Hva er 5052 aluminiumssirkel

5052 aluminium sirkler er AL-Mg legert aluminium sirkler. Magnesium er det viktigste legeringselementet i 5052 legert aluminium sirkel og er den mest brukte anti-rust aluminium. Blant legeringer som ikke kan varmebehandles, 5052 regnes som et av de sterkeste alternativene.

Hva er 5052 aluminiumssirkel

5052 aluminiumssirkel har høy styrke, spesielt utmattelsesmotstand: høy plastisitet og korrosjonsbestandighet, kan ikke styrkes ved varmebehandling, god plastisitet under halvkald arbeidsherding, lav plastisitet under kaldarbeidsherding, god korrosjonsbestandighet, god sveisbarhet, og kan Dårlig kutteytelse, kan poleres. Brukes hovedsakelig i lamper, kjøkkenutstyr, elektroniske og elektriske kabinetter, trafikkskilt, osv.

5052 kjemisk sammensetning av aluminiumslegering

| Legering | Og | Fe | Cu | Mn | Mg | Cr | Zn | Av | Andre-Hver | Andre Totalt | Al |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 5052 | 0.25 | 0.40 | 0.10 | 0.10 | 2.2-2.8 | 0.15-0.35 | 0.10 | – | 0.05 | 0.15 | Rest |

Magnesiuminnholdet i 5052 aluminium sirkler er 2.2-2.8%, så tettheten er bare 2.68. Vekten av 5052 legert aluminium sirkler er det letteste legeringstallet blant hele 5000 serie aluminiumslegeringer.

5052 aluminiumslegering inneholder også små mengder mangan, krom, beryllium, titan, osv. Bortsett fra en liten mengde mangan i legeringen, det meste danner MnAl6. Rollen til krom i 5052 aluminiumsirkler ligner på mangan. Det forbedrer motstanden mot spenningskorrosjon, øker styrken til grunnmetallet og sveisene, og reduserer tendensen til sveisesprekker, men innholdet overskrider vanligvis ikke 0.35%.

Spesifikasjon av 5052 aluminiumssirkel

| Produkt | 5052 Aluminiumssirkel |

| Temperament | O, H12, H14, H18, H22, H32, H34, H111 |

| Tykkelse | 0.5mm-10,0 mm |

| Diameter | 100mm-1200 mm |

| Ledetid | Innenfor 30-45 dager etter mottak av innskudd |

| Pakking | Standard Eksporterer trepaller eller basert på kundekrav |

| Materiale | Bruker høyteknologisk maskineri som bruker førsteklasses aluminiumsspole. Tilpasset i henhold til kundenes behov og krav, kan disse benyttes med forskjellige tekniske spesifikasjoner. |

| Flate: | Lys & glatt overflate, fri for defekter som hvitrust, oljelapp, kantskade. |

| Søknad | Aluminiumsirkler brukes i reflekterende skiltplater, Veimøbler, Utstyr, Sand heks Bunn, Komfyr, non-stick osv. |

| Legg merke til | Spesifikke krav til legering temperament eller spesifikasjoner kan produseres som din forespørsel. |

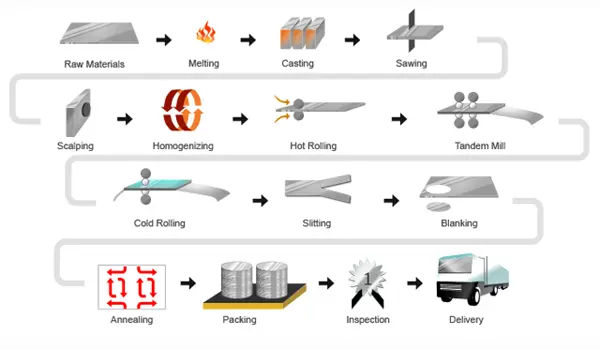

5052 Aluminium sirkel produksjonslinje

- 1.Forbered masterlegeringene

- 2.Smelteovn :legg legeringene inn i smelteovnen

- 3.D.C.-støpt aluminiumsblokk:Å lage moren ingot

- 4.Fres aluminiumsblokken:for å gjøre overflaten og siden glatt

- 5.Oppvarmingsovn

- 6.Varmvalseverk:laget moderspolen

- 7.Avkjølende valseverk:moderspolen ble rullet som tykkelsen du ønsker å kjøpe

- 8.Stanseprosess:bli den størrelsen du ønsker

- 9.Glødeovn:endre temperamentet

- 10.Sluttkontroll

- 11.Pakking:trekasse eller trepall

- 12.Leveranse

Produksjonsprosess for aluminiumsirkel

Når du utfører trinn 8, forskjellige prosesser vil bli brukt på grunn av forskjellige tykkelser på aluminiumsirkler.

1. Tykkelse: 0.012″ – 0,15″ (0.3mm – 4 mm)

Stempling

Stempling er en metode for maskinering av ferdige deler ved å mate metallplater, vanligvis fra en rull, gjennom en rekke stasjoner. Disse stasjonene kan inkludere stempling, bøying, kutting, og andre formingsteknikker, og utføres i en bestemt rekkefølge langs banen til metallplaten.

2. Tykkelse: 0.15″ – 0,39″ (4mm – 10 mm)

laserskjæring

5052 ytelsesegenskaper for aluminiumsskive/sirkel

Hardhet: Strekkstyrken til 5052 serien rekker mellom 210-230, som betyr at hardheten av 5052 er 100% høyere enn hardheten til 1060.

Forlengelse: Forlengelsen av 5052 serien rekker mellom 12-20%. Det kan også tenkes at når 5052 serien er 100% vanskeligere enn 1060, forlengelsen øker også med ca 200%.

Kjemiske egenskaper: 5052 er en legert aluminium. I spesielle miljøer, 5052 har bedre korrosjonsbestandighet.

5052 Behandlingsegenskaper for aluminiumsplater

Formbarhet:

1. Legeringen har god plastisitet i varm tilstand.

2. Den kalde stemplingsytelsen er relatert til legeringstilstanden. Kaldstemplingsytelsen til den glødede O-tilstanden er god, etterfulgt av H32 og H34 temperament.

Sveiseytelse:

1. Denne legeringen har god ytelse ved gassveising, buesveising, motstandssveising, punktsveising og sømsveising. Den har en tendens til krystalliseringssprekker ved argonbuesveising. Den har god loddingsytelse, men dårlig mykloddeytelse.

2. Sveisesømmen har høy styrke og plastisitet.

Typisk anvendelse av 5052 aluminiumssirkel

Aluminiumssirkel for lamper: høy overflatefinish, ingen riper, og høy forlengelse. Kornstørrelsen er godt kontrollert og egnet for dyptrekking og stempling. Aluminiumsskiver med forskjellige diametre kan leveres i henhold til brukerkrav.

Kjøkkenutstyr: aluminiums gryter, aluminiums gryter, lokk i aluminium, aluminiumsbokser, tebokser, aluminiumsbøtter, aluminiumsbokser, medisinbokser, kjøkkenutstyr, kjøkkenutstyr, servise, bakeverktøy, bakeplater, kakeformer, toastformer, anodisert kjøkkenutstyr, anodisert kokekar, anodisert servise, hardanodisert kokekar, hardanodisert kokekar, hardanodisert servise, utendørs kokekar, utendørs kokekar, utendørs servise, piknikgryter, utendørs kokekar sett

5052 aluminium sirkelapplikasjon

Veiskilt aluminiumsskive: Det er en buet skive, som behandles av aluminiumsplate gjennom rundbøyeutstyr. De er egnet for ulike trafikkskilt. De kan tilpasses etter diameter.

Lukedeksel aluminiumsirkel: 5052 aluminium sirkel er et ideelt materiale for yacht oljetette lukedeksler. Den skal ha sterk korrosjonsbestandighet, anti-aldringsytelse og anti-ultrafiolett ytelse. Vanlig størrelse er 2,0*600mm.

Yachtoljelukedeksel: 5052 aluminiumsirkel er et av de typiske aluminiumsproduktene av marinekvalitet. Den kan ikke bare effektivt motstå korrosjon fra havvind og sjøvann, men også redusere vekten på skroget.

5052 aluminiumssirkel for kokekar

Maskinvareprodukter: maskinvaredeler, metall stempling deler, maskinvare tegning deler, ulike former, tekstil skyttelbuss, satellittantenner, osv.

Huawei 5052 kvalitetskontroll av aluminiumsirkel

- 1. Ingen sprekker, korrosjonsflekker eller spor av nitratsalt er tillatt på overflaten.

- 2. Peeling, bobler, overflateruhet og lokale mekaniske skader med en dybde som ikke overstiger 8% av den nominelle veggtykkelsen til den defekte delen tillates på overflaten, men den maksimale dybden på defekten kan ikke overstige 0,5 mm, og det totale arealet av defekten ikke overstiger det totale arealet av platen. 5%.

- 3. Leverandøren får polere profilen på langs til overflaten er glatt.

- 4. Andre krav: Etterspørr og leverandør skal formulere egne krav.

5052 kvalitetskontroll av aluminiumsirkel

5052 Sirkelpakke i aluminium

- 1.Sett tørketrommelen på siden av aluminiumsirkelen, hold produktene tørre og rene.

- 2.Bruk det rene plastpapiret, pakking av aluminiumsirkelen, hold god forsegling.

- 3.Bruk slangeskinnspapiret, pakking av overflaten av plastpapiret, hold god forsegling.

- 4.Neste, Det er to måter å pakke på: En måte er trepallemballasje, ved å bruke det skorpepapiret som pakker overflaten;

En annen måte er emballasje av tre, ved hjelp av trekassen som pakker overflaten. - 5.Finale, legg stålbeltet på overflaten til treboksen, hold treboksen fast og sikker.

Hva er forskjellen mellom 3003 og 5052 aluminium?

5052 aluminiumsplate og 3003 aluminiumsplater er de vanligste legeringsaluminiumsplatene på markedet. Nå tar vi 3003 H24 aluminiumsplate og 5052 H32 aluminiumsplate som eksempler for å popularisere kunnskap på dette området. ?

1. Kjemisk sammensetning: 3003 aluminiumsplate er en aluminium-manganlegering, og hovedlegeringselementet er mangan. 5052 aluminiumsplate er en aluminium-magnesium-legering, og hovedlegeringselementet er magnesium. Aluminiuminnholdet i 3003 aluminiumsplate er litt høyere enn for 5052 aluminiumsplate.

2. Mekaniske egenskaper: 3003 H24 aluminiumsplate er en aluminium-manganlegering, og hovedlegeringselementet er mangan. Strekkfastheten til 3003 H24 aluminiumsplate er 145-195Rm/MPa, mens strekkfastheten til 5052 H34 aluminiumsplate er 230-280Rm/MPa, som er mye høyere enn 3003 H24 aluminiumsplate; forlengelsesstyrken til 3003 H24 aluminiumsplate er 115Rm/MPa, mens forlengelsesstyrken til 5052 H34 aluminiumsplate er 150Rm/MPa. Derfor, ytelsen til 5052 aluminiumsplate er betydelig bedre enn den til 3003 aluminiumsplate. ?

3003 aluminiumsplate med beskyttelsesfilm

3. Spesifikasjoner: 3003 H14 aluminiumsplater er hovedsakelig tynne plater, og tykke plater er ikke mye brukt; mens 5052 aluminiumsplater er også mye brukt i tillegg til tynne plater og tykke plater. ?

4. Bruk: 3003 aluminiumsplater brukes hovedsakelig i fuktige miljøer, som produktemballasje, kjøleskap, klimaanlegg, kjølelagre, ventilasjonskanaler, osv. 5052 aluminiumsplater brukes ofte i elektriske skap, transportkjøretøyer, trykkbeholdere, osv. Vanlig brukt materiale i produksjon av drivstofftanker og drivstoffrør for biler og fly.

5. Aluminiumsplate pris: Prisen på 3003 aluminiumsplate er litt høyere enn for ren aluminiumsplate, mens prisen på 5052 aluminiumsplate er betydelig høyere enn for 3003 aluminiumsplate. Avhengig av spesifikasjoner og tykkelse, prisen på et tonn 5052 aluminiumsplater er høyere enn prisen på et tonn 3003 aluminiumsplater.

Kan 5052 aluminium sirkel/skive være eloksert?

Anodiserte aluminiumsirkler er mye brukt i mange prosjekter. Anodiserte aluminiumsirkler er egnet for varmvalsede materialer (DC materialer). 5052 legert aluminium sirkel er et varmvalset materiale (DC materiale), så den er av god kvalitet og egnet for anodisering.

Den anodiserende effekten av 5052 aluminium sirkel er veldig bra, og den kan også anodiseres i forskjellige farger, som svart, rød, blå, osv. Oksydfilmen vil beskytte aluminiumsirkelen, forlenge levetiden, og gjør aluminiumslegeringsproduktet vakrere.

Produksjonsprosessen for støping og introduksjonen av den

Hensikten med smelting og støping er å produsere legeringer med tilfredsstillende sammensetning og høy renhet av smelten, for å skape gunstige forhold for støping av legeringer av forskjellige former.

Smelte- og støpeprosesstrinn: batching --- fôring --- smelting --- omrøring etter smelting, slaggfjerning --- prøvetaking før analyse --- legge til legering for å justere sammensetningen, røring --- raffinering --- statisk innstilling——Guide ovnsstøping.

Varmvalsende produksjonsprosess og dens introduksjon

- 1. Varmvalsing refererer generelt til valsing over metallrekrystalliseringstemperaturen;

- 2. Under varmvalsingsprosessen, metallet har både herde- og mykningsprosesser. På grunn av påvirkningen av deformasjonshastigheten, så lenge gjenopprettings- og rekrystalliseringsprosessen er for sent, det blir en viss arbeidsherding;

- 3. Omkrystalliseringen av metallet etter varmvalsing er ufullstendig, det vil si, sameksistensen av rekrystallisert struktur og deformert struktur;

- 4. Varmvalsing kan forbedre prosessytelsen til metaller og legeringer, redusere eller eliminere støpefeil.

- 1. Støpe- og valsetemperaturen er vanligvis mellom 680°C og 700°C. Jo lavere jo bedre, den stabile støpe- og rullelinjen stopper vanligvis en gang i måneden eller mer for å stå igjen. Under produksjonsprosessen, det er nødvendig å strengt kontrollere væskenivået i fronttanken for å forhindre lavt væskenivå;

- 2. Smøring bruker C-pulver med ufullstendig forbrenning av gass til smøring, som også er en av grunnene til den skitne overflaten til støpe- og valsematerialer;

- 3. Produksjonshastigheten er vanligvis mellom 1,5 m/min-2,5 m/min;

- 4. Overflatekvaliteten på produkter produsert ved støping og valsing er generelt relativt lav, og kan generelt ikke oppfylle produkter med spesielle fysiske og kjemiske ytelseskrav.

- 1. Kaldvalsing refererer til rullende produksjonsmetode under rekrystalliseringstemperaturen;

- 2. Det vil ikke være noen dynamisk rekrystallisering under valseprosessen, og temperaturen vil stige til gjenvinningstemperaturen på det meste, og kaldvalsingen vil fremstå i en arbeidsherdende tilstand, og arbeidsherdehastigheten vil være stor;

- 3. Det kaldvalsede arket og båndet har høy dimensjonsnøyaktighet, god overflatekvalitet, enhetlig struktur og ytelse, og produkter i forskjellige tilstander kan oppnås med varmebehandling;

- 4. Kaldrulling kan rulle ut tynne strimler, men samtidig, den har ulempene med høyt energiforbruk for deformasjon og mange behandlingspass.

- 1. Etterbehandling er en bearbeidingsmetode for å få det kaldvalsede arket til å møte kundens krav, eller for å lette den etterfølgende behandlingen av produktet;

- 2. Etterbehandlingsutstyret kan rette opp defektene som er produsert i produksjonsprosessen for varm- og kaldvalsing, som sprukket kant, fet, dårlig plateform, gjenværende stress, osv. Den må sørge for at ingen andre defekter kommer inn i produksjonsprosessen;

- 3. Det finnes ulike etterbehandlingsutstyr, hovedsakelig inkludert tverrskjæring, spalting, strekking og retting, glødeovn, skli, osv.

Støpe- og valseprosess

Støpe- og valseprosess: flytende metall, frontboks (væskenivåkontroll), støpe- og valsemaskin (smøresystem, kjølevann), klippemaskin, kveilmaskin.

Kaldvalsende produksjonsprosess

Introduksjon til etterbehandling av produksjonsprosessen

Aluminiumslegering har egenskapene til lav tetthet, gode mekaniske egenskaper, god behandlingsytelse, ikke-giftig, lett å resirkulere, utmerket elektrisk ledningsevne, varmeoverføring og korrosjonsbestandighet, så den har et bredt spekter av bruksområder.

Luftfart: brukes til å lage flyskinn, flykroppsrammer, dragere, rotorer, propeller, drivstofftanker, veggpaneler og landingsstellstag, samt rakettsmieringer, romfartøyets veggpaneler, osv.

Aluminiumslegering brukt til romfart

Transport: brukes til karosserimaterialer til biler, t-banekjøretøyer, jernbane personbiler, høyhastighets personbiler, dører og vinduer, hyller, deler til bilmotorer, klimaanlegg, radiatorer, kroppspaneler, hjul og skipsmateriell.

Trafikksøknad

Emballasje: Popbokser i aluminium brukes hovedsakelig som metallemballasjematerialer i form av tynne plater og folier, og lages til bokser, lokk, flasker, fat, og emballasjefolier. Mye brukt i emballasje av drikkevarer, mat, kosmetikk, medisiner, sigaretter, industrielle produkter, medisiner, osv.

Emballasjeapplikasjon

Printing: Brukes hovedsakelig til å lage PS-plater, aluminiumsbaserte PS-plater er en ny type materiale i trykkeribransjen, brukes til automatisk platefremstilling og utskrift.

PS utskrift

Arkitektonisk dekorasjon: aluminiumslegering er mye brukt i bygningskonstruksjoner, dører og vinduer, undertak, dekorative overflater, osv. på grunn av sin gode korrosjonsbestandighet, tilstrekkelig styrke, utmerket prosessytelse og sveiseytelse.

Konstruksjonsapplikasjon i aluminiumslegering

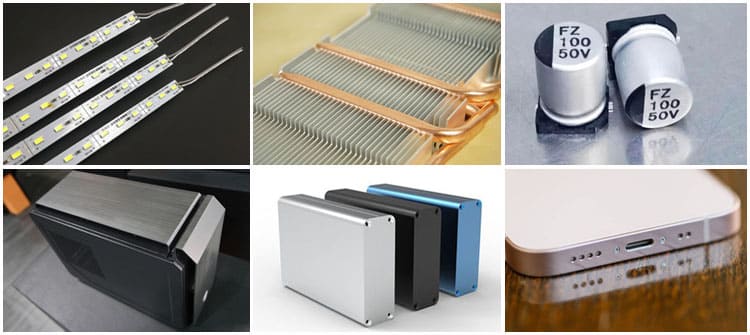

Elektroniske produkter: datamaskiner, mobiltelefoner, kjøleskapsskall, radiatorer, osv.

Elektronisk produktapplikasjon

Kjøkkenutstyr: aluminiums gryter, kummer i aluminium, riskokerforinger, husholdnings aluminiumsfolie, osv.

Kjøkkenapplikasjon

Emballasje av aluminiumsplate/coil

Hver detalj av emballasjen er der vi streber etter perfekt service. Vår pakkeprosess som helhet er som følger:

Laminering: klar film, blå film, mikro-slimhinnen, høy slimhinne, laserskjærende film (2 merkevarer, Novacell og Polyfem);

Beskyttelse: papirhjørnebeskyttere, anti-trykk pads;

tørking: tørkemiddel;

Brett: fumigert ufarlig trebrett, gjenbrukbart jernbrett;

Pakking: Tic-tac-toe stålbelte, eller PVC-pakkebelte;

Materialkvalitet: Helt fri for defekter som hvitrust, oljeflekker, rullende merker, kantskade, bøyer, bulker, hull, bryte linjer, riper, osv., ingen spole satt.

Havn: Qingdao eller andre havner i Kina.

Ledetid: 15-45 dager.

Emballasjeprosess for aluminiumsplater/plater

Emballasjeprosess for aluminiumsspole

F: Er du produsent eller handelsmann?

Q: Vi er en produsent, fabrikken vår er på No.3 Weier Road, Industrisone, Gongyi, Henan, Kina.

F: Hva er MOQ for å bestille produktet?

Q: Vår MOQ er 5 tonn, og noen spesialprodukter vil ha et minimumsbestillingsantall på 1 eller 2 tonn.

F: Hvor lang er ledetiden din?

Q: Vanligvis er ledetiden vår ca 30 dager.

F: Har produktene dine kvalitetssikring?

Q: Ja, hvis det er et kvalitetsproblem med produktene våre, vi vil kompensere kunden til de er fornøyd.

Relaterte produkter

Siste blogger

Speilark i aluminium med ultrahøy reflektivitet

Speilplate i aluminium med ultrahøy reflektivitet med 95–98 % synlig reflektans, lav spredning (TIS <1%), og spesifikasjonsråd for BRDF, spektralkurver og belegg.

Klarert 3003 Leverandører av plater av aluminium over hele verden

Finn pålitelig 3003 Aluminium Checker Plate Sheet Leverandører som tilbyr sertifisert kvalitet, konkurransedyktige priser, tilpassede størrelser, og rask global levering for dine prosjekter.

6061 T6 vs 7075 Aluminium: Styrke, Vekt & Beste bruksområder

Sammenligne 6061 T6 vs 7075 aluminium lett. Oppdag forskjeller i styrke, vekt, og applikasjoner for å velge det beste for dine prosjekter.

Industrialisering og påføring av honeycomb aluminiumsfolie

Denne bloggen utforsker industrialiseringen av honeycomb aluminiumsfolie, med fokus på 3003 legeringsproduksjonsprosess. Den dekker varmvalsing, kontinuerlig støping, og den kontinuerlige støping-valsemetoden, fremheve fordelene med prosessoptimalisering for å forbedre mekaniske egenskaper, redusere energiforbruket, og redusere produksjonskostnadene.