12,996 Näkymät 2025-07-24 03:03:09

Alumiinikelan painolaskin: A Guide for Procurement Professionals

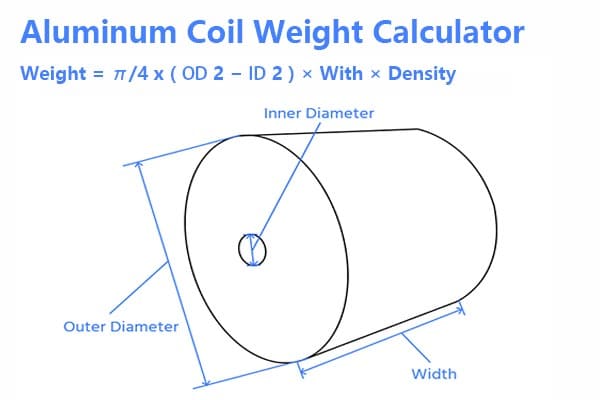

Accurate coil weight estimates are critical for procurement planning. An aluminum coil weight calculator uses coil dimensions and material properties to compute weight, helping buyers budget, plan shipping, and compare materials.

To perform this calculation, you need the coil’s inner diameter (Henkilöllisyystodistus), outer diameter (OD), width, paksuus (gauge), and the alloy’s density.

This article explains the calculation step by step, provides example computations for common alloys (5052 ja 1100), and offers a sample weight chart.

We also compare aluminum coils to steel and copper in density, cost, and handling to inform procurement decisions.

Alumiinikelan painolaskin

Key Parameters: Henkilöllisyystodistus, OD, Leveys, Paksuus, and Density

An aluminum coil can be visualized as a cylindrical shell of rolled sheet. Its weight depends on the volume of aluminum and the material’s density. The primary parameters are:

- Outer Diameter (OD) – the full outside diameter of the coil (including all layers).

- Inner Diameter (Henkilöllisyystodistus) – the diameter of the central arbor or void at the coil’s center.

- Leveys – the face width of the coil (length of the strip measured along the coil’s axis).

- Paksuus (Gauge) – the sheet thickness. Note that thickness is implicit in the coil diameters: larger OD (for a given ID) implies thicker or more layers.

- Tiheys – the mass per unit volume of the specific aluminum alloy (typically around 2.7 g/cm³ or 2700 kg/m³ for common alloys). Different alloys vary slightly (esim. 1100 is ≈2.71 g/cm³, 5052 ≈2.68 g/cm³).

In practical terms, for a given coil ID, OD, and width, a higher density (heavier alloy) yields a larger weight.

Esimerkiksi, metalliseos 1100 (nearly pure Al) has a density ~2700 kg/m³, so its coils are marginally heavier than the same size coil in alloy 5052 (density ~2680 kg/m³).

Calculating Coil Weight: Formula and Steps

Se coil weight is found by computing the volume of the cylindrical shell and multiplying by density. The key formula is:

where OD, Henkilöllisyystodistus, and Width are in the same units and Density is in mass per volume (esim. lb/in³ or kg/mm³). Esimerkiksi, using metric units (mm and g/cm³), the formula from industry sources is:

Paino (kg) = π × (OD² – ID²) / 4 × Width × ρ ÷ 10^6,

where ρ is density in g/cm³, OD, Henkilöllisyystodistus, Width in mm. (The factor 10^6 converts mm³·g/cm³ into kilograms.) This formula comes from the cross-sectional area of the coil (a ring) times width times density.

Step-by-step Calculation:

- Measure or obtain the coil dimensions. Convert them to consistent units (esim. mm or inches).

- Apply the formula. Compute

to get the ring area. Multiply by the coil width and the alloy density.

- Convert units as needed. If using mm and g/cm³, divide by 1,000,000 to get weight in kg. If using inches and lb/in³ (≈0.0975 for Al), the result is directly in pounds.

- Include weight of core (if needed). The formula calculates the weight of the aluminum alone. If the coil has an inner core or arbor, add that weight separately.

Esimerkiksi, consider a coil with OD = 1000 mm, ID = 200 mm, and Width = 1000 mm in alloy 1100 (density ~2.71 g/cm³). Using the formula:

Calculating this gives about 2043 kg (see worked example below). If the same coil is alloy 5052 (ρ≈2.68 g/cm³), the weight is slightly lower (≈2021 kg).

These results show the process of an aluminum coil weight calculation in action, giving procurement professionals confidence in their estimates.

Aluminum Alloy Density Table (Individual Grades)

| Alloy Grade | Common Temper(s) | Tiheys (g/cm³) | Tiheys (kg/m³) |

|---|---|---|---|

| 1050 | H14, H24 | 2.71 | 2710 |

| 1060 | H24 | 2.70 | 2700 |

| 1070 | N | 2.70 | 2700 |

| 1085 | N, H18 | 2.70 | 2700 |

| 1100 | H14 | 2.71 | 2710 |

| 1200 | N, H14 | 2.71 | 2710 |

| 1235 | N, H18 | 2.71 | 2710 |

| 1350 | N | 2.70 | 2700 |

| 2011 | T3, T8 | 2.83 | 2830 |

| 2014 | T6 | 2.80 | 2800 |

| 2024 | T3, T351 | 2.78 | 2780 |

| 2219 | T6 | 2.84 | 2840 |

| 3003 | H14 | 2.73 | 2730 |

| 3004 | H34 | 2.72 | 2720 |

| 3005 | H26 | 2.72 | 2720 |

| 3A21 | H112 | 2.73 | 2730 |

| 3105 | H24 | 2.75 | 2750 |

| 4032 | T6 | 2.77 | 2770 |

| 4045 | - | 2.71 | 2710 |

| 5005 | H34 | 2.70 | 2700 |

| 5052 | H32 | 2.68 | 2680 |

| 5083 | H116, N | 2.66 | 2660 |

| 5086 | H32, H116 | 2.66 | 2660 |

| 5182 | H48 | 2.68 | 2680 |

| 5454 | H32 | 2.69 | 2690 |

| 5754 | H22, H111 | 2.67 | 2670 |

| 6016 | T4 | 2.70 | 2700 |

| 6061 | T6, T651 | 2.70 | 2700 |

| 6063 | T5, T6 | 2.69 | 2690 |

| 6082 | T6 | 2.70 | 2700 |

| 7005 | T6 | 2.78 | 2780 |

| 7021 | T6 | 2.79 | 2790 |

| 7050 | T7451 | 2.83 | 2830 |

| 7075 | T6, T651 | 2.81 | 2810 |

| 7475 | T6, T761 | 2.82 | 2820 |

| 8006 | N, H18 | 2.71 | 2710 |

| 8011 | H14, H18 | 2.71 | 2710 |

| 8021 | N, H18 | 2.72 | 2720 |

| 8079 | N, H14 | 2.72 | 2720 |

Example Calculations for 1100 ja 5052 Seokset

To illustrate, let’s work through two examples using the above formula:

- Example 1 (Metalliseos 1100):

OD = 1000 mm, ID = 200 mm, Width = 1000 mm, Thickness implied. Metalliseos 1100 density ≈ 2.71 g/cm³. - Example 2 (Metalliseos 5052):

Same dimensions (OD 1000 mm, Henkilöllisyystodistus 200 mm, Leveys 1000 mm), mutta 5052 density ≈ 2.68 g/cm³.

These calculations (edellä 2000 kg for a large coil) underscore that even slight density differences yield noticeable weight changes.

Procurement can use such formulas or an aluminum coil weight calculator tool to get quick estimates.

For clarity, here are the calculation steps:

- Compute area difference:

. This gives the cross-sectional area of the coil (in mm² if inputs are mm).

- Multiply by width: to get volume (in mm³).

- Multiply by density: (in g/cm³) to get mass in grams (convert units appropriately).

- Convert to desired weight unit: esim. kilograms.

These steps can be followed manually or automated in a spreadsheet. The key is to keep units consistent.

Sample Coil Weight Chart

The table below illustrates approximate weights for sample coils of different sizes in alloys 1100 ja 5052.

All dimensions are in millimeters, and weights in kilograms (kg). These values are computed using the formula above with ρ(1100)=2.71 g/cm³ and ρ(5052)=2.68 g/cm³.

| Inner Diameter (Henkilöllisyystodistus) | Outer Diameter (OD) | Leveys | Paino (1100 metalliseos, kg) | Paino (5052 metalliseos, kg) |

|---|---|---|---|---|

| 150 mm | 600 mm | 1000 mm | 718.3 kg | 710.4 kg |

| 200 mm | 1000 mm | 1000 mm | 2043.3 kg | 2020.7 kg |

| 300 mm | 1200 mm | 1500 mm | 4310.1 kg | 4262.4 kg |

| 500 mm | 1500 mm | 2000 mm | 8513.7 kg | 8419.5 kg |

Table: Example weights for aluminum coils of various sizes (widths fixed as shown) in alloys 1100 vs. 5052.

This chart gives a sense of scale: larger outer diameters and widths dramatically increase weight.

Procurement professionals can adjust the formula or use a calculator to generate similar charts for any required dimensions and alloy types.

Alumiini vs.. Steel and Copper: Density and Cost Comparison

Compared to steel and copper coils, aluminum offers major advantages in weight and cost-efficiency.

Densities illustrate this: aluminum’s ~2700 kg/m³ (2.70 g/cm³) is far below mild steel’s ~7850 kg/m³ or copper’s ~8940 kg/m³.

In practical terms, a given volume of aluminum weighs about one-third as much as steel and only about 30% of copper’s weight.

This lower density yields actionable benefits:

- Lower Shipping Weight:

A steel coil (2.5–3× denser) will weigh much more than an equivalent aluminum coil.

In fact, logistics guidelines note that steel coils often exceed 3,500 lbs, triggering extra regulatory requirements, whereas aluminum’s lighter mass more easily stays below such limits.

Lower weight means cheaper freight and easier handling (esimerkiksi, shipping an aluminum coil may avoid overweight surcharges that a heavy steel coil incurs). - Cost Efficiency:

Aluminum’s market price per pound is generally far lower than copper’s.

Copper is about five times more expensive per pound (esim. ~$5.80/lb for copper vs ~$1.20/lb for aluminum) and still heavier.

Siten, using aluminum can provide similar performance (like conductivity or strength per weight) at lower total material cost, which procurement teams leverage for budget savings. - Helppo käsittely:

Lighter coils are easier to move and install. Aluminum’s weight advantage reduces the number of forklifts or cranes needed and lowers labor risk.

This ease translates into time and cost savings on the plant floor.

In summary, aluminum coils combine low density (≈2700 kg/m³) with relatively low cost, giving them a “weight advantage” over steel and copper.

For procurement, this means more flexible shipping options and better value: less weight shipped per ton of material purchased.

Using Coil Weight Data in Procurement

Understanding and calculating aluminum coil weight builds confidence in sourcing decisions. With accurate weight estimates, procurement professionals can:

- Budget Accurately: Estimate total metal needs and costs. Knowing weight helps convert between linear measures (feet, metri) and mass for quoting purposes.

- Optimize Shipping: Plan containers/truckloads and avoid unexpected freight charges. Weight data informs quotes from carriers and ensures compliance with weight regulations.

- Compare Suppliers: Verify supplier data (coil weight vs. dimensions) for consistency, spotting errors or variations in density/alloy as needed.

- Evaluate Material Choices: Use weight (and density) comparisons when choosing between aluminum, steel, copper, jne., based on application weight requirements and cost targets.

By following the formula and examples above, procurement teams gain actionable knowledge of coil weight.

They can confidently use or build an aluminum coil weight calculator, or simply apply the provided steps, to support reliable purchasing and logistics planning.

Sources: Coil weight formula and methods are adapted from industry references, and material densities/cost insights are supported by engineering data.

These ensure the guidance is both accurate and trustworthy for professional use.