The Intersection of Performance and Aesthetics

In the world of modern materials, few products offer the same blend of sleek appearance, holdbarhed, and versatility as the white powder coated aluminium sheet.

You see it everywhere: on architectural facades, in clean-room interiors, on high-end signage, and as components in premium appliances.

But what exactly is this material, and what makes it such a superior choice for so many demanding applications?

This is your definitive guide. We will break down the science behind the powder coating process, explore its extensive benefits, compare it directly with other popular finishing methods, and showcase its most common uses.

By the end, you will have a comprehensive understanding of why this material is a go-to solution for architects, Ingeniører, and designers.

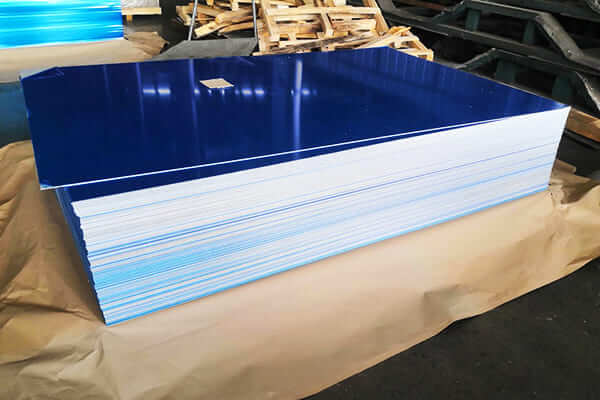

Hvidt pulverlakeret aluminiumsark

What is a White Powder Coated Aluminium Sheet?

The name itself describes a three-part system, where each component plays a critical role in the final product’s outstanding performance.

Først, you have the Aluminiumsark. This is the substrate, chosen for its inherent advantages: it is lightweight, inherently corrosion-resistant, and has an excellent strength-to-weight ratio. It’s the perfect canvas.

Næste, you have the powder coating. Unlike traditional liquid paint, a powder coating is a dry finishing process.

It involves applying a finely ground powder—a mixture of polymer resins, pigments, curatives, and leveling agents—to the surface of the aluminum.

Endelig, the process binds them together. The powder is applied electrostatically and then cured under heat, flowing and forming a “skin.”

The result is a white powder coated aluminium sheet with a finish that is not just painted on, but fused to the surface of the metal, creating a hard, uniform, and incredibly durable layer.

White aluminium sheet display

The Manufacturing Process: From Raw Metal to Flawless Finish

Creating a high-quality powder coated surface is a multi-stage process where precision is key. Skipping or rushing any step can compromise the final quality.

- Forbehandling (The Critical Foundation):

This is the most important stage. The raw aluminum sheet must be impeccably clean for the powder to adhere properly.

This involves a series of chemical baths to degrease, etch, and deoxidize the surface.

A conversion coating (often chromate or a non-chrome alternative) is then applied to enhance corrosion resistance and promote adhesion. - Powder Application:

The clean, dry sheet moves into a spray booth. An electrostatic spray gun gives the dry powder particles a positive electrical charge.

Since the aluminum sheet is grounded (negatively charged), the charged powder particles are powerfully attracted to it, wrapping evenly around the surface and edges. - Curing:

The coated sheet is then moved into a large curing oven. The heat (typically 180-200°C or 355-390°F) melts the powder, causing it to flow into a smooth, liquid film.

As it cures, a chemical cross-linking reaction occurs, creating the durable, hard finish that is characteristic of powder coating.

This process ensures a consistent, high-quality finish that is far superior to simply spraying liquid paint.

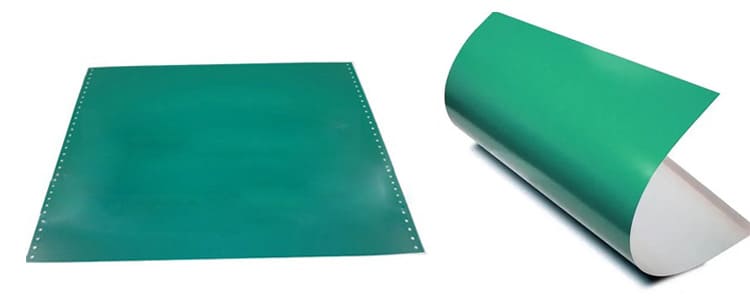

White powder coated aluminium sheet Perforated

Common Alloys for White Powder Coated Aluminium Sheet

The outstanding performance of a white powder coated aluminium sheet is not solely due to the coating itself.

The choice of the underlying aluminum alloy—the substrate—is equally critical.

The alloy determines the material’s inherent strength, Korrosionsmodstand, Formbarhed, and ultimately, its suitability for a specific application.

| Legering | Nickname / Primary Role | Key Characteristics | Best For… |

| 1100 | The Formability Specialist | Commercially pure, maximum ductility, softest grade. | Intricate decorative parts, nameplates, applications requiring deep drawing or complex forming. |

| 3003 | The General All-Rounder | Fremragende formbarhed, good general corrosion resistance. | General architectural panels, skiltning, truck-trailer roofing, and all-purpose fabrication. |

| 3105 | The Building Product Staple | Similar to 3003 Aluminiumsark but often with higher recycled content; excellent value. | Residential siding, rain gutters, mobile home skin, and pre-painted building products. |

| 5005 | The Architectural Finish Grade | Fine grain structure, excellent for high-quality, uniform finishes. | Premium architectural facades and curtain walls where visual consistency is critical. |

| 5052 | The Marine-Grade Champion | Overlegen korrosionsbestandighed (especially saltwater), higher strength. | Marine components, vehicle bodies, chemical storage, and high-vibration environments. |

| 6061 | The Structural Powerhouse | Heat-treatable, høj styrke, good weldability. | Load-bearing panels, base plates, platforms, and structural applications needing a durable finish. |

How to Choose the Right Alloy for Your Project

The decision ultimately comes down to balancing three key factors: Environment, Formbarhed, and Strength.

- For harsh environments involving saltwater, Kemikalier, or constant moisture, 5052 aluminium is the only reliable choice. For general architectural or interior use, 3003 is perfectly sufficient.

- For parts requiring complex bends or deep drawing, 1100 offers the best workability. For standard bends and simple shapes, 3003 provides a better balance with more strength.

- For applications needing higher impact resistance and rigidity, 5052 is the stronger material.

White powder coated aluminium sheet for building

Nøglefordele: Why Choose Powder Coating on Aluminum?

Opting for a white powder coated aluminium sheet brings a host of tangible benefits that other materials or finishes struggle to match.

- Exceptional Durability: The cured finish is highly resistant to chipping, scratching, and abrasion. It stands up to daily wear and tear, making it ideal for high-traffic areas and exterior applications.

- Superior Weather and UV Resistance: High-quality polyester powders (the standard for exterior use) are formulated to resist fading and chalking from prolonged sun exposure. This ensures the brilliant white finish remains vibrant for years.

- Enhanced Corrosion Protection: While aluminum is naturally rust-proof, the powder coating provides an impermeable barrier that protects it from environmental pollutants, fugtighed, and chemicals, significantly extending its service life.

- Aesthetic Uniformity: The electrostatic process ensures a perfectly even coating thickness across the entire sheet, free from the drips, runs, or brush marks associated with liquid paint. You can also specify various gloss levels, from a sleek matte to a high-gloss finish.

- Environmentally Friendly: Powder coating is a green technology. It contains no solvents and releases negligible volatile organic compounds (VOCs) into the atmosphere. Derudover, any overspray powder can be collected and reused, dramatically reducing waste.

Performance Comparison: How Does It Stack Up?

The best way to understand the value of a white powder coated aluminium sheet is to compare it against other common finishes for aluminum.

| Finishing Method | Powder Coating | Pvdf (Liquid Paint) | Anodisering |

| Holdbarhed & Hårdhed | Fremragende. Highly resistant to scratching and impact. | God. More flexible, but softer and can scratch easier. | Exceptional. Hardest surface, but can be brittle. |

| UV & Fade modstand | God til fremragende (with super-durable powders). | Superior. The industry benchmark for long-term color stability. | God. But color options are limited and can vary by batch. |

| Appearance | Uniform, Glat finish. Wide range of gloss levels. | Smooth liquid finish. Often has a specific luster. | Metallic, translucent finish. The metal grain is visible. |

| Environmental Impact | Meget lav. No VOCs, recyclable overspray. | Higher. Contains solvents (VOCs). | Moderat. Involves heavy acids and high energy use. |

| Koste | Moderat. Excellent performance for the price. | Høj. A premium finish for high-end projects. | Moderat til høj. |

| Bedst til | Architectural trim, skiltning, interior panels, machinery. | Monumental architecture, Gardinvægge, tagdækning. | Window frames, high-wear surfaces, decorative trim. |

In essence, white powder coated aluminium sheet offers a fantastic balance of performance, æstetik, og omkostninger, making it the most versatile and widely used option.

PVDF is reserved for projects where 20+ year warranties on color are required, while anodizing is chosen for its unique metallic look and extreme hardness.

Common Applications Across Industries

The versatile properties of this material make it a staple in numerous sectors:

- Architecture and Construction: Used extensively for wall cladding, facade panels, soffits, window and door frames, and roofing trim. Its clean look and durability are perfect for modern building design.

- Signage and Display: The smooth, white surface provides an ideal canvas for vinyl graphics and printing, making it a top choice for corporate signs, wayfinding systems, and retail displays.

- Interior Design: Designers use it for decorative wall panels, kitchen splashbacks, ceiling tiles, and custom furniture, especially in commercial, healthcare, and hospitality settings.

- Transport: Found as interior panels in buses, trains, and marine vessels, where it offers a durable, let, and easy-to-clean surface.

Signage used White powder coated aluminium sheet

Konklusion

Ultimately, -en white powder coated aluminium sheet is more than just a painted piece of metal.

It is a highly engineered product that provides a long-lasting, attractive, and sustainable solution for countless applications.

It successfully combines the lightweight and corrosion-resistant nature of aluminum with a tough, protective, and beautiful finish.

For projects that demand a clean aesthetic, robust performance, and excellent value, it remains the undisputed champion.

It is a testament to how modern material science can deliver a product that is both beautiful and built to last.

Casting produktionsproces og introduktion

Formålet med smeltning og støbning er at fremstille legeringer med tilfredsstillende sammensætning og høj renhed af smelte, for at skabe gunstige betingelser for støbning af legeringer i forskellige former.

Smeltning og støbningsprocesstrin: batching --- fodring --- smeltning --- omrøring efter smeltning, Fjernelse af slagge --- Pre-analyse prøveudtagning --- Tilføjelse af legering for at justere sammensætningen, omrøring --- Raffinering --- Statisk indstilling - - Guide Furnace Casting.

Hot rullende produktionsproces og dens introduktion

- 1. Hot rulling henviser generelt til rullende over metalrecrystallisationstemperaturen;

- 2. Under den varme rullende proces, metallet har både hærdning og blødgøringsprocesser. På grund af påvirkningen af deformationshastighed, Så længe gendannelse og omkrystallisationsprocessen er for sent, Der vil være et bestemt arbejdehærdning;

- 3. Omkrystallisationen af metallet efter varm rulling er ufuldstændig, det er, Sameksistensen af omkrystalliseret struktur og deformeret struktur;

- 4. Hot rulling kan forbedre behandlingens ydeevne for metaller og legeringer, Reducer eller eliminering af støbningsfejl.

- 1. Støbning og rulletemperatur er generelt mellem 680 ° C og 700 ° C. Jo lavere jo bedre, Den stabile støbe- og rullende linje stopper normalt en gang om måneden eller mere for at se på. Under produktionsprocessen, Det er nødvendigt at kontrollere væskeeniveauet for den forreste tank for at forhindre lavt væskeniveau;

- 2. Smøring bruger C -pulver med ufuldstændig forbrænding af gas til smøring, hvilket også er en af grundene til den beskidte overflade af støbning og rullende materialer;

- 3. Produktionshastigheden er generelt mellem 1,5 m/min-2,5 m/min;

- 4. Overfladekvaliteten af produkter produceret ved støbning og rulle er generelt relativt lav, og kan generelt ikke opfylde produkter med særlige fysiske og kemiske ydelseskrav.

- 1. Kold rullende henviser til den rullende produktionsmetode under omkrystallisationstemperaturen;

- 2. Der vil ikke være nogen dynamisk omkrystallisation under rullende proces, og temperaturen stiger højst til gendannelsestemperaturen, Og den kolde rulling vises i en arbejdshærdningstilstand, og arbejdshærdningshastigheden vil være stort;

- 3. Det koldvalsede ark og strimmel har høj dimensionel nøjagtighed, God overfladekvalitet, ensartet struktur og ydeevne, og produkter i forskellige stater kan opnås med varmebehandling;

- 4. Kold rulling kan rulle ud tynde strimler, Men på samme tid, Det har ulemperne ved højt energiforbrug til deformation og mange behandlingspas.

- 1. Efterbehandling er en behandlingsmetode til at få det koldvalsark til at imødekomme kundens krav, eller for at lette den efterfølgende behandling af produktet;

- 2. Efterbehandlingsudstyret kan korrigere de defekter, der er produceret i den varme rullende og kolde rullende produktionsproces, såsom knækket kant, olieagtig, Dårlig pladeform, Reststress, osv. Det skal sikre, at ingen andre defekter bringes ind i produktionsprocessen;

- 3. Der er forskellige efterbehandlingsudstyr, hovedsageligt inklusive tværgående, Slæden, strækning og udretning, Udglødningsovn, Slitter, osv.

Støbning og rulleproces

Støbning og rulleproces: flydende metal, frontboks (Kontrol af væskeniveau), støbning og rullende maskine (Smøresystem, kølevand), klipmaskine, Spilemaskine.

Kold rullende produktionsproces

Introduktion til efterbehandling af produktionsprocessen

Aluminiumslegering har egenskaberne ved lav densitet, Gode mekaniske egenskaber, God behandlingsydelse, Ikke-giftig, Let at genbruge, Fremragende elektrisk ledningsevne, Varmeoverførsel og korrosionsbestandighed, Så det har en bred vifte af applikationer.

Rumfart: Bruges til at fremstille flyskind, Fuselage -rammer, bælter, Rotorer, propeller, brændstofbeholdere, Vægpaneler og landingsudstyrsstiver, såvel som raket smedningsringe, rumfartøjsvægpaneler, osv.

Aluminiumslegering, der bruges til rumfart

Transport: Brugt til bilkropsstrukturmaterialer af biler, Subway -køretøjer, Jernbanepassagerbiler, Højhastighedsbeholdere, Døre og vinduer, hylder, Automotive motordele, klimaanlæg, radiatorer, kropspaneler, hjul og skibsmaterialer.

Trafikansøgning

Emballage: Aluminiums pop-dåser bruges hovedsageligt som metalemballagematerialer i form af tynde plader og folier, og er lavet til dåser, låg, flasker, tønder, og emballeringsfolier. Bredt brugt til emballage af drikkevarer, mad, Kosmetik, lægemidler, cigaretter, Industrielle produkter, lægemidler, osv.

Emballageapplikation

Trykning: Hovedsageligt brugt til at fremstille PS -plader, Aluminiumbaserede PS-plader er en ny type materiale i trykbranchen, Bruges til automatisk pladefremstilling og udskrivning.

PS -udskrivning

Arkitektonisk dekoration: Aluminiumslegering er vidt brugt til bygningsstrukturer, Døre og vinduer, Suspenderede lofter, Dekorative overflader, osv. På grund af dens gode korrosionsbestandighed, tilstrækkelig styrke, Fremragende procesydelse og svejsestyring.

Anvendelse af aluminiumslegeringskonstruktion

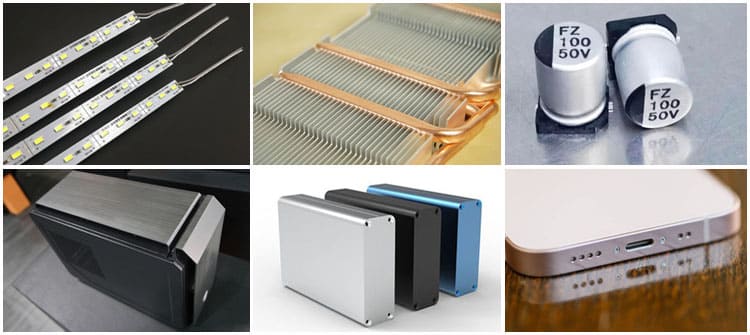

Elektroniske produkter: Computere, mobiltelefoner, Køleskabsskaller, radiatorer, osv.

Elektronisk produktapplikation

Køkkenforsyninger: Aluminiumspotter, Aluminiumsbassiner, Ris komfurforinger, Husholdningsaluminiumsfolie, osv.

Køkkenapplikation

Emballage af aluminiumsark/spole

Hver detalje i emballagen er, hvor vi forfølger perfekt service. Vores emballageproces som helhed er som følger:

Laminering: Klar film, Blå film, Mikroblimhinde, Høj flimhinde, Laserskærende film (2 mærker, Novacell og Polyphem);

Beskyttelse: Paper Corner Protectors, Anti-tryk puder;

tørring: tørremiddel;

Bakke: fumigated ufarlig træbakke, Genanvendelig jernbakke;

Pakning: Tic-tac-toe stålbælte, eller PVC -pakningsbælte;

Materialekvalitet: Helt fri for defekter såsom hvid rust, oliepletter, rullende mærker, kantskade, bøjer sig, buler, huller, Bryde linjer, ridser, osv., Intet spiralsæt.

Havn: Qingdao eller andre havne i Kina.

Ledetid: 15-45 dage.

Aluminiumsark/pladeemballageproces

Aluminiumsspoleemballageproces

F: Er du en producent eller en erhvervsdrivende?

Q: Vi er en producent, Vores fabrik er på No.3 Weier Road, Industriel zone, Gongyi, Henan, Kina.

F: Hvad er MOQ for at bestille produktet?

Q: Vores MOQ er 5 tonsvis, Og nogle specielle produkter vil have en minimumsordre -mængde på 1 eller 2 tonsvis.

F: Hvor lang er din ledetid?

Q: Generelt handler vores ledetid om 30 dage.

F: Har dine produkter kvalitetssikring?

Q: Ja, Hvis der er et kvalitetsproblem med vores produkter, Vi kompenserer kunden, indtil de er tilfredse.

Relaterede produkter

Seneste blogs

Er aluminiumsfolie giftig? | Sikkerhedsfakta, du har brug for at vide

Spekulerer på er aluminiumsfolie giftig? Vi debunk almindelige myter og giver videnskabsstøttede fakta om dens sikkerhed for opbevaring af madlavning og mad.

Topkvalitet 3004 Honeycomb aluminiumsfolie Dubai

Få 3004 Honeycomb aluminiumsfolie Dubai til konstruktion, rumfart, og emballagebehov. Let, holdbar, og omkostningseffektiv, Perfekt til applikationer med højtydende.

Marine Grad 5052-H32 Aluminiumsark-Letvægt & Styrke

Sørg for pålidelighed på vandet med Marine Grade 5052-H32 Aluminiumsark. Dens imponerende mekaniske egenskaber og modstand mod saltvandskorrosion gør det til det perfekte valg til både, dokker, og marine strukturer.

3003 H18 belagt aluminiumsstrimmel - stærk, Holdbar & Rustbestandig

Høj kvalitet 3003 H18 belagt aluminiumsstrimmel med fremragende korrosionsbestandighed, Glat finish, og høj styrke, Ideel til tagdækning, beklædning, og dekorative applikationer.