Hvad er 5052 Aluminiumscirkel

5052 aluminium cirkler er AL-Mg legeret aluminium cirkler. Magnesium er det vigtigste legeringselement i 5052 legeret aluminium cirkel og er den mest udbredte anti-rust aluminium. Blandt ikke-varmebehandlelige legeringer, 5052 betragtes som en af de stærkeste muligheder.

Hvad er 5052 Aluminiumscirkel

5052 aluminium cirkel har høj styrke, især træthedsmodstand: høj plasticitet og korrosionsbestandighed, kan ikke forstærkes ved varmebehandling, god plasticitet under halvkoldt arbejdshærdning, lav plasticitet under koldbearbejdningshærdning, God korrosionsmodstand, god svejsbarhed, og kan Dårlig skæreydelse, kan poleres. Anvendes hovedsageligt i lamper, køkkenudstyr, elektroniske og elektriske kabinetter, trafikskilte, osv.

5052 kemisk sammensætning af aluminiumslegering

| Legering | Og | Fe | Cu | Mn | Mg | Cr | Zn | Af | Andre-Hver | Andre i alt | Al |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 5052 | 0.25 | 0.40 | 0.10 | 0.10 | 2.2-2.8 | 0.15-0.35 | 0.10 | – | 0.05 | 0.15 | Resten |

Magnesiumindholdet af 5052 aluminium cirkler er 2.2-2.8%, så tætheden er kun 2.68. Vægten af 5052 legeret aluminium cirkler er det letteste legeringsnummer blandt hele 5000 serien aluminiumslegeringer.

5052 aluminiumslegering indeholder også små mængder mangan, krom, beryllium, titanium, osv. Bortset fra en lille mængde mangan i legeringen, det meste af det danner MnAl6. Chroms rolle i 5052 aluminiumscirkler svarer til mangans. Det forbedrer modstanden mod spændingskorrosion, øger styrken af basismetallet og svejsninger, og reducerer tendensen til svejserevner, men dens indhold overstiger generelt ikke 0.35%.

Specifikation af 5052 Aluminiumscirkel

| Produkt | 5052 Aluminiumscirkel |

| Temperament | O, H12, H14, H18, H22, H32, H34, H111 |

| Tykkelse | 0.5mm-10,0 mm |

| Diameter | 100mm-1200 mm |

| Ledetid | Inden for 30-45 dage efter modtagelse af depositum |

| Pakning | Standard Eksport af træpaller eller baseret på kundekrav |

| Materiale | Brug af højteknologisk maskineri, der bruger premium-kvalitets aluminiumsspole. Skræddersyet efter kundernes behov og krav, kan disse benyttes ved forskellige tekniske specifikationer. |

| Overflade: | Lys & glat overflade, fri for fejl som hvid rust, olieplaster, kantskade. |

| Anvendelse | Aluminiumscirkler bruges i reflekterende skilte, Vejmøbler, Redskaber, Sand heks Bund, Komfur, non-stick osv. |

| Meddelelse | Specifikke krav til legeringstemperament eller specifikation kan fremstilles som din anmodning. |

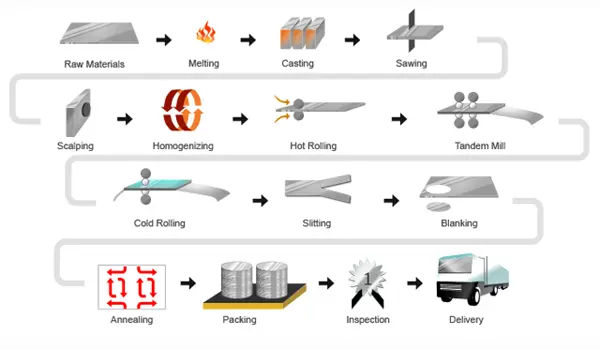

5052 Aluminium cirkel produktionslinje

- 1.Forbered masterlegeringerne

- 2.Smelteovn :anbring legeringerne i smelteovnen

- 3.D.C.støbt aluminium barre:At lave moderen barre

- 4.Fræs aluminiumsstangen:for at gøre overfladen og siden glatte

- 5.Varmeovn

- 6.Varmvalseværk:lavet moderspolen

- 7.Kølende valseværk:moderspolen blev rullet som den tykkelse du ønsker at købe

- 8.Stanseproces:blive den størrelse, du ønsker

- 9.Udglødningsovn:ændre temperamentet

- 10.Afsluttende eftersyn

- 11.Pakning:trækasse eller træpalle

- 12.Levering

Fremstillingsproces af aluminiumscirkler

Når du udfører trin 8, forskellige processer vil blive brugt på grund af forskellige tykkelser af aluminiumscirkler.

1. Tykkelse: 0.012″ – 0,15″ (0.3mm – 4 mm)

Stempling

Stempling er en metode til bearbejdning af færdige emner ved at fremføre metalplader, typisk fra en rulle, gennem en række stationer. Disse stationer kan omfatte stempling, bøjning, skære, og andre formgivningsteknikker, og udføres i en bestemt rækkefølge langs metalpladens bane.

2. Tykkelse: 0.15″ – 0,39″ (4mm – 10 mm)

Laserskæring

5052 ydelsesegenskaber for aluminiumskive/cirkel

Hårdhed: Trækstyrken af 5052 serie rækker imellem 210-230, hvilket betyder, at hårdheden af 5052 er 100% højere end hårdheden af 1060.

Forlængelse: Forlængelsen af 5052 serie rækker imellem 12-20%. Det kan også tænkes, at når 5052 serien er 100% sværere end 1060, forlængelsen øges også med ca 200%.

Kemiske egenskaber: 5052 er en legeret aluminium. I specielle miljøer, 5052 har bedre korrosionsbestandighed.

5052 bearbejdningsegenskaber for aluminiumskive

Formbarhed:

1. Legeringen har god plasticitet i varm tilstand.

2. Den kolde stempling er relateret til legeringstilstanden. Den koldstemplingsydeevne af den udglødede O-tilstand er god, efterfulgt af H32 og H34 temperamenterne.

Svejseydelse:

1. Denne legering har god ydeevne ved gassvejsning, buesvejsning, modstandssvejsning, punktsvejsning og sømsvejsning. Det har en tendens til krystallisationsrevner ved argonbuesvejsning. Den har god loddeevne, men dårlig blødloddeevne.

2. Svejsesømmen har høj styrke og plasticitet.

Typisk anvendelse af 5052 Aluminiumscirkel

Aluminiumscirkel til lamper: høj overfladefinish, ingen ridser, og høj forlængelse. Kornstørrelsen er velkontrolleret og velegnet til dybtegning og stempling. Aluminiumsskiver med forskellige diametre kan leveres i henhold til brugerkrav.

Køkkenudstyr: Aluminiumspotter, Aluminiumspotter, aluminium låg, alu kasser, teæsker, aluminium spande, aluminium dåser, medicindåser, køkkenredskaber, Madlavningsredskaber, service, bageredskaber, bageplader, kageforme, toastforme, anodiseret køkkengrej, anodiseret køkkengrej, anodiseret service, hårdanodiseret køkkengrej, hårdanodiseret køkkengrej, hårdanodiseret service, udendørs køkkengrej, udendørs køkkengrej, udendørs service, picnic gryder, udendørs køkkengrej sæt

5052 aluminium cirkel applikation

Vejskilte aluminiumsskive: Det er en buet skive, som forarbejdes af aluminiumsplade gennem rundbøjningsudstyr. De er velegnede til forskellige trafikskilte. De kan tilpasses efter diameter.

Lugedæksel aluminiumscirkel: 5052 aluminiumscirkel er et ideelt materiale til yachts olietætte lugedæksler. Det skal have stærk korrosionsbestandighed, anti-aging ydeevne og anti-ultraviolet ydeevne. Almindelig størrelse er 2,0*600 mm.

Yacht olie luge dæksel: 5052 aluminium cirkel er en af de typiske marine-grade aluminium produkter. Det kan ikke kun effektivt modstå korrosion fra havvind og havvand, men også reducere vægten af skroget.

5052 aluminiumscirkel til køkkengrej

Hardwareprodukter: hardware dele, metal stempling dele, hardware tegning dele, forskellige forme, tekstil shuttles, satellitantenner, osv.

Huawei 5052 kvalitetskontrol af aluminiumscirkel

- 1. Ingen revner, Korrosionssteder eller spor af nitratsalt er tilladt på overfladen.

- 2. Skrælning, bobler, Overflades ruhed og lokal mekanisk skade med en dybde, der ikke overstiger 8% af den defekte del af den defekte del af den nominelle vægtykkelse er tilladt på overfladen, men den maksimale dybde af defekten må ikke overstige 0,5 mm, og det samlede areal af defekten ikke overstiger pladens samlede areal. 5%.

- 3. Leverandøren får lov til at polere profilen i længderetningen, indtil overfladen er glat.

- 4. Andre krav: Efterspørger og leverandør skal selv formulere deres krav.

5052 kvalitetskontrol af aluminiumscirkel

5052 Cirkelpakke af aluminium

- 1.Sæt tørretumblerne på siden af aluminiumscirklen, holde produkterne tørre og rene.

- 2.Brug det rene plastikpapir, pakning af aluminiumscirklen, holde god tætning.

- 3.Brug slangeskindspapiret, pakning af plastpapirets overflade, holde god tætning.

- 4.Næste, Der er to måder at pakke på: En måde er træpalleemballage, ved at bruge det sprøde papir, der pakker overfladen;

En anden måde er trækasseemballage, ved hjælp af trækassen, der pakker overfladen. - 5.Finale, læg stålbåndet på trækassens overflade, hold trækassen fast og sikker.

Hvad er forskellen mellem 3003 og 5052 aluminium?

5052 alu plade og 3003 aluminiumsplader er de mest almindelige legerede aluminiumsplader på markedet. Nu tager vi 3003 H24 alu plade og 5052 H32 aluminiumsplade som eksempler på at popularisere viden på dette område. ,

1. Kemisk sammensætning: 3003 Aluminiumsplade er en aluminium-manganlegering, og det vigtigste legeringselement er mangan. 5052 aluminiumsplade er en aluminium-magnesium legering, og det vigtigste legeringselement er magnesium. Aluminiumindholdet i 3003 aluminiumsplade er lidt højere end den af 5052 Aluminiumsplade.

2. Mekaniske egenskaber: 3003 H24 aluminiumsplade er en aluminium-manganlegering, og det vigtigste legeringselement er mangan. Trækstyrken af 3003 H24 aluminiumsplade er 145-195Rm/MPa, mens trækstyrken af 5052 H34 aluminiumsplade er 230-280Rm/MPa, hvilket er meget højere end 3003 H24 aluminiumsplade; forlængelsesstyrken af 3003 H24 aluminiumsplade er 115Rm/MPa, mens forlængelsesstyrken af 5052 H34 aluminiumsplade er 150Rm/MPa. Derfor, udførelsen af 5052 aluminiumsplade er væsentligt bedre end den af 3003 Aluminiumsplade. ,

3003 aluminiumsplade med beskyttelsesfilm

3. Specifikationer: 3003 H14 aluminiumsplader er hovedsageligt tynde plader, og tykke plader er ikke meget brugt; mens 5052 aluminiumsplader er også meget brugt udover tynde plader og tykke plader. ,

4. Bruge: 3003 aluminiumsplader bruges hovedsageligt i fugtige omgivelser, såsom produktemballage, køleskabe, klimaanlæg, kølerum, ventilationskanaler, osv. 5052 aluminiumsplader bruges ofte i elektriske kabinetter, transportkøretøjer, Trykfartøjer, osv. Almindeligt anvendt materiale til fremstilling af brændstoftanke og brændstofrør til biler og fly.

5. Alu plade pris: Prisen på 3003 aluminiumsplade er lidt højere end for ren aluminiumsplade, mens prisen på 5052 aluminiumsplade er væsentligt højere end for 3003 Aluminiumsplade. Afhængig af specifikationer og tykkelse, prisen på et ton 5052 aluminiumsplader er højere end prisen på et ton 3003 alu plader.

Kan 5052 aluminium cirkel/skive være anodiseret?

Anodiseret aluminium cirkler er meget udbredt i mange projekter. Anodiseret aluminium cirkler er velegnede til varmtvalsede materialer (DC materialer). 5052 legeret aluminium cirkel er et varmvalset materiale (DC materiale), så den er af god kvalitet og velegnet til anodisering.

Den anodiserende effekt af 5052 aluminium cirkel er meget god, og det kan også anodiseres i forskellige farver, såsom sort, rød, blå, osv. Oxidfilmen vil beskytte aluminiumscirklen, forlænge dens levetid, og gør aluminiumslegeringsproduktet smukkere.

Casting produktionsproces og introduktion

Formålet med smeltning og støbning er at fremstille legeringer med tilfredsstillende sammensætning og høj renhed af smelte, for at skabe gunstige betingelser for støbning af legeringer i forskellige former.

Smeltning og støbningsprocesstrin: batching --- fodring --- smeltning --- omrøring efter smeltning, Fjernelse af slagge --- Pre-analyse prøveudtagning --- Tilføjelse af legering for at justere sammensætningen, omrøring --- Raffinering --- Statisk indstilling - - Guide Furnace Casting.

Hot rullende produktionsproces og dens introduktion

- 1. Hot rulling henviser generelt til rullende over metalrecrystallisationstemperaturen;

- 2. Under den varme rullende proces, metallet har både hærdning og blødgøringsprocesser. På grund af påvirkningen af deformationshastighed, Så længe gendannelse og omkrystallisationsprocessen er for sent, Der vil være et bestemt arbejdehærdning;

- 3. Omkrystallisationen af metallet efter varm rulling er ufuldstændig, det er, Sameksistensen af omkrystalliseret struktur og deformeret struktur;

- 4. Hot rulling kan forbedre behandlingens ydeevne for metaller og legeringer, Reducer eller eliminering af støbningsfejl.

- 1. Støbning og rulletemperatur er generelt mellem 680 ° C og 700 ° C. Jo lavere jo bedre, Den stabile støbe- og rullende linje stopper normalt en gang om måneden eller mere for at se på. Under produktionsprocessen, Det er nødvendigt at kontrollere væskeeniveauet for den forreste tank for at forhindre lavt væskeniveau;

- 2. Smøring bruger C -pulver med ufuldstændig forbrænding af gas til smøring, hvilket også er en af grundene til den beskidte overflade af støbning og rullende materialer;

- 3. Produktionshastigheden er generelt mellem 1,5 m/min-2,5 m/min;

- 4. Overfladekvaliteten af produkter produceret ved støbning og rulle er generelt relativt lav, og kan generelt ikke opfylde produkter med særlige fysiske og kemiske ydelseskrav.

- 1. Kold rullende henviser til den rullende produktionsmetode under omkrystallisationstemperaturen;

- 2. Der vil ikke være nogen dynamisk omkrystallisation under rullende proces, og temperaturen stiger højst til gendannelsestemperaturen, Og den kolde rulling vises i en arbejdshærdningstilstand, og arbejdshærdningshastigheden vil være stort;

- 3. Det koldvalsede ark og strimmel har høj dimensionel nøjagtighed, God overfladekvalitet, ensartet struktur og ydeevne, og produkter i forskellige stater kan opnås med varmebehandling;

- 4. Kold rulling kan rulle ud tynde strimler, Men på samme tid, Det har ulemperne ved højt energiforbrug til deformation og mange behandlingspas.

- 1. Efterbehandling er en behandlingsmetode til at få det koldvalsark til at imødekomme kundens krav, eller for at lette den efterfølgende behandling af produktet;

- 2. Efterbehandlingsudstyret kan korrigere de defekter, der er produceret i den varme rullende og kolde rullende produktionsproces, såsom knækket kant, olieagtig, Dårlig pladeform, Reststress, osv. Det skal sikre, at ingen andre defekter bringes ind i produktionsprocessen;

- 3. Der er forskellige efterbehandlingsudstyr, hovedsageligt inklusive tværgående, Slæden, strækning og udretning, Udglødningsovn, Slitter, osv.

Støbning og rulleproces

Støbning og rulleproces: flydende metal, frontboks (Kontrol af væskeniveau), støbning og rullende maskine (Smøresystem, kølevand), klipmaskine, Spilemaskine.

Kold rullende produktionsproces

Introduktion til efterbehandling af produktionsprocessen

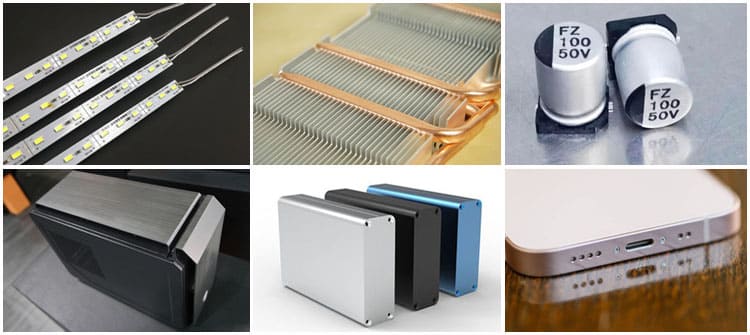

Aluminiumslegering har egenskaberne ved lav densitet, Gode mekaniske egenskaber, God behandlingsydelse, Ikke-giftig, Let at genbruge, Fremragende elektrisk ledningsevne, Varmeoverførsel og korrosionsbestandighed, Så det har en bred vifte af applikationer.

Rumfart: Bruges til at fremstille flyskind, Fuselage -rammer, bælter, Rotorer, propeller, brændstofbeholdere, Vægpaneler og landingsudstyrsstiver, såvel som raket smedningsringe, rumfartøjsvægpaneler, osv.

Aluminiumslegering, der bruges til rumfart

Transport: Brugt til bilkropsstrukturmaterialer af biler, Subway -køretøjer, Jernbanepassagerbiler, Højhastighedsbeholdere, Døre og vinduer, hylder, Automotive motordele, klimaanlæg, radiatorer, kropspaneler, hjul og skibsmaterialer.

Trafikansøgning

Emballage: Aluminiums pop-dåser bruges hovedsageligt som metalemballagematerialer i form af tynde plader og folier, og er lavet til dåser, låg, flasker, tønder, og emballeringsfolier. Bredt brugt til emballage af drikkevarer, mad, Kosmetik, lægemidler, cigaretter, Industrielle produkter, lægemidler, osv.

Emballageapplikation

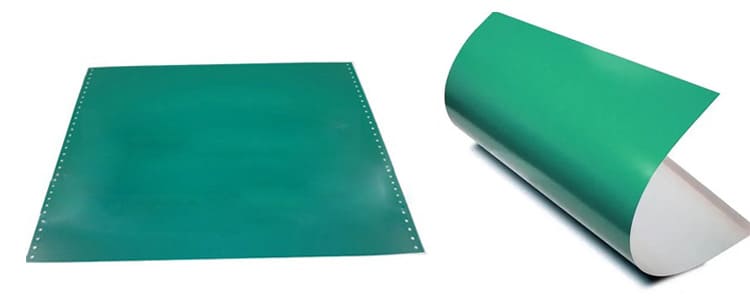

Trykning: Hovedsageligt brugt til at fremstille PS -plader, Aluminiumbaserede PS-plader er en ny type materiale i trykbranchen, Bruges til automatisk pladefremstilling og udskrivning.

PS -udskrivning

Arkitektonisk dekoration: Aluminiumslegering er vidt brugt til bygningsstrukturer, Døre og vinduer, Suspenderede lofter, Dekorative overflader, osv. På grund af dens gode korrosionsbestandighed, tilstrækkelig styrke, Fremragende procesydelse og svejsestyring.

Anvendelse af aluminiumslegeringskonstruktion

Elektroniske produkter: Computere, mobiltelefoner, Køleskabsskaller, radiatorer, osv.

Elektronisk produktapplikation

Køkkenforsyninger: Aluminiumspotter, Aluminiumsbassiner, Ris komfurforinger, Husholdningsaluminiumsfolie, osv.

Køkkenapplikation

Emballage af aluminiumsark/spole

Hver detalje i emballagen er, hvor vi forfølger perfekt service. Vores emballageproces som helhed er som følger:

Laminering: Klar film, Blå film, Mikroblimhinde, Høj flimhinde, Laserskærende film (2 mærker, Novacell og Polyphem);

Beskyttelse: Paper Corner Protectors, Anti-tryk puder;

tørring: tørremiddel;

Bakke: fumigated ufarlig træbakke, Genanvendelig jernbakke;

Pakning: Tic-tac-toe stålbælte, eller PVC -pakningsbælte;

Materialekvalitet: Helt fri for defekter såsom hvid rust, oliepletter, rullende mærker, kantskade, bøjer sig, buler, huller, Bryde linjer, ridser, osv., Intet spiralsæt.

Havn: Qingdao eller andre havne i Kina.

Ledetid: 15-45 dage.

Aluminiumsark/pladeemballageproces

Aluminiumsspoleemballageproces

F: Er du en producent eller en erhvervsdrivende?

Q: Vi er en producent, Vores fabrik er på No.3 Weier Road, Industriel zone, Gongyi, Henan, Kina.

F: Hvad er MOQ for at bestille produktet?

Q: Vores MOQ er 5 tonsvis, Og nogle specielle produkter vil have en minimumsordre -mængde på 1 eller 2 tonsvis.

F: Hvor lang er din ledetid?

Q: Generelt handler vores ledetid om 30 dage.

F: Har dine produkter kvalitetssikring?

Q: Ja, Hvis der er et kvalitetsproblem med vores produkter, Vi kompenserer kunden, indtil de er tilfredse.

Relaterede produkter

Seneste blogs

Spejlplade i aluminium med ultrahøj reflektivitet

Spejlplade i aluminium med ultrahøj reflektivitet med 95–98 % synlig reflektans, lav spredning (TIS <1%), og specifikationsrådgivning for BRDF, spektralkurver og belægninger.

Betroet 3003 Leverandører af pladeplader af aluminium i hele verden

Find pålidelige 3003 Leverandører af pladeplader af aluminium, der tilbyder certificeret kvalitet, konkurrencedygtige priser, brugerdefinerede størrelser, og hurtig global levering til dine projekter.

6061 T6 vs 7075 Aluminium: Styrke, Vægt & Bedste anvendelser

Sammenligne 6061 T6 vs 7075 let aluminium. Opdag forskelle i styrke, vægt, og applikationer til at vælge det bedste til dine projekter.

Industrialisering og anvendelse af honeycomb aluminiumsfolie

Denne blog udforsker industrialiseringen af honeycomb aluminiumsfolie, med fokus på 3003 legeringsproduktionsproces. Det dækker varmvalsning, kontinuerlig støbning, og den kontinuerlige støbe-valsemetode, fremhæver fordelene ved procesoptimering til at forbedre mekaniske egenskaber, reducere energiforbruget, og sænke produktionsomkostningerne.