1. Introduction

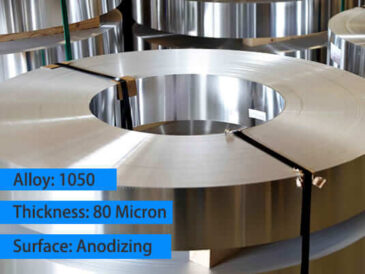

The 80-micron Anodized Aluminum Foil Strip is a high-performance, precision-engineered material that combines the inherent properties of an aluminum substrate with the superior characteristics of a ceramic surface layer.

With a nominal thickness of 0.08 mm, this material is not a simple foil but a composite system created through a sophisticated electrochemical process called anodization.

This process grows a controlled layer of aluminum oxide (Al₂O₃) directly from the base metal, fundamentally transforming its surface properties.

The resulting material retains the excellent thermal conductivity and light weight of the aluminum core while gaining high dielectric strength (making it an excellent electrical insulator), exceptional surface hardness (often exceeding 500 HV), and superior corrosion resistance.

This unique combination of properties makes it an indispensable material for demanding applications in the electronics and new energy sectors, such as transformer and motor windings, lithium-ion battery tab insulation, and thermally conductive insulating substrates.

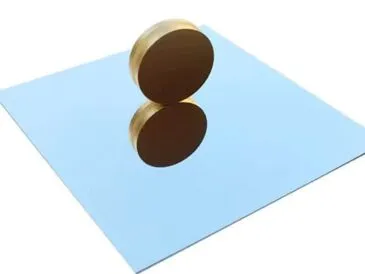

80-Micron Anodized Aluminum Foil Strip

2. Fundamental Characteristics of 80-Micron Anodized Aluminum Foil Strip

Base Aluminum Alloy

| Alloy | Typical composition highlights (major elements, wt%) | Typical tempers for 80 µm strip | Typical mechanical ranges* | Key advantages for anodized foil strip | Limitations/remarks |

|---|---|---|---|---|---|

| 1085 | Al ≥ 99.85% | O, H14 | UTS ~70–110 MPa; elongation >25% | Extremely high purity; most uniform anodic films; excellent dyeing consistency; superior ductility | Low mechanical strength; higher cost than standard 1xxx alloys |

| 1100 | Al ≥ 99.0% | O, H14 | UTS ~70–115 MPa; elongation >20% | Good surface quality; excellent formability; preferred for decorative anodizing | Limited rigidity and wear resistance |

| 1235 | Al ≥ 99.35% | O, H18 | UTS ~60–110 MPa (foil condition) | Mature foil alloy; stable rolling behavior; suitable for ultra-thin and narrow slit strips | Very low structural strength; mainly functional or conductive applications |

| 3003 | Mn ~1.0–1.5% | H14, H24 | UTS ~115–165 MPa; elongation 10–25% | Balanced strength and formability; widely used; stable anodizing behavior | Slightly less color uniformity than high-purity aluminum |

| 5052 | Mg ~2.2–2.8% | H32, H34 | UTS ~200–280 MPa; elongation 8–15% | Excellent corrosion resistance; suitable for humid or marine environments | Narrower forming window; anodized color may appear slightly gray |

| 8021 | Controlled Fe/Si (foil-grade alloy) | O, H18 | Producer-specific engineered ranges | Good surface control; suitable for precision coating and laminating | Anodizing compatibility must be process-validated |

| 8079 | Lower and more uniform Fe/Si content | O, H18 | Producer-specific engineered ranges | Premium foil alloy; high surface cleanliness; excellent slitting stability | Higher cost; stronger dependence on qualified suppliers |

| 8011 | Fe/Si ~0.6–1.0% | H18 | Typical foil-engineering range | Industry-standard foil alloy; wide processing window; strong availability | Anodized appearance requires optimized pretreatment |

| 6061 | Mg ~1.0%, Si ~0.6% | O, H14 (limited for thin gauges) | UTS ~260–320 MPa | High strength and rigidity; mature anodizing behavior | Not suitable for high-flexibility 80 µm strip applications |

- Mechanical values are indicative. Actual thin-gauge behavior depends on rolling history, temper, and supplier-specific processing.

Anodized layer composition

- The anodic film is primarily amorphous/nanoporous aluminum oxide (Al₂O₃) formed electrochemically.

- Typical decorative/hard anodize processes produce film thicknesses in the range ~2 – 25 µm (decorative: ~5–15 µm; hardcoat: 20–60 µm but hardcoat at very high µm is usually not applied to very thin foils because of brittleness).

- Films are sealed (hot water, nickel acetate or silicate seal) to reduce porosity, increase corrosion resistance and lock in dyes where applied.

- The oxide is electrically insulating and much harder than the base metal.

Aluminum alloy anodizing process

3. Mechanical and Physical Properties — 80-Micron Anodized Aluminum Foil Strip

Thickness and dimensions

Nominal substrate thickness

- 80 µm (0.080 mm). Specify tolerance in POs — typical industrial tolerances are ±3–5 µm for precision foil/strip (adjust per supplier capability).

Typical coil / strip formats

- Coil ID / OD: common inner diameters 152 mm (6″) or 305 mm (12″) depending on customer equipment; outer diameter limited by coil mass handling.

- Slit widths: from 3 mm up to 300+ mm (customer-specified).

- Edge quality: specify maximum burr height (e.g., ≤ 10 µm) and maximum edge roll for automatic handling.

Physical properties

| Property | Typical value / range | Test / note |

|---|---|---|

| Substrate thickness | 80 µm (0.080 mm); tolerance example ±3–5 µm | Specify gauge tolerance per PO |

| Areal mass (substrate) | 0.216 kg·m⁻² (216 g/m²) — see worked calc | Computed from t×ρt×ρt×ρ |

| Areal mass (substrate + 8 µm film) | ~0.248 kg·m⁻² (approx.) | Illustrative; verify with supplier |

| Density (Al substrate) | ~2.70 g·cm⁻³ (2700 kg·m⁻³) | Material constant |

| Surface finish (pre-anodize) | Bright / matte / pretreated | Specify surface roughness Ra if critical |

| Surface roughness (typical Ra) | ~0.2–2.0 µm before anodize (depends on mill finish) | Measure with stylus or optical profilometer |

| Coil/strip width | customer-specified (3–300+ mm) | Tolerance on width ±0.1–0.5 mm typical |

| Maximum recommended handling tension | supplier-dependent; typical < 50 N/mm for thin strip | Avoid plastic elongation or edge cracking |

Mechanical properties

| Alloy (typical temper for strip) | UTS (MPa) | Yield (0.2% offset, MPa) | Elongation (%) | Notes for thin gauge behavior |

|---|---|---|---|---|

| 1085 / 1100 (O / H14) | 70 – 115 | not always reported for foil | >20 | High ductility; excellent forming capability |

| 1235 (foil) | 60 – 110 | – | high (>20) | Foil-specific rolling yields very stable narrow strip |

| 3003 (H14 / H24) | 115 – 165 | 60 – 110 | 10 – 25 | Good balance of formability & strength |

| 5052 (H32) | 200 – 280 | 110 – 200 | 8 – 15 | Higher strength; better handling, lower elongation |

| 8011 / 8021 / 8079 (foil grades) | producer-engineered ranges | – | dependent | Engineered for gauge control and slit stability |

| 6061 (thin O/H14) | ~260 – 320 (T6 higher) | ~240–276 (T6) | 8–12 | Strong but less ductile; risk of springback & cracking in tight forming |

Corrosion resistance

What anodize does

- A properly sealed anodic film converts the metal surface into a corrosion-resistant Al₂O₃ barrier. For decorative/architectural exposure, a sealed Type II film (5–12 µm) plus PVDF topcoat typically meets long-life expectations.

Typical qualification tests & guideline hours

- Salt spray (NSS — ASTM B117 / ISO 9227): for painted or sealed anodize on architectural components, 240 h is often the baseline acceptance; 480 h or more is specified for marine/coastal hardware. (Set specific hours per project risk.)

- Cyclic corrosion / condensation tests recommended for coastal/industrial environments because real-world exposure cycles are more aggressive than static NSS.

Surface hardness

Anodic film hardness (typical)

- Decorative (sulfuric, 5–15 µm): micro-Vickers hardness on the oxide typically ~300 – 600 HV (process dependent).

- Hard anodize (20–60 µm): ~600 – 1000 HV or higher, but brittle and not recommended on very thin strip without qualification.

Thermal and electrical properties

Thermal properties

- Thermal conductivity (substrate): bulk aluminium ~205 – 235 W·m⁻¹·K⁻¹ (depends on alloy). For thin strip the conduction is dominated by substrate; anodic film is a poor thermal conductor and contributes negligibly to in-plane conduction.

- Thermal mass: combined areal heat capacity approximated from substrate mass per area (0.216 kg·m⁻²) × specific heat (~900 J·kg⁻¹·K⁻¹) → ≈0.216×900=194.4≈ 0.216 × 900 = 194.4≈0.216×900=194.4 J·m⁻²·K⁻¹ (approximate). If you require the digit-by-digit check, I can show it similarly to above.

Electrical properties — oxide as dielectric

- Oxide is insulating. Typical practical dielectric strength for anodic films is often used as a rough engineering rule of ~10–20 V/µm (process dependent). This means:

- A 5 µm film → ~50–100 V (rough estimate),

- A 10 µm film → ~100–200 V (rough estimate).

- Capacitance per unit area of the film can be estimated using the oxide thickness and relative permittivity (εr ≈ 8–10) if you are designing sensors or capacitive components — but always validate with dielectric breakdown and leakage tests on production material.

Aluminum strip slitting

4. Manufacturing Process of 80-Micron Anodized Aluminum Foil Strips

Foil production

- Casting/rolling: primary aluminium slab → hot roll → cold roll to final gauge (80 µm) with controlled anneal steps as needed. For narrow strip, master coils may be cold-slit or milled to width after rolling.

- Tempering & cleaning: final temper (O, H14, etc.) and cleaning/degreasing are performed before anodizing to ensure proper oxide formation and adhesion.

Anodization process

- Electrolytic oxidation: aluminum strip is made anodic in an electrolyte (commonly sulfuric acid for Type II decorative anodize). Current density, temperature and time control film thickness and porosity.

- Typical decorative film thickness: ~5–15 µm; hard anodize thicker (20–60 µm) but not commonly applied to very thin foil because thick hard oxides can crack and flake when the substrate bends or is slit.

- Sealing: immediate post-anodize sealing (hot water or chemical seal) hydrates/blocks pores improving corrosion resistance and dye retention.

- Coloring (optional): dyes infiltrate pores before sealing; electrolytic coloring or interference methods are alternatives.

Key constraints for 80 µm strip: the oxide is brittle relative to metal; deep/hard anodize film can cause cracking on slit edges or during bending. Process parameters must be matched to reduce internal stresses and preserve strip flexibility.

Surface finishing & post-treatments

- Dry film coatings (PVDF, polyurethane) can be applied after anodize for outdoor durability or to add functionality (scratch resistance).

- Masking & slitting: care is taken to avoid scoring the anodic surface; slitting tools and winding tension must be controlled to avoid flaking.

Quality control

- Film thickness measurement: eddy-current (non-destructive) or cross-section microscopy for calibration.

- Porosity/pinhole inspection: visual or electrolytic dye tests.

- Adhesion tests: tape/cross-cut or bend tests to ensure oxide and any topcoat adhesion.

- Electrical/dielectric testing: breakdown voltage tests if anodize used as dielectric.

- Salt spray & abrasion tests: for environmental durability.

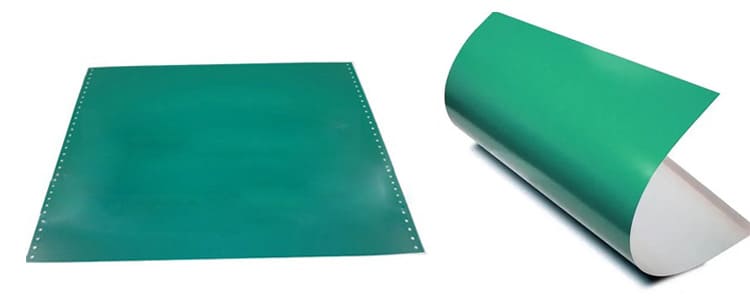

Huawei Packaging 80-Micron Anodized Aluminum Strip

5. Advantages of 80-Micron Anodized Aluminum Foil Strip

Electrical properties — transition from conductor to insulator

Anodize turns the thin surface into an insulating film while leaving a conductive substrate beneath.

That enables patterned insulation, local dielectric behavior for sensors, and safer handling where surface insulation is required.

Designers should test actual dielectric strength of the film + substrate stack for target voltages.

Mechanical properties — improved surface hardness

The oxide layer provides a hard, wear-resistant surface (better scratch resistance) while substrate flexibility allows bending and forming within limits.

For light wear applications, anodized strips perform significantly better than bare thin foil.

Thermal properties — efficient thermal management

For heat-spreading or lightweight thermal solutions the substrate (80 µm Al) provides good thermal conductivity with minimal mass.

The anodic layer has low thermal conductivity but is thin enough that substrate conduction dominates; therefore anodized strip can serve as a lightweight heat spreader with a protective surface.

Chemical properties — excellent corrosion resistance

Properly sealed anodic films substantially increase corrosion life against moisture and many corrosives.

When combined with a corrosion-resistant alloy (e.g., 5052) and proper edge sealing the assembly performs well in humid and mildly corrosive environments.

80-Micron Aluminum Foil Strip for Transformer

6. Applications of 80-Micron Anodized Aluminum Foil Strips

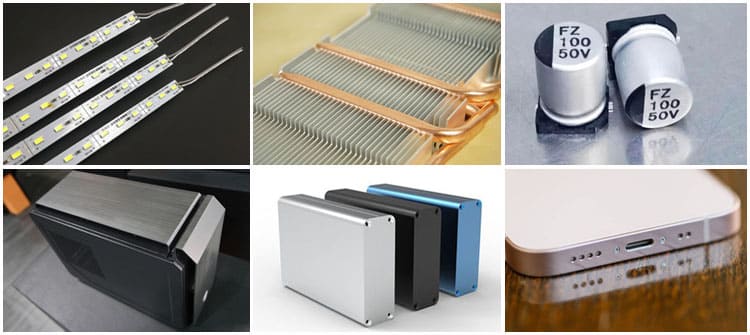

Electrical and Electronic Components

- Insulating spacer strips in transformers and inductors

- Busbar insulation layers (low-voltage, compact designs)

- Capacitor components and current collectors

- EMI shielding elements with controlled insulation

Thermal Management and Heat-Control Systems

- Heat spreader layers in LED modules

- Thermal interface backings in electronic assemblies

- Heat dissipation substrates combined with insulating layers

- Radiant heat control and reflective elements

80-Micron Aluminum strip for interior decoration

Precision Insulation and Functional Laminates

- Laminated insulation tapes

- Composite barrier layers in industrial equipment

- Backing layers for pressure-sensitive adhesives

- Multilayer technical foils

Decorative and Architectural Trim Elements

- Narrow decorative strips and inlays

- Interior design accents

- Furniture trim and appliance detailing

- Anti-glare reflective elements

Industrial Labeling and Identification Systems

- High-durability nameplates

- Warning and instruction labels

- Barcode and QR code carriers

- Asset tracking tags for industrial equipment

Specialized and Emerging Applications

- Sensor substrates and functional electrodes

- Battery and energy-storage components (non-current-carrying roles)

- Optical and reflective control layers

- Laboratory and analytical equipment components

7. Comparison with Other Aluminum Foil Products

| Performance Dimension | 80μm Anodized Aluminum Foil | 80μm Bare Aluminum Foil | 80μm Coated/Laminated Foil | Polymer Insulating Films (e.g., Kapton®, Mylar®) |

|---|---|---|---|---|

| Surface Nature | Integral Ceramic Layer (Al₂O₃) | Metallic Aluminum Surface | Applied Polymer Layer | Pure Polymer |

| Electrical Insulation | Excellent (High Dielectric Strength) | None (Conductor) | Good (Depends on coating) | Excellent (Specialized Insulator) |

| Surface Hardness/Abrasion Resistance | Very High (Ceramic-like) | Very Low (Very soft) | Low (Depends on coating) | Moderate |

| Thermal Performance | Excellent (Conductive Core + Emissive Surface) | Good (Conductive core only) | Poor (Polymer layer is a thermal barrier) | Very Poor (Thermal Insulator) |

| Bond Strength (Surface to Substrate) | Perfect (Integrally grown) | N/A | Good (but can delaminate) | N/A |

| Max. Operating Temperature | High ( >300°C ) | High ( >500°C ) | Low ( <150°C, limited by coating ) | Medium to High (Depends on polymer) |

| Thickness Uniformity/Precision | High | High | Fair (Coating adds variables) | High |

| Cost | Medium-High | Low | Medium | Medium to High |

| Core Application Scenario | Motor windings, battery tab insulation, insulating heat sinks. | General heat fins, packaging, EMI shielding. | Food packaging, cable shielding, decorative panels. | Pure electrical insulation, flexible circuit substrates. |

8. Conclusion

The 80-micron Anodized Aluminum Foil Strip is a testament to the power of advanced surface engineering.

By transforming the surface of a basic metal into a high-performance ceramic layer, it creates a new material with a combination of properties that neither constituent could achieve alone.

It is not simply a piece of aluminum foil; it is a sophisticated, multifunctional solution engineered to solve the increasingly complex challenges of insulation, thermal management, and durability in the modern electronics and energy sectors.

Its ability to provide electrical insulation, surface hardness, and efficient heat dissipation in a single, lightweight package makes it an indispensable and intelligent material choice for high-performance applications.

FAQs

Q1 — Does “80 µm” refer to the anodic film thickness or the substrate?

Usually it denotes the substrate thickness (foil) = 80 µm. If you require an 80 µm anodic film, explicitly state “anodic film thickness = 80 µm” — this is uncommon and will impose severe handling constraints.

Q2 — What anodize film thickness is typical on 80 µm strip?

Decorative anodize: ~5–15 µm. Hard anodize: 20–60 µm but thick hardcoats risk cracking on thin substrates. Choose modest film thickness for flexible strips.

Q3 — How much does an 80 µm strip weigh per m²?

Calculated earlier: 0.216 kg/m² (substrate only). Add a few g/m² for anodic film & seal depending on film thickness.

Q4 — Can an anodized 80 µm strip be bent or formed?

Yes within limits. Bending radius limits depend on alloy/temper and film thickness; tight bending can crack the oxide. Run forming trials for critical bends.

Q5 — How does anodize affect electrical conductivity?

The oxide is insulating. The bulk substrate remains conductive if oxide is removed locally (mechanically or chemically) or pierced. If anodize is used as dielectric, measure dielectric strength on the manufactured lot.

Casting production process and its introduction

The purpose of melting and casting is to produce alloys with satisfactory composition and high purity of melt, so as to create favorable conditions for casting alloys of various shapes.

Melting and casting process steps: batching --- feeding --- melting --- stirring after melting, slag removal --- pre-analysis sampling --- adding alloy to adjust the composition, stirring --- refining --- static Setting——Guide furnace casting.

Hot rolling production process and its introduction

- 1. Hot rolling generally refers to rolling above the metal recrystallization temperature;

- 2. During the hot rolling process, the metal has both hardening and softening processes. Due to the influence of deformation speed, as long as the recovery and recrystallization process is too late, there will be a certain work hardening;

- 3. The recrystallization of the metal after hot rolling is incomplete, that is, the coexistence of recrystallized structure and deformed structure;

- 4. Hot rolling can improve the processing performance of metals and alloys, reduce or eliminate casting defects.

- 1. The casting and rolling temperature is generally between 680°C and 700°C. The lower the better, the stable casting and rolling line usually stops once a month or more to re-stand. During the production process, it is necessary to strictly control the liquid level of the front tank to prevent low liquid level;

- 2. Lubrication uses C powder with incomplete combustion of gas for lubrication, which is also one of the reasons for the dirty surface of casting and rolling materials;

- 3. The production speed is generally between 1.5m/min-2.5m/min;

- 4. The surface quality of products produced by casting and rolling is generally relatively low, and generally cannot meet products with special physical and chemical performance requirements.

- 1. Cold rolling refers to the rolling production method below the recrystallization temperature;

- 2. There will be no dynamic recrystallization during the rolling process, and the temperature will rise to the recovery temperature at most, and the cold rolling will appear in a work hardening state, and the work hardening rate will be large;

- 3. The cold-rolled sheet and strip have high dimensional accuracy, good surface quality, uniform structure and performance, and products in various states can be obtained with heat treatment;

- 4. Cold rolling can roll out thin strips, but at the same time, it has the disadvantages of high energy consumption for deformation and many processing passes.

- 1. Finishing is a processing method to make the cold-rolled sheet meet the customer's requirements, or to facilitate the subsequent processing of the product;

- 2. The finishing equipment can correct the defects produced in the hot rolling and cold rolling production process, such as cracked edge, oily, poor plate shape, residual stress, etc. It needs to ensure that no other defects are brought into the production process;

- 3. There are various finishing equipments, mainly including cross-cutting, slitting, stretching and straightening, annealing furnace, slitter, etc.

Casting and rolling process

Casting and rolling process: liquid metal, front box (liquid level control), casting and rolling machine (lubrication system, cooling water), shearing machine, coiling machine.

Cold rolling production process

Introduction to finishing production process

Aluminum alloy has the characteristics of low density, good mechanical properties, good processing performance, non-toxic, easy to recycle, excellent electrical conductivity, heat transfer and corrosion resistance, so it has a wide range of applications.

Aerospace: used to make aircraft skins, fuselage frames, girders, rotors, propellers, fuel tanks, wall panels and landing gear struts, as well as rocket forging rings, spacecraft wall panels, etc.

Aluminum alloy used for aerospace

Transportation: used for car body structure materials of automobiles, subway vehicles, railway passenger cars, high-speed passenger cars, doors and windows, shelves, automotive engine parts, air conditioners, radiators, body panels, wheels and ship materials.

Traffic application

Packaging: All-aluminum pop cans are mainly used as metal packaging materials in the form of thin plates and foils, and are made into cans, lids, bottles, barrels, and packaging foils. Widely used in the packaging of beverages, food, cosmetics, medicines, cigarettes, industrial products, medicines, etc.

Packaging application

Printing: Mainly used to make PS plates, aluminum-based PS plates are a new type of material in the printing industry, used for automatic plate making and printing.

PS printing

Architectural decoration: aluminum alloy is widely used in building structures, doors and windows, suspended ceilings, decorative surfaces, etc. due to its good corrosion resistance, sufficient strength, excellent process performance and welding performance.

Aluminum alloy construction application

Electronic products: computers, mobile phones, refrigerator shells, radiators, etc.

Electronic product application

Kitchen supplies: aluminum pots, aluminum basins, rice cooker liners, household aluminum foil, etc.

Kitchen application

Packaging Of Aluminum Sheet/Coil

Every detail of packaging is where we pursue perfect service. Our packaging process as a whole is as follows:

Lamination: clear film, blue film, micro-mucosal, high-mucosal, laser cutting film (2 brands, Novacell and Polyphem);

Protection: paper corner protectors, anti-pressure pads;

drying: desiccant;

Tray: fumigated harmless wooden tray, reusable iron tray;

Packing: Tic-tac-toe steel belt, or PVC packing belt;

Material Quality: Completely free from defects such as white rust, oil spots, rolling marks, edge damage, bends, dents, holes, break lines, scratches, etc., no coil set.

Port: Qingdao or other ports in China.

Lead time: 15-45 days.

Aluminum sheet/plate packaging process

Aluminum coil packaging process

F: Are you a manufacturer or a trader?

Q: We are a manufacturer, our factory is at No.3 Weier Road, Industrial Zone, Gongyi, Henan, China.

F: What is the MOQ for ordering the product?

Q: Our MOQ is 5 tons, and some special products will have a minimum order quantity of 1 or 2 tons.

F: How long is your lead time?

Q: Generally our lead time is about 30 days.

F: Do your products have quality assurance?

Q: Yes, if there is a quality problem with our products, we will compensate the customer until they are satisfied.

Related Products

Latest Blogs

Ultra-high reflectivity aluminum mirror sheet

Ultra-high reflectivity aluminum mirror sheet with 95–98% visible reflectance, low scatter (TIS <1%), and specification advice for BRDF, spectral curves and coatings.

Trusted 3003 Aluminium Checker Plate Sheet Suppliers Worldwide

Find reliable 3003 Aluminium Checker Plate Sheet Suppliers offering certified quality, competitive pricing, custom sizes, and fast global delivery for your projects.

6061 T6 vs 7075 Aluminum: Strength, Weight & Best Uses

Compare 6061 T6 vs 7075 aluminum easily. Discover differences in strength, weight, and applications to choose the best for your projects.

Industrialization and Application of Honeycomb Aluminum Foil

This blog explores the industrialization of honeycomb aluminum foil, focusing on the 3003 alloy production process. It covers hot rolling, continuous casting, and the continuous casting-rolling method, highlighting the benefits of process optimization in improving mechanical properties, reducing energy consumption, and lowering production costs.