Quick Understanding Of 3105 Aluminiumsark

3105 aluminum sheet is essentially a 98% aluminum alloy with a small amount of manganese added for strength, making it more than alloys 1100 og 3003 Aluminiumsark.

3105 aluminum alloy cannot be strengthened by heat treatment, har god korrosionsbestandighed, good plasticity and processing performance, and has good gas welding and arc welding performance.

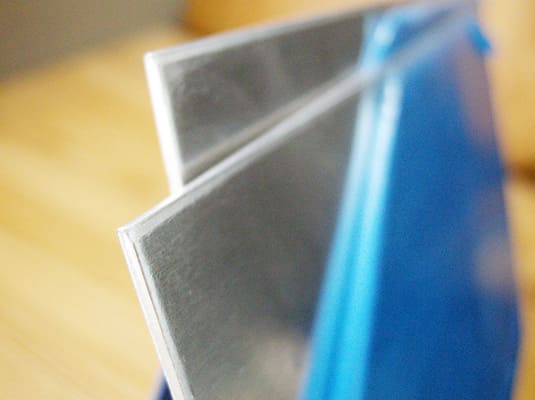

3105 Aluminiumsark display

Typical applications for 3105 aluminum sheet include metal products that require higher strength than 1000 serien aluminiumslegeringer, residential siding, mobile homes, and sign making.

Kemisk sammensætning af 3105 Aluminiumsark

| Elementer | Og | Fe | Cu | Mn | Mg | Cr | Zn | Af | Andre | Al |

| Tilfreds (maks) | 0.6 | 0.70 | 0.30 | 0.3.-0.80 | 0.20-0.80 | 0.20 | 0.40 | 0.10 | 0.15 | remain |

3105 aluminum is a 3000 serie aluminiumslegering: the main alloy addition is manganese, which improves the strength of the alloy.

0.3% copper is added to 3105 Aluminiumslegering, so the conductivity is good, and the conductivity can reach 41%;

Mechanical Properties With Different Temper

Requirements for strain hardened H14 temper (½ hard)

as specified in ASTM B209 and ASME SB209

| Materiale | Temperament | Trækstyrke (N/mm²) | Udbyttestyrke (N/mm²) | Elongation on 50mm | |||

| 0.5 mm | 0.8mm | 1.3mm | 2.6mm | ||||

| 3105 Aluminiumsark | 0 | 110-155 | – | 16 | 18 | 20 | 20 |

| 3105 Aluminiumsark | H12 | 130-175 | 115 | 2 | 3 | 4 | 5 |

| 3105 Aluminiumsark | H14 | 160-205 | 145 | 2 | 2 | 3 | 4 |

| 3105 Aluminiumsark | H16 | 185-230 | 170 | 1 | 1 | 2 | 3 |

| 3105 Aluminiumsark | H18 | 215 min | 190 | 1 | 1 | 1 | 2 |

3105 aluminum sheet has high plasticity in the annealing state, in the semi cold hardened, the plasticity is still better, it has low plasticity, God korrosionsmodstand, good weld-ability and poor cutting properties in cold hardening state.

3105 Aluminum Sheet Physical Properties

| Ejendom | Data |

| Calomel Potential | -750 mV |

| Densitet | 175 Ib/ft3′ |

| Electrical Conductity | 44 % IACS |

| Elektrisk resistivitet | 1.504 μQ-in |

| Melting Onset (Solidus) | 1180 °F (638 ℃) |

| Specific Heat Capacity | 0.214 BTU/Ib-oF |

| Termisk ledningsevne | 98 BTU/ft Hr oF |

| Thermnal Difusivity | 721 ft/s |

| CTE (68-212F) | 13.1 pin/in-9F |

3105 Aluminum Plate Advantages

- 1. Good conductivity, adding 0.3% copper element, the conductivity can reach 41%;

- 2. Deep drawing ability. The deep drawing performance of 3105 aluminum alloy plate in O state is better than that in H26 state, and the deep drawing performance of 3105 aluminum alloy plate before low temperature treatment is better than that after 24h treatment.

- 3. De 3105 aluminum sheet has high plasticity in the annealed state, good plasticity in semi-cold work hardening, and low plasticity in cold work hardening.

- 4. The excellent weldability of 3105 aluminum plate is suitable for all existing welding techniques, among which arc welding is the best method.

- 5. Other features. God korrosionsmodstand, good anodic oxidation performance, poor machinability, osv.

advantages of 3105 Aluminiumsark

Due to its good anti-corrosion performance, this series of aluminum plates are often used in humid environments such as air conditioners, køleskabe, and the bottom of cars.

Typiske kendetegn ved 3105 aluminium

| Principal Design Features | This is an essentially 98% pure aluminum alloy with minor additions for strength. It is not hardenable by heat treatment. Korrosionsmodstand,formability and welding characteristics are excellent. |

| Bearbejdelighed | Machinability of AL 3105 is fair. Oil lubricants should be used for all machining operations. Machinability of the alloy when in the harder (H) tempers is improved over machining in the annealed (O) condition. |

| Dannelse | The forming characteristics of the alloy are very good by all conventional processes regardless of temper. Bend radii should be in the one thickness to 2 t range for annealed, H12, H14 and H16 tempers. The H18 temper requires bend radii of2 to 7 t, depending upon thickness of the material. |

| Svejsning | Weldability of this alloy is excellent by all commercial techniques. Arc welding is preferred for the best results. |

| Varmebehandling | A non-heat treatable alloy. |

| Hot Working | The hot working range (as for forging) is 205°C to 372°C. In that range the alloy is easily hot worked. |

| Cold Working | The cold working characteristics of AL 3105 are very good, even in the harder cold worked tempers. Bend radi for sheet up to 1/16″ thick vary from 1/2 to one t for all tempers. |

| Udglødning | Annealing from a cold worked condition may be accomplished at 345°C followed by air cooling. |

| Aldring | Not applicable to this alloy. |

| Hardening | Hardens as a result of cold working only. |

| Typiske applikationer | Aluminium 3105 is most commonly used where a painted finish is desired.Typical applications include general sheet metal work requiring greater strength than is provided by 1000 serien aluminiumslegeringer, residential siding, room partition, baffle, mobile homes, rain carrying goods and sign making. |

| Pakke | Packed in waterproof Kraft, fastened by steel straps on wood pallets, suitable for handling, loading and unloading from the trunks or containers, suitable for export ocean forwarding. |

| Handling | Prevent the goods hurting the people who are moving, loading, unloading, especially pay attention to the rlling and dropping for the coils. |

| Opbevaring | Stored in indoor area on plain floor, free away from moisture, vand, sne, animal oils and dye wastes, avoid storing with acid or basic chemical goods. |

Datakilder: 3105 aluminium

Sizas Huawei Aluminum Supply Of 3105 aluminum Sheet

Huawei Aluminium har været engageret i produktion og salg af aluminiumsprodukter til 22 år. It has rich experience in the production and export of aluminum sheets. We provide customized 3105 Aluminiumsark. The following are common sizes:

- 4× 8 Aluminiumspladeplade

- 4×10 aluminiumsplade

- 5×10 aluminiumsplade

- 1000 x 1500 mm aluminiumsplade

- 1500 x 2000mm aluminum sheet

- 1500 x 3000mm aluminum sheet

- 2000 x 3000mm aluminum sheet

Different types of 3105 Aluminiumsark

3105 anodiseret aluminiumsplade: This aluminum sheet is anodized to form an oxide layer, which improves its surface hardness and wear resistance. Anodized aluminum sheets are usually used in electronic equipment casings, decorative parts and other occasions that require surface protection and aesthetics.

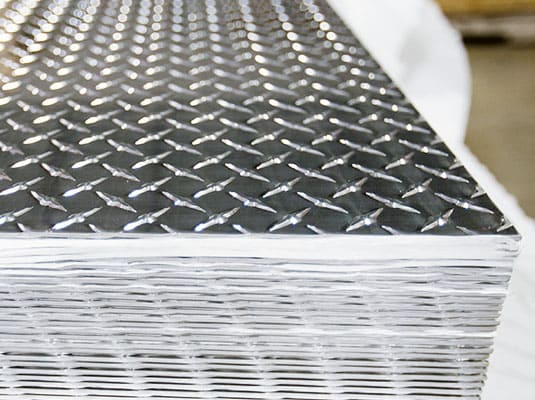

traffic sign

3105 embossed aluminum sheet: Embossed aluminum sheet undergoes special processing technology to make its surface present different patterns, textures or patterns. This not only increases the aesthetics of the aluminum sheet, but also increases the skid resistance of its surface, so it is often used in stair treads, floors and other places that require anti-skid functions.

- Diamond aluminum sheet of 3105

- 1 bar 3105 Aluminiumsark

- 3 bar 3105 Aluminiumsark

- 5 bar 3105 Aluminiumsplade

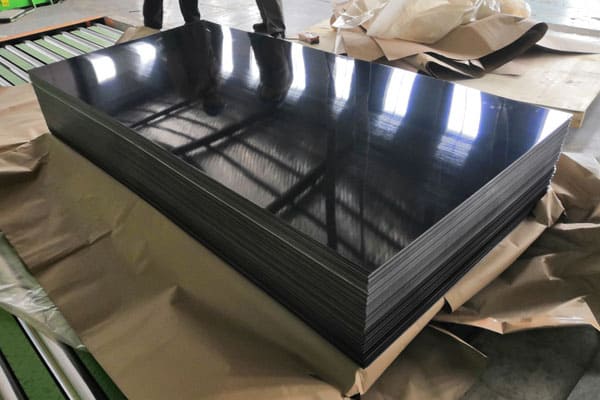

3105 color-coated aluminum sheet: 3105 aluminum sheet has been coated, and different colors and coating types can be selected to meet different decoration and protection needs. Common prepainted colors are:

- Sort

- White

- Orange

- Champagne

- Charcoal

- Red

- Silver

- Brandywine

- Emerald Green

- Indigo Blue

- Pewter

- Penske Yellow

- Burgundy

- Brite One Side

Sort 3105 Aluminiumsark

3105 perforated aluminum plate: 3105 perforated aluminum plate is a product made by processing 3105 aluminum alloy plate through punching process. Punching is a processing method in which sheet metal is punched through a die to form a specific hole pattern.

3105 brushed aluminum plate: 3105 aluminum sheet plate is an aluminum alloy plate that has been processed by wire drawing. Wire drawing is a processing method that forms uniform textures and lines on the metal surface by mechanical means, thus giving the metal surface a unique appearance and texture.

Application Of 3105 Aluminiumsark

3105 aluminum sheet has good tensile strength and corrosion resistance, so it is often used in room partitions, baffles, mobile room panels, color-coated aluminum substrates, shutters, and lamp head materials. Gutters and downspouts, sheet formed parts, Flaskehætter, stoppers, transportation and more.

3105 aluminum roofing sheet production

3105 Aluminum Roofing Sheet

3105 aluminum sheet is very advantageous for aluminum roofing sheet because of its high strength to weight ratio.

Reduce the weight of the roof while meeting the strength needs of the shingle.

Not only that, the strong corrosion resistance of 3105 aluminum sheet also improves the service life of aluminum roofing sheet.

3105 Diamond Aluminum Sheet

Diamond aluminum sheets, also known as diamond plate or tread plate, are aluminum sheets with a raised diamond pattern on their surface. This pattern provides a textured and slip-resistant surface, making diamond aluminum sheets suitable for various applications. Here are some common applications of diamond aluminum sheets:

Diamond Plate Of 3105 Aluminium

Gulvbelægning: Diamond aluminum sheets are often used as flooring material in places where slip resistance is crucial, such as industrial facilities, ramper, trappetrin, and walkways. The raised diamond pattern provides traction, mindske risikoen for ulykker.

Transport: These sheets are commonly used for flooring and walls in vehicles like trucks, trailere, and buses. The textured surface prevents cargo or equipment from shifting during transportation and helps maintain safe footing for workers inside the vehicles.

Decorative Elements: The distinct diamond pattern of these sheets can add an industrial or rugged aesthetic to interiors and exteriors of buildings, køretøjer, and other structures. They are used for decorative wall panels, wainscoting, backsplashes, Og mere.

3105 aluminum sheet for car

Toolboxes and Storage: Diamond aluminum sheets are often used for constructing toolboxes, storage cabinets, and chests. The pattern adds strength to the structure while also enhancing the appearance.

Trailers and Loading Ramps: Diamond aluminum sheets are commonly used on trailer floors, especially for trailers that carry heavy equipment or vehicles. They also find application in constructing loading ramps for easy loading and unloading.

Marine applikationer: The corrosion-resistant properties of aluminum make diamond sheets suitable for marine applications, including boat decks, dokker, and other waterfront structures.

Casting produktionsproces og introduktion

Formålet med smeltning og støbning er at fremstille legeringer med tilfredsstillende sammensætning og høj renhed af smelte, for at skabe gunstige betingelser for støbning af legeringer i forskellige former.

Smeltning og støbningsprocesstrin: batching --- fodring --- smeltning --- omrøring efter smeltning, Fjernelse af slagge --- Pre-analyse prøveudtagning --- Tilføjelse af legering for at justere sammensætningen, omrøring --- Raffinering --- Statisk indstilling - - Guide Furnace Casting.

Hot rullende produktionsproces og dens introduktion

- 1. Hot rulling henviser generelt til rullende over metalrecrystallisationstemperaturen;

- 2. Under den varme rullende proces, metallet har både hærdning og blødgøringsprocesser. På grund af påvirkningen af deformationshastighed, Så længe gendannelse og omkrystallisationsprocessen er for sent, Der vil være et bestemt arbejdehærdning;

- 3. Omkrystallisationen af metallet efter varm rulling er ufuldstændig, det er, Sameksistensen af omkrystalliseret struktur og deformeret struktur;

- 4. Hot rulling kan forbedre behandlingens ydeevne for metaller og legeringer, Reducer eller eliminering af støbningsfejl.

- 1. Støbning og rulletemperatur er generelt mellem 680 ° C og 700 ° C. Jo lavere jo bedre, Den stabile støbe- og rullende linje stopper normalt en gang om måneden eller mere for at se på. Under produktionsprocessen, Det er nødvendigt at kontrollere væskeeniveauet for den forreste tank for at forhindre lavt væskeniveau;

- 2. Smøring bruger C -pulver med ufuldstændig forbrænding af gas til smøring, hvilket også er en af grundene til den beskidte overflade af støbning og rullende materialer;

- 3. Produktionshastigheden er generelt mellem 1,5 m/min-2,5 m/min;

- 4. Overfladekvaliteten af produkter produceret ved støbning og rulle er generelt relativt lav, og kan generelt ikke opfylde produkter med særlige fysiske og kemiske ydelseskrav.

- 1. Kold rullende henviser til den rullende produktionsmetode under omkrystallisationstemperaturen;

- 2. Der vil ikke være nogen dynamisk omkrystallisation under rullende proces, og temperaturen stiger højst til gendannelsestemperaturen, Og den kolde rulling vises i en arbejdshærdningstilstand, og arbejdshærdningshastigheden vil være stort;

- 3. Det koldvalsede ark og strimmel har høj dimensionel nøjagtighed, God overfladekvalitet, ensartet struktur og ydeevne, og produkter i forskellige stater kan opnås med varmebehandling;

- 4. Kold rulling kan rulle ud tynde strimler, Men på samme tid, Det har ulemperne ved højt energiforbrug til deformation og mange behandlingspas.

- 1. Efterbehandling er en behandlingsmetode til at få det koldvalsark til at imødekomme kundens krav, eller for at lette den efterfølgende behandling af produktet;

- 2. Efterbehandlingsudstyret kan korrigere de defekter, der er produceret i den varme rullende og kolde rullende produktionsproces, såsom knækket kant, olieagtig, Dårlig pladeform, Reststress, osv. Det skal sikre, at ingen andre defekter bringes ind i produktionsprocessen;

- 3. Der er forskellige efterbehandlingsudstyr, hovedsageligt inklusive tværgående, Slæden, strækning og udretning, Udglødningsovn, Slitter, osv.

Støbning og rulleproces

Støbning og rulleproces: flydende metal, frontboks (Kontrol af væskeniveau), støbning og rullende maskine (Smøresystem, kølevand), klipmaskine, Spilemaskine.

Kold rullende produktionsproces

Introduktion til efterbehandling af produktionsprocessen

Aluminiumslegering har egenskaberne ved lav densitet, Gode mekaniske egenskaber, God behandlingsydelse, Ikke-giftig, Let at genbruge, Fremragende elektrisk ledningsevne, Varmeoverførsel og korrosionsbestandighed, Så det har en bred vifte af applikationer.

Rumfart: Bruges til at fremstille flyskind, Fuselage -rammer, bælter, Rotorer, propeller, brændstofbeholdere, Vægpaneler og landingsudstyrsstiver, såvel som raket smedningsringe, rumfartøjsvægpaneler, osv.

Aluminiumslegering, der bruges til rumfart

Transport: Brugt til bilkropsstrukturmaterialer af biler, Subway -køretøjer, Jernbanepassagerbiler, Højhastighedsbeholdere, Døre og vinduer, hylder, Automotive motordele, klimaanlæg, radiatorer, kropspaneler, hjul og skibsmaterialer.

Trafikansøgning

Emballage: Aluminiums pop-dåser bruges hovedsageligt som metalemballagematerialer i form af tynde plader og folier, og er lavet til dåser, låg, flasker, tønder, og emballeringsfolier. Bredt brugt til emballage af drikkevarer, mad, Kosmetik, lægemidler, cigaretter, Industrielle produkter, lægemidler, osv.

Emballageapplikation

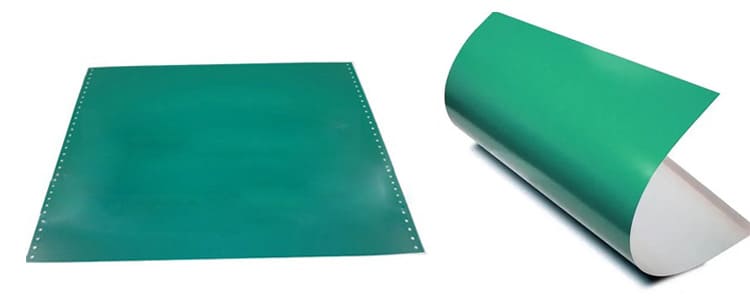

Trykning: Hovedsageligt brugt til at fremstille PS -plader, Aluminiumbaserede PS-plader er en ny type materiale i trykbranchen, Bruges til automatisk pladefremstilling og udskrivning.

PS -udskrivning

Arkitektonisk dekoration: Aluminiumslegering er vidt brugt til bygningsstrukturer, Døre og vinduer, Suspenderede lofter, Dekorative overflader, osv. På grund af dens gode korrosionsbestandighed, tilstrækkelig styrke, Fremragende procesydelse og svejsestyring.

Anvendelse af aluminiumslegeringskonstruktion

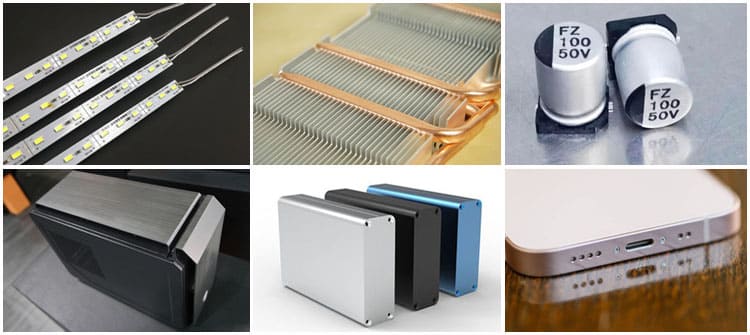

Elektroniske produkter: Computere, mobiltelefoner, Køleskabsskaller, radiatorer, osv.

Elektronisk produktapplikation

Køkkenforsyninger: Aluminiumspotter, Aluminiumsbassiner, Ris komfurforinger, Husholdningsaluminiumsfolie, osv.

Køkkenapplikation

Emballage af aluminiumsark/spole

Hver detalje i emballagen er, hvor vi forfølger perfekt service. Vores emballageproces som helhed er som følger:

Laminering: Klar film, Blå film, Mikroblimhinde, Høj flimhinde, Laserskærende film (2 mærker, Novacell og Polyphem);

Beskyttelse: Paper Corner Protectors, Anti-tryk puder;

tørring: tørremiddel;

Bakke: fumigated ufarlig træbakke, Genanvendelig jernbakke;

Pakning: Tic-tac-toe stålbælte, eller PVC -pakningsbælte;

Materialekvalitet: Helt fri for defekter såsom hvid rust, oliepletter, rullende mærker, kantskade, bøjer sig, buler, huller, Bryde linjer, ridser, osv., Intet spiralsæt.

Havn: Qingdao eller andre havne i Kina.

Ledetid: 15-45 dage.

Aluminiumsark/pladeemballageproces

Aluminiumsspoleemballageproces

F: Er du en producent eller en erhvervsdrivende?

Q: Vi er en producent, Vores fabrik er på No.3 Weier Road, Industriel zone, Gongyi, Henan, Kina.

F: Hvad er MOQ for at bestille produktet?

Q: Vores MOQ er 5 tonsvis, Og nogle specielle produkter vil have en minimumsordre -mængde på 1 eller 2 tonsvis.

F: Hvor lang er din ledetid?

Q: Generelt handler vores ledetid om 30 dage.

F: Har dine produkter kvalitetssikring?

Q: Ja, Hvis der er et kvalitetsproblem med vores produkter, Vi kompenserer kunden, indtil de er tilfredse.

Relaterede produkter

Seneste blogs

8011 Aluminiumsfolie 90 Mikrofon til luftkanal | Stærk & Fleksibel

Præmie 8011 Aluminiumsfolie 90 mikrofon til luftkanalsystemer - giver fremragende fleksibilitet, fugtmodstand, og termisk isoleringsevne.

Nålehuller på PTP aluminiumsfolie | Årsager, Testning & Specifikationer

Forstå hvordan pinholes på PTP aluminiumsfolie, deres indvirkning på fugt/iltbarrieren, og testmetoderne & acceptgrænser, der holder vabler i spec.

Er aluminiumsfolie giftig? | Sikkerhedsfakta, du har brug for at vide

Spekulerer på er aluminiumsfolie giftig? Vi debunk almindelige myter og giver videnskabsstøttede fakta om dens sikkerhed for opbevaring af madlavning og mad.