The Practical Guide to 3 16 Aluminum Sheet Metal

When you’re working with aluminum, thickness matters. And few thicknesses offer the unique blend of strength and workability found in 3 16 aluminum sheet metal.

This isn’t just another dimension; it represents a critical transition point—the “sweet spot” where a material is robust enough for structural use but not so heavy that it becomes unmanageable.

At a thickness of 0.1875 inches (or 4.76mm), this material technically straddles the line between “sheet” and “plate.”

But what truly matters is understanding how to use it.

This guide moves beyond mere specifications to provide the practical, experience-based knowledge you need to select the right alloy, anticipate fabrication challenges, and confidently apply 3/16 aluminum sheet to your project.

3 16 Aluminum Sheet Metal

Why Choose 3/16 Inch? The All-Rounder’s Advantage

Opting for a 3/16″ thickness is a deliberate engineering choice. It offers a compelling balance that thinner gauges and thicker plates cannot match.

- Substantial Structural Rigidity: Unlike thinner sheets that can flex and warp easily, 3/16″ aluminum provides significant stiffness. It can serve as a base plate, a gusset, or a mounting bracket without buckling under moderate loads.

- Enhanced Durability and Impact Resistance: This thickness offers excellent resistance to dents, punctures, and deformation. This makes it ideal for high-wear surfaces like truck bed liners, toolboxes, or protective skid plates.

- Manageable Workability: While it demands powerful tools, 3/16″ aluminum can still be cut, bent, and welded with standard fabrication shop equipment. It is far more cooperative than a 1/2″ plate, which often requires specialized heavy machinery.

Of course. Here is the expanded section, incorporating more alloy grades into the comparison table.

This provides a richer, more comprehensive overview for users with specialized needs beyond the common workhorses.

Common and Specialty Alloys for 3 16 Aluminum Sheet Metal

While the vast majority of 3 16 Aluminum Sheet Metal projects are perfectly served by the “big three”—5052, 6061, and 3003—a world of specialty alloys exists for applications demanding peak performance.

When your project requires extreme strength, heavy-duty marine durability, or unique physical properties, turning to these less common but highly capable grades is essential.

The following table expands our comparison to include these specialty alloys, providing a comprehensive guide for engineers, fabricators, and designers facing advanced material selection challenges.

| Alloy Grade | 6061-T6 | 5052-H32 | 5083-H321 | 2024-T3 | 7075-T6 | 1100-H14 |

| Core Identity | The Structural Powerhouse | The Marine-Grade Workhorse | The Heavy-Duty Ship Plate | The Classic Aerospace Alloy | The Ultimate Strength Champion | The Pure & Pliable Conductor |

| Primary Advantage | Highest Strength & Rigidity | Superb Formability & Durability | Maximum Weld Strength & Toughness | High Strength & Fatigue Resistance | Highest Strength of Common Alloys | Maximum Formability & Conductivity |

| Strength | ★★★★★ | ★★★☆☆ | ★★★★☆ | ★★★★★ | ★★★★★+ | ★☆☆☆☆ |

| Formability (Bending) | ★☆☆☆☆ (Poor) | ★★★★★ (Excellent) | ★★★★☆ (Very Good) | ★★☆☆☆ (Fair in T3) | ★☆☆☆☆ (Poor) | ★★★★★ (Excellent) |

| Corrosion Resistance | ★★★★☆ (Very Good) | ★★★★★ (Excellent) | ★★★★★ (Excellent) | ★☆☆☆☆ (Poor) | ★★☆☆☆ (Poor) | ★★★★★ (Excellent) |

| Weldability | ★★★★☆ (Good, but HAZ weakens) | ★★★★★ (Excellent) | ★★★★★ (Excellent) | ★☆☆☆☆ (Not Recommended) | ★☆☆☆☆ (Not Recommended) | ★★★★☆ (Good, but soft) |

| Machinability | ★★★★★ (Excellent) | ★★★☆☆ (Good) | ★★☆☆☆ (Fair) | ★★★★★ (Excellent) | ★★★★★ (Excellent) | ★☆☆☆☆ (Poor – Gummy) |

| Best For | Structural frames, machine base plates, precision CNC parts. Any application where strength is the top priority. | Boat parts, fuel tanks, formed brackets, high-vibration panels. Any part requiring tight bends and weather resistance. | Shipbuilding, cryogenic tanks, LNG transport, heavy-duty dump truck bodies. Applications needing maximum welded strength and toughness. | Aircraft skins and structures, high-stress components, parts needing high fatigue life. | Highly stressed aerospace frames, high-performance molds, military applications where absolute strength is critical. | Electrical busbars, chemical equipment, heat exchangers, metal spinning, and decorative trim. |

| Key Limitation | Will crack if bent sharply. Welding significantly reduces its T6 strength. | Lower strength than 6061. Not ideal for purely structural parts that are not reinforced. | More expensive and less available than 5052. Susceptible to sensitization at elevated service temperatures. | Poor corrosion resistance (requires cladding or coating). Virtually non-weldable. | Expensive. Prone to Stress Corrosion Cracking (SCC). Poor weldability. | Extremely low strength. Very soft and easily dented or damaged. |

| Main Alloying Element | Magnesium & Silicon | Magnesium | Magnesium | Copper | Zinc | 99.0% Pure Aluminum |

The Critical Choice: 5052 vs. 6061 Alloy

The thickness is only half the story. The alloy you choose will define the material’s personality and performance.

For 3/16 inch sheet, the choice almost always comes down to two dominant players: 5052-H32 and 6061-T6.

6061 T6 Aluminum 3 16 Sheet Metal

5052-H32: The Formable & Durable Champion

Think of 5052 as the tough, flexible workhorse. Its primary alloying element is magnesium, which gives it excellent corrosion resistance, especially in saltwater environments.

The H32 temper means it has been strain-hardened and then stabilized at a low temperature to ensure it doesn’t become too brittle.

Choose 5052-H32 when your priority is:

- Excellent Formability: It can be bent to a tight radius without cracking.

- Superior Corrosion Resistance: It is considered a true “marine grade” aluminum.

- Good Weldability: It is easily welded and produces strong joints.

6061-T6: The Structural Powerhouse

In contrast, 6061 aluminum sheet is the high-strength structural hero.

Its strength comes from a combination of magnesium and silicon, and the T6 temper means it has been heat-treated and artificially aged to its maximum hardness and strength.

Huawei Packaged Aluminum Sheet

Choose 6061-T6 when your priority is:

- High Strength-to-Weight Ratio: It provides exceptional strength for load-bearing applications.

- Excellent Machinability: It cuts cleanly, producing small chips, making it ideal for CNC milling and drilling.

- Good Weldability: Like 5052, it welds well, but welding will reduce the strength in the heat-affected zone.

| Feature | 5052-H32 Aluminum | 6061-T6 Aluminum | The Bottom Line |

|---|---|---|---|

| Primary Strength | Formability & Durability | High Strength & Hardness | Choose 5052 for bending; 6061 for load-bearing. |

| Corrosion Resistance | ★★★★★ (Excellent) | ★★★★☆ (Very Good) | 5052 is superior, especially for marine use. |

| Weldability | ★★★★★ (Excellent) | ★★★★☆ (Very Good) | Both are great, but 5052 is slightly more forgiving. |

| Formability (Bending) | ★★★★★ (Excellent) | ★★☆☆☆ (Fair) | 5052 bends easily; 6061 is brittle and may crack. |

| Machinability | ★★★☆☆ (Good) | ★★★★★ (Excellent) | 6061 is the clear winner for any machining work. |

| Common Use | Boat hulls, fuel tanks, panels | Base plates, machine parts, frames | Use 5052 for tough skins; 6061 for rigid skeletons. |

A Fabricator’s Guide to Working with 3 16 Aluminum Sheet Metal

This thickness demands respect and the right equipment. Here’s what you need to know before you start cutting, bending, or welding.

- Cutting:

While a heavy-duty shear can cut 3 16 Aluminum Sheet Metal, it may cause some edge deformation.

For cleaner, more precise cuts, waterjet, laser, or plasma cutting are far superior methods.

A circular saw with a carbide-tipped blade designed for non-ferrous metals can also work for straight cuts. - Bending and Forming:

You cannot bend this material by hand. You will need a hydraulic press brake.

The key here is the minimum bend radius. Trying to bend 6061-T6 too sharply will cause it to crack along the outer edge.

5052-H32 is much more forgiving and can handle a much tighter bend. Always bend “with the grain” if possible for the best results. - Welding:

Both alloys weld well with TIG or MIG processes. However, because of its thickness, 3/16″ aluminum acts as a significant heat sink.

You will need higher amperage settings on your welder to establish and maintain a proper weld puddle.

Thorough pre-weld cleaning to remove the aluminum oxide layer is absolutely critical for a strong, pore-free weld. - Drilling and Machining:

Use sharp drill bits designed for metal and a lubricant to prevent galling.

As noted, 6061-T6 is a dream to machine, while 5052 can be “gummier.”

Bending process of 3 16 Aluminum Sheet Metal

By the Numbers: Key Properties of 3/16″ Sheet

Understanding the physical data helps in planning and design.

Weight: One of aluminum’s greatest assets is its light weight.

- Weight of 3/16″ Aluminum Sheet: Approximately 2.35 lbs per square foot (or 11.47 kg per square meter).

A standard 4 ft x 8 ft sheet of 3/16″ aluminum will weigh around 75.2 lbs (34.1 kg), making it a two-person job to handle safely.

Real-World Applications: 3 16 Aluminum Sheet Metal

You can see 3/16″ aluminum sheet metal performing in a variety of demanding roles:

- Marine Industry: Building durable boat hulls, transoms, and decks (primarily 5052-H32).

- Automotive & Transportation: Fabricating custom flatbeds, heavy-duty toolboxes, skid plates, and trailer side walls.

- Structural & Industrial: Creating machine base plates, mounting brackets, gussets, and equipment enclosures (primarily 6061-T6).

- Architectural: Used for robust decorative panels, signage, and high-wear surfaces.

Conclusion

Choosing 3/16 inch aluminum sheet metal is a strategic decision for projects demanding a serious upgrade in strength and durability over thinner gauges.

It is a versatile and powerful material, but its successful application hinges entirely on selecting the right alloy for the job.

Remember the fundamental choice: 5052-H32 for superior formability and corrosion resistance, and 6061-T6 for maximum strength and machinability.

By understanding this core difference and respecting the fabrication demands of this robust material, you can leverage the unique advantages of 3/16″ aluminum to build projects that are strong, durable, and built to last.

Frequently Asked Questions (FAQs)

Q1: Is 3/16″ aluminum considered sheet or plate?

Technically, the industry standard in North America defines “sheet” as anything up to 0.249″ thick. So, 3/16″ (0.1875″) is officially a sheet.

However, due to its rigidity and structural applications, many fabricators refer to it colloquially as “plate.”

Q2: Can I bend 3/16″ aluminum in a bench vise?

No. It is far too thick and strong to be bent accurately or safely with hand tools or a standard bench vise.

It requires a hydraulic press brake with appropriate tooling to achieve a clean, controlled bend.

Q3: What is the best way to cut a 3/16″ aluminum sheet at home?

For a DIY setting, the best option is a high-quality circular saw equipped with a carbide-tipped blade specifically designed for cutting non-ferrous metals (like aluminum).

Ensure the sheet is securely clamped, and always wear safety glasses and hearing protection.

Casting production process and its introduction

The purpose of melting and casting is to produce alloys with satisfactory composition and high purity of melt, so as to create favorable conditions for casting alloys of various shapes.

Melting and casting process steps: batching --- feeding --- melting --- stirring after melting, slag removal --- pre-analysis sampling --- adding alloy to adjust the composition, stirring --- refining --- static Setting——Guide furnace casting.

Hot rolling production process and its introduction

- 1. Hot rolling generally refers to rolling above the metal recrystallization temperature;

- 2. During the hot rolling process, the metal has both hardening and softening processes. Due to the influence of deformation speed, as long as the recovery and recrystallization process is too late, there will be a certain work hardening;

- 3. The recrystallization of the metal after hot rolling is incomplete, that is, the coexistence of recrystallized structure and deformed structure;

- 4. Hot rolling can improve the processing performance of metals and alloys, reduce or eliminate casting defects.

- 1. The casting and rolling temperature is generally between 680°C and 700°C. The lower the better, the stable casting and rolling line usually stops once a month or more to re-stand. During the production process, it is necessary to strictly control the liquid level of the front tank to prevent low liquid level;

- 2. Lubrication uses C powder with incomplete combustion of gas for lubrication, which is also one of the reasons for the dirty surface of casting and rolling materials;

- 3. The production speed is generally between 1.5m/min-2.5m/min;

- 4. The surface quality of products produced by casting and rolling is generally relatively low, and generally cannot meet products with special physical and chemical performance requirements.

- 1. Cold rolling refers to the rolling production method below the recrystallization temperature;

- 2. There will be no dynamic recrystallization during the rolling process, and the temperature will rise to the recovery temperature at most, and the cold rolling will appear in a work hardening state, and the work hardening rate will be large;

- 3. The cold-rolled sheet and strip have high dimensional accuracy, good surface quality, uniform structure and performance, and products in various states can be obtained with heat treatment;

- 4. Cold rolling can roll out thin strips, but at the same time, it has the disadvantages of high energy consumption for deformation and many processing passes.

- 1. Finishing is a processing method to make the cold-rolled sheet meet the customer's requirements, or to facilitate the subsequent processing of the product;

- 2. The finishing equipment can correct the defects produced in the hot rolling and cold rolling production process, such as cracked edge, oily, poor plate shape, residual stress, etc. It needs to ensure that no other defects are brought into the production process;

- 3. There are various finishing equipments, mainly including cross-cutting, slitting, stretching and straightening, annealing furnace, slitter, etc.

Casting and rolling process

Casting and rolling process: liquid metal, front box (liquid level control), casting and rolling machine (lubrication system, cooling water), shearing machine, coiling machine.

Cold rolling production process

Introduction to finishing production process

Aluminum alloy has the characteristics of low density, good mechanical properties, good processing performance, non-toxic, easy to recycle, excellent electrical conductivity, heat transfer and corrosion resistance, so it has a wide range of applications.

Aerospace: used to make aircraft skins, fuselage frames, girders, rotors, propellers, fuel tanks, wall panels and landing gear struts, as well as rocket forging rings, spacecraft wall panels, etc.

Aluminum alloy used for aerospace

Transportation: used for car body structure materials of automobiles, subway vehicles, railway passenger cars, high-speed passenger cars, doors and windows, shelves, automotive engine parts, air conditioners, radiators, body panels, wheels and ship materials.

Traffic application

Packaging: All-aluminum pop cans are mainly used as metal packaging materials in the form of thin plates and foils, and are made into cans, lids, bottles, barrels, and packaging foils. Widely used in the packaging of beverages, food, cosmetics, medicines, cigarettes, industrial products, medicines, etc.

Packaging application

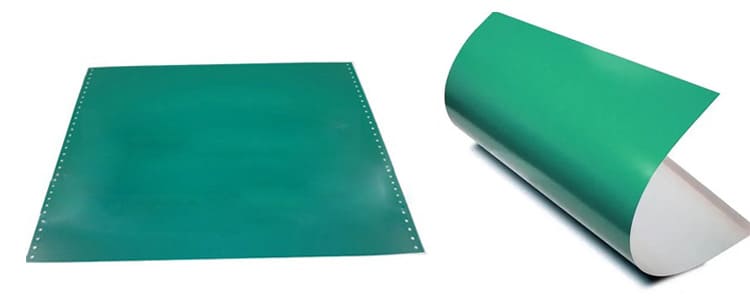

Printing: Mainly used to make PS plates, aluminum-based PS plates are a new type of material in the printing industry, used for automatic plate making and printing.

PS printing

Architectural decoration: aluminum alloy is widely used in building structures, doors and windows, suspended ceilings, decorative surfaces, etc. due to its good corrosion resistance, sufficient strength, excellent process performance and welding performance.

Aluminum alloy construction application

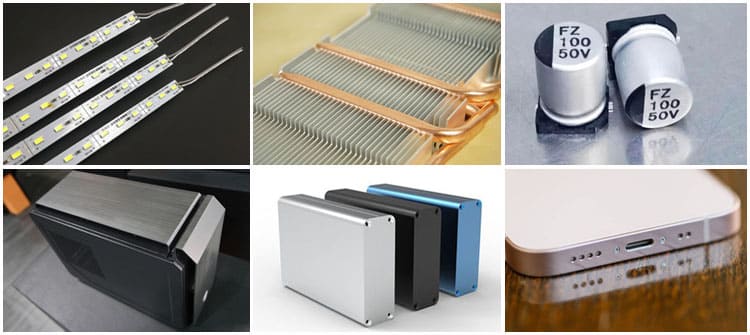

Electronic products: computers, mobile phones, refrigerator shells, radiators, etc.

Electronic product application

Kitchen supplies: aluminum pots, aluminum basins, rice cooker liners, household aluminum foil, etc.

Kitchen application

Packaging Of Aluminum Sheet/Coil

Every detail of packaging is where we pursue perfect service. Our packaging process as a whole is as follows:

Lamination: clear film, blue film, micro-mucosal, high-mucosal, laser cutting film (2 brands, Novacell and Polyphem);

Protection: paper corner protectors, anti-pressure pads;

drying: desiccant;

Tray: fumigated harmless wooden tray, reusable iron tray;

Packing: Tic-tac-toe steel belt, or PVC packing belt;

Material Quality: Completely free from defects such as white rust, oil spots, rolling marks, edge damage, bends, dents, holes, break lines, scratches, etc., no coil set.

Port: Qingdao or other ports in China.

Lead time: 15-45 days.

Aluminum sheet/plate packaging process

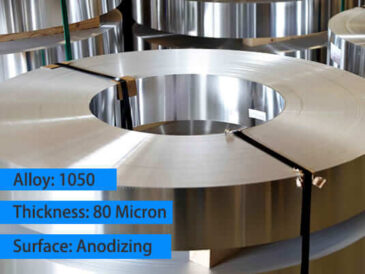

Aluminum coil packaging process

F: Are you a manufacturer or a trader?

Q: We are a manufacturer, our factory is at No.3 Weier Road, Industrial Zone, Gongyi, Henan, China.

F: What is the MOQ for ordering the product?

Q: Our MOQ is 5 tons, and some special products will have a minimum order quantity of 1 or 2 tons.

F: How long is your lead time?

Q: Generally our lead time is about 30 days.

F: Do your products have quality assurance?

Q: Yes, if there is a quality problem with our products, we will compensate the customer until they are satisfied.

Related Products

Latest Blogs

Ultra-high reflectivity aluminum mirror sheet

Ultra-high reflectivity aluminum mirror sheet with 95–98% visible reflectance, low scatter (TIS <1%), and specification advice for BRDF, spectral curves and coatings.

Trusted 3003 Aluminium Checker Plate Sheet Suppliers Worldwide

Find reliable 3003 Aluminium Checker Plate Sheet Suppliers offering certified quality, competitive pricing, custom sizes, and fast global delivery for your projects.

6061 T6 vs 7075 Aluminum: Strength, Weight & Best Uses

Compare 6061 T6 vs 7075 aluminum easily. Discover differences in strength, weight, and applications to choose the best for your projects.

Industrialization and Application of Honeycomb Aluminum Foil

This blog explores the industrialization of honeycomb aluminum foil, focusing on the 3003 alloy production process. It covers hot rolling, continuous casting, and the continuous casting-rolling method, highlighting the benefits of process optimization in improving mechanical properties, reducing energy consumption, and lowering production costs.