1. Perkenalan

9-mikron 1235 aluminium foil komposit adalah sangat terspesialisasi, multi-layer material that serves as a cornerstone of the modern flexible packaging industry.

This material system is engineered to provide a high-performance barrier at an optimal cost and weight. Its core is an ultra-thin, 9mikron (0.009mm) foil made from 1235 paduan aluminium, kemurnian tinggi (≥99,35% Al) grade prized for its exceptional softness and workability.

While the 9-micron foil itself provides a near-perfect barrier to light, gas, dan kelembaban, its thinness makes it mechanically fragile and susceptible to pinholes.

These weaknesses are overcome by laminating it with other polymer films (such as PET, BOPP, and PE). The resulting composite structure leverages the absolute barrier of the aluminum core while gaining the strength, kemampuan cetak, and sealability of the polymer layers.

This makes 9-micron 1235 composite foil the go-to solution for a vast range of applications, termasuk kemasan makanan (makanan ringan, kopi, bubuk susu) and pharmaceutical sachets, where a high barrier, ringan, and cost-effectiveness are all critical requirements.

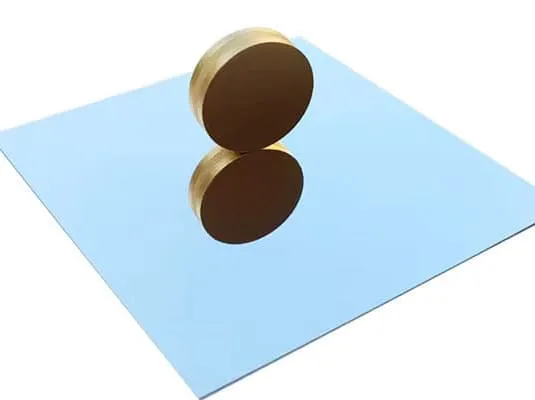

9-mikron 1235 aluminium foil komposit

2. Memahami 1235 Paduan aluminium

2.1 Komposisi kimia

Itu 1235 alumunium foil belongs to the 1xxx series of commercial purity aluminum, specifically engineered for converter foil applications where formability and barrier performance take precedence over structural strength.

The chemical composition adheres to strict limits that maximize rolling efficiency and surface quality.

| Elemen | Minimum | Maksimum | Functional Role in 9μm Foil |

|---|---|---|---|

| Aluminium (Al) | 99.35% | - - | Matrix providing ductility, daya pemantulan, dan ketahanan terhadap korosi |

| Silikon (Dan) | - - | 0.10% | Tight control ensures smooth rolling surface and minimizes inclusion defects |

| Besi (Fe) | - - | 0.60% | Provides slight strengthening; excessive levels increase pinhole risk |

| Tembaga (Cu) | - - | 0.05% | Kept minimal to preserve electrical conductivity and corrosion resistance |

| Mangan (M N) | - - | 0.05% | Trace element limited to prevent work hardening |

| Magnesium (Mg) | - - | 0.05% | Controlled to avoid surface oxidation issues |

| Seng (Zn) | - - | 0.10% | Impurity management for anodizing compatibility |

| Titanium (Dari) | - - | 0.03% | Grain refinement in cast ingots |

| Elemen Lainnya (Setiap) | - - | 0.03% | Aggregate impurity cap ensuring consistency |

| Elemen Lainnya (Total) | - - | 0.10% | Overall purity protection |

2.2 Microstructure and Temper

Itu 1235 alloy achieves its optimal properties through careful thermal processing.

Manufacturers produce 9-micron foil in two primary tempers, each serving distinct converting requirements:

O Temper (Lembut, Anil):

- Daya tarik: 60–90 MPa (8.7–13.0 ksi)

- Kekuatan Hasil: 20–35 MPa (2.9–5.1 ksi)

- Pemanjangan: 25–35% (A50mm gauge)

- Kekerasan: 20–25 HB

- Struktur mikro: Fully recrystallized equiaxed grains (ASTM 6–9) with minimal dislocation density

The O temper maximizes ductility for deep drawing, Melipat, and complex forming operations.

The 25–35% elongation enables 9-micron foil to conform to sharp creases in cigarette inner liners and sachet corners without cracking.

This temper also optimizes adhesive wet-out during lamination, as the soft surface conforms to microscopic surface irregularities in plastic films.

9-mikron 1235 alumunium foil H18

H18 Temper (Penuh Keras, Cold-Worked):

- Daya tarik: 110–150 MPa (16.0–21.8 ksi)

- Kekuatan Hasil: 100–130 MPa (14.5–18.9 ksi)

- Pemanjangan: 1–3%

- Kekerasan: 45–55 HB

- Struktur mikro: Elongated grains with high dislocation density from cold rolling

H18 temper provides handling stiffness for unwind operations and slit-edge stability.

Converters often specify H18 for foil that must traverse long web paths at high speed before lamination, as the increased rigidity reduces wrinkling and edge weaving.

The laminate structure subsequently provides flexibility in the finished product.

3. 9 Micrometer (m) Ketebalan: Opportunities and Challenges

3.1 Opportunities (Why pursue 9 mikrometer?)

- Ringan & material cost reduction. Moving from e.g., 12–15 µm down to 9 µm reduces aluminum mass by ~25–40%, lowering raw-material cost and package weight. (9 µm = 0.009 mm).

- Excellent barrier per unit mass. Even at 9 µm a continuous aluminum layer provides near-opaque light barrier and very low oxygen and moisture transmission when incorporated into a laminate; suppliers report OTR and WVTR figures that place such laminates in “high barrier” class for many food and pharmaceutical applications.

- Improved form-factor and aesthetics. Thin foil conforms to complex shapes (labels, lidding) with smaller step heights and less bulk.

3.2 Tantangan (Inherent weaknesses of 9 mikrometer)

- Mechanical fragility: reduced puncture resistance, higher sensitivity to handling, and increased risk of pinholes during rolling and lamination. Typical practical tensile/puncture performance must be validated for the stack and forming process.

- lubang kecil & defects control: process cleanliness and rolling/anneal schedules must be tightly controlled; pinhole density scales unfavorably with decreasing gauge.

- Adhesion and delamination risk: ultra-thin foil has less cohesive thickness for adhesives to “bite”; surface treatments or lacquers are often required to secure bond strength to polymers.

- Converting difficulty: menggorok, embossing, die-cutting and rewinding require specialized tension control, anti-static measures and skilled equipment operators.

4. Structure of 9-Micron 1235 Composite Aluminum Foil

4.1 Typical Composite Structures

The 9-micron 1235 foil rarely serves as standalone packaging. Alih-alih, it functions as the critical barrier layer within multi-material laminates that combine complementary properties.

Engineers design these structures to position each material where its properties deliver maximum value:

Struktur 1: PET/AL/PE (General-Purpose Food Packaging)

- PELIHARAAN (12–25μm): Exterior print carrier providing mechanical strength, stabilitas dimensi, and gloss

- Perekat (1.5–3.0 g/m²): Polyurethane two-component system creating chemical bond

- AL (9m): Core barrier layer blocking oxygen, kelembaban, dan cahaya

- Perekat (1.5–3.0 g/m²): Tie layer for polyethylene adhesion

- pe (40–80μm): Interior sealant providing heat-sealability, chemical resistance, and food contact compliance

Total thickness: ~65–120μm | Penghalang: OTR <0.1 cc/m²·day, WVTR <0.01 g/m²·hari

Struktur 2: Paper/AL/PE (Cigarette Inner Liner)

- Kertas (40–60 g/m²): Exterior providing dead-fold characteristics, kegelapan, and tactile quality

- AL (9m): Barrier against moisture and aroma loss

- pe (20–60μm): Heat-seal layer for pack closure

This structure leverages the “dead-fold” property of 1235-O foil—the ability to retain a crease without spring-back—essential for cigarette pack forming at 400+ packs/minute.

Struktur 3: BOPP/AL/CPP (Confectionery and Snacks)

- BOPP (20m): High-clarity exterior with excellent machinability

- AL (9m): Barrier and light protection

- CPP (40–70μm): Hot-tack sealant for high-speed form-fill-seal operations

The biaxially oriented polypropylene (BOPP) provides superior crack resistance compared to PET, while cast polypropylene (CPP) offers broader heat-seal windows for confectionery packaging.

Struktur 4: PA/AL/PE (Puncture-Resistant Pouches)

- PA (15m, Nylon): Exterior providing exceptional puncture and abrasion resistance

- AL (9m): Barrier layer

- pe (60–80μm): Sealant and structural bulk

This configuration suits vacuum-packed meats and cheeses where bone edges or sharp corners threaten package integrity.

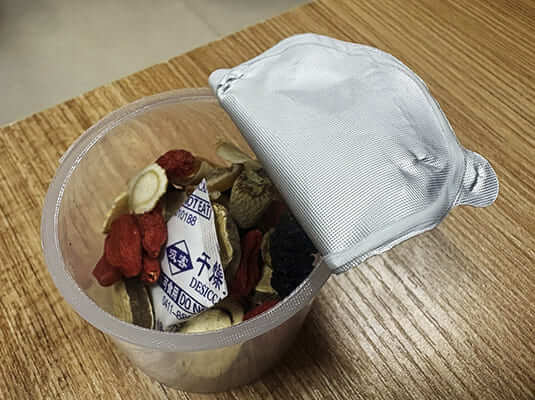

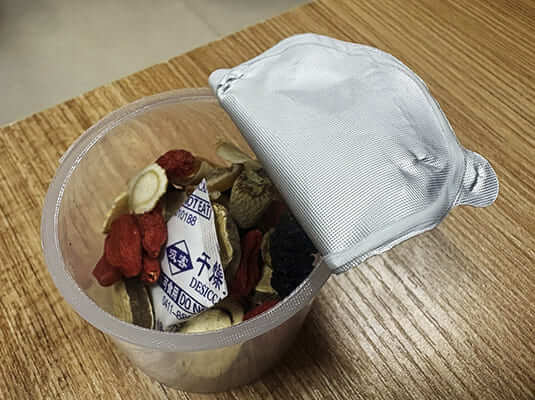

Tea packaging used 9-micron 1235 aluminium foil komposit

4.2 Why Composite for 9-Micron Aluminum Foil

Mechanical Protection:

The 9-micron foil cannot survive handling, pengiriman, or retail display as a single layer.

PELIHARAAN (tensile strength 200–300 MPa) or paper (stiffness 2–5 Nm/g) provide structural armor that prevents flex cracks and abrasion.

Integritas segel:

Aluminum lacks thermoplasticity—it cannot heat-seal. PE or CPP layers (melting point 110–135°C) create hermetic closures through impulse or hot-bar sealing.

Chemical Isolation:

Acidic or alkaline products (saus tomat, deterjen) corrode aluminum. PE and PP provide inert barriers preventing chemical attack.

Kemampuan cetak:

Aluminum accepts only limited printing technologies. PET and paper substrates enable high-resolution gravure or flexographic decoration.

Cost Optimization:

At $8–12/kg for aluminum foil versus $2–4/kg for PE, composite structures minimize aluminum usage to the absolute barrier requirement while leveraging cheaper polymers for bulk.

5. Manufacturing Process of 9-Micron 1235 Composite Aluminum Foil

Key steps and control points:

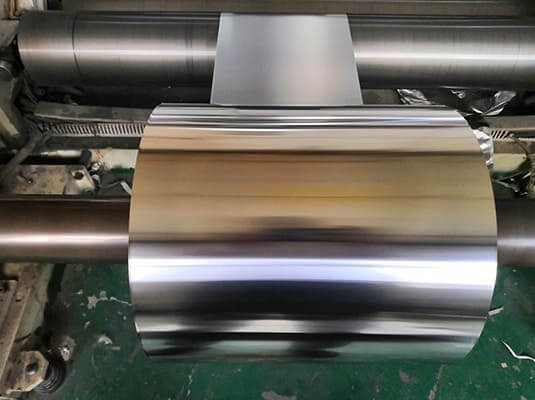

- Casting and hot rolling to produce coil stock.

- Cold rolling schedules with multiple passes to progressively reduce gauge toward foil thickness. Intermediate and final anneals are applied to restore ductility and control grain structure. Precise pass schedules and roll gap control are critical to reach a uniform 9 µm target without excessive edge-wave or thickness variation.

- Surface preparation and cleaning to remove rolling oils and particulates (important to minimize pinholes).

- Coating/lacquering (opsional) to provide printability and corrosion resistance prior to lamination.

- Laminasi (composite formation) — can be by solventless adhesive, laminasi ekstrusi (melt adhesive), or solvent/wet adhesives depending on stack and end-use. Proper adhesive selection, nip temperature and pressure are tuned to avoid foil wrinkles and to achieve peel strength targets.

- Slitting and rewinding with strict tension control and anti-static handling for 9 µm gauges.

- Quality inspection (pinhole detection, pemetaan ketebalan, surface inspection) and final packing.

Process control charts for foil production typically track gauge tolerance (misalnya, ±0.5 µm target for 9 mikron), pinhole counts per m², and laminate peel strength.

6. Applications of 9-Micron 1235 Composite Aluminum Foil

6.1 Kemasan Makanan Fleksibel

The 9-micron 1235 foil serves as the barrier backbone for dry goods packaging:

- Coffee and Tea: Aroma retention critical; 9μm foil with <40 pinholes/m² maintains freshness 12–18 months

- Snack Foods: PET/AL/PE structures provide light protection for photosensitive vitamins and flavors

- Powdered Beverages: WVTR <0.01 g/m²·day prevents caking and preserves solubility

High-speed form-fill-seal (FFS) lines operate at 200+ cycles/minute with 9-micron foil, validating its mechanical stability under rapid flexing.

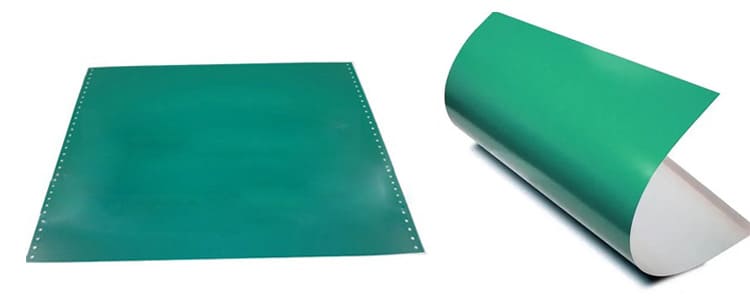

Sachet Strips For Medical Packaging

6.2 Pharmaceutical and Medical Packaging

Secondary overwraps for pharmaceuticals utilize 9-micron foil in:

- Sachet Strips: PET/AL/PE for unit-dose powders and granules

- Lidding Foil: 9μm 1235-O replaces thicker gauges for cost-sensitive OTC products

- Tropical Blister Alternatives: Non-PVC laminates for high-humidity markets

Migration testing per EU 10/2011 and FDA 21 CFR 177.1390 ensures compliance for indirect food contact.

6.3 Tobacco Packaging

Cigarette inner liners represent a major 9-micron application:

- Struktur: Kertas (40–60 g/m²)/AL (9m)/pe (20–30μm)

- Lipat Mati: 1235-O temper retains sharp creases without spring-back

- Penghalang Aroma: Prevents moisture loss and flavor cross-contamination

- Speed Compatibility: Runs at 400+ packs/minute on G.D. and Focke machines

6.4 Industrial and Technical Applications

Cable Wrap: Non-woven/AL/PE laminates provide electromagnetic interference (EMI) shielding with 9-micron foil delivering >60 dB attenuation at 1 GHz.

Membangun isolasi: Foil-faced radiant barriers utilize 9μm 1235 for cost-effective reflectivity (>88% solar reflectance).

Battery Pouch Films: Lamination with nylon and polypropylene creates containment for lithium-ion cells, with 9-micron foil providing moisture barrier and electrical isolation.

1235 aluminum foil for Cable Wrap

7. Comparative Alloy Analysis

Engineers selecting aluminum foil must evaluate alternatives to 1235. The following matrix compares key options for 9-micron applications:

| Atribut | 1235 | 8079 | 8011 | Selection Guidance |

|---|---|---|---|---|

| Kemurnian Aluminium | ≥99.35% | ≥99.0% | ~97.0% (Al-Fe-Si) | 1235 for highest purity; 8079 for pinhole-critical <7m |

| Daya tarik (Wahai amarah) | 60–90 MPa | 80–110 MPa | 80–120MPa | Higher strength in 8079/8011 for handling stiffness |

| Pemanjangan (Wahai amarah) | 25–35% | 15–25% | 15–25% | 1235 superior for deep drawing and folding |

| Dead-Fold Characteristics | Bagus sekali | Sangat bagus | Bagus | 1235 preferred for cigarette/tobacco |

| Pinhole Resistance at 9μm | Enhanced: ≤40/m² | Enhanced: ≤30/m² | Enhanced: ≤25/m² | 8079/8011 intermetallics improve rolling; 1235 requires tighter process control |

| Cost Position | $ (Terendah) | $$ | $$ | 1235 offers 10–15% cost advantage |

| Aplikasi Khas | Mainstream food, tembakau, general lamination | High-barrier pharma, abuse-resistant pouches | Penutup, tube laminates, heat-seal applications |

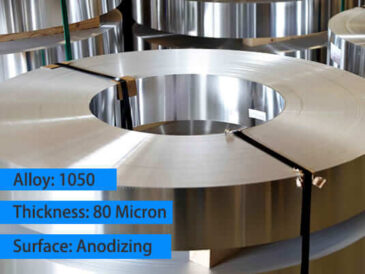

8. Huawei 9-Micron 1235 Composite Aluminum Foil Specification

(Representative supplier specification drawn from typical product pages — engineers should request a manufacturer-run Material Test Certificate and sample tests before approving for production.)

Supplier example: Henan Huawei Aluminium Co., Ltd (commercial supplier listing for “9-Micron 1235 Composite Aluminum Foil”). Reported or typical specification items include:

- Paduan: 1235 (O temper typical for lamination).

- Nominal aluminum thickness: 9 mikron (0.009 mm).

- Composite stacks offered: PET/AL(9)/pe; Paper/AL(9)/pe; BOPP/AL(9)/pe.

- Typical WVTR / OTR for laminated structures (supplier reported example): OTR < 0.1 (units depend on test method; usually cc/m²·day), WVTR < 0.01 (g/m²·hari) for finished laminate — confirm test method and units with supplier before quoting shelf life.

- Kepadatan lubang jarum: marketed as “low pinhole density” — suppliers commonly specify pinhole counts per m² or qualitative grades; ask for measured pinhole counts at acceptance.

- Melunakkan: HAI (anil) or light cold-work (as required).

- Lapisan: optional lacquer for printability; adhesive systems per laminate.

- Kemasan: jumbo rolls, typical widths 200–1,600 mm; coil ID/OD to buyer spec.

- Kontrol kualitas: thickness tolerance band (untuk 9 µm often specified ±0.5–1.0 µm depending on supplier), visual surface class, pinhole acceptance, MTC available on request.

Huawei Aluminum Foil Export Packaging

9. Kesimpulan

Itu 9-mikron 1235 aluminium foil komposit is a testament to the power of systems thinking in material science.

It is a highly optimized solution that acknowledges the limitations of a single material and overcomes them through intelligent combination.

By pairing the absolute barrier potential of an ultra-thin 1235 aluminum foil with the mechanical strength of polymer films, the packaging industry has created a material that is both high-performing and highly economical.

It is not the most robust barrier available, but for the vast majority of flexible packaging needs, it represents the perfect equilibrium of protection, biaya, dan efisiensi.

FAQ

1. If 9-micron foil has pinholes, is it still a “high barrier”?

Ya. In a composite structure, the barrier performance is not determined by the foil alone. The adhesive and polymer layers create a “tortuous path” that effectively seals the microscopic pinholes. The final laminate still provides an exceptionally low OTR and WVTR (misalnya, <0.5), which is firmly in the high-barrier category and far superior to any non-foil-based film.

2. Why not just use a thicker foil to avoid pinholes?

You can, but it comes with trade-offs. A thicker foil (misalnya, 12µm or 15µm) will have fewer pinholes and more strength, but it will be more expensive, heavier, and result in a stiffer final package, which may not be desirable. 9 microns is often the most cost-effective solution that meets the required barrier specifications for a huge range of products.

3. What is the difference between this and “Alu-Alu” foil?

“Alu-Alu” (bentuk dingin) foil is a much thicker, soft-temper aluminum foil (khas 45-60 mikron) laminated with OPA and PVC. It is designed to be plastically deformed (cold-formed) into a blister cavity, providing an absolute, 100% penghalang. 9-micron composite foil is a thin, flexible material used for flat pouches and bags; it cannot be formed into a deep cavity.

Proses produksi pengecoran dan pengenalannya

Tujuan peleburan dan pengecoran adalah untuk menghasilkan paduan dengan komposisi yang memuaskan dan kemurnian lelehan yang tinggi, sehingga menciptakan kondisi yang menguntungkan untuk pengecoran paduan berbagai bentuk.

Langkah-langkah proses peleburan dan pengecoran: pengelompokan --- makanan --- meleleh --- pengadukan setelah pencairan, penghapusan terak --- sampling pra-analisis --- menambahkan paduan untuk menyesuaikan komposisi, mengaduk --- pengilangan --- Pengaturan statis——Panduan pengecoran tungku.

Proses produksi hot rolling dan pengenalannya

- 1. Pengerolan panas umumnya mengacu pada penggulungan di atas suhu rekristalisasi logam;

- 2. Selama proses pengerolan panas, logam mengalami proses pengerasan dan pelunakan. Karena pengaruh kecepatan deformasi, selama proses pemulihan dan rekristalisasi terlambat, akan ada pengerasan kerja tertentu;

- 3. Rekristalisasi logam setelah pengerolan panas tidak lengkap, itu adalah, koeksistensi struktur rekristalisasi dan struktur terdeformasi;

- 4. Rolling panas dapat meningkatkan kinerja pemrosesan logam dan paduan, mengurangi atau menghilangkan cacat pengecoran.

- 1. Temperatur casting dan rolling umumnya antara 680°C dan 700°C. Semakin rendah semakin baik, jalur casting dan rolling yang stabil biasanya berhenti sebulan sekali atau lebih untuk berdiri kembali. Selama proses produksi, tingkat cairan tangki depan harus dikontrol secara ketat untuk mencegah tingkat cairan rendah;

- 2. Pelumasan menggunakan bubuk C dengan pembakaran gas yang tidak sempurna untuk pelumasan, yang juga menjadi salah satu penyebab kotornya permukaan material casting dan rolling;

- 3. Kecepatan produksi umumnya antara 1,5m/min-2,5m/min;

- 4. Kualitas permukaan produk yang dihasilkan oleh casting dan rolling umumnya relatif rendah, dan umumnya tidak dapat memenuhi produk dengan persyaratan kinerja fisik dan kimia khusus.

- 1. Cold rolling mengacu pada metode produksi rolling di bawah suhu rekristalisasi;

- 2. Tidak akan ada rekristalisasi dinamis selama proses rolling, dan suhu akan naik ke suhu pemulihan paling banyak, dan penggulungan dingin akan muncul dalam kondisi pengerasan kerja, dan tingkat pengerasan kerja akan besar;

- 3. Lembaran dan strip cold-rolled memiliki akurasi dimensi yang tinggi, kualitas permukaan yang baik, struktur dan kinerja yang seragam, dan produk di berbagai negara dapat diperoleh dengan perlakuan panas;

- 4. Penggulungan dingin dapat menggulung strip tipis, tapi diwaktu yang sama, itu memiliki kerugian konsumsi energi yang tinggi untuk deformasi dan banyak proses yang lewat.

- 1. Finishing adalah metode pemrosesan untuk membuat lembaran cold-rolled memenuhi kebutuhan pelanggan, atau untuk memfasilitasi pemrosesan produk selanjutnya;

- 2. Peralatan finishing dapat memperbaiki cacat yang dihasilkan dalam proses produksi hot rolling dan cold rolling, seperti tepi retak, berminyak, bentuk piring yang buruk, tegangan sisa, dll.. Perlu dipastikan bahwa tidak ada cacat lain yang dibawa ke dalam proses produksi;

- 3. Ada berbagai peralatan finishing, terutama termasuk lintas sektoral, menggorok, peregangan dan pelurusan, tungku anil, meluncur, dll..

Proses pengecoran dan rolling

Proses pengecoran dan rolling: logam cair, kotak depan (kontrol level cairan), pengecoran dan mesin rolling (Sistem pelumasan, air pendingin), mesin pencukur, mesin melingkar.

Proses produksi cold rolling

Pengantar untuk menyelesaikan proses produksi

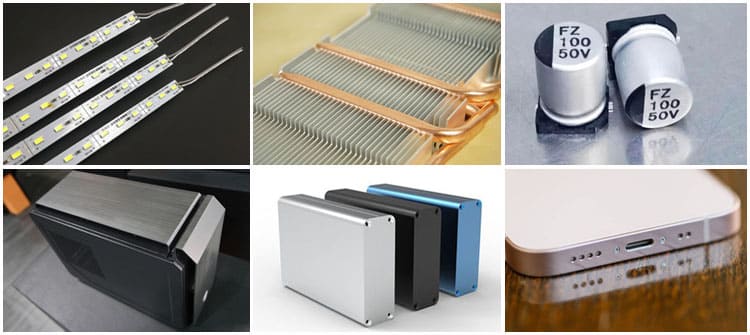

Paduan aluminium memiliki karakteristik kepadatan rendah, sifat mekanik yang baik, kinerja pemrosesan yang baik, tidak beracun, mudah untuk didaur ulang, konduktivitas listrik yang sangat baik, perpindahan panas dan ketahanan korosi, sehingga memiliki berbagai macam aplikasi.

Dirgantara: digunakan untuk membuat kulit pesawat, rangka badan pesawat, balok penopang, rotor, baling-baling, tangki bahan bakar, panel dinding dan penyangga roda pendaratan, serta cincin penempaan roket, panel dinding pesawat ruang angkasa, dll..

Paduan aluminium digunakan untuk ruang angkasa

Angkutan: digunakan untuk bahan struktur bodi mobil mobil, kendaraan kereta bawah tanah, mobil penumpang kereta api, mobil penumpang berkecepatan tinggi, pintu dan jendela, rak, suku cadang mesin otomotif, AC, radiator, panel bodi, roda dan material kapal.

Aplikasi lalu lintas

Kemasan: Kaleng pop all-aluminium terutama digunakan sebagai bahan kemasan logam dalam bentuk pelat tipis dan foil, dan dibuat menjadi kaleng, tutup, botol, barel, dan foil kemasan. Banyak digunakan dalam kemasan minuman, makanan, kosmetik, obat, rokok, produk industri, obat, dll..

Aplikasi pengemasan

Pencetakan: Terutama digunakan untuk membuat pelat PS, Pelat PS berbasis aluminium adalah jenis material baru dalam industri percetakan, digunakan untuk pembuatan dan pencetakan pelat otomatis.

pencetakan PS

Dekorasi arsitektur: paduan aluminium banyak digunakan dalam struktur bangunan, pintu dan jendela, plafon gantung, permukaan dekoratif, dll.. karena ketahanan korosinya yang baik, kekuatan yang cukup, kinerja proses yang sangat baik dan kinerja pengelasan.

Aplikasi konstruksi paduan aluminium

Produk elektronik: komputer, ponsel, cangkang kulkas, radiator, dll..

aplikasi produk elektronik

Persediaan dapur: pot aluminium, baskom aluminium, lapisan penanak nasi, aluminium foil rumah tangga, dll..

Aplikasi dapur

Pengemasan Aluminium Sheet/Coil

Setiap detail kemasan adalah tempat kami mengejar pelayanan yang sempurna. Proses pengemasan kami secara keseluruhan adalah sebagai berikut:

Laminasi: film bening, film biru, mikro-mukosa, mukosa tinggi, film pemotongan laser (2 merek, Novacell dan Polyphem);

Perlindungan: pelindung sudut kertas, bantalan anti-tekanan;

pengeringan: pengering;

Baki: nampan kayu yang tidak berbahaya difumigasi, nampan besi yang dapat digunakan kembali;

Sedang mengemas: Sabuk baja tic-tac-toe, atau sabuk pengepakan PVC;

Kualitas Bahan: Benar-benar bebas dari cacat seperti karat putih, noda minyak, tanda bergulir, kerusakan tepi, tikungan, penyok, lubang, garis putus-putus, goresan, dll., tidak ada set kumparan.

Pelabuhan: Qingdao atau pelabuhan lain di Cina.

Waktu memimpin: 15-45 hari.

Proses pengemasan lembaran/pelat aluminium

Proses pengemasan koil aluminium

F: Apakah Anda produsen atau pedagang?

Q: Kami adalah produsen, pabrik kami berada di No.3 Weier Road, Zona industri, Gongyi, Henan, Cina.

F: Apa MOQ untuk memesan produk?

Q: MOQ kami adalah 5 ton, dan beberapa produk khusus akan memiliki jumlah pesanan minimum 1 atau 2 ton.

F: Berapa lama waktu tunggu Anda?

Q: Umumnya lead time kami adalah tentang 30 hari.

F: Apakah produk Anda memiliki jaminan kualitas?

Q: Ya, jika ada masalah kualitas dengan produk kami, kami akan memberi kompensasi kepada pelanggan sampai mereka puas.

Produk-produk terkait

Blog Terbaru

Lembar cermin aluminium reflektifitas ultra-tinggi

Lembaran cermin aluminium dengan reflektifitas sangat tinggi dengan reflektansi tampak 95–98%., sebaran rendah (ini <1%), dan saran spesifikasi untuk BRDF, kurva spektral dan lapisan.

Tepercaya 3003 Pemasok Lembar Plat Pemeriksa Aluminium Di Seluruh Dunia

Temukan yang dapat diandalkan 3003 Pemasok Lembar Plat Aluminium Checker menawarkan kualitas bersertifikat, harga yang kompetitif, ukuran khusus, dan pengiriman global yang cepat untuk proyek Anda.

6061 T6 vs 7075 Aluminium: Kekuatan, Berat & Penggunaan Terbaik

Membandingkan 6061 T6 vs 7075 aluminium dengan mudah. Temukan perbedaan kekuatan, berat, dan aplikasi untuk memilih yang terbaik untuk proyek Anda.

Industrialisasi dan Penerapan Honeycomb Aluminium Foil

Blog ini mengeksplorasi industrialisasi aluminium foil sarang lebah, berfokus pada 3003 proses produksi paduan. Ini mencakup pengerolan panas, pengecoran terus menerus, dan metode pengecoran-penggulungan kontinyu, menyoroti manfaat optimasi proses dalam meningkatkan sifat mekanik, mengurangi konsumsi energi, dan menurunkan biaya produksi.