1. Indledning

9-mikron 1235 Sammensat aluminiumsfolie er en højt specialiseret, multi-layer material that serves as a cornerstone of the modern flexible packaging industry.

This material system is engineered to provide a high-performance barrier at an optimal cost and weight. Its core is an ultra-thin, 9µm (0.009mm) foil made from 1235 Aluminiumslegering, en høj renhed (≥99,35% Al) grade prized for its exceptional softness and workability.

While the 9-micron foil itself provides a near-perfect barrier to light, Gasser, og fugt, its thinness makes it mechanically fragile and susceptible to pinholes.

These weaknesses are overcome by laminating it with other polymer films (such as PET, BOPP, and PE). The resulting composite structure leverages the absolute barrier of the aluminum core while gaining the strength, printbar, and sealability of the polymer layers.

This makes 9-micron 1235 composite foil the go-to solution for a vast range of applications, herunder fødevareemballage (snacks, kaffe, mælkepulver) and pharmaceutical sachets, where a high barrier, let vægt, and cost-effectiveness are all critical requirements.

9-mikron 1235 Sammensat aluminiumsfolie

2. Forståelse 1235 Aluminiumslegering

2.1 Kemisk sammensætning

De 1235 Aluminiumsfolie belongs to the 1xxx series of commercial purity aluminum, specifically engineered for converter foil applications where formability and barrier performance take precedence over structural strength.

The chemical composition adheres to strict limits that maximize rolling efficiency and surface quality.

| Element | Minimum | Maksimum | Functional Role in 9μm Foil |

|---|---|---|---|

| Aluminium (Al) | 99.35% | — | Matrix providing ductility, refleksionsevne, og korrosionsbestandighed |

| Silicium (Og) | — | 0.10% | Tight control ensures smooth rolling surface and minimizes inclusion defects |

| Jern (Fe) | — | 0.60% | Provides slight strengthening; excessive levels increase pinhole risk |

| Kobber (Cu) | — | 0.05% | Kept minimal to preserve electrical conductivity and corrosion resistance |

| Mangan (Mn) | — | 0.05% | Trace element limited to prevent work hardening |

| Magnesium (Mg) | — | 0.05% | Controlled to avoid surface oxidation issues |

| Zink (Zn) | — | 0.10% | Impurity management for anodizing compatibility |

| Titanium (Af) | — | 0.03% | Grain refinement in cast ingots |

| Andre elementer (Hver) | — | 0.03% | Aggregate impurity cap ensuring consistency |

| Andre elementer (Total) | — | 0.10% | Overall purity protection |

2.2 Microstructure and Temper

De 1235 alloy achieves its optimal properties through careful thermal processing.

Manufacturers produce 9-micron foil in two primary tempers, each serving distinct converting requirements:

O temperament (Blød, Annealed):

- Trækstyrke: 60–90 MPa (8.7–13.0 ksi)

- Udbyttestyrke: 20–35 MPa (2.9–5.1 ksi)

- Forlængelse: 25–35 % (A50mm gauge)

- Hårdhed: 20–25 HB

- Mikrostruktur: Fully recrystallized equiaxed grains (ASTM 6–9) with minimal dislocation density

The O temper maximizes ductility for deep drawing, foldning, and complex forming operations.

The 25–35% elongation enables 9-micron foil to conform to sharp creases in cigarette inner liners and sachet corners without cracking.

This temper also optimizes adhesive wet-out during lamination, as the soft surface conforms to microscopic surface irregularities in plastic films.

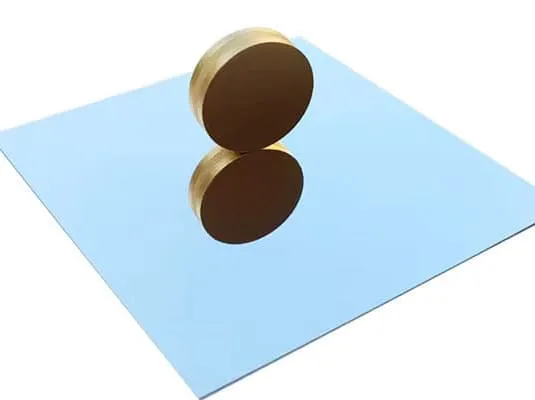

9-mikron 1235 H18 aluminiumsfolie

H18 Temper (Fuld hårdt, Cold-Worked):

- Trækstyrke: 110–150 MPa (16.0–21.8 ksi)

- Udbyttestyrke: 100–130 MPa (14.5–18.9 ksi)

- Forlængelse: 1–3%

- Hårdhed: 45–55 HB

- Mikrostruktur: Elongated grains with high dislocation density from cold rolling

H18 temper provides handling stiffness for unwind operations and slit-edge stability.

Converters often specify H18 for foil that must traverse long web paths at high speed before lamination, as the increased rigidity reduces wrinkling and edge weaving.

The laminate structure subsequently provides flexibility in the finished product.

3. 9 Micrometer (μm) Tykkelse: Opportunities and Challenges

3.1 Opportunities (Why pursue 9 mikrometer?)

- Letvægtning & material cost reduction. Moving from e.g., 12–15 µm down to 9 µm reduces aluminum mass by ~25–40%, lowering raw-material cost and package weight. (9 µm = 0.009 mm).

- Excellent barrier per unit mass. Even at 9 µm a continuous aluminum layer provides near-opaque light barrier and very low oxygen and moisture transmission when incorporated into a laminate; suppliers report OTR and WVTR figures that place such laminates in “high barrier” class for many food and pharmaceutical applications.

- Improved form-factor and aesthetics. Thin foil conforms to complex shapes (labels, lidding) with smaller step heights and less bulk.

3.2 Udfordringer (Inherent weaknesses of 9 mikrometer)

- Mechanical fragility: reduced puncture resistance, higher sensitivity to handling, and increased risk of pinholes during rolling and lamination. Typical practical tensile/puncture performance must be validated for the stack and forming process.

- Pinholes & defects control: process cleanliness and rolling/anneal schedules must be tightly controlled; pinhole density scales unfavorably with decreasing gauge.

- Adhesion and delamination risk: ultra-thin foil has less cohesive thickness for adhesives to “bite”; surface treatments or lacquers are often required to secure bond strength to polymers.

- Converting difficulty: Slæden, embossing, die-cutting and rewinding require specialized tension control, anti-static measures and skilled equipment operators.

4. Structure of 9-Micron 1235 Composite Aluminum Foil

4.1 Typical Composite Structures

The 9-micron 1235 foil rarely serves as standalone packaging. I stedet, it functions as the critical barrier layer within multi-material laminates that combine complementary properties.

Engineers design these structures to position each material where its properties deliver maximum value:

Struktur 1: PET/AL/PE (General-Purpose Food Packaging)

- KÆLEDYR (12–25μm): Exterior print carrier providing mechanical strength, Dimensionel stabilitet, and gloss

- Klæbemiddel (1.5–3.0 g/m²): Polyurethane two-component system creating chemical bond

- Al (9μm): Core barrier layer blocking oxygen, fugtighed, og lys

- Klæbemiddel (1.5–3.0 g/m²): Tie layer for polyethylene adhesion

- Pe (40–80μm): Interior sealant providing heat-sealability, chemical resistance, and food contact compliance

Total thickness: ~65–120μm | Barriere: Otr <0.1 cc/m²·day, WVTR <0.01 g/m²·dag

Struktur 2: Paper/AL/PE (Cigarette Inner Liner)

- Papir (40–60 g/m²): Exterior providing dead-fold characteristics, uigennemsigtighed, and tactile quality

- Al (9μm): Barrier against moisture and aroma loss

- Pe (20–60μm): Heat-seal layer for pack closure

This structure leverages the “dead-fold” property of 1235-O foil—the ability to retain a crease without spring-back—essential for cigarette pack forming at 400+ packs/minute.

Struktur 3: BOPP/AL/CPP (Confectionery and Snacks)

- BOPP (20μm): High-clarity exterior with excellent machinability

- Al (9μm): Barrier and light protection

- CPP (40–70μm): Hot-tack sealant for high-speed form-fill-seal operations

The biaxially oriented polypropylene (BOPP) provides superior crack resistance compared to PET, while cast polypropylene (CPP) offers broader heat-seal windows for confectionery packaging.

Struktur 4: PA/AL/PE (Puncture-Resistant Pouches)

- PA (15μm, Nylon): Exterior providing exceptional puncture and abrasion resistance

- Al (9μm): Barrier layer

- Pe (60–80μm): Sealant and structural bulk

This configuration suits vacuum-packed meats and cheeses where bone edges or sharp corners threaten package integrity.

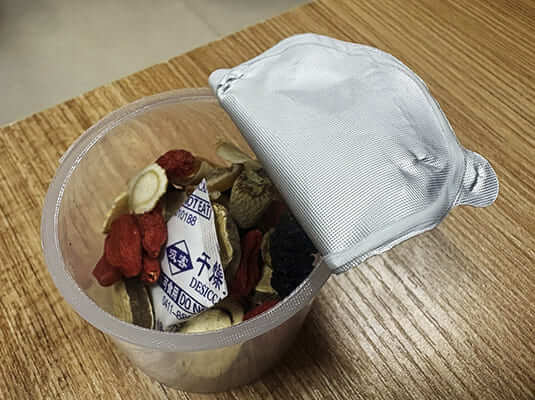

Tea packaging used 9-micron 1235 Sammensat aluminiumsfolie

4.2 Why Composite for 9-Micron Aluminum Foil

Mechanical Protection:

The 9-micron foil cannot survive handling, forsendelse, or retail display as a single layer.

KÆLEDYR (tensile strength 200–300 MPa) or paper (stiffness 2–5 Nm/g) provide structural armor that prevents flex cracks and abrasion.

Seglintegritet:

Aluminum lacks thermoplasticity—it cannot heat-seal. PE or CPP layers (melting point 110–135°C) create hermetic closures through impulse or hot-bar sealing.

Chemical Isolation:

Acidic or alkaline products (tomatsauce, rengøringsmidler) corrode aluminum. PE and PP provide inert barriers preventing chemical attack.

Printbarhed:

Aluminum accepts only limited printing technologies. PET and paper substrates enable high-resolution gravure or flexographic decoration.

Cost Optimization:

At $8–12/kg for aluminum foil versus $2–4/kg for PE, composite structures minimize aluminum usage to the absolute barrier requirement while leveraging cheaper polymers for bulk.

5. Manufacturing Process of 9-Micron 1235 Composite Aluminum Foil

Key steps and control points:

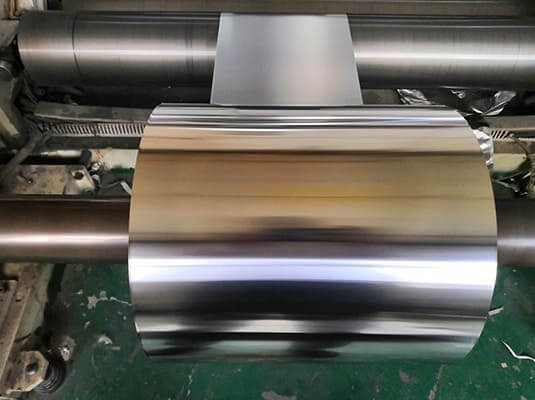

- Casting and hot rolling to produce coil stock.

- Cold rolling schedules with multiple passes to progressively reduce gauge toward foil thickness. Intermediate and final anneals are applied to restore ductility and control grain structure. Precise pass schedules and roll gap control are critical to reach a uniform 9 µm target without excessive edge-wave or thickness variation.

- Surface preparation and cleaning to remove rolling oils and particulates (important to minimize pinholes).

- Coating/lacquering (valgfri) to provide printability and corrosion resistance prior to lamination.

- Laminering (composite formation) — can be by solventless adhesive, ekstruderingslaminering (melt adhesive), or solvent/wet adhesives depending on stack and end-use. Proper adhesive selection, nip temperature and pressure are tuned to avoid foil wrinkles and to achieve peel strength targets.

- Slitting and rewinding with strict tension control and anti-static handling for 9 µm gauges.

- Quality inspection (pinhole detection, tykkelseskortlægning, surface inspection) and final packing.

Process control charts for foil production typically track gauge tolerance (F.eks., ±0.5 µm target for 9 µm), pinhole counts per m², and laminate peel strength.

6. Applications of 9-Micron 1235 Composite Aluminum Foil

6.1 Fleksibel fødevareemballage

The 9-micron 1235 foil serves as the barrier backbone for dry goods packaging:

- Coffee and Tea: Aroma retention critical; 9μm foil with <40 pinholes/m² maintains freshness 12–18 months

- Snack Foods: PET/AL/PE structures provide light protection for photosensitive vitamins and flavors

- Powdered Beverages: WVTR <0.01 g/m²·day prevents caking and preserves solubility

High-speed form-fill-seal (FFS) lines operate at 200+ cycles/minute with 9-micron foil, validating its mechanical stability under rapid flexing.

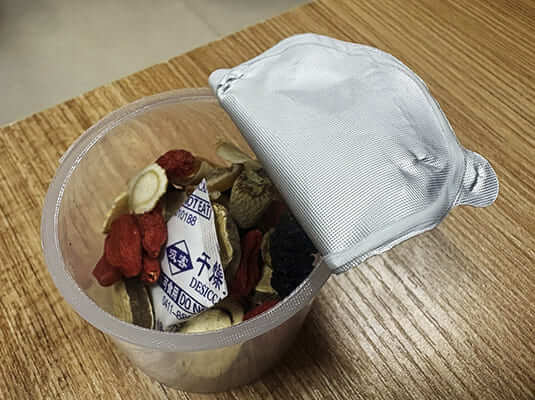

Sachet Strips For Medical Packaging

6.2 Pharmaceutical and Medical Packaging

Secondary overwraps for pharmaceuticals utilize 9-micron foil in:

- Sachet Strips: PET/AL/PE for unit-dose powders and granules

- Lågfolie: 9μm 1235-O replaces thicker gauges for cost-sensitive OTC products

- Tropical Blister Alternatives: Non-PVC laminates for high-humidity markets

Migration testing per EU 10/2011 and FDA 21 CFR 177.1390 ensures compliance for indirect food contact.

6.3 Tobacco Packaging

Cigarette inner liners represent a major 9-micron application:

- Struktur: Papir (40–60 g/m²)/Al (9μm)/Pe (20–30μm)

- Død-fold: 1235-O temper retains sharp creases without spring-back

- Aroma barriere: Prevents moisture loss and flavor cross-contamination

- Speed Compatibility: Runs at 400+ packs/minute on G.D. and Focke machines

6.4 Industrial and Technical Applications

Cable Wrap: Non-woven/AL/PE laminates provide electromagnetic interference (Emi) shielding with 9-micron foil delivering >60 dB attenuation at 1 GHz.

Bygningsisolering: Foil-faced radiant barriers utilize 9μm 1235 for cost-effective reflectivity (>88% solar reflectance).

Battery Pouch Films: Lamination with nylon and polypropylene creates containment for lithium-ion cells, with 9-micron foil providing moisture barrier and electrical isolation.

1235 aluminum foil for Cable Wrap

7. Comparative Alloy Analysis

Engineers selecting aluminum foil must evaluate alternatives to 1235. The following matrix compares key options for 9-micron applications:

| Attribut | 1235 | 8079 | 8011 | Selection Guidance |

|---|---|---|---|---|

| Aluminiums renhed | ≥99.35% | ≥99,0 % | ~97.0% (Al-Fe-Si) | 1235 for highest purity; 8079 for pinhole-critical <7μm |

| Trækstyrke (O temperament) | 60–90 MPa | 80–110 MPa | 80–120 MPa | Higher strength in 8079/8011 for handling stiffness |

| Forlængelse (O temperament) | 25–35 % | 15–25 % | 15–25 % | 1235 superior for deep drawing and folding |

| Dead-Fold Characteristics | Fremragende | Meget god | God | 1235 preferred for cigarette/tobacco |

| Pinhole Resistance at 9μm | Enhanced: ≤40/m² | Enhanced: ≤30/m² | Enhanced: ≤25/m² | 8079/8011 intermetallics improve rolling; 1235 requires tighter process control |

| Cost Position | $ (Laveste) | $$ | $$ | 1235 offers 10–15% cost advantage |

| Typiske applikationer | Mainstream food, tobak, general lamination | High-barrier pharma, abuse-resistant pouches | Låg, tube laminates, heat-seal applications |

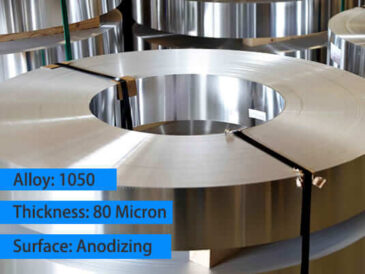

8. Huawei 9-Micron 1235 Composite Aluminum Foil Specification

(Representative supplier specification drawn from typical product pages — engineers should request a manufacturer-run Material Test Certificate and sample tests before approving for production.)

Supplier example: Henan Huawei Aluminium Co., Ltd (commercial supplier listing for “9-Micron 1235 Composite Aluminum Foil”). Reported or typical specification items include:

- Legering: 1235 (O temper typical for lamination).

- Nominal aluminum thickness: 9 µm (0.009 mm).

- Composite stacks offered: PET/AL(9)/Pe; Paper/AL(9)/Pe; BOPP/AL(9)/Pe.

- Typical WVTR / OTR for laminated structures (supplier reported example): Otr < 0.1 (units depend on test method; usually cc/m²·day), WVTR < 0.01 (g/m²·dag) for finished laminate — confirm test method and units with supplier before quoting shelf life.

- Pinhole tæthed: marketed as “low pinhole density” — suppliers commonly specify pinhole counts per m² or qualitative grades; ask for measured pinhole counts at acceptance.

- Temperament: O (Annealed) or light cold-work (as required).

- Belægning: optional lacquer for printability; adhesive systems per laminate.

- Pakke: jumbo rolls, typical widths 200–1,600 mm; coil ID/OD to buyer spec.

- Kvalitetskontrol: thickness tolerance band (for 9 µm often specified ±0.5–1.0 µm depending on supplier), visual surface class, pinhole acceptance, MTC available on request.

Huawei Aluminum Foil Export Packaging

9. Konklusion

De 9-mikron 1235 Sammensat aluminiumsfolie is a testament to the power of systems thinking in material science.

It is a highly optimized solution that acknowledges the limitations of a single material and overcomes them through intelligent combination.

By pairing the absolute barrier potential of an ultra-thin 1235 aluminum foil with the mechanical strength of polymer films, the packaging industry has created a material that is both high-performing and highly economical.

It is not the most robust barrier available, but for the vast majority of flexible packaging needs, it represents the perfect equilibrium of protection, koste, og effektivitet.

FAQS

1. If 9-micron foil has pinholes, is it still a “high barrier”?

Ja. In a composite structure, the barrier performance is not determined by the foil alone. The adhesive and polymer layers create a “tortuous path” that effectively seals the microscopic pinholes. The final laminate still provides an exceptionally low OTR and WVTR (F.eks., <0.5), which is firmly in the high-barrier category and far superior to any non-foil-based film.

2. Why not just use a thicker foil to avoid pinholes?

You can, but it comes with trade-offs. A thicker foil (F.eks., 12µm or 15µm) will have fewer pinholes and more strength, but it will be more expensive, heavier, and result in a stiffer final package, which may not be desirable. 9 microns is often the most cost-effective solution that meets the required barrier specifications for a huge range of products.

3. What is the difference between this and “Alu-Alu” foil?

“Alu-Alu” (kold form) foil is a much thicker, soft-temper aluminum foil (typisk 45-60 Mikron) laminated with OPA and PVC. It is designed to be plastically deformed (cold-formed) into a blister cavity, providing an absolute, 100% barriere. 9-micron composite foil is a thin, flexible material used for flat pouches and bags; it cannot be formed into a deep cavity.

Casting produktionsproces og introduktion

Formålet med smeltning og støbning er at fremstille legeringer med tilfredsstillende sammensætning og høj renhed af smelte, for at skabe gunstige betingelser for støbning af legeringer i forskellige former.

Smeltning og støbningsprocesstrin: batching --- fodring --- smeltning --- omrøring efter smeltning, Fjernelse af slagge --- Pre-analyse prøveudtagning --- Tilføjelse af legering for at justere sammensætningen, omrøring --- Raffinering --- Statisk indstilling - - Guide Furnace Casting.

Hot rullende produktionsproces og dens introduktion

- 1. Hot rulling henviser generelt til rullende over metalrecrystallisationstemperaturen;

- 2. Under den varme rullende proces, metallet har både hærdning og blødgøringsprocesser. På grund af påvirkningen af deformationshastighed, Så længe gendannelse og omkrystallisationsprocessen er for sent, Der vil være et bestemt arbejdehærdning;

- 3. Omkrystallisationen af metallet efter varm rulling er ufuldstændig, det er, Sameksistensen af omkrystalliseret struktur og deformeret struktur;

- 4. Hot rulling kan forbedre behandlingens ydeevne for metaller og legeringer, Reducer eller eliminering af støbningsfejl.

- 1. Støbning og rulletemperatur er generelt mellem 680 ° C og 700 ° C. Jo lavere jo bedre, Den stabile støbe- og rullende linje stopper normalt en gang om måneden eller mere for at se på. Under produktionsprocessen, Det er nødvendigt at kontrollere væskeeniveauet for den forreste tank for at forhindre lavt væskeniveau;

- 2. Smøring bruger C -pulver med ufuldstændig forbrænding af gas til smøring, hvilket også er en af grundene til den beskidte overflade af støbning og rullende materialer;

- 3. Produktionshastigheden er generelt mellem 1,5 m/min-2,5 m/min;

- 4. Overfladekvaliteten af produkter produceret ved støbning og rulle er generelt relativt lav, og kan generelt ikke opfylde produkter med særlige fysiske og kemiske ydelseskrav.

- 1. Kold rullende henviser til den rullende produktionsmetode under omkrystallisationstemperaturen;

- 2. Der vil ikke være nogen dynamisk omkrystallisation under rullende proces, og temperaturen stiger højst til gendannelsestemperaturen, Og den kolde rulling vises i en arbejdshærdningstilstand, og arbejdshærdningshastigheden vil være stort;

- 3. Det koldvalsede ark og strimmel har høj dimensionel nøjagtighed, God overfladekvalitet, ensartet struktur og ydeevne, og produkter i forskellige stater kan opnås med varmebehandling;

- 4. Kold rulling kan rulle ud tynde strimler, Men på samme tid, Det har ulemperne ved højt energiforbrug til deformation og mange behandlingspas.

- 1. Efterbehandling er en behandlingsmetode til at få det koldvalsark til at imødekomme kundens krav, eller for at lette den efterfølgende behandling af produktet;

- 2. Efterbehandlingsudstyret kan korrigere de defekter, der er produceret i den varme rullende og kolde rullende produktionsproces, såsom knækket kant, olieagtig, Dårlig pladeform, Reststress, osv. Det skal sikre, at ingen andre defekter bringes ind i produktionsprocessen;

- 3. Der er forskellige efterbehandlingsudstyr, hovedsageligt inklusive tværgående, Slæden, strækning og udretning, Udglødningsovn, Slitter, osv.

Støbning og rulleproces

Støbning og rulleproces: flydende metal, frontboks (Kontrol af væskeniveau), støbning og rullende maskine (Smøresystem, kølevand), klipmaskine, Spilemaskine.

Kold rullende produktionsproces

Introduktion til efterbehandling af produktionsprocessen

Aluminiumslegering har egenskaberne ved lav densitet, Gode mekaniske egenskaber, God behandlingsydelse, Ikke-giftig, Let at genbruge, Fremragende elektrisk ledningsevne, Varmeoverførsel og korrosionsbestandighed, Så det har en bred vifte af applikationer.

Rumfart: Bruges til at fremstille flyskind, Fuselage -rammer, bælter, Rotorer, propeller, brændstofbeholdere, Vægpaneler og landingsudstyrsstiver, såvel som raket smedningsringe, rumfartøjsvægpaneler, osv.

Aluminiumslegering, der bruges til rumfart

Transport: Brugt til bilkropsstrukturmaterialer af biler, Subway -køretøjer, Jernbanepassagerbiler, Højhastighedsbeholdere, Døre og vinduer, hylder, Automotive motordele, klimaanlæg, radiatorer, kropspaneler, hjul og skibsmaterialer.

Trafikansøgning

Emballage: Aluminiums pop-dåser bruges hovedsageligt som metalemballagematerialer i form af tynde plader og folier, og er lavet til dåser, låg, flasker, tønder, og emballeringsfolier. Bredt brugt til emballage af drikkevarer, mad, Kosmetik, lægemidler, cigaretter, Industrielle produkter, lægemidler, osv.

Emballageapplikation

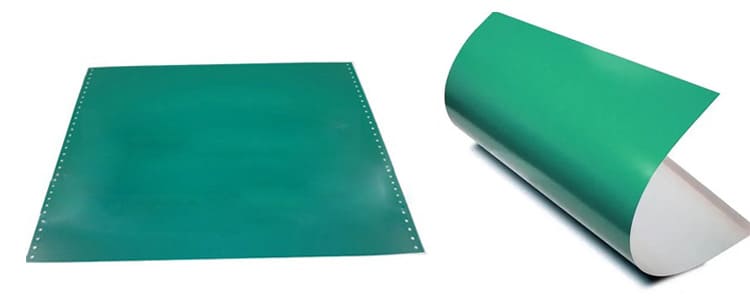

Trykning: Hovedsageligt brugt til at fremstille PS -plader, Aluminiumbaserede PS-plader er en ny type materiale i trykbranchen, Bruges til automatisk pladefremstilling og udskrivning.

PS -udskrivning

Arkitektonisk dekoration: Aluminiumslegering er vidt brugt til bygningsstrukturer, Døre og vinduer, Suspenderede lofter, Dekorative overflader, osv. På grund af dens gode korrosionsbestandighed, tilstrækkelig styrke, Fremragende procesydelse og svejsestyring.

Anvendelse af aluminiumslegeringskonstruktion

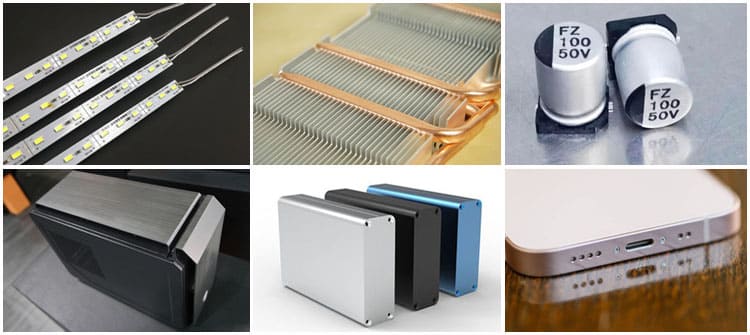

Elektroniske produkter: Computere, mobiltelefoner, Køleskabsskaller, radiatorer, osv.

Elektronisk produktapplikation

Køkkenforsyninger: Aluminiumspotter, Aluminiumsbassiner, Ris komfurforinger, Husholdningsaluminiumsfolie, osv.

Køkkenapplikation

Emballage af aluminiumsark/spole

Hver detalje i emballagen er, hvor vi forfølger perfekt service. Vores emballageproces som helhed er som følger:

Laminering: Klar film, Blå film, Mikroblimhinde, Høj flimhinde, Laserskærende film (2 mærker, Novacell og Polyphem);

Beskyttelse: Paper Corner Protectors, Anti-tryk puder;

tørring: tørremiddel;

Bakke: fumigated ufarlig træbakke, Genanvendelig jernbakke;

Pakning: Tic-tac-toe stålbælte, eller PVC -pakningsbælte;

Materialekvalitet: Helt fri for defekter såsom hvid rust, oliepletter, rullende mærker, kantskade, bøjer sig, buler, huller, Bryde linjer, ridser, osv., Intet spiralsæt.

Havn: Qingdao eller andre havne i Kina.

Ledetid: 15-45 dage.

Aluminiumsark/pladeemballageproces

Aluminiumsspoleemballageproces

F: Er du en producent eller en erhvervsdrivende?

Q: Vi er en producent, Vores fabrik er på No.3 Weier Road, Industriel zone, Gongyi, Henan, Kina.

F: Hvad er MOQ for at bestille produktet?

Q: Vores MOQ er 5 tonsvis, Og nogle specielle produkter vil have en minimumsordre -mængde på 1 eller 2 tonsvis.

F: Hvor lang er din ledetid?

Q: Generelt handler vores ledetid om 30 dage.

F: Har dine produkter kvalitetssikring?

Q: Ja, Hvis der er et kvalitetsproblem med vores produkter, Vi kompenserer kunden, indtil de er tilfredse.

Relaterede produkter

Seneste blogs

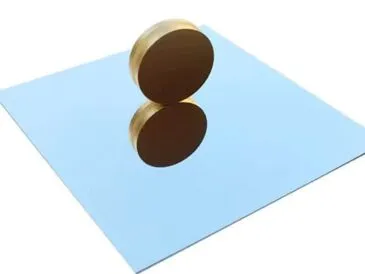

Spejlplade i aluminium med ultrahøj reflektivitet

Spejlplade i aluminium med ultrahøj reflektivitet med 95–98 % synlig reflektans, lav spredning (TIS <1%), og specifikationsrådgivning for BRDF, spektralkurver og belægninger.

Betroet 3003 Leverandører af pladeplader af aluminium i hele verden

Find pålidelige 3003 Leverandører af pladeplader af aluminium, der tilbyder certificeret kvalitet, konkurrencedygtige priser, brugerdefinerede størrelser, og hurtig global levering til dine projekter.

6061 T6 vs 7075 Aluminium: Styrke, Vægt & Bedste anvendelser

Sammenligne 6061 T6 vs 7075 let aluminium. Opdag forskelle i styrke, vægt, og applikationer til at vælge det bedste til dine projekter.

Industrialisering og anvendelse af honeycomb aluminiumsfolie

Denne blog udforsker industrialiseringen af honeycomb aluminiumsfolie, med fokus på 3003 legeringsproduktionsproces. Det dækker varmvalsning, kontinuerlig støbning, og den kontinuerlige støbe-valsemetode, fremhæver fordelene ved procesoptimering til at forbedre mekaniske egenskaber, reducere energiforbruget, og sænke produktionsomkostningerne.