1. Úvod

9-mikrón 1235 kompozitná hliníková fólia je vysoko špecializovaný, multi-layer material that serves as a cornerstone of the modern flexible packaging industry.

This material system is engineered to provide a high-performance barrier at an optimal cost and weight. Its core is an ultra-thin, 9um (0.009mm) foil made from 1235 hliníkovej zliatiny, vysoká čistota (> 99,35 % Al) grade prized for its exceptional softness and workability.

While the 9-micron foil itself provides a near-perfect barrier to light, plynov, a vlhkosťou, its thinness makes it mechanically fragile and susceptible to pinholes.

These weaknesses are overcome by laminating it with other polymer films (such as PET, BOPP, and PE). The resulting composite structure leverages the absolute barrier of the aluminum core while gaining the strength, tlačiteľné, and sealability of the polymer layers.

This makes 9-micron 1235 composite foil the go-to solution for a vast range of applications, vrátane balenia potravín (občerstvenie, kávu, sušené mlieko) and pharmaceutical sachets, where a high barrier, nízka hmotnosť, and cost-effectiveness are all critical requirements.

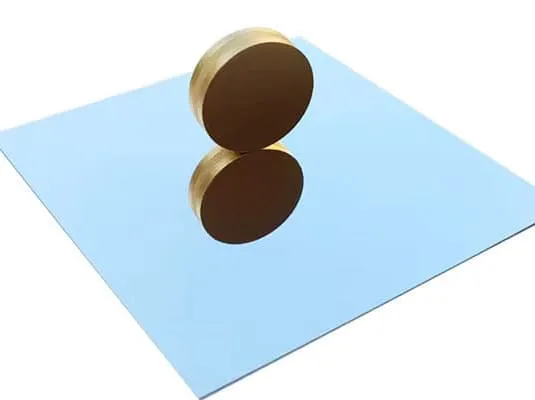

9-mikrón 1235 kompozitná hliníková fólia

2. Porozumenie 1235 Zliatina hliníka

2.1 Chemické zloženie

The 1235 hliníková fólia belongs to the 1xxx series of commercial purity aluminum, specifically engineered for converter foil applications where formability and barrier performance take precedence over structural strength.

The chemical composition adheres to strict limits that maximize rolling efficiency and surface quality.

| Prvok | Minimum | Maximálne | Functional Role in 9μm Foil |

|---|---|---|---|

| hliník (Al) | 99.35% | — | Matrix providing ductility, odrazivosť, a odolnosť proti korózii |

| Silikón (A) | — | 0.10% | Tight control ensures smooth rolling surface and minimizes inclusion defects |

| Železo (Fe) | — | 0.60% | Provides slight strengthening; excessive levels increase pinhole risk |

| Meď (Cu) | — | 0.05% | Kept minimal to preserve electrical conductivity and corrosion resistance |

| mangán (Mn) | — | 0.05% | Trace element limited to prevent work hardening |

| magnézium (Mg) | — | 0.05% | Controlled to avoid surface oxidation issues |

| Zinok (Zn) | — | 0.10% | Impurity management for anodizing compatibility |

| titán (z) | — | 0.03% | Grain refinement in cast ingots |

| Ostatné prvky (Každý) | — | 0.03% | Aggregate impurity cap ensuring consistency |

| Ostatné prvky (Celkom) | — | 0.10% | Overall purity protection |

2.2 Microstructure and Temper

The 1235 alloy achieves its optimal properties through careful thermal processing.

Manufacturers produce 9-micron foil in two primary tempers, each serving distinct converting requirements:

O Temper (Mäkký, Žíhané):

- Pevnosť v ťahu: 60–90 MPa (8.7–13.0 ksi)

- Medza klzu: 20–35 MPa (2.9–5.1 ksi)

- Predĺženie: 25– 35 % (A50mm gauge)

- Tvrdosť: 20–25 HB

- Mikroštruktúra: Fully recrystallized equiaxed grains (ASTM 6–9) with minimal dislocation density

The O temper maximizes ductility for deep drawing, skladanie, and complex forming operations.

The 25–35% elongation enables 9-micron foil to conform to sharp creases in cigarette inner liners and sachet corners without cracking.

This temper also optimizes adhesive wet-out during lamination, as the soft surface conforms to microscopic surface irregularities in plastic films.

9-mikrón 1235 H18 hliníková fólia

H18 Temper (Full Hard, Cold-Worked):

- Pevnosť v ťahu: 110–150 MPa (16.0–21.8 ksi)

- Medza klzu: 100–130 MPa (14.5–18.9 ksi)

- Predĺženie: 1–3%

- Tvrdosť: 45–55 HB

- Mikroštruktúra: Elongated grains with high dislocation density from cold rolling

H18 temper provides handling stiffness for unwind operations and slit-edge stability.

Converters often specify H18 for foil that must traverse long web paths at high speed before lamination, as the increased rigidity reduces wrinkling and edge weaving.

The laminate structure subsequently provides flexibility in the finished product.

3. 9 Micrometer (μm) Hrúbka: Opportunities and Challenges

3.1 Opportunities (Why pursue 9 mikrometre?)

- Odľahčenie & material cost reduction. Moving from e.g., 12–15 µm down to 9 µm reduces aluminum mass by ~25–40%, lowering raw-material cost and package weight. (9 µm = 0.009 mm).

- Excellent barrier per unit mass. Even at 9 µm a continuous aluminum layer provides near-opaque light barrier and very low oxygen and moisture transmission when incorporated into a laminate; suppliers report OTR and WVTR figures that place such laminates in “high barrier” class for many food and pharmaceutical applications.

- Improved form-factor and aesthetics. Thin foil conforms to complex shapes (labels, lidding) with smaller step heights and less bulk.

3.2 Výzvy (Inherent weaknesses of 9 mikrometre)

- Mechanical fragility: reduced puncture resistance, higher sensitivity to handling, and increased risk of pinholes during rolling and lamination. Typical practical tensile/puncture performance must be validated for the stack and forming process.

- Pinholes & defects control: process cleanliness and rolling/anneal schedules must be tightly controlled; pinhole density scales unfavorably with decreasing gauge.

- Adhesion and delamination risk: ultra-thin foil has less cohesive thickness for adhesives to “bite”; surface treatments or lacquers are often required to secure bond strength to polymers.

- Converting difficulty: strihanie, embossing, die-cutting and rewinding require specialized tension control, anti-static measures and skilled equipment operators.

4. Structure of 9-Micron 1235 Composite Aluminum Foil

4.1 Typical Composite Structures

The 9-micron 1235 foil rarely serves as standalone packaging. Namiesto toho, it functions as the critical barrier layer within multi-material laminates that combine complementary properties.

Engineers design these structures to position each material where its properties deliver maximum value:

Štruktúra 1: PET/AL/PE (General-Purpose Food Packaging)

- PET (12–25μm): Exterior print carrier providing mechanical strength, rozmerová stálosť, and gloss

- Lepidlo (1.5–3.0 g/m²): Polyurethane two-component system creating chemical bond

- AL (9μm): Core barrier layer blocking oxygen, vlhkosť, a svetlo

- Lepidlo (1.5–3.0 g/m²): Tie layer for polyethylene adhesion

- PE (40–80μm): Interior sealant providing heat-sealability, chemical resistance, and food contact compliance

Total thickness: ~65–120μm | Bariéra: OTR <0.1 cc/m²·day, WVTR <0.01 g/m²·deň

Štruktúra 2: Paper/AL/PE (Cigarette Inner Liner)

- Papier (40–60 g/m²): Exterior providing dead-fold characteristics, nepriehľadnosť, and tactile quality

- AL (9μm): Barrier against moisture and aroma loss

- PE (20–60μm): Heat-seal layer for pack closure

This structure leverages the “dead-fold” property of 1235-O foil—the ability to retain a crease without spring-back—essential for cigarette pack forming at 400+ packs/minute.

Štruktúra 3: BOPP/AL/CPP (Confectionery and Snacks)

- BOPP (20μm): High-clarity exterior with excellent machinability

- AL (9μm): Barrier and light protection

- CPP (40–70μm): Hot-tack sealant for high-speed form-fill-seal operations

The biaxially oriented polypropylene (BOPP) provides superior crack resistance compared to PET, while cast polypropylene (CPP) offers broader heat-seal windows for confectionery packaging.

Štruktúra 4: PA/AL/PE (Puncture-Resistant Pouches)

- PA (15μm, Nylon): Exterior providing exceptional puncture and abrasion resistance

- AL (9μm): Barrier layer

- PE (60–80μm): Sealant and structural bulk

This configuration suits vacuum-packed meats and cheeses where bone edges or sharp corners threaten package integrity.

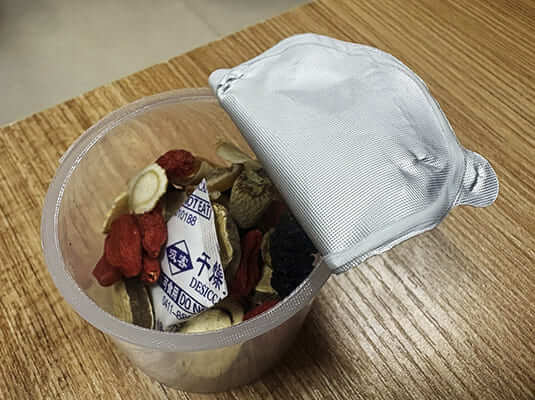

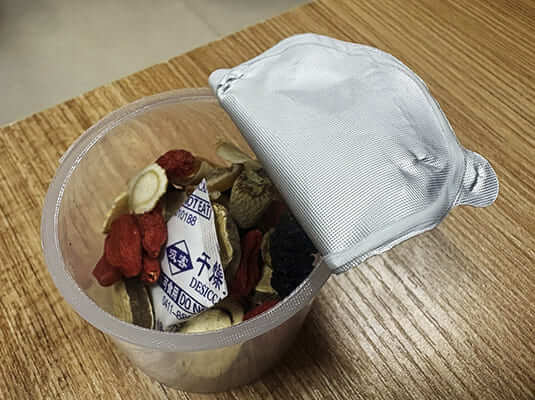

Tea packaging used 9-micron 1235 kompozitná hliníková fólia

4.2 Why Composite for 9-Micron Aluminum Foil

Mechanical Protection:

The 9-micron foil cannot survive handling, preprava, or retail display as a single layer.

PET (tensile strength 200–300 MPa) or paper (stiffness 2–5 Nm/g) provide structural armor that prevents flex cracks and abrasion.

Integrita pečate:

Aluminum lacks thermoplasticity—it cannot heat-seal. PE or CPP layers (melting point 110–135°C) create hermetic closures through impulse or hot-bar sealing.

Chemical Isolation:

Acidic or alkaline products (paradajková omáčka, čistiace prostriedky) corrode aluminum. PE and PP provide inert barriers preventing chemical attack.

Možnosť tlače:

Aluminum accepts only limited printing technologies. PET and paper substrates enable high-resolution gravure or flexographic decoration.

Cost Optimization:

At $8–12/kg for aluminum foil versus $2–4/kg for PE, composite structures minimize aluminum usage to the absolute barrier requirement while leveraging cheaper polymers for bulk.

5. Manufacturing Process of 9-Micron 1235 Composite Aluminum Foil

Key steps and control points:

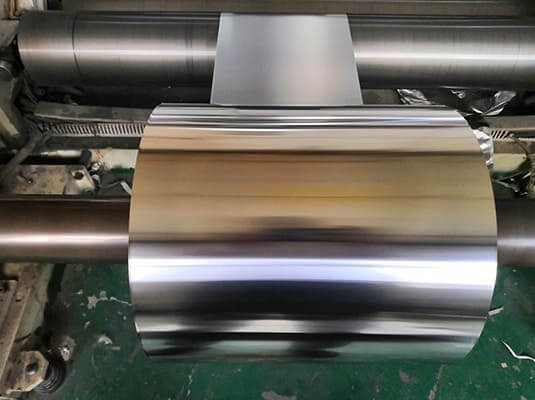

- Casting and hot rolling to produce coil stock.

- Cold rolling schedules with multiple passes to progressively reduce gauge toward foil thickness. Intermediate and final anneals are applied to restore ductility and control grain structure. Precise pass schedules and roll gap control are critical to reach a uniform 9 µm target without excessive edge-wave or thickness variation.

- Surface preparation and cleaning to remove rolling oils and particulates (important to minimize pinholes).

- Coating/lacquering (voliteľné) to provide printability and corrosion resistance prior to lamination.

- Laminovanie (composite formation) — can be by solventless adhesive, extrúzna laminácia (melt adhesive), or solvent/wet adhesives depending on stack and end-use. Proper adhesive selection, nip temperature and pressure are tuned to avoid foil wrinkles and to achieve peel strength targets.

- Slitting and rewinding with strict tension control and anti-static handling for 9 µm gauges.

- Quality inspection (pinhole detection, mapovanie hrúbky, surface inspection) and final packing.

Process control charts for foil production typically track gauge tolerance (napr., ±0.5 µm target for 9 um), pinhole counts per m², and laminate peel strength.

6. Applications of 9-Micron 1235 Composite Aluminum Foil

6.1 Flexibilné balenie potravín

The 9-micron 1235 foil serves as the barrier backbone for dry goods packaging:

- Coffee and Tea: Aroma retention critical; 9μm foil with <40 pinholes/m² maintains freshness 12–18 months

- Snack Foods: PET/AL/PE structures provide light protection for photosensitive vitamins and flavors

- Powdered Beverages: WVTR <0.01 g/m²·day prevents caking and preserves solubility

High-speed form-fill-seal (FFS) lines operate at 200+ cycles/minute with 9-micron foil, validating its mechanical stability under rapid flexing.

Sachet Strips For Medical Packaging

6.2 Pharmaceutical and Medical Packaging

Secondary overwraps for pharmaceuticals utilize 9-micron foil in:

- Sachet Strips: PET/AL/PE for unit-dose powders and granules

- Krycia fólia: 9μm 1235-O replaces thicker gauges for cost-sensitive OTC products

- Tropical Blister Alternatives: Non-PVC laminates for high-humidity markets

Migration testing per EU 10/2011 and FDA 21 CFR 177.1390 ensures compliance for indirect food contact.

6.3 Tobacco Packaging

Cigarette inner liners represent a major 9-micron application:

- Štruktúra: Papier (40–60 g/m²)/AL (9μm)/PE (20–30μm)

- Dead-fold: 1235-O temper retains sharp creases without spring-back

- Aroma bariéra: Prevents moisture loss and flavor cross-contamination

- Speed Compatibility: Runs at 400+ packs/minute on G.D. and Focke machines

6.4 Industrial and Technical Applications

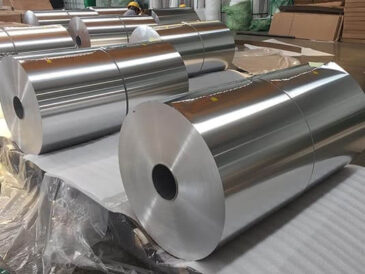

Cable Wrap: Non-woven/AL/PE laminates provide electromagnetic interference (EMI) shielding with 9-micron foil delivering >60 dB attenuation at 1 GHz.

Izolácia budovy: Foil-faced radiant barriers utilize 9μm 1235 for cost-effective reflectivity (>88% solar reflectance).

Battery Pouch Films: Lamination with nylon and polypropylene creates containment for lithium-ion cells, with 9-micron foil providing moisture barrier and electrical isolation.

1235 aluminum foil for Cable Wrap

7. Comparative Alloy Analysis

Engineers selecting aluminum foil must evaluate alternatives to 1235. The following matrix compares key options for 9-micron applications:

| Atribút | 1235 | 8079 | 8011 | Selection Guidance |

|---|---|---|---|---|

| Čistota hliníka | ≥99.35% | ≥99,0 % | ~97.0% (Al-Fe-Si) | 1235 for highest purity; 8079 for pinhole-critical <7μm |

| Pevnosť v ťahu (O temperament) | 60–90 MPa | 80-110 MPa | 80-120 MPa | Higher strength in 8079/8011 for handling stiffness |

| Predĺženie (O temperament) | 25– 35 % | 15–25 % | 15–25 % | 1235 superior for deep drawing and folding |

| Dead-Fold Characteristics | Výborne | Veľmi dobré | Dobre | 1235 preferred for cigarette/tobacco |

| Pinhole Resistance at 9μm | Enhanced: ≤40/m² | Enhanced: ≤30/m² | Enhanced: ≤25/m² | 8079/8011 intermetallics improve rolling; 1235 requires tighter process control |

| Cost Position | $ (Najnižšia) | $$ | $$ | 1235 offers 10–15% cost advantage |

| Typické aplikácie | Mainstream food, tabak, general lamination | High-barrier pharma, abuse-resistant pouches | Pokrytie, tube laminates, heat-seal applications |

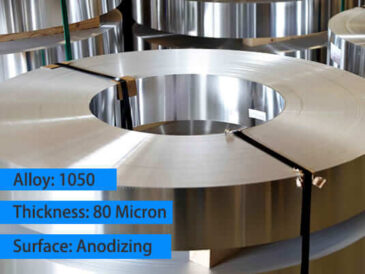

8. Huawei 9-Micron 1235 Composite Aluminum Foil Specification

(Representative supplier specification drawn from typical product pages — engineers should request a manufacturer-run Material Test Certificate and sample tests before approving for production.)

Supplier example: Henan Huawei Aluminium Co., Ltd (commercial supplier listing for “9-Micron 1235 Composite Aluminum Foil”). Reported or typical specification items include:

- Zliatina: 1235 (O temper typical for lamination).

- Nominal aluminum thickness: 9 um (0.009 mm).

- Composite stacks offered: PET/AL(9)/PE; Paper/AL(9)/PE; BOPP/AL(9)/PE.

- Typical WVTR / OTR for laminated structures (supplier reported example): OTR < 0.1 (units depend on test method; usually cc/m²·day), WVTR < 0.01 (g/m²·deň) for finished laminate — confirm test method and units with supplier before quoting shelf life.

- Hustota dierky: marketed as “low pinhole density” — suppliers commonly specify pinhole counts per m² or qualitative grades; ask for measured pinhole counts at acceptance.

- Temper: O (žíhané) or light cold-work (as required).

- Náter: optional lacquer for printability; adhesive systems per laminate.

- Balíček: jumbo rolls, typical widths 200–1,600 mm; coil ID/OD to buyer spec.

- Kontrola kvality: thickness tolerance band (pre 9 µm often specified ±0.5–1.0 µm depending on supplier), visual surface class, pinhole acceptance, MTC available on request.

Huawei Aluminum Foil Export Packaging

9. Záver

The 9-mikrón 1235 kompozitná hliníková fólia is a testament to the power of systems thinking in material science.

It is a highly optimized solution that acknowledges the limitations of a single material and overcomes them through intelligent combination.

By pairing the absolute barrier potential of an ultra-thin 1235 aluminum foil with the mechanical strength of polymer films, the packaging industry has created a material that is both high-performing and highly economical.

It is not the most robust barrier available, but for the vast majority of flexible packaging needs, it represents the perfect equilibrium of protection, náklady, a efektívnosť.

často kladené otázky

1. If 9-micron foil has pinholes, is it still a “high barrier”?

áno. In a composite structure, the barrier performance is not determined by the foil alone. The adhesive and polymer layers create a “tortuous path” that effectively seals the microscopic pinholes. The final laminate still provides an exceptionally low OTR and WVTR (napr., <0.5), which is firmly in the high-barrier category and far superior to any non-foil-based film.

2. Why not just use a thicker foil to avoid pinholes?

You can, but it comes with trade-offs. A thicker foil (napr., 12µm or 15µm) will have fewer pinholes and more strength, but it will be more expensive, heavier, and result in a stiffer final package, which may not be desirable. 9 microns is often the most cost-effective solution that meets the required barrier specifications for a huge range of products.

3. What is the difference between this and “Alu-Alu” foil?

“Alu-Alu” (studená forma) foil is a much thicker, soft-temper aluminum foil (zvyčajne 45-60 mikrónov) laminated with OPA and PVC. It is designed to be plastically deformed (cold-formed) into a blister cavity, providing an absolute, 100% bariéra. 9-micron composite foil is a thin, flexible material used for flat pouches and bags; it cannot be formed into a deep cavity.

Proces výroby odliatku a jeho zavedenie

Účelom tavenia a odlievania je výroba zliatin s vyhovujúcim zložením a vysokou čistotou taveniny, tak, aby sa vytvorili priaznivé podmienky pre odlievanie zliatin rôznych tvarov.

Kroky procesu tavenia a odlievania: dávkovanie --- kŕmenie --- topenie --- miešanie po roztavení, odstraňovanie trosky --- odber vzoriek pred analýzou --- pridanie zliatiny na úpravu zloženia, miešanie --- rafinácia --- statické nastavenie——Smerujte odlievanie pece.

Výrobný proces valcovania za tepla a jeho zavedenie

- 1. Valcovanie za tepla sa všeobecne týka valcovania nad teplotou rekryštalizácie kovu;

- 2. Počas procesu valcovania za tepla, kov má procesy tvrdnutia aj zmäkčovania. Vplyvom rýchlosti deformácie, pokiaľ je proces regenerácie a rekryštalizácie príliš neskoro, dôjde k určitému pracovnému otužovaniu;

- 3. Rekryštalizácia kovu po valcovaní za tepla nie je úplná, to jest, koexistencia rekryštalizovanej štruktúry a deformovanej štruktúry;

- 4. Valcovanie za tepla môže zlepšiť výkonnosť spracovania kovov a zliatin, znížiť alebo odstrániť chyby odliatku.

- 1. Teplota odlievania a valcovania je všeobecne medzi 680 °C a 700 °C. Čím nižšie, tým lepšie, stabilná odlievacia a valcovacia linka sa zvyčajne zastaví raz za mesiac alebo viackrát, aby sa znovu postavila. Počas výrobného procesu, je potrebné prísne kontrolovať hladinu kvapaliny v prednej nádrži, aby sa zabránilo nízkej hladine kvapaliny;

- 2. Na mazanie sa používa prášok C s nedokonalým spaľovaním plynu na mazanie, čo je aj jednou z príčin znečistenia povrchu odlievacích a valcovacích materiálov;

- 3. Výrobná rýchlosť je všeobecne medzi 1,5 m/min-2,5 m/min;

- 4. Kvalita povrchu výrobkov vyrábaných odlievaním a valcovaním je vo všeobecnosti relatívne nízka, a vo všeobecnosti nemôžu spĺňať produkty so špeciálnymi požiadavkami na fyzikálne a chemické vlastnosti.

- 1. Valcovanie za studena sa týka spôsobu výroby valcovania pod teplotou rekryštalizácie;

- 2. Počas procesu valcovania nedôjde k dynamickej rekryštalizácii, a teplota stúpne maximálne na regeneračnú teplotu, a valcovanie za studena sa objaví v stave mechanického vytvrdzovania, a rýchlosť vytvrdzovania bude veľká;

- 3. Plechy a pásy valcované za studena majú vysokú rozmerovú presnosť, dobrá kvalita povrchu, jednotná štruktúra a výkon, a výrobky v rôznych skupenstvách možno získať tepelným spracovaním;

- 4. Valcovaním za studena môžete vyvaľkať tenké pásiky, ale zároveň, má nevýhodu vysokej spotreby energie na deformáciu a mnohých prechodov na spracovanie.

- 1. Konečná úprava je spôsob spracovania, aby plech valcovaný za studena spĺňal požiadavky zákazníka, alebo na uľahčenie následného spracovania produktu;

- 2. Dokončovacie zariadenie môže opraviť chyby vzniknuté vo výrobnom procese valcovania za tepla a valcovania za studena, ako je prasknutý okraj, mastný, zlý tvar dosky, zvyškové napätie, atď. Musí zabezpečiť, aby sa do výrobného procesu nedostali žiadne ďalšie chyby;

- 3. Existujú rôzne dokončovacie zariadenia, hlavne vrátane priečnych rezov, strihanie, naťahovanie a narovnávanie, žíhacia pec, kĺzať sa, atď.

Proces odlievania a valcovania

Proces odlievania a valcovania: tekutý kov, predný box (kontrola hladiny kvapaliny), odlievací a valcovací stroj (mazací systém, chladiaca voda), strihací stroj, navíjací stroj.

Výrobný proces valcovania za studena

Úvod do dokončovacieho výrobného procesu

Hliníková zliatina má vlastnosti nízkej hustoty, dobré mechanické vlastnosti, dobrý výkon spracovania, netoxický, ľahko recyklovateľné, vynikajúca elektrická vodivosť, prenos tepla a odolnosť proti korózii, takže má široké uplatnenie.

Letectvo a kozmonautika: používané na výrobu plášťov lietadiel, trupové rámy, nosníky, rotory, vrtule, palivové nádrže, stenové panely a vzpery podvozku, ako aj krúžky na kovanie rakiet, stenové panely kozmickej lode, atď.

Hliníková zliatina používaná v letectve

Doprava: používané na materiály konštrukcie karosérií automobilov, vozidlá metra, železničné osobné autá, vysokorýchlostné osobné autá, dvere a okná, police, časti automobilových motorov, klimatizácie, radiátory, panely karosérie, kolesá a lodný materiál.

Dopravná aplikácia

Balenie: Celohliníkové dózy sa používajú najmä ako kovové obalové materiály vo forme tenkých dosiek a fólií, a vyrábajú sa z nich plechovky, viečka, fľaše, sudy, a baliace fólie. Široko používaný pri balení nápojov, jedlo, kozmetika, lieky, cigarety, priemyselné výrobky, lieky, atď.

Aplikácia balenia

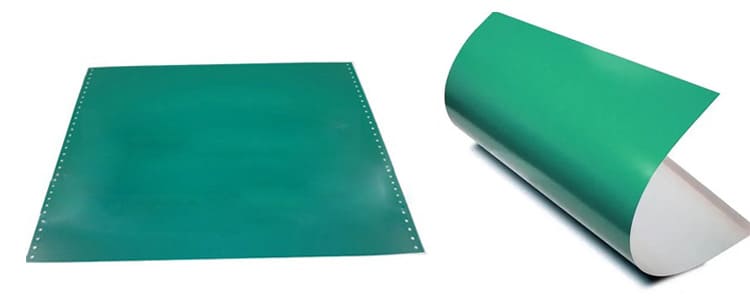

Tlač: Používa sa hlavne na výrobu dosiek PS, PS platne na báze hliníka sú novým typom materiálu v polygrafickom priemysle, používa sa na automatickú výrobu a tlač platní.

PS tlač

Architektonická výzdoba: hliníková zliatina je široko používaná v stavebných konštrukciách, dvere a okná, zavesené podhľady, dekoratívne povrchy, atď. vďaka svojej dobrej odolnosti proti korózii, dostatočná pevnosť, vynikajúci procesný výkon a zvárací výkon.

Aplikácia konštrukcie z hliníkovej zliatiny

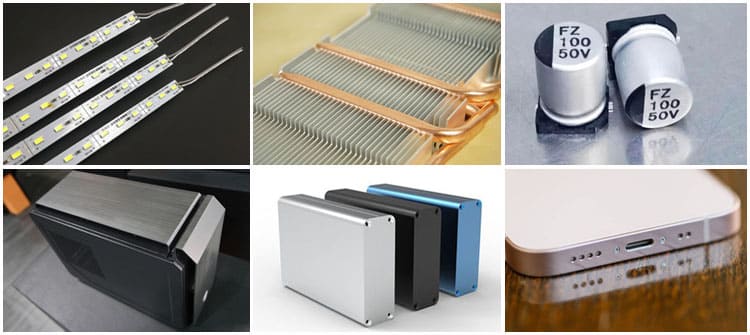

Elektronické produkty: počítačov, mobilné telefóny, plášte chladničky, radiátory, atď.

Elektronická aplikácia produktu

Kuchynské potreby: hliníkové hrnce, hliníkové misky, vložky do ryžových varičov, hliníková fólia pre domácnosť, atď.

Aplikácia do kuchyne

Balenie hliníkového plechu/zvitku

Každý detail balenia je miestom, kde sa snažíme o dokonalé služby. Náš proces balenia ako celok je nasledovný:

Laminovanie: priehľadný film, modrý film, mikroslizničné, vysokoslizničný, film na rezanie laserom (2 značky, Novacell a Polyphem);

Ochrana: papierové chrániče rohov, protitlakové podložky;

sušenie: sušidlo;

Podnos: fumigovaná nezávadná drevená tácka, opakovane použiteľný zásobník na železo;

Balenie: Oceľový opasok tic-tac-toe, alebo PVC baliaci pás;

Kvalita materiálu: Úplne bez chýb, ako je biela hrdza, olejové škvrny, valivé značky, poškodenie okraja, ohyby, preliačiny, diery, zlomové čiary, škrabance, atď., žiadna sada cievok.

Port: Qingdao alebo iné prístavy v Číne.

Dodacia lehota: 15-45 dní.

Proces balenia hliníkových plechov/doštičiek

Proces balenia hliníkovej cievky

F: Ste výrobca alebo obchodník?

Q: Sme výrobca, naša továreň je na Weier Road č.3, Priemyselná zóna, Gongyi, Henan, Čína.

F: Aké je MOQ pre objednanie produktu?

Q: Naše MOQ je 5 ton, a niektoré špeciálne produkty budú mať minimálne objednané množstvo 1 alebo 2 ton.

F: Aký dlhý je váš dodací čas?

Q: Vo všeobecnosti je náš dodacia lehota približne 30 dní.

F: Majú vaše produkty záruku kvality?

Q: áno, ak sa vyskytne problém s kvalitou našich produktov, odškodníme zákazníka, kým nebude spokojný.

Súvisiace produkty

Najnovšie blogy

Hliníkový zrkadlový plech s ultra vysokou odrazivosťou

Hliníkový zrkadlový plech s ultra vysokou odrazivosťou a viditeľnou odrazivosťou 95–98 %., nízky rozptyl (TIS <1%), a špecifikácie rady pre BRDF, spektrálne krivky a povlaky.

dôveryhodný 3003 Dodávatelia hliníkových plechov z celého sveta

Nájdite spoľahlivé 3003 Dodávatelia hliníkových plechov s certifikovanou kvalitou, konkurenčné ceny, vlastné veľkosti, a rýchle globálne dodanie pre vaše projekty.

6061 T6 vs 7075 hliník: Pevnosť, Hmotnosť & Najlepšie využitie

Porovnaj 6061 T6 vs 7075 hliník ľahko. Objavte rozdiely v sile, hmotnosť, a aplikácií, aby ste si vybrali to najlepšie pre svoje projekty.

Industrializácia a aplikácia voštinovej hliníkovej fólie

Tento blog skúma industrializáciu voštinovej hliníkovej fólie, so zameraním na 3003 proces výroby zliatiny. Zahŕňa valcovanie za tepla, kontinuálne liatie, a metódou kontinuálneho liatia a valcovania, zdôrazňujúc výhody optimalizácie procesov pri zlepšovaní mechanických vlastností, zníženie spotreby energie, a zníženie výrobných nákladov.