3003 kepingan aluminium vs 1060 kepingan aluminium

188 Pandangan 2024-05-21 09:49:37

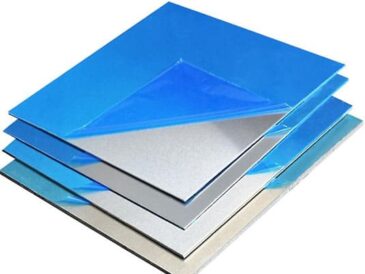

3003 kepingan aluminium dan 1060 kepingan aluminium adalah kedua-dua kepingan aluminium biasa. Mereka boleh menggantikan satu sama lain dalam beberapa senario penggunaan, tetapi mereka mempunyai sisihan besar dalam komposisi kimia, sifat mekanikal dan harga. Oleh itu, you need to understand your usage scenarios before ordering aluminum sheets. And the difference between 3003 kepingan aluminium dan 1060 kepingan aluminium.

3003 pengenalan kepingan aluminium

3003 kepingan aluminium is one of the most common alloy aluminum sheets. Ia adalah produk perwakilan daripada 3000 siri (Al-Mn) plat aluminium. It is a widely used anti-rust aluminum. The strength of this alloy is not high (slightly higher than industrial pure aluminum).

Ia tidak boleh dikuatkan dengan rawatan haba, so cold working methods are used to improve its mechanical properties: it has high plasticity in the annealed state, keplastikan yang baik semasa pengerasan kerja separa sejuk, keplastikan rendah semasa pengerasan kerja sejuk, rintangan kakisan yang baik, kebolehkimpalan yang baik, and can be cut. Poor performance.

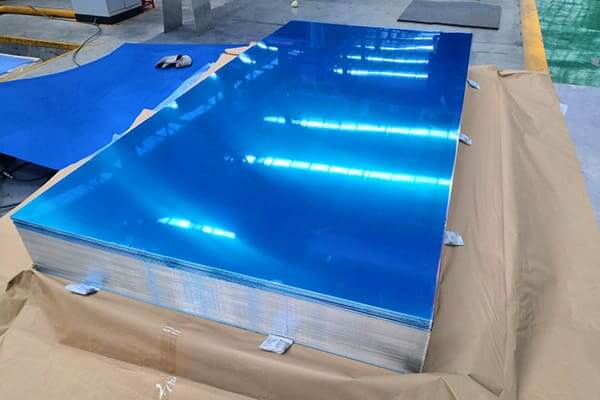

3003 kepingan aluminium dibungkus

It is mainly used for low-load parts that require high plasticity and good weldability and work in liquid or gas media, such as fuel tanks, gasoline or lubricating oil conduits, various liquid containers and other small-load parts made by deep drawing: Wire is used to make rivets.

Komposisi kimia

In terms of chemical composition, the main elements of 3003 aluminum plate include aluminum (Al) and manganese (Mn), of which the aluminum content is greater than 98% and the manganese content is between 1-1.5%. 3003 aluminum sheet also contains a small amount of copper (Cu) and other impurity elements. The content and proportion of these alloy elements play an important role in the hardness, kekuatan, corrosion resistance and other properties of 3003 plat aluminium.

Mechanical standards

Mechanical standards are an important indicator for measuring material performance and an important basis for evaluating the quality of 3003 kepingan aluminium. In terms of mechanical standards, the hardness, kekuatan, ductility and corrosion resistance of 3003 aluminum plates are all key indicators.

Kekerasan daripada 3003 aluminum sheet is mainly reflected in its tensile strength and yield strength. Mengikut piawaian antarabangsa, the tensile strength of 3003 aluminum sheet is between 110-205MPa and the yield strength is between 40-150MPa. This shows that 3003 aluminum plate has a certain hardness and strength to a certain extent and can meet the needs of different fields.

The ductility of 3003 aluminum plate is also one of its important mechanical standards. The elongation rate of 3003 aluminum sheet is usually above 10%, which means that it has good sheet forming performance and is suitable for various stamping and forming processes.

Rintangan kakisan daripada 3003 aluminum sheet is also one of the important indicators in its mechanical standards. Because it contains manganese and other alloying elements, 3003 aluminum plates have good corrosion resistance and can be used in humid and corrosive environments for a long time without being damaged.

Pengenalan kepada 1060 kepingan aluminium

1060 aluminum sheet and strip, mengandungi 99.6% aluminium, is also called pure aluminum plate. It is a commonly used series in the aluminum sheet and strip family. The advantages of this series of aluminum plates: the most commonly used series, the production process is relatively simple, the technology is relatively mature, and the price has a huge advantage compared to other high-end alloy aluminum plates. It has good elongation and tensile strength, dan boleh memenuhi sepenuhnya keperluan pemprosesan konvensional (mengecap, regangan) dan kebolehbentukan yang tinggi.

1060 kepingan aluminium is industrial pure aluminum with high plasticity, rintangan kakisan, Kekonduksian elektrik dan kekonduksian terma, tetapi kekuatan rendah, tidak boleh dikuatkan dengan rawatan haba, dan mempunyai kebolehmesinan yang lemah; it can be gas welded, hydrogen atom welded and contact welded, but is not easy to braze; Easy to withstand various pressure processing, stretching and bending.

3003 kepingan aluminium vs 1060 kepingan aluminium

1060 aluminum plate is widely used in products that do not require high strength. Products are commonly used in signboards, papan iklan, building exterior decorations, bus bodies, high-rise building and factory wall decorations, kitchen sinks, lamp holders, fan blades, electronic parts, chemical instruments, bahagian pemprosesan plat nipis, deep drawing or spinning concave parts. Shaped utensils, welded parts, penukar haba, clock surfaces and disks, papan nama, peralatan dapur, hiasan, peralatan reflektif, dan lain-lain.

3003 kepingan aluminium vs 1060 kepingan aluminium

Alloy differences

| Al(%) | Dan (%) | Cu (%) | Mg(%) | Zn (%) | Mn(%) | Daripada(%) | V (%) | Fe(%) |

| 99.60 | 0.25 | 0.05 | 0.03 | 0.05 | 0.03 | 0.03 | 0.05 | 0.35 |

| 96.8-99.0 | 0.60 | 0.05-0.20 | 0-0.05 | 0.10 | 1.00-1.50 | – | – | 0.70 |

Differences in mechanical properties

| Aloi | Kekuatan tegangan | Kekuatan Hasil |

| 1060 | 110-136 | ≥35 |

| 3003 | 120-160 | ≥85 |

Differences in use

Sejak 1060 aluminum plate has good electrical conductivity, it is usually used in electronic devices, bateri, capacitors and other fields. Due to its higher strength and corrosion resistance, 3003 aluminum sheet is suitable for manufacturing body panels, tangki bahan api, ships and other fields with high strength requirements.

1060 aplikasi kepingan aluminium

- Produk elektronik: used to manufacture electronic components, sarung elektrik, LED heat sinks, dan lain-lain., taking advantage of its good electrical and thermal conductivity properties.

- Building materials: used to make decorative panels, dinding langsir, bahan bumbung, dan lain-lain., with good corrosion resistance and aesthetics.

- Advertising signs: used to make signs and billboards, thanks to its good formability and surface treatment capabilities.

- Household appliances: such as kitchen sinks, tudung lampu, fan blades, dan lain-lain., taking advantage of their ease of processing and corrosion resistance.

- Chemical equipment: used to make certain parts of chemical equipment to take advantage of its chemical stability.

Aplikasi daripada 1060 kepingan aluminium

3003 aluminum plate application

- Chemical equipment and containers: In the pharmaceutical and food industries, 3003 aluminum plates are used to make containers and packaging materials. Because they will not react with chemical substances, they ensure the safety and quality of the products.

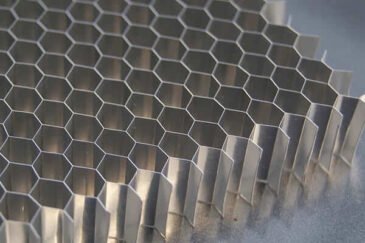

- Aeroangkasa: Leveraging its lightweight, corrosion-resistant and ability to withstand extreme conditions, 3003 aluminum sheets are used to manufacture aerospace components and equipment, helping to improve aircraft performance and fuel efficiency.

- Pembuatan kereta: In vehicles such as cars, kereta api, trem, dan lain-lain., 3003 aluminum sheets are used as body panels, compartment panels, roof panels, dan lain-lain. to reduce weight and improve fuel economy.

- Medan elektronik: used in electronic product casings, radiator, dan lain-lain., using its conductive properties and heat dissipation capabilities to protect electronic components.

- Building materials: Used for building exterior siding, roof panels, siling, dan lain-lain., both as decorative materials and to take advantage of its light weight and weather resistance.

- Pengangkutan: Not limited to cars, but also body parts for trains, trem, dan lain-lain. to achieve lightweight design.