Top-Quality 3004 Honeycomb Aluminum Foil Dubai

12,273 Views 2025-09-11 02:44:58

Architectural Innovation Meets Extreme Demands: The Power of 3004 Honeycomb Aluminum Foil in Dubai’s Landscape

In the dazzling panorama of Dubai’s rapid development, where architectural ambition meets the relentless challenges of an extreme desert climate, the selection of advanced building and industrial materials is paramount.

Amidst this quest for innovation and resilience, 3004 Honeycomb Aluminum Foil Dubai has emerged as a truly transformative solution, underpinning structures and systems that demand an unparalleled synergy of lightness, rigidity, thermal efficiency, and durability.

3004 Honeycomb Aluminum Foil Dubai

This intricate composite material, born from the versatile 3004 aluminum alloy and a clever geometric design, embodies a cutting-edge approach to engineering.

This comprehensive article delves into the precise composition, the innovative honeycomb structure, and the broad spectrum of applications that collectively underscore 3004 honeycomb aluminum foil’s pivotal role in Dubai’s dynamic industrial and construction ecosystem, offering profound insights for architects, engineers, and product developers navigating this demanding market.

The Foundation: Understanding 3004 Aluminum Alloy

The exceptional performance of 3004 aluminum foil, particularly when forming a honeycomb core, begins with its meticulously engineered chemical composition.

It belongs to the 3xxx series of aluminum alloys, primarily distinguished by manganese as its key alloying element.

Huawei 3004 Aluminum Foil

Chemical Composition of 3004 Aluminum Foil

3004 aluminum foil is an aluminum-manganese alloy with additional magnesium content, offering excellent corrosion resistance, moderate strength, and good formability.

Below is the chemical composition of 3004 aluminum foil, defined as a percentage by weight:

| Element | Composition (%) | Purpose/Effect |

|---|---|---|

| Aluminum (Al) | 95.0 – 98.0 | Base material providing lightweight, corrosion resistance, and flexibility. |

| Manganese (Mn) | 1.0 – 1.5 | Increases strength, corrosion resistance, and wear resistance. |

| Magnesium (Mg) | 0.8 – 1.3 | Improves strength, hardness, and fatigue resistance. |

| Iron (Fe) | ≤ 0.7 | Enhances toughness and strength. |

| Silicon (Si) | ≤ 0.3 | Improves corrosion resistance and thermal stability. |

| Copper (Cu) | ≤ 0.25 | Adds strength but is kept low to preserve corrosion resistance. |

| Zinc (Zn) | ≤ 0.25 | Improves hardness but is kept minimal for corrosion resistance. |

| Other Elements | ≤ 0.15 (total) | Impurities controlled to maintain aluminum quality. |

Physical and Mechanical Properties of 3004 Aluminum Foil

3004 aluminum foil is an aluminum-manganese-magnesium alloy known for its moderate strength, good corrosion resistance, and excellent formability.

Below is a detailed overview of its physical and mechanical properties:

Physical Properties

| Property | Value | Description |

|---|---|---|

| Density | 2.73 g/cm³ | Lightweight material, typical of aluminum alloys. |

| Melting Point | 610 – 660 °C | Suitable for applications requiring thermal resistance. |

| Thermal Conductivity | ~ 160 – 180 W/m·K | Excellent heat transfer properties, ideal for cooking and heat exchangers. |

| Electrical Conductivity | ~ 38% IACS | Good electrical conductivity, though lower than pure aluminum (like 1100 alloy). |

| Coefficient of Thermal Expansion | 23.1 × 10⁻⁶ /K | Expands moderately with temperature changes, typical of aluminum alloys. |

| Corrosion Resistance | Excellent | Highly resistant to corrosion in moist and chemically aggressive environments. |

Mechanical Properties

| Property | Value | Description |

|---|---|---|

| Ultimate Tensile Strength | 145 – 185 MPa | Moderate strength, higher than 1100 and 8011 alloys. |

| Yield Strength | ~ 115 MPa | Good resistance to deformation under load. |

| Elongation at Break | 10% – 20% (depending on temper) | Excellent ductility, ideal for forming and rolling processes. |

| Hardness (Brinell) | ~ 46 HB | Moderate hardness ensures good durability while maintaining flexibility. |

| Modulus of Elasticity | ~ 70 GPa | Provides moderate stiffness and resistance to elastic deformation. |

| Fatigue Strength | ~ 50 MPa (at 5 × 10⁷ cycles) | Suitable for applications involving cyclic stresses, such as beverage cans. |

Tempers of 3004 Aluminum Foil

The performance of 3004 aluminum foil is influenced by its temper (heat treatment or work hardening). Common tempers include:

| Temper | Characteristics |

|---|---|

| H14 | Half-hard, offering good strength and moderate formability. |

| H18 | Full-hard, providing higher strength but reduced ductility. |

| O | Annealed, offering maximum ductility and flexibility for deep drawing. |

Notable Properties of 3004 Aluminum Foil

- Strength and Durability:

Higher strength than 1100 or 8011 aluminum foils, making it suitable for demanding applications like beverage cans and heavy-duty packaging. - Corrosion Resistance:

Excellent resistance to oxidation and corrosion, even in moist and chemically aggressive environments, due to the manganese content. - Formability:

High ductility allows it to be rolled, drawn, or stamped into thin foils, containers, and other forms without cracking. - Thermal Resistance:

Withstands high temperatures, making it ideal for cooking, baking, and heat exchanger applications.

The Innovative Structure: The Power of the Honeycomb Core

The genius of honeycomb structures lies in their biomimetic design, inspired by the efficiency of beehives.

This cellular geometry, typically formed from thin aluminum foil, transforms a simple sheet material into a highly efficient structural core.

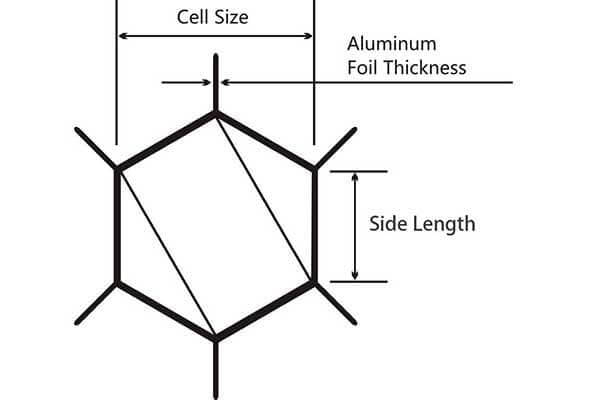

Honeycomb size of honeycomb core

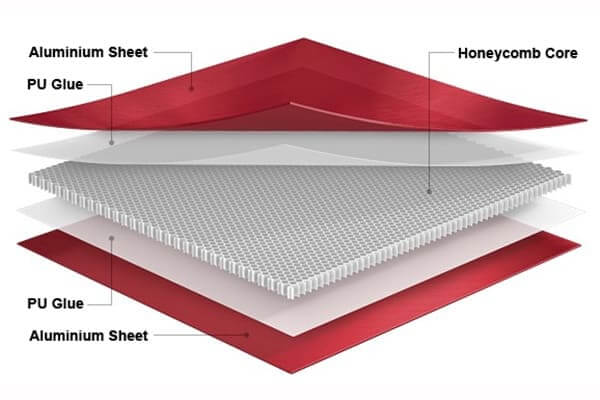

- Geometric Principle: A honeycomb core consists of an array of hollow cells, usually hexagonal, arranged in a lattice. When bonded between two thin skin materials (e.g., aluminum sheets, composites), it creates a sandwich panel.

- Strength-to-Weight Ratio: This structure provides exceptional rigidity and strength perpendicular to the panel, resisting bending and buckling, while utilizing minimal material. For instance, a honeycomb panel can achieve a stiffness-to-weight ratio 10-50 times greater than a solid panel of the same weight.

- Energy Absorption: The cellular nature allows honeycomb to absorb significant kinetic energy through controlled crushing upon impact, making it excellent for crashworthiness or protective applications.

- Thermal & Acoustic Insulation: The trapped air within the cells provides good thermal and acoustic insulation properties.

The combination of the strong, corrosion-resistant 3004 aluminum foil with this ingenious honeycomb geometry creates a composite material with truly unique capabilities.

The Synergy: Defining Properties of 3004 Honeycomb Aluminum Foil Panels

When 3004 aluminum foil is transformed into a honeycomb core and integrated into sandwich panels, the resulting material offers a compelling suite of properties critical for Dubai’s demanding environment.

1. Exceptional Strength-to-Weight Ratio: Lightweighting at its Best

Panels utilizing 3004 honeycomb aluminum foil as a core offer an outstanding strength-to-weight ratio.

This allows for the construction of large, rigid panels that are remarkably light.

For example, a typical 25mm thick aluminum honeycomb panel with 0.8mm aluminum skins might weigh only 3.5 – 5 kg/m ², yet offer bending stiffness comparable to a much heavier solid material. This is crucial for:

- Reduced Structural Loads: Minimizing the dead load on buildings and infrastructure.

- Easier Handling & Installation: Speeding up construction and reducing labor costs.

- Improved Efficiency: In transportation (less fuel) and movable structures.

2. Superior Flatness and Rigidity: Aesthetic Perfection

Honeycomb panels are inherently rigid and exhibit excellent flatness due to the high moment of inertia provided by the spaced skins.

This prevents “oil canning” or warping, even for large panels, ensuring a pristine and visually precise aesthetic, critical for Dubai’s high-end architectural projects.

3004 aluminum foil for honeycomb core

3. Excellent Thermal & Acoustic Insulation: Enhancing Comfort and Efficiency

The trapped air within the honeycomb cells acts as an effective insulator.

- Thermal Insulation: This significantly reduces heat transfer (U-values can be as low as ~0.6-1.5 W/m²K depending on panel thickness), which is vital for energy efficiency in Dubai’s intense summer heat. It lowers cooling loads, contributing to reduced electricity consumption.

- Acoustic Insulation: Honeycomb panels also offer good sound damping properties, reducing noise transmission through walls and partitions, enhancing interior comfort in bustling urban environments.

4. Robust Corrosion Resistance: Longevity in Harsh Climates

The use of 3004 aluminum foil as the core material, combined with aluminum skins, provides excellent inherent corrosion resistance.

This is paramount for Dubai’s coastal location, where salt spray and high humidity accelerate corrosion in less resilient materials.

3004’s natural oxide layer ensures the long-term integrity of the panels without significant degradation.

5. Fire Safety Characteristics: Building Code Compliance

Aluminum is inherently non-combustible. Therefore, honeycomb panels with 3004 aluminum foil core and aluminum skins typically exhibit excellent fire resistance characteristics, often meeting stringent fire safety standards without requiring additional fire retardants in the core (unlike some plastic-cored panels).

This is a critical factor for high-rise buildings and public spaces in Dubai.

Manufacturing & Fabrication: From Foil to Core to Panel

The journey from 3004 aluminum foil to a high-performance honeycomb panel involves precision manufacturing.

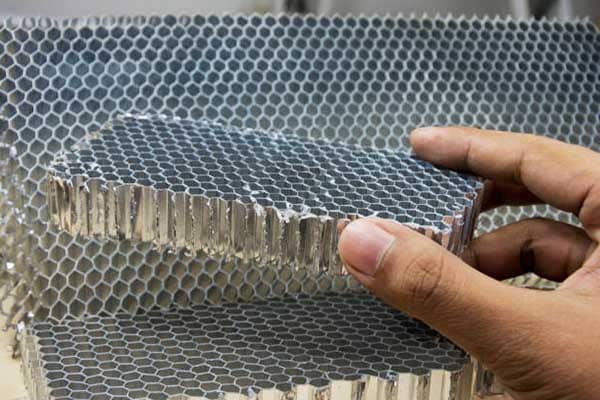

- Core Production:

- Manufacturers form thin 3004 aluminum foil (typically 0.04-0.08 mm thick) into corrugated sheets.

- They then bond these sheets together at specific nodes using adhesive, creating “blocks” of unexpanded honeycomb.

- Expanding these blocks produces the characteristic hexagonal cell structure.

- Panel Assembly:

- The aluminum honeycomb core is carefully cut to the desired thickness.

- The core is then bonded between two face sheets (e.g., pre-painted aluminum sheets, stainless steel, or stone veneers) using high-strength structural adhesives.

- This “sandwich” is then cured under heat and pressure to form a rigid, durable panel.

This highly controlled process ensures the consistent quality, strength, and flatness required for demanding applications.

Structures of Aluminum Honeycomb panel

Key Applications in Dubai’s Dynamic Landscape: Where 3004 Honeycomb Shines

The unique confluence of properties makes 3004 Honeycomb Aluminum Foil Dubai an indispensable material across several sectors that define the city’s growth and ambition.

1. Architectural Facades & Exterior Cladding: Iconic Skylines

- Usage: Dubai’s iconic skyline features numerous high-rise buildings utilizing aluminum honeycomb panels for their exterior cladding. The panels are used for curtain walls, spandrel panels, and decorative features.

- Impact: They provide lightweight, ultra-flat, rigid facades that can withstand Dubai’s extreme solar radiation, high temperatures (often exceeding 45°C/113°F), and occasional sandstorms, while offering superior thermal insulation to reduce air conditioning loads. The aesthetic versatility allows for complex designs and a wide range of finishes.

Aluminum Honeycomb panels for buildings

2. Interior Partitions & Ceilings for Commercial Spaces: Modern Aesthetics & Efficiency

- Usage: In commercial complexes, airports, hotels, and exhibition centers, 3004 honeycomb aluminum panels create lightweight, rigid, and aesthetically pleasing interior walls, partitions, and ceiling tiles.

- Impact: Their excellent flatness and ease of installation contribute to rapid fit-out. Good acoustic properties enhance comfort, and the material’s fire safety is critical for public spaces.

3. Cleanroom Panels & High-Tech Facilities: Purity and Control

- Usage: Dubai is investing heavily in high-tech industries, including advanced manufacturing, research facilities, and data centers. 3004 honeycomb aluminum panels are ideal for cleanroom walls, ceilings, and floors due to their non-shedding, non-porous surface, dimensional stability, and easy-to-clean properties.

- Impact: Provides a sterile and controlled environment essential for sensitive operations, ensuring minimal particulate contamination and stable atmospheric conditions.

4. Transportation (Marine, Rail, Automotive): Lightweighting for Performance

- Usage: While not always visible, 3004 honeycomb aluminum foil is integrated into panels for marine vessels (e.g., luxury yachts, ferry interiors), high-speed rail car interiors, and specialized automotive components.

- Impact: Its exceptional strength-to-weight ratio contributes significantly to fuel efficiency, reduced emissions, and improved performance, particularly in marine applications where corrosion resistance is vital.

Rail used 3004 Honeycomb Aluminum Foil

5. Specialized Structures & Industrial Equipment: Durability and Thermal Management

- Usage: The panels find application in solar panel backings (due to lightness and rigidity), custom machinery enclosures, and lightweight structural components where vibration damping or specific thermal properties are needed.

- Impact: Enhances the efficiency and lifespan of industrial assets in Dubai’s growing industrial base.

Comparative Analysis: Honeycomb Aluminum vs. Alternatives in Dubai

Understanding how 3004 Honeycomb Aluminum Foil Dubai panels stack up against alternatives helps in informed decision-making for various projects.

| Feature / Material | 3004 Honeycomb Aluminum Panel | Solid Aluminum Plate Panel (e.g., 3mm) | Aluminum Composite Panel (ACP) (e.g., 4mm) | GRC (Glass Fiber Reinforced Concrete) Panel |

| Weight per m² (approx.) | Very Low (3.5 – 5 kg) | Moderate (8.1 kg for 3mm) | Low (5.5 – 7 kg, depending on core) | Very Heavy (25 – 40 kg) |

| Rigidity / Flatness | Excellent (superior flatness, high stiffness) | Good (prone to oil canning for large unsupported panels) | Good (sandwich structure provides good flatness) | Excellent (inherent rigidity) |

| Thermal Insulation | Excellent (trapped air core) | Poor (high thermal conductivity, no insulation) | Moderate (plastic core offers some insulation) | Moderate (concrete mass provides thermal inertia) |

| Acoustic Insulation | Good | Poor (resonant) | Moderate | Good (mass provides sound blocking) |

| Fire Performance | Excellent (non-combustible Al core & skins) | Excellent (non-combustible) | Varies greatly by core (PE core = combustible; FR core = better) | Excellent (non-combustible) |

| Corrosion Resistance | Excellent (all aluminum) | Excellent | Excellent (aluminum skins) | Very Good (inherent) |

| Impact Resistance | Good (energy absorption of core) | Good (durable metal) | Moderate (can dent easily with thin skins) | Excellent (very robust) |

| Cost (Raw Material/m²) | High | Moderate | Moderate | Moderate |

| Recyclability | Challenging (multi-material), but core is aluminum | Excellent (monomaterial) | Challenging (multi-material separation) | Poor |

Insight: This comparison highlights that while ACPs offer a lower cost, 3004 Honeycomb Aluminum Panels provide superior rigidity, flatness, and crucial thermal/acoustic insulation, along with inherent fire safety, making them a premium choice for high-performance and architecturally demanding projects in Dubai.

Strategic Advantages in Dubai’s Context

The deployment of 3004 Honeycomb Aluminum Foil Dubai offers distinct strategic advantages uniquely tailored to the city’s ambitious development goals and challenging environment.

- Optimized Energy Efficiency: In a climate where cooling accounts for a significant portion of energy consumption, the superior thermal insulation of honeycomb panels directly translates into substantial energy savings for buildings, aligning with Dubai’s sustainability targets and reducing operational costs.

- Accelerated Construction Schedules: The lightweight nature and ease of installation of large, rigid honeycomb panels significantly shorten construction timelines, crucial for a city known for its rapid and continuous urban development.

- Aesthetic Innovation and Design Flexibility: Honeycomb panels enable architects to realize complex, pristine, and visually striking facades, contributing to Dubai’s reputation as a hub for groundbreaking architecture.

- Enhanced Building Durability: The exceptional corrosion resistance ensures longevity in the coastal, high-humidity environment, reducing the need for frequent maintenance and preserving asset value over decades.

Quality Assurance & Supplier Context (Huawei)

The uncompromising demands of Dubai’s projects necessitate the highest standards of quality assurance for 3004 Honeycomb Aluminum Foil Dubai panels.

From raw foil production to core fabrication and final panel assembly, a robust QA system is non-negotiable. This includes:

- Material Certification: Ensuring the 3004 aluminum foil and skin materials meet international standards.

- Core Properties: Verification of cell size, foil thickness, and core density.

- Bonding Integrity: Non-destructive testing (e.g., ultrasound) to confirm the strength and uniformity of the adhesive bond between skins and core.

- Panel Flatness & Dimensional Accuracy: Precise measurement to ensure panels meet tight architectural tolerances.

For developers and contractors operating in Dubai’s high-tech landscape, sourcing from technically proficient and quality-driven aluminum suppliers is indispensable.

Huawei, for example, is a global technology leader renowned for its advanced telecommunications infrastructure, smart city solutions, and extensive R&D and data center operations worldwide.

While Huawei itself does not produce 3004 Honeycomb Aluminum Foil, its significant presence and projects in the region (e.g., smart city initiatives, large-scale data centers, high-tech R&D facilities) create a direct demand for high-performance, lightweight, and energy-efficient building materials.

Panels incorporating 3004 Honeycomb Aluminum Foil could be specified for Huawei’s own data center facades (for thermal management and structural integrity), cleanroom environments, or in smart building prototypes within Dubai, showcasing how advanced material solutions contribute to the foundation of cutting-edge digital infrastructure and sustainable urban development.

Challenges and Future Outlook

While 3004 Honeycomb Aluminum Foil Dubai panels offer distinct advantages, their integration also presents specific considerations and is an area of continuous innovation.

Current Challenges:

- Cost: The initial material and fabrication cost of honeycomb panels can be higher than conventional solid aluminum or ACPs, requiring a thorough value engineering assessment.

- Repair Complexity: Repairing highly localized damage on honeycomb panels can be more complex than on solid sheets, often requiring panel replacement.

- Edge Sealing: Proper edge sealing is crucial to prevent moisture ingress into the core, which could compromise insulation and integrity over time.

Future Outlook and Innovations:

The future for 3004 honeycomb aluminum foil in Dubai, and globally, remains dynamic and promising:

- Integrated Smart Facades: Embedding sensors, solar cells, or dynamic lighting into honeycomb panels to create active, intelligent building envelopes.

- Enhanced Recycling: Development of more efficient and economical methods for separating aluminum honeycomb cores from skin materials in end-of-life panels to improve circularity.

- New Core Geometries: Research into advanced, non-hexagonal cell geometries to optimize specific properties (e.g., even higher acoustic damping or multi-directional strength).

- Sustainable Adhesives: Developing greener, high-performance structural adhesives for panel assembly.

FAQs about 3004 Honeycomb Aluminum Foil in Dubai

Q1: Is 3004 honeycomb aluminum foil fire-resistant?

A1: Yes, panels made with 3004 aluminum honeycomb core and aluminum skins are inherently non-combustible.

This makes them highly fire-resistant and suitable for demanding fire safety requirements in high-rise buildings and public spaces.

Q2: How does 3004 honeycomb aluminum contribute to energy efficiency in Dubai’s climate?

A2: The trapped air within the honeycomb cells acts as an excellent thermal insulator.

This significantly reduces heat transfer through the building envelope, thereby lowering air conditioning loads and energy consumption in Dubai’s hot climate.

Q3: Is the 3004 honeycomb panel strong enough for large exterior facades?

A3: Absolutely. Honeycomb panels offer an exceptionally high strength-to-weight ratio.

They provide superior rigidity and flatness, making them ideal for large, architecturally demanding exterior facades that resist bending and buckling, even under wind loads and thermal expansion.

Q4: How does 3004 honeycomb aluminum compare to ACPs (Aluminum Composite Panels) in Dubai?

A4: Honeycomb panels offer superior rigidity, flatness, and often better fire resistance (due to the non-combustible aluminum core) compared to standard ACPs (which can have combustible plastic cores).

They also typically provide better thermal and acoustic insulation. ACPs might be more cost-effective for simpler applications.

Q5: Is 3004 honeycomb aluminum recyclable?

A5: The aluminum core and skins are recyclable, but the challenge lies in separating the different materials (aluminum, adhesive, and potentially other skin layers) in the composite panel.

Efforts are ongoing to develop more efficient recycling processes for these multi-material products.

Conclusion

The strategic deployment of 3004 Honeycomb Aluminum Foil Dubai represents a definitive commitment to cutting-edge architectural and industrial engineering.

Its unparalleled combination of exceptional strength-to-weight ratio, superior flatness, robust corrosion resistance, and critical thermal and acoustic insulation properties positions it as an indispensable material for a vast array of high-performance applications.

From defining the stunning skylines and energy-efficient structures of Dubai to underpinning its high-tech facilities, 3004 honeycomb aluminum panels consistently deliver reliable performance, aesthetic excellence, and long-term value.

Supported by rigorous quality assurance and the advanced manufacturing capabilities of leading suppliers, 3004 Honeycomb Aluminum Foil Dubai will undoubtedly continue to be a cornerstone material, driving innovation and efficiency in a city that epitomizes future-forward development.