1. Panimula

9-mikron 1235 composite aluminum foil is a highly specialized, multi-layer material that serves as a cornerstone of the modern flexible packaging industry.

This material system is engineered to provide a high-performance barrier at an optimal cost and weight. Its core is an ultra-thin, 9M (0.009mm) foil made from 1235 aluminyo haluang metal, isang mataas na kadalisayan (≥99.35% Al) grade prized for its exceptional softness and workability.

While the 9-micron foil itself provides a near-perfect barrier to light, mga gas, at kahalumigmigan, its thinness makes it mechanically fragile and susceptible to pinholes.

These weaknesses are overcome by laminating it with other polymer films (such as PET, BOPP, and PE). The resulting composite structure leverages the absolute barrier of the aluminum core while gaining the strength, kakayahang i-print, and sealability of the polymer layers.

This makes 9-micron 1235 composite foil the go-to solution for a vast range of applications, kasama na ang food packaging (snacks, kape na kape, gatas pulbos) and pharmaceutical sachets, where a high barrier, magaan ang timbang, and cost-effectiveness are all critical requirements.

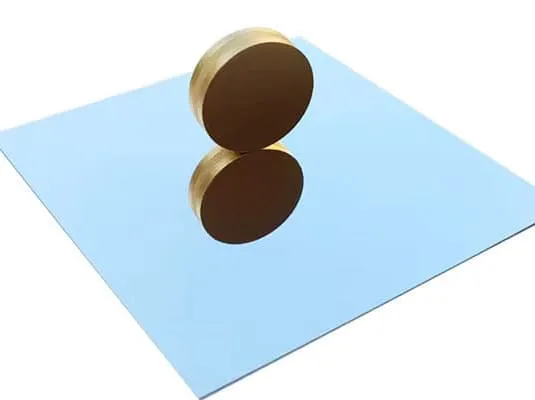

9-mikron 1235 composite aluminum foil

2. Pag-unawa 1235 aluminyo haluang metal

2.1 Komposisyon ng Kemikal

Ang 1235 aluminyo foil belongs to the 1xxx series of commercial purity aluminum, specifically engineered for converter foil applications where formability and barrier performance take precedence over structural strength.

The chemical composition adheres to strict limits that maximize rolling efficiency and surface quality.

| Elemento | Minimum | Maximum na | Functional Role in 9μm Foil |

|---|---|---|---|

| Aluminyo (Al) | 99.35% | — | Matrix providing ductility, Reflectivity, at paglaban sa kaagnasan |

| Silicon (Si Si) | — | 0.10% | Tight control ensures smooth rolling surface and minimizes inclusion defects |

| bakal na bakal (Fe) | — | 0.60% | Provides slight strengthening; excessive levels increase pinhole risk |

| Tanso (Cu) | — | 0.05% | Kept minimal to preserve electrical conductivity and corrosion resistance |

| Mga mangganeso (Mn) | — | 0.05% | Trace element limited to prevent work hardening |

| Magnesium (Mg) | — | 0.05% | Controlled to avoid surface oxidation issues |

| Sink (Zn) | — | 0.10% | Impurity management for anodizing compatibility |

| Titanium (Ti) | — | 0.03% | Grain refinement in cast ingots |

| Iba pang mga Elemento (Ang bawat isa) | — | 0.03% | Aggregate impurity cap ensuring consistency |

| Iba pang mga Elemento (Kabuuang) | — | 0.10% | Overall purity protection |

2.2 Microstructure and Temper

Ang 1235 alloy achieves its optimal properties through careful thermal processing.

Manufacturers produce 9-micron foil in two primary tempers, each serving distinct converting requirements:

O Temper (Malambot na, Annealed na ang mga):

- Lakas ng Paghatak: 60–90 MPa (8.7–13.0 ksi)

- Yield Lakas: 20–35 MPa (2.9–5.1 ksi)

- Pagpapahaba: 25–35% (A50mm gauge)

- Ang katigasan ng ulo: 20–25 HB

- Microstructure: Fully recrystallized equiaxed grains (ASTM 6–9) with minimal dislocation density

The O temper maximizes ductility for deep drawing, pagtitiklop, and complex forming operations.

The 25–35% elongation enables 9-micron foil to conform to sharp creases in cigarette inner liners and sachet corners without cracking.

This temper also optimizes adhesive wet-out during lamination, as the soft surface conforms to microscopic surface irregularities in plastic films.

9-mikron 1235 H18 aluminyo foil

H18 Temper (Full Hard, Cold-Worked):

- Lakas ng Paghatak: 110–150 MPa (16.0–21.8 ksi)

- Yield Lakas: 100–130 MPa (14.5–18.9 ksi)

- Pagpapahaba: 1–3%

- Ang katigasan ng ulo: 45–55 HB

- Microstructure: Elongated grains with high dislocation density from cold rolling

H18 temper provides handling stiffness for unwind operations and slit-edge stability.

Converters often specify H18 for foil that must traverse long web paths at high speed before lamination, as the increased rigidity reduces wrinkling and edge weaving.

The laminate structure subsequently provides flexibility in the finished product.

3. 9 Micrometer (M) Ang kapal: Opportunities and Challenges

3.1 Opportunities (Why pursue 9 micrometers?)

- Lightweighting & material cost reduction. Moving from e.g., 12–15 µm down to 9 µm reduces aluminum mass by ~25–40%, lowering raw-material cost and package weight. (9 µm = 0.009 mm).

- Excellent barrier per unit mass. Even at 9 µm a continuous aluminum layer provides near-opaque light barrier and very low oxygen and moisture transmission when incorporated into a laminate; suppliers report OTR and WVTR figures that place such laminates in “high barrier” class for many food and pharmaceutical applications.

- Improved form-factor and aesthetics. Thin foil conforms to complex shapes (labels, lidding) with smaller step heights and less bulk.

3.2 Mga Hamon (Inherent weaknesses of 9 micrometers)

- Mechanical fragility: reduced puncture resistance, higher sensitivity to handling, and increased risk of pinholes during rolling and lamination. Typical practical tensile/puncture performance must be validated for the stack and forming process.

- Pinholes & defects control: process cleanliness and rolling/anneal schedules must be tightly controlled; pinhole density scales unfavorably with decreasing gauge.

- Adhesion and delamination risk: ultra-thin foil has less cohesive thickness for adhesives to “bite”; surface treatments or lacquers are often required to secure bond strength to polymers.

- Converting difficulty: pagputol ng hiwa, embossing, die-cutting and rewinding require specialized tension control, anti-static measures and skilled equipment operators.

4. Structure of 9-Micron 1235 Composite Aluminum Foil

4.1 Typical Composite Structures

The 9-micron 1235 foil rarely serves as standalone packaging. Instead, it functions as the critical barrier layer within multi-material laminates that combine complementary properties.

Engineers design these structures to position each material where its properties deliver maximum value:

Structure 1: PET/AL/PE (General-Purpose Food Packaging)

- Mga Alagang Hayop (12–25μm): Exterior print carrier providing mechanical strength, dimensional stability, and gloss

- Pandikit (1.5–3.0 g/m²): Polyurethane two-component system creating chemical bond

- AL (9M): Core barrier layer blocking oxygen, kahalumigmigan, at liwanag

- Pandikit (1.5–3.0 g/m²): Tie layer for polyethylene adhesion

- PE (40–80μm): Interior sealant providing heat-sealability, chemical resistance, and food contact compliance

Total thickness: ~65–120μm | Barrier: OTR <0.1 cc/m²·day, WVTR <0.01 g/m²·day

Structure 2: Paper/AL/PE (Cigarette Inner Liner)

- Paper (40–60 g/m²): Exterior providing dead-fold characteristics, opacity, and tactile quality

- AL (9M): Barrier against moisture and aroma loss

- PE (20–60μm): Heat-seal layer for pack closure

This structure leverages the “dead-fold” property of 1235-O foil—the ability to retain a crease without spring-back—essential for cigarette pack forming at 400+ packs/minute.

Structure 3: BOPP/AL/CPP (Confectionery and Snacks)

- BOPP (20M): High-clarity exterior with excellent machinability

- AL (9M): Barrier and light protection

- CPP (40–70μm): Hot-tack sealant for high-speed form-fill-seal operations

The biaxially oriented polypropylene (BOPP) provides superior crack resistance compared to PET, while cast polypropylene (CPP) offers broader heat-seal windows for confectionery packaging.

Structure 4: PA/AL/PE (Puncture-Resistant Pouches)

- PA (15M, Nylon): Exterior providing exceptional puncture and abrasion resistance

- AL (9M): Barrier layer

- PE (60–80μm): Sealant and structural bulk

This configuration suits vacuum-packed meats and cheeses where bone edges or sharp corners threaten package integrity.

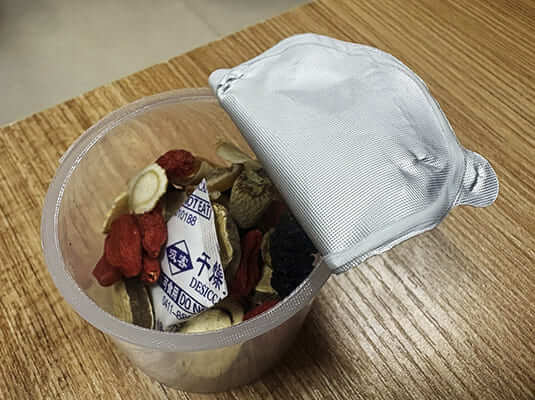

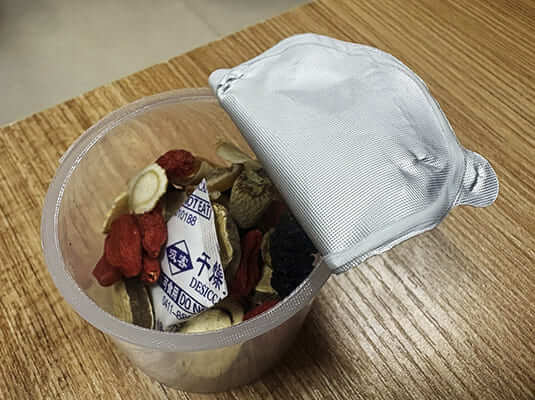

Tea packaging used 9-micron 1235 composite aluminum foil

4.2 Why Composite for 9-Micron Aluminum Foil

Mechanical Protection:

The 9-micron foil cannot survive handling, pagpapadala, or retail display as a single layer.

Mga Alagang Hayop (tensile strength 200–300 MPa) or paper (stiffness 2–5 Nm/g) provide structural armor that prevents flex cracks and abrasion.

Integridad ng Seal:

Aluminum lacks thermoplasticity—it cannot heat-seal. PE or CPP layers (melting point 110–135°C) create hermetic closures through impulse or hot-bar sealing.

Chemical Isolation:

Acidic or alkaline products (tomato sauce, detergents) corrode aluminum. PE and PP provide inert barriers preventing chemical attack.

Printability:

Aluminum accepts only limited printing technologies. PET and paper substrates enable high-resolution gravure or flexographic decoration.

Cost Optimization:

At $8–12/kg for aluminum foil versus $2–4/kg for PE, composite structures minimize aluminum usage to the absolute barrier requirement while leveraging cheaper polymers for bulk.

5. Manufacturing Process of 9-Micron 1235 Composite Aluminum Foil

Key steps and control points:

- Casting and hot rolling to produce coil stock.

- Cold rolling schedules with multiple passes to progressively reduce gauge toward foil thickness. Intermediate and final anneals are applied to restore ductility and control grain structure. Precise pass schedules and roll gap control are critical to reach a uniform 9 µm target without excessive edge-wave or thickness variation.

- Surface preparation and cleaning to remove rolling oils and particulates (important to minimize pinholes).

- Coating/lacquering (opsyonal na) to provide printability and corrosion resistance prior to lamination.

- Paglalamina (composite formation) — can be by solventless adhesive, extrusion lamination (melt adhesive), or solvent/wet adhesives depending on stack and end-use. Proper adhesive selection, nip temperature and pressure are tuned to avoid foil wrinkles and to achieve peel strength targets.

- Slitting and rewinding with strict tension control and anti-static handling for 9 µm gauges.

- Quality inspection (pinhole detection, thickness mapping, surface inspection) and final packing.

Process control charts for foil production typically track gauge tolerance (hal., ±0.5 µm target for 9 M), pinhole counts per m², and laminate peel strength.

6. Applications of 9-Micron 1235 Composite Aluminum Foil

6.1 Flexible Food Packaging

The 9-micron 1235 foil serves as the barrier backbone for dry goods packaging:

- Coffee and Tea: Aroma retention critical; 9μm foil with <40 pinholes/m² maintains freshness 12–18 months

- Snack Foods: PET/AL/PE structures provide light protection for photosensitive vitamins and flavors

- Powdered Beverages: WVTR <0.01 g/m²·day prevents caking and preserves solubility

High-speed form-fill-seal (FFS) lines operate at 200+ cycles/minute with 9-micron foil, validating its mechanical stability under rapid flexing.

Sachet Strips For Medical Packaging

6.2 Pharmaceutical and Medical Packaging

Secondary overwraps for pharmaceuticals utilize 9-micron foil in:

- Sachet Strips: PET/AL/PE for unit-dose powders and granules

- Lidding Foil: 9μm 1235-O replaces thicker gauges for cost-sensitive OTC products

- Tropical Blister Alternatives: Non-PVC laminates for high-humidity markets

Migration testing per EU 10/2011 and FDA 21 CFR 177.1390 ensures compliance for indirect food contact.

6.3 Tobacco Packaging

Cigarette inner liners represent a major 9-micron application:

- Structure: Paper (40–60 g/m²)/AL (9M)/PE (20–30μm)

- Dead-Fold: 1235-O temper retains sharp creases without spring-back

- Aroma Barrier: Prevents moisture loss and flavor cross-contamination

- Speed Compatibility: Runs at 400+ packs/minute on G.D. and Focke machines

6.4 Industrial and Technical Applications

Cable Wrap: Non-woven/AL/PE laminates provide electromagnetic interference (EMI) shielding with 9-micron foil delivering >60 dB attenuation at 1 GHz.

Building Insulation: Foil-faced radiant barriers utilize 9μm 1235 for cost-effective reflectivity (>88% solar reflectance).

Battery Pouch Films: Lamination with nylon and polypropylene creates containment for lithium-ion cells, with 9-micron foil providing moisture barrier and electrical isolation.

1235 aluminum foil for Cable Wrap

7. Comparative Alloy Analysis

Engineers selecting aluminum foil must evaluate alternatives to 1235. The following matrix compares key options for 9-micron applications:

| Attribute | 1235 | 8079 | 8011 | Selection Guidance |

|---|---|---|---|---|

| Kadalisayan ng Aluminum | ≥99.35% | ≥99.0% | ~97.0% (Al-Fe-Si) | 1235 for highest purity; 8079 for pinhole-critical <7M |

| Lakas ng Paghatak (O kahinahunan) | 60–90 MPa | 80–110 MPa | 80–120 MPa | Higher strength in 8079/8011 for handling stiffness |

| Pagpapahaba (O kahinahunan) | 25–35% | 15–25% | 15–25% | 1235 superior for deep drawing and folding |

| Dead-Fold Characteristics | Napakahusay | Napakaganda | Mabuti na lang | 1235 preferred for cigarette/tobacco |

| Pinhole Resistance at 9μm | Enhanced: ≤40/m² | Enhanced: ≤30/m² | Enhanced: ≤25/m² | 8079/8011 intermetallics improve rolling; 1235 requires tighter process control |

| Cost Position | $ (Lowest) | $$ | $$ | 1235 offers 10–15% cost advantage |

| Mga Karaniwang Aplikasyon | Mainstream food, tabako, general lamination | High-barrier pharma, abuse-resistant pouches | Lidding, tube laminates, heat-seal applications |

8. Huawei 9-Micron 1235 Composite Aluminum Foil Specification

(Representative supplier specification drawn from typical product pages — engineers should request a manufacturer-run Material Test Certificate and sample tests before approving for production.)

Supplier example: Henan Huawei Aluminyo Co., Ltd (commercial supplier listing for “9-Micron 1235 Composite Aluminum Foil”). Reported or typical specification items include:

- haluang metal: 1235 (O temper typical for lamination).

- Nominal aluminum thickness: 9 M (0.009 mm).

- Composite stacks offered: PET/AL(9)/PE; Paper/AL(9)/PE; BOPP/AL(9)/PE.

- Typical WVTR / OTR for laminated structures (supplier reported example): OTR < 0.1 (units depend on test method; usually cc/m²·day), WVTR < 0.01 (g/m²·day) for finished laminate — confirm test method and units with supplier before quoting shelf life.

- Pinhole density: marketed as “low pinhole density” — suppliers commonly specify pinhole counts per m² or qualitative grades; ask for measured pinhole counts at acceptance.

- Temper: O (annealed na nga ba) or light cold-work (as required).

- Patong na patong: optional lacquer for printability; adhesive systems per laminate.

- Pakete: jumbo rolls, typical widths 200–1,600 mm; coil ID/OD to buyer spec.

- Kontrol sa kalidad: thickness tolerance band (for 9 µm often specified ±0.5–1.0 µm depending on supplier), visual surface class, pinhole acceptance, MTC available on request.

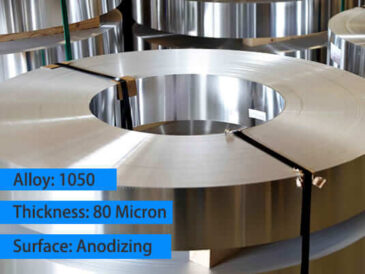

Huawei Aluminum Foil Export Packaging

9. Pangwakas na Salita

Ang 9-mikron 1235 composite aluminum foil is a testament to the power of systems thinking in material science.

It is a highly optimized solution that acknowledges the limitations of a single material and overcomes them through intelligent combination.

By pairing the absolute barrier potential of an ultra-thin 1235 aluminum foil with the mechanical strength of polymer films, the packaging industry has created a material that is both high-performing and highly economical.

It is not the most robust barrier available, but for the vast majority of flexible packaging needs, it represents the perfect equilibrium of protection, cost, at kahusayan.

Mga FAQ

1. If 9-micron foil has pinholes, is it still a “high barrier”?

Oo nga. In a composite structure, the barrier performance is not determined by the foil alone. The adhesive and polymer layers create a “tortuous path” that effectively seals the microscopic pinholes. The final laminate still provides an exceptionally low OTR and WVTR (hal., <0.5), which is firmly in the high-barrier category and far superior to any non-foil-based film.

2. Why not just use a thicker foil to avoid pinholes?

You can, but it comes with trade-offs. A thicker foil (hal., 12µm or 15µm) will have fewer pinholes and more strength, but it will be more expensive, heavier, and result in a stiffer final package, which may not be desirable. 9 microns is often the most cost-effective solution that meets the required barrier specifications for a huge range of products.

3. What is the difference between this and “Alu-Alu” foil?

“Alu-Alu” (cold form) foil is a much thicker, soft-temper aluminum foil (Karaniwan 45-60 mga micron) laminated with OPA and PVC. It is designed to be plastically deformed (cold-formed) into a blister cavity, providing an absolute, 100% barrier. 9-micron composite foil is a thin, flexible material used for flat pouches and bags; it cannot be formed into a deep cavity.

Proseso ng paghahagis ng produksyon at ang pagpapakilala nito

Ang layunin ng pagtunaw at paghahagis ay upang makabuo ng mga haluang metal na may kasiya siyang komposisyon at mataas na kadalisayan ng matunaw, upang lumikha ng mga kanais nais na kondisyon para sa paghahagis ng mga haluang metal ng iba't ibang mga hugis.

Mga hakbang sa proseso ng pagtunaw at paghahagis: mga ka batch --- pagpapakain --- natutunaw na --- pagpapakilos pagkatapos matunaw, pag alis ng slag --- sampling bago ang pagsusuri --- pagdaragdag ng haluang metal upang ayusin ang komposisyon, nakakapukaw ng damdamin --- pagpipino --- static na Setting——Guide furnace casting.

Mainit na proseso ng produksyon ng pagulong at ang pagpapakilala nito

- 1. Mainit na pagulong sa pangkalahatan ay tumutukoy sa paggulong sa itaas ng metal recrystallization temperatura;

- 2. Sa panahon ng mainit na proseso ng pagulong, ang metal ay may parehong mga proseso ng pagpapatigas at paglambot. Dahil sa impluwensya ng bilis ng pagpapapangit, basta huli na ang recovery at recrystallization process, magkakaroon ng tiyak na gawaing pagpapatigas;

- 3. Ang recrystallization ng metal pagkatapos ng mainit na pagulong ay hindi kumpleto, na ang ibig sabihin ay, ang magkakasamang buhay ng recrystallized istraktura at deformed istraktura;

- 4. Ang mainit na pagulong ay maaaring mapabuti ang pagganap ng pagproseso ng mga metal at haluang metal, bawasan o alisin ang mga depekto sa paghahagis.

- 1. Ang temperatura ng paghahagis at pagulong ay karaniwang nasa pagitan ng 680 o C at 700 o C. Ang mas mababa ang mas mahusay na, Ang matatag na paghahagis at rolling line ay karaniwang tumitigil nang isang beses sa isang buwan o higit pa upang muling tumayo. Sa panahon ng proseso ng produksyon, kinakailangang mahigpit na kontrolin ang antas ng likido ng front tank upang maiwasan ang mababang antas ng likido;

- 2. Ang pagpapadulas ay gumagamit ng C powder na may hindi kumpletong pagkasunog ng gas para sa pagpapadulas, na isa rin sa mga dahilan ng maruming ibabaw ng casting at rolling materials;

- 3. Ang bilis ng produksyon ay karaniwang sa pagitan ng 1.5m / min-2.5m / min;

- 4. Ang kalidad ng ibabaw ng mga produkto na ginawa sa pamamagitan ng paghahagis at paggulong ay karaniwang medyo mababa, at sa pangkalahatan ay hindi maaaring matugunan ang mga produkto na may espesyal na pisikal at kemikal na mga kinakailangan sa pagganap.

- 1. Ang malamig na pagulong ay tumutukoy sa paraan ng paggulong ng produksyon sa ibaba ng temperatura ng recrystallization;

- 2. Hindi magkakaroon ng dynamic na recrystallization sa panahon ng proseso ng paggulong, at ang temperatura ay tataas sa temperatura ng pagbawi sa karamihan, at ang malamig na paggulong ay lilitaw sa isang trabaho hardening estado, at ang trabaho hardening rate ay magiging malaki;

- 3. Ang malamig na ginulong sheet at strip ay may mataas na dimensional na katumpakan, magandang kalidad ng ibabaw, unipormeng istraktura at pagganap, at mga produkto sa iba't ibang estado ay maaaring makuha sa heat treatment;

- 4. Malamig na pagulong ay maaaring i roll out manipis na strips, pero sabay sabay, ito ay may mga disadvantages ng mataas na pagkonsumo ng enerhiya para sa pagpapapangit at maraming mga pasa sa pagproseso.

- 1. Ang pagtatapos ay isang paraan ng pagproseso upang matugunan ng malamig na ginulong sheet ang mga kinakailangan ng customer, o upang mapadali ang kasunod na pagproseso ng produkto;

- 2. Ang mga kagamitan sa pagtatapos ay maaaring iwasto ang mga depekto na ginawa sa mainit na pagulong at malamig na proseso ng produksyon, tulad ng basag na gilid, may langis na, mahina ang hugis ng plato, natitirang stress, atbp. Kailangan nitong tiyakin na walang iba pang mga depekto na dinala sa proseso ng produksyon;

- 3. Mayroong iba't ibang mga kagamitan sa pagtatapos, pangunahin kabilang ang cross-cutting, pagputol ng hiwa, pag unat at pagtutuwid, annealing furnace, mga slitter, atbp.

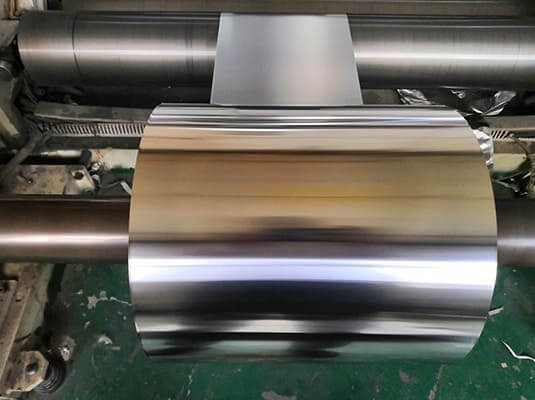

Proseso ng paghahagis at paggulong

Proseso ng paghahagis at paggulong: likidong metal, kahon sa harap (Kontrol sa antas ng likido), paghahagis at rolling machine (sistema ng pagpapadulas, paglamig ng tubig), paggupit ng makina, makina ng pag coiling.

Malamig na proseso ng produksyon ng pagulong

Panimula sa pagtatapos ng proseso ng produksyon

Aluminyo haluang metal ay may mga katangian ng mababang density, magandang mekanikal na katangian, magandang pagganap ng pagproseso, di nakakalason, madaling i recycle, mahusay na electrical kondaktibiti, paglipat ng init at paglaban sa kaagnasan, kaya ito ay may malawak na hanay ng mga application.

Aerospace: ginagamit upang gumawa ng mga balat ng sasakyang panghimpapawid, mga frame ng fuselage, mga girder, mga rotors, mga propeller, mga tangke ng gasolina, mga panel ng pader at mga struts ng landing gear, pati na rin ang rocket forging rings, mga panel ng pader ng spacecraft, atbp.

Aluminyo haluang metal na ginagamit para sa aerospace

Transportasyon: ginagamit para sa kotse katawan istraktura materyales ng mga sasakyan, Mga Sasakyan ng Subway, mga kotse ng pasahero ng tren, mabilis na mga kotse ng pasahero, mga pinto at bintana, mga istante, mga bahagi ng automotive engine, mga aircon, mga radiator, mga panel ng katawan, mga gulong at mga materyales ng barko.

Application ng trapiko

Packaging: Ang lahat ng aluminyo pop lata ay pangunahing ginagamit bilang mga materyales sa packaging ng metal sa anyo ng mga manipis na plato at foils, at ginagawang lata, mga takip, mga bote, mga bariles, at packaging foils. Malawakang ginagamit sa packaging ng mga inumin, pagkain, mga pampaganda, mga gamot, mga sigarilyo, mga produktong pang industriya, mga gamot, atbp.

Application ng packaging

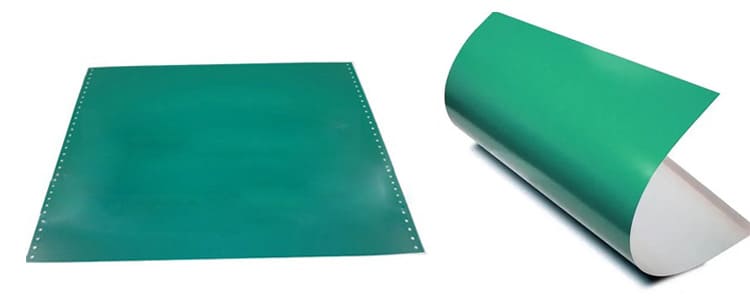

Pag-print: Pangunahing ginagamit upang gumawa ng PS plates, ang mga PS plate na nakabase sa aluminyo ay isang bagong uri ng materyal sa industriya ng pag print, ginagamit para sa awtomatikong paggawa ng plato at pag print.

Pag print ng PS

Dekorasyon ng arkitektura: aluminyo haluang metal ay malawakang ginagamit sa mga istraktura ng gusali, mga pinto at bintana, suspendido ang mga kisame, pandekorasyon na ibabaw, atbp. dahil sa magandang kaagnasan nito paglaban, sapat na lakas, mahusay na pagganap ng proseso at pagganap ng hinang.

Application ng konstruksiyon ng haluang metal ng aluminyo

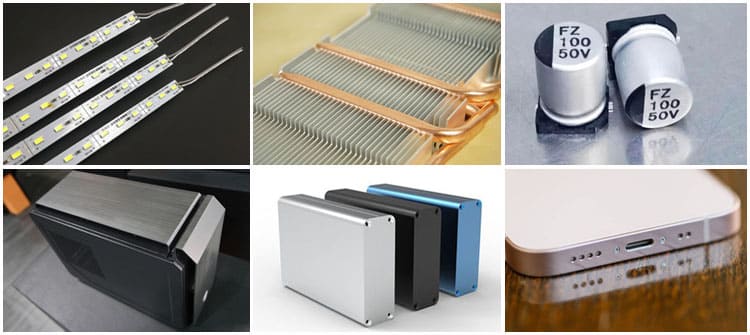

Mga produktong elektroniko: mga computer, mga mobile phone, mga shell ng refrigerator, mga radiator, atbp.

Electronic application ng produkto

Mga gamit sa kusina: mga kaldero ng aluminyo, aluminyo basins, mga liner ng rice cooker, sambahayan aluminyo foil, atbp.

Application ng kusina

Packaging Ng Aluminum Sheet / Coil

Ang bawat detalye ng packaging ay kung saan namin ituloy ang perpektong serbisyo. Ang aming proseso ng packaging sa kabuuan ay ang mga sumusunod:

Paglalamina: malinaw na pelikula, asul na pelikula, mikro-mucosal, mataas na mucosal, laser pagputol ng pelikula (2 mga tatak, Novacell at Polyphem);

Proteksyon: mga tagapagtanggol ng sulok ng papel, mga pads laban sa presyon;

pagpapatayo ng mga: desiccant;

Tray: fumigated hindi nakakapinsala kahoy na tray, magagamit muli ang bakal na tray;

Pag-iimpake: Tik-tik-toe bakal sinturon, o PVC packing belt;

Kalidad ng Materyal: Ganap na libre mula sa mga depekto tulad ng puting kalawang, mga spot ng langis, mga rolling mark, pinsala sa gilid, mga baluktot, mga dent, mga butas, mga break lines, mga gasgas na, atbp., walang coil set.

Port: Qingdao o iba pang mga port sa China.

Lead oras: 15-45 mga araw.

Aluminyo sheet / plate packaging proseso

Aluminyo likawin packaging proseso

F: Ikaw ba ay isang tagagawa o isang mangangalakal?

Q: Kami ay isang tagagawa, ang factory namin ay sa No.3 Weier Road, Sonang Pang industriya, Gongyi, Henan, Tsina.

F: Ano ang MOQ para sa pag order ng produkto?

Q: Ang MOQ natin ay 5 tonelada, at ang ilang mga espesyal na produkto ay magkakaroon ng isang minimum na dami ng order ng 1 o 2 tonelada.

F: Gaano katagal ang iyong oras ng lead?

Q: Sa pangkalahatan ang aming lead time ay tungkol sa 30 mga araw.

F: Mayroon bang kalidad ng katiyakan ang iyong mga produkto?

Q: Oo nga, kung may problema sa quality sa products namin, kami ay mabayaran ang customer hanggang sa sila ay nasiyahan.

Mga Kaugnay na Produkto

Mga Pinakabagong Blog

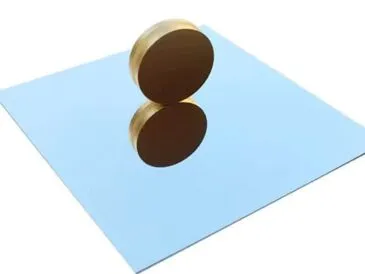

Ultra-high reflectivity aluminum mirror sheet

Ultra-high reflectivity aluminum mirror sheet with 95–98% visible reflectance, low scatter (TIS <1%), and specification advice for BRDF, spectral curves and coatings.

Trusted 3003 Aluminium Checker Plate Sheet Suppliers Worldwide

Find reliable 3003 Aluminium Checker Plate Sheet Suppliers offering certified quality, competitive pricing, custom sizes, and fast global delivery for your projects.

6061 T6 vs 7075 Aluminyo: Lakas ng loob, Timbang & Best Uses

Compare 6061 T6 vs 7075 aluminum easily. Discover differences in strength, bigat ng katawan, and applications to choose the best for your projects.

Industrialization and Application of Honeycomb Aluminum Foil

This blog explores the industrialization of honeycomb aluminum foil, focusing on the 3003 alloy production process. It covers hot rolling, patuloy na paghahagis, and the continuous casting-rolling method, highlighting the benefits of process optimization in improving mechanical properties, reducing energy consumption, and lowering production costs.