

- 4. The surface quality of products produced by casting and rolling is generally relatively low, and generally cannot meet products with special physical and chemical performance requirements.

- 1. Cold rolling refers to the rolling production method below the recrystallization temperature;

- 2. There will be no dynamic recrystallization during the rolling process, and the temperature will rise to the recovery temperature at most, and the cold rolling will appear in a work hardening state, and the work hardening rate will be large;

- 3. The cold-rolled sheet and strip have high dimensional accuracy, good surface quality, uniform structure and performance, and products in various states can be obtained with heat treatment;

- 4. Cold rolling can roll out thin strips, but at the same time, it has the disadvantages of high energy consumption for deformation and many processing passes.

- 1. Finishing is a processing method to make the cold-rolled sheet meet the customer's requirements, or to facilitate the subsequent processing of the product;

- 2. The finishing equipment can correct the defects produced in the hot rolling and cold rolling production process, such as cracked edge, oily, poor plate shape, residual stress, etc. It needs to ensure that no other defects are brought into the production process;

- 3. There are various finishing equipments, mainly including cross-cutting, slitting, stretching and straightening, annealing furnace, slitter, etc.

Casting and rolling process

Casting and rolling process: liquid metal, front box (liquid level control), casting and rolling machine (lubrication system, cooling water), shearing machine, coiling machine.

Cold rolling production process

Introduction to finishing production process

Aluminum alloy has the characteristics of low density, good mechanical properties, good processing performance, non-toxic, easy to recycle, excellent electrical conductivity, heat transfer and corrosion resistance, so it has a wide range of applications.

Aerospace: used to make aircraft skins, fuselage frames, girders, rotors, propellers, fuel tanks, wall panels and landing gear struts, as well as rocket forging rings, spacecraft wall panels, etc.

Aluminum alloy used for aerospace

Transportation: used for car body structure materials of automobiles, subway vehicles, railway passenger cars, high-speed passenger cars, doors and windows, shelves, automotive engine parts, air conditioners, radiators, body panels, wheels and ship materials.

Traffic application

Packaging: All-aluminum pop cans are mainly used as metal packaging materials in the form of thin plates and foils, and are made into cans, lids, bottles, barrels, and packaging foils. Widely used in the packaging of beverages, food, cosmetics, medicines, cigarettes, industrial products, medicines, etc.

Packaging application

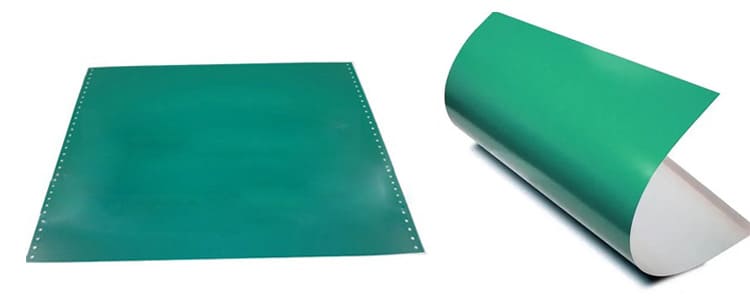

Printing: Mainly used to make PS plates, aluminum-based PS plates are a new type of material in the printing industry, used for automatic plate making and printing.

PS printing

Architectural decoration: aluminum alloy is widely used in building structures, doors and windows, suspended ceilings, decorative surfaces, etc. due to its good corrosion resistance, sufficient strength, excellent process performance and welding performance.

Aluminum alloy construction application

Electronic products: computers, mobile phones, refrigerator shells, radiators, etc.

Electronic product application

Kitchen supplies: aluminum pots, aluminum basins, rice cooker liners, household aluminum foil, etc.

Kitchen application

Packaging Of Aluminum Sheet/Coil

Every detail of packaging is where we pursue perfect service. Our packaging process as a whole is as follows:

Lamination: clear film, blue film, micro-mucosal, high-mucosal, laser cutting film (2 brands, Novacell and Polyphem);

Protection: paper corner protectors, anti-pressure pads;

drying: desiccant;

Tray: fumigated harmless wooden tray, reusable iron tray;

Packing: Tic-tac-toe steel belt, or PVC packing belt;

Material Quality: Completely free from defects such as white rust, oil spots, rolling marks, edge damage, bends, dents, holes, break lines, scratches, etc., no coil set.

Port: Qingdao or other ports in China.

Lead time: 15-45 days.

Aluminum sheet/plate packaging process

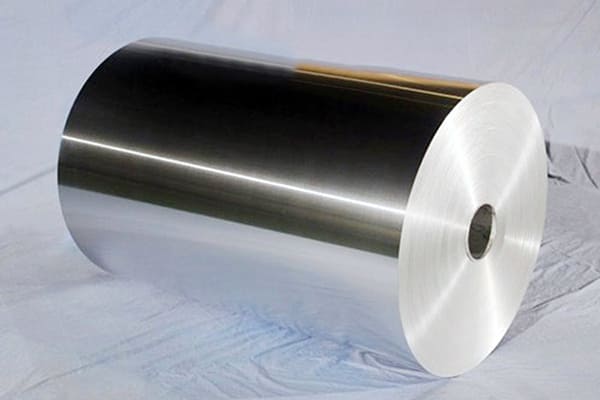

Aluminum coil packaging process

F: Are you a manufacturer or a trader?

Q: We are a manufacturer, our factory is at No.3 Weier Road, Industrial Zone, Gongyi, Henan, China.

F: What is the MOQ for ordering the product?

Q: Our MOQ is 5 tons, and some special products will have a minimum order quantity of 1 or 2 tons.

F: How long is your lead time?

Q: Generally our lead time is about 30 days.

F: Do your products have quality assurance?

Q: Yes, if there is a quality problem with our products, we will compensate the customer until they are satisfied.

Related Products

Latest Blogs

6061 vs 7075 aluminum

"6061" and "7075" are two common aluminum alloy grades, which are widely used in many industrial fields, especially in aviation, aerospace, transportation and structural manufacturing.

Aluminum Foil Used in Air Fryers

Aluminum foil is widely used in daily life, mainly due to its light weight, good ductility, moderate price, and excellent heat conduction and light-shielding properties.

Reasons why the surface of honeycomb aluminum foil cannot be bonded with the adhesive

Aluminum honeycomb panels have good performance in use. They have good strength and good impact resistance. They can be well designed in use. Therefore, they are widely used at present.

Introduction hardness of 1000-8000 series aluminum alloys

1000-8000 series basically covers all aluminum alloy series products. Different series of products have different performance and hardness.