1. Introduction

12 gauge aluminum sheet, with a nominal thickness of 2.053 mm (0.0808 inches) as defined by the American Wire Gauge (AWG) standard, represents a significant step up from thin-gauge materials into the realm of semi-structural and high-durability applications.

This medium-thickness sheet provides a powerful combination of substantial rigidity, high strength, and excellent impact resistance while retaining the core aluminum advantages of light weight and corrosion immunity.

Commonly specified in high-performance alloys such as 5052-H32 for marine and transportation use and 6061-T6 for structural and mechanical components, its properties are heavily influenced by the chosen alloy and temper.

12 gauge aluminum sheet is a cornerstone material for applications like boat hulls, heavy-duty truck bodies, industrial tread plate, and structural base plates, offering a perfectly balanced solution where the lightness of thin-gauge sheets is insufficient and the weight of heavy plates is unnecessary.

12 Gauge Aluminum Sheet

2. What is a 12 Gauge Aluminum Sheet?

A 12 gauge aluminum sheet is a mid-thickness sheet commonly used where a balance of stiffness, formability and durability is needed.

In standard U.S. sheet-metal gauge for aluminum, 12 gauge ≈ 0.0808 in ≈ 2.0523 mm.

Exact conversions

- Nominal gauge (U.S. aluminium gauge): 12 ga = 0.0808 inches.

- Convert to millimetres:

0.0808 in × 25.4 mm/in = 2.05232 mm→ 2.0523 mm (commonly quoted as 2.05 mm). - Convert to metres for areal mass:

2.05232 mm = 0.00205232 m.

Mass per unit area

Use aluminium density ≈ 2,700 kg/m³.

- Mass per m² = density × thickness (m)

=2,700 kg/m³ × 0.00205232 m = 5.541264 kg/m²→ ≈ 5.54 kg/m². - In imperial units:

5.541264 kg/m² × 0.204816 lb·ft⁻² per (kg·m⁻²)≈ 1.135 lb/ft².

(Practical example: a standard 4’×8′ sheet ≈ 2.973 m² → mass ≈ 2.973 × 5.5413 ≈ 16.47 kg.)

Typical supply forms & sizes

- Coil (for continuous processing) or cut sheets/plates.

- Common sheet sizes: 4′×8′ (1219 × 2438 mm), 4′×10′, 1,220 × 2,440 mm, and custom cut-to-length/blanking to customer drawings.

- Edge condition: mill edge, sheared, or slitted — specify if burr-free or saw cut is required.

Typical tolerances & finishes to specify

- Thickness tolerance (typical): ±0.03–0.05 mm for commercial stock; tighter tolerances available on request.

- Flatness: vary by supplier — state maximum bow/warp if critical (e.g., ≤0.5 mm/m or a flatness value).

- Surface finishes: mill, brushed, stucco/embossed, anodized, painted, protective film — choose per appearance and corrosion needs.

12 Gauge 4×8 Aluminum Sheet

3. Common Alloys of 12 Gauge Aluminum Sheet

| Alloy | Series | Main Alloying Elements | Common Tempers (12 ga) | Typical Strength Range (MPa)* | Corrosion Resistance | Typical 12 Gauge Applications |

|---|---|---|---|---|---|---|

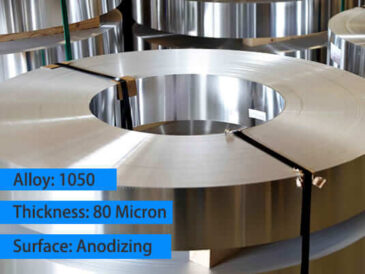

| 1050 | 1xxx | ≥99.5% Al | H14 / O | YS: ~30–55 UTS: ~80–105 | Very Good | Decorative panels, lighting reflectors, light-duty structures |

| 1060 | 1xxx | ≥99.6% Al | H14 / O | YS: ~35–60 UTS: ~90–110 | Very Good | Electrical enclosures, chemical linings |

| 1100 | 1xxx | ≥99.0% Al | H14 / O | YS: ~35–60 UTS: ~90–115 | Very Good | Deep-drawn parts, signage, decorative sheet metal |

| 3003 | 3xxx | Al–Mn (~1.0%) | H14 / H24 | YS: ~80–110 UTS: ~150–190 | Very Good | HVAC ducting, appliance panels, architectural sheet |

| 3004 | 3xxx | Al–Mn–Mg | H34 | YS: ~120–170 UTS: ~200–285 | Very Good | Transport panels, containers |

| 3105 | 3xxx | Al–Mn–Mg | H14 / H24 | YS: ~90–130 UTS: ~160–205 | Very Good | Building facades, color-coated base sheets |

| 5052 | 5xxx | Al–Mg (2.2–2.8%) | H32 / H34 | YS: ~110–170 UTS: ~200–300 | Excellent | Marine structures, fuel tanks, outdoor enclosures |

| 5754 | 5xxx | Al–Mg (2.6–3.6%) | H22 / H114 | YS: ~120–185 UTS: ~220–290 | Excellent | Marine flooring, automotive panels, platforms |

| 5083 | 5xxx | Al–Mg–Mn | H111 | YS: ~125–215 UTS: ~275–350 | Excellent | Offshore structures, shipbuilding (secondary structures at 12 ga) |

| 6061 | 6xxx | Al–Mg–Si | T6 / T4 | YS: ~150–240 UTS: ~310–420 | Fair to Good | Structural brackets, anodized components |

| 6063 | 6xxx | Al–Mg–Si | T5 / T6 | YS: ~100–180 UTS: ~190–310 | Good | Architectural panels, anodized decorative sheets |

*YS = Yield Strength (0.2% offset); UTS = Ultimate Tensile Strength

Boat Hull used 12 Gauge Aluminum Sheet

4. Properties of 12 Gauge Aluminum Sheet

The properties of a 12 gauge aluminum sheet are influenced by alloy series, temper condition, and manufacturing route.

At approximately 2.05 mm thickness, 12 gauge aluminum provides a balanced combination of structural integrity, formability, corrosion resistance, and thermal performance, making it suitable for both structural and non-structural applications.

Physical Properties

Aluminum’s inherent physical characteristics remain consistent across most alloys, with minor variations due to alloying elements.

| Property | Typical Value |

|---|---|

| Density | ~2.70 g/cm³ |

| Melting point | ~660 °C |

| Modulus of elasticity | ~69 GPa |

| Poisson’s ratio | ~0.33 |

| Sheet thickness (12 gauge) | ~2.05 mm |

| Surface appearance | Metallic silver, matte to bright |

Key insight:

At 12 gauge thickness, aluminum weighs approximately one-third of carbon steel of equivalent thickness, delivering significant weight savings without sacrificing functional rigidity.

Representative Mechanical Properties

Mechanical performance varies significantly by alloy and temper.

| Alloy Series | Typical Temper | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|---|

| 1xxx (1050/1060/1100) | H14 / O | 30–60 | 90–115 | 25–40 |

| 3xxx (3003/3105) | H14 / H24 | 80–130 | 150–205 | 15–25 |

| 5xxx (5052/5754) | H32 / H22 | 110–185 | 200–300 | 12–22 |

| 6xxx (6061/6063) | T4 / T6 | 100–240 | 190–420 | 8–18 |

Engineering relevance:

- Lower-strength alloys offer superior forming and bending capability

- 5xxx and 6xxx series provide enhanced structural performance at 12 gauge thickness

12 Gauge 3004 h14 Aluminum Sheet

Thermal and Electrical Conductivity

Aluminum is widely valued for its ability to efficiently conduct heat and electricity.

| Property | Typical Range |

|---|---|

| Thermal conductivity | ~130–235 W/m·K |

| Electrical conductivity | ~35–61% IACS |

| Thermal expansion coefficient | ~23 ×10⁻⁶ /K |

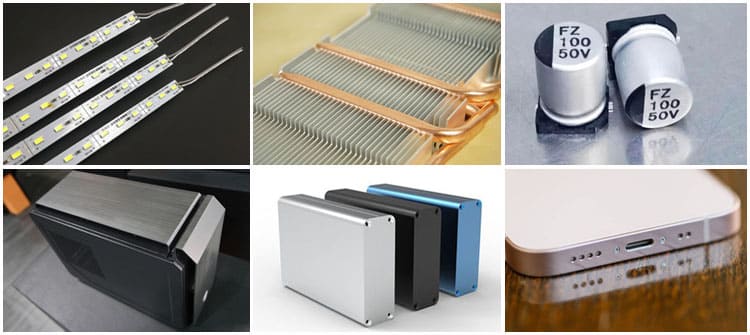

Practical advantage:

12 gauge aluminum sheets are commonly used in heat shields, enclosures, and electrical housings, where moderate strength and efficient heat dissipation are required.

Corrosion Resistance

Aluminum naturally forms a dense aluminum oxide (Al₂O₃) film, providing intrinsic corrosion protection.

- Excellent resistance in atmospheric and freshwater environments

- 5xxx series alloys (5052, 5754) exhibit superior resistance to marine and saline conditions

- 6xxx series alloys perform well outdoors but may require surface treatments in aggressive environments

Enhancement methods: anodizing, powder coating, painting, or cladding.

5. Manufacturing Process of 12 Gauge Aluminum Sheets

Typical industrial route and key quality control points:

- Feedstock & melting: primary ingots or cleaned scrap melted; degassing and fluxing reduce hydrogen and inclusions.

- Casting: ingot casting or continuous casting (CC) to produce slabs/strips. Continuous casting + rolling (CCR) gives good surface quality.

- Hot rolling: slab → hot pass reductions to homogenize and prepare for cold rolling; scale removal and pickling between passes.

- Cold rolling: to final gauge with inter-anneals as required; tight thickness control achieved with modern rolling mills and online gauges.

- Annealing / tempering: controlled furnaces to achieve O or H tempers; stretcher leveling may be applied for flatness.

- Surface finishing: bright-rolling, stucco/embossing, pre-anodize chemical treatments or cleaning.

- Cutting / slitting / blanking: to customer sizes; waterjet/laser used for tight profiles; careful edge processing avoids burrs.

- Inspection & packaging: thickness mapping, visual surface inspection, MTC issuance and protective packing to avoid scratches.

Huawei packaged Aluminum Sheet

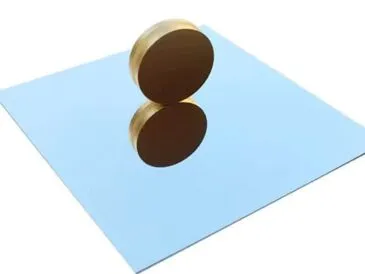

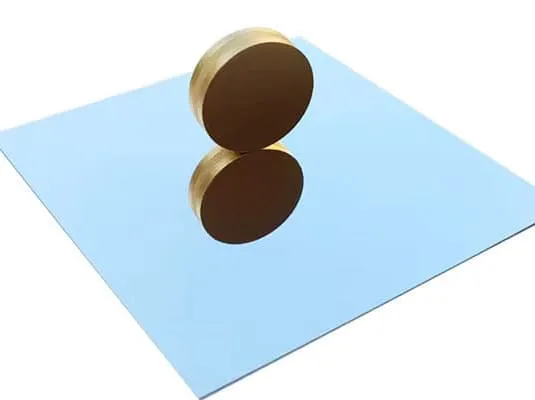

6. Surface finishes, coatings & aesthetics

- Mill finish: economical, raw surface appearance.

- Brushed: hides scratches and gives attractive linear grain for panels and architecturals.

- Bright-rolled / mirror polish: high reflectivity used for reflectors and decorative trims (requires high-purity alloys and controlled rolling).

- Stucco/embossed: used for slip resistance (tread) or to hide marks.

- Anodized: enhances corrosion resistance and appearance; note colour range and adhesion differ by alloy (6xxx alloys anodize better than pure 1xxx).

- Powder coating / liquid paint: requires pre-treatment (chemical film / conversion coating) and bake curing; provides durable colours and extra corrosion protection.

- Food-grade coatings: if used in food contact areas, require documented compliance (FDA / EU food contact) and thermal stability certification.

7. Applications of 12 Gauge Aluminum Sheet

With a thickness of approximately 2.05 mm, 12 gauge aluminum sheet offers an optimal balance between strength, formability, and weight efficiency. This makes it suitable for a wide range of structural, semi-structural, and decorative applications across multiple industries.

Construction and Architectural Applications

- Exterior wall panels and façade systems

- Roofing sheets, flashing, and coping

- Decorative cladding and architectural trims

- Sunshades, louvers, and canopies

Advantages: corrosion resistance, low maintenance, and compatibility with anodized or coated finishes.

12 Gauge Aluminum Sheet for Construction

Transportation and Automotive Industry

- Truck and trailer panels

- Vehicle body panels and reinforcements

- Bus flooring substrates and sidewalls

- Railway carriage interior and exterior panels

Using aluminum instead of steel at this thickness can reduce component weight by up to 60–65%, contributing to improved fuel efficiency and lower emissions.

Marine and Offshore Applications

When produced from 5xxx series alloys (e.g., 5052 or 5754), 12 gauge aluminum sheets perform well in marine environments:

- Small boat hull components and decks

- Walkways and access platforms

- Marine equipment housings

- Dock and pier structural panels

Their excellent resistance to seawater corrosion and good weldability make them a preferred choice for marine fabrication.

Industrial Equipment and Enclosures

- Machine guards and safety covers

- Electrical and control cabinets

- Heat shields and insulation panels

- Storage containers and bins

HVAC and Energy Systems

- HVAC ducting and casings

- Heat exchanger covers

- Solar panel frames and backing sheets

- Battery and energy storage enclosures

12 Gauge Aluminum Sheet For HVAC

Consumer Products and General Fabrication

- Appliance housings and panels

- Furniture frames and decorative elements

- Signage, nameplates, and display systems

- Custom metal fabrication projects

8. Standards, testing & certification

When specifying 12-ga sheet, reference the appropriate standards and require documentation:

- ASTM B209 — aluminium & aluminium-alloy sheet and plate (North America).

- EN 485 / EN 573 — European standards for chemical & mechanical properties and tolerances.

- ISO 6361 — international standard for wrought aluminium plates & sheets.

- EN 10204 3.1 — mill test certificate for chemical and tensile results (or equivalent).

- Surface/coating standards: e.g., AA-5xx anodizing practice, paint system test methods (ASTM D3359 adhesion, salt spray ASTM B117).

- Inspection tests to request: thickness mapping, tensile coupons, visual surface acceptance, bend test if forming critical, and coating adhesion / salt spray where required.

9. Huawei Aluminum — 12 Gauge Aluminum Plate Specifications

Product: 12 gauge aluminium sheet — nominal 0.0808 in / 2.052 mm

Alloy/Temper options: 1100-H14, 3003-H14, 5052-H32, 5754-H22, 6061-T6, etc.

Thickness tolerance: ±0.03 mm (standard) — tighter tolerances available on agreement.

Sheet sizes: standard 4′×8′ (1219×2438 mm), 5′×10′ and custom cut-to-length.

Finish: mill / brushed / anodized / pre-paint (specify).

Documentation: EN 10204 3.1 MTC per heat/lot, chemical analysis and tensile report.

Packaging: interleaved with protective film, strapped to pallet, labeled with alloy/temper/heat number.

Inspection: supplier to provide dimensional report and two sample tensile coupons per lot.

(Adapt the clause to your corporate QA language; require sample approval before full production for critical lots.)

10. Comparisons with alternatives

| Characteristic | 12 ga Aluminum (typical alloy 5052) | 12 ga Steel (mild) | Stainless steel 304 (12 ga) | Composite panel |

|---|---|---|---|---|

| Density (kg/m³) | ~2,700 | ~7,850 | ~7,900 | varies (lighter) |

| Mass per m² (for 2.052 mm) | ~5.54 kg/m² | ~16.09 kg/m² | ~16.20 kg/m² | depends |

| Corrosion resistance | Very good (esp. 5xxx) | Poor (needs coatings) | Excellent | Good (depending on resin) |

| Formability | Excellent | Poorer at thin gauges | Moderate | Moldable |

| Welding & joining | Excellent | Excellent | Good | Adhesive/laminate |

| Cost per kg | Higher than steel per kg | Lower per kg | Much higher per kg | Variable |

| Typical choice when | Weight, corrosion, finish matter | low cost & high stiffness | sanitation, high temp | bespoke properties (insulation/weight) |

Key takeaway: aluminium at 12 ga delivers large weight savings and corrosion resistance vs steel, with easier forming and aesthetic finishes; choose steel or stainless when stiffness, impact resistance or extreme wear are primary drivers.

11. Conclusion

12 gauge aluminium sheet (~2.05 mm) is a practical, widely used thickness combining strength, formability and surface finish potential.

Success hinges on picking the correct alloy and temper for the environment and fabrication method, specifying finishes and tolerances explicitly, and requiring appropriate test certificates.

When designed intelligently (stiffening, fastening, finish), 12 ga aluminium provides low weight, long service life and attractive aesthetics for industrial, architectural and transportation applications.

12. FAQs

Q1 — Exactly how thick is 12 gauge aluminum in mm?

A: 12 gauge ≈ 0.0808 inches = 2.05232 mm. Always show metric thickness on drawings to remove ambiguity.

Q2 — How much does 12 ga aluminum weigh per square metre?

A: Using ρ = 2,700 kg/m³, mass ≈ 5.54 kg/m².

Q3 — Can I weld 12 ga aluminium with MIG?

A: Yes — MIG (GMAW) and TIG (GTAW) are common. Control heat input to avoid warpage; use appropriate filler for alloy (e.g., ER5356 for 5xxx alloys).

Q4 — What bend radius should I use for 12 ga?

A: As a practical starting point, use an internal bend radius of ~1–2× thickness → ~2–4 mm. Validate with sample parts because temper and alloy affect springback.

Q5 — Which alloy should I choose for exterior marine use?

A: Prefer 5052 or 5754 for marine-exposed panels and topside applications. For primary hull plating use higher-strength marine alloys (e.g., 5083).

Casting production process and its introduction

The purpose of melting and casting is to produce alloys with satisfactory composition and high purity of melt, so as to create favorable conditions for casting alloys of various shapes.

Melting and casting process steps: batching --- feeding --- melting --- stirring after melting, slag removal --- pre-analysis sampling --- adding alloy to adjust the composition, stirring --- refining --- static Setting——Guide furnace casting.

Hot rolling production process and its introduction

- 1. Hot rolling generally refers to rolling above the metal recrystallization temperature;

- 2. During the hot rolling process, the metal has both hardening and softening processes. Due to the influence of deformation speed, as long as the recovery and recrystallization process is too late, there will be a certain work hardening;

- 3. The recrystallization of the metal after hot rolling is incomplete, that is, the coexistence of recrystallized structure and deformed structure;

- 4. Hot rolling can improve the processing performance of metals and alloys, reduce or eliminate casting defects.

- 1. The casting and rolling temperature is generally between 680°C and 700°C. The lower the better, the stable casting and rolling line usually stops once a month or more to re-stand. During the production process, it is necessary to strictly control the liquid level of the front tank to prevent low liquid level;

- 2. Lubrication uses C powder with incomplete combustion of gas for lubrication, which is also one of the reasons for the dirty surface of casting and rolling materials;

- 3. The production speed is generally between 1.5m/min-2.5m/min;

- 4. The surface quality of products produced by casting and rolling is generally relatively low, and generally cannot meet products with special physical and chemical performance requirements.

- 1. Cold rolling refers to the rolling production method below the recrystallization temperature;

- 2. There will be no dynamic recrystallization during the rolling process, and the temperature will rise to the recovery temperature at most, and the cold rolling will appear in a work hardening state, and the work hardening rate will be large;

- 3. The cold-rolled sheet and strip have high dimensional accuracy, good surface quality, uniform structure and performance, and products in various states can be obtained with heat treatment;

- 4. Cold rolling can roll out thin strips, but at the same time, it has the disadvantages of high energy consumption for deformation and many processing passes.

- 1. Finishing is a processing method to make the cold-rolled sheet meet the customer's requirements, or to facilitate the subsequent processing of the product;

- 2. The finishing equipment can correct the defects produced in the hot rolling and cold rolling production process, such as cracked edge, oily, poor plate shape, residual stress, etc. It needs to ensure that no other defects are brought into the production process;

- 3. There are various finishing equipments, mainly including cross-cutting, slitting, stretching and straightening, annealing furnace, slitter, etc.

Casting and rolling process

Casting and rolling process: liquid metal, front box (liquid level control), casting and rolling machine (lubrication system, cooling water), shearing machine, coiling machine.

Cold rolling production process

Introduction to finishing production process

Aluminum alloy has the characteristics of low density, good mechanical properties, good processing performance, non-toxic, easy to recycle, excellent electrical conductivity, heat transfer and corrosion resistance, so it has a wide range of applications.

Aerospace: used to make aircraft skins, fuselage frames, girders, rotors, propellers, fuel tanks, wall panels and landing gear struts, as well as rocket forging rings, spacecraft wall panels, etc.

Aluminum alloy used for aerospace

Transportation: used for car body structure materials of automobiles, subway vehicles, railway passenger cars, high-speed passenger cars, doors and windows, shelves, automotive engine parts, air conditioners, radiators, body panels, wheels and ship materials.

Traffic application

Packaging: All-aluminum pop cans are mainly used as metal packaging materials in the form of thin plates and foils, and are made into cans, lids, bottles, barrels, and packaging foils. Widely used in the packaging of beverages, food, cosmetics, medicines, cigarettes, industrial products, medicines, etc.

Packaging application

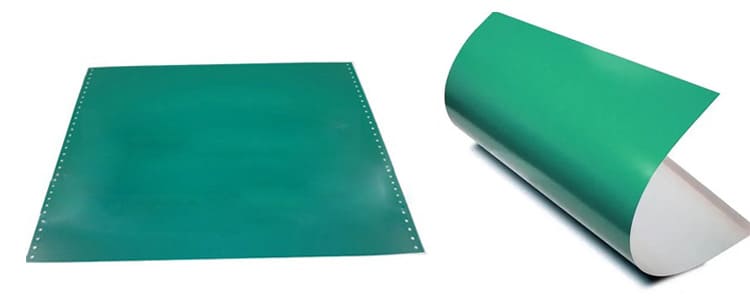

Printing: Mainly used to make PS plates, aluminum-based PS plates are a new type of material in the printing industry, used for automatic plate making and printing.

PS printing

Architectural decoration: aluminum alloy is widely used in building structures, doors and windows, suspended ceilings, decorative surfaces, etc. due to its good corrosion resistance, sufficient strength, excellent process performance and welding performance.

Aluminum alloy construction application

Electronic products: computers, mobile phones, refrigerator shells, radiators, etc.

Electronic product application

Kitchen supplies: aluminum pots, aluminum basins, rice cooker liners, household aluminum foil, etc.

Kitchen application

Packaging Of Aluminum Sheet/Coil

Every detail of packaging is where we pursue perfect service. Our packaging process as a whole is as follows:

Lamination: clear film, blue film, micro-mucosal, high-mucosal, laser cutting film (2 brands, Novacell and Polyphem);

Protection: paper corner protectors, anti-pressure pads;

drying: desiccant;

Tray: fumigated harmless wooden tray, reusable iron tray;

Packing: Tic-tac-toe steel belt, or PVC packing belt;

Material Quality: Completely free from defects such as white rust, oil spots, rolling marks, edge damage, bends, dents, holes, break lines, scratches, etc., no coil set.

Port: Qingdao or other ports in China.

Lead time: 15-45 days.

Aluminum sheet/plate packaging process

Aluminum coil packaging process

F: Are you a manufacturer or a trader?

Q: We are a manufacturer, our factory is at No.3 Weier Road, Industrial Zone, Gongyi, Henan, China.

F: What is the MOQ for ordering the product?

Q: Our MOQ is 5 tons, and some special products will have a minimum order quantity of 1 or 2 tons.

F: How long is your lead time?

Q: Generally our lead time is about 30 days.

F: Do your products have quality assurance?

Q: Yes, if there is a quality problem with our products, we will compensate the customer until they are satisfied.

Related Products

Latest Blogs

Ultra-high reflectivity aluminum mirror sheet

Ultra-high reflectivity aluminum mirror sheet with 95–98% visible reflectance, low scatter (TIS <1%), and specification advice for BRDF, spectral curves and coatings.

Trusted 3003 Aluminium Checker Plate Sheet Suppliers Worldwide

Find reliable 3003 Aluminium Checker Plate Sheet Suppliers offering certified quality, competitive pricing, custom sizes, and fast global delivery for your projects.

6061 T6 vs 7075 Aluminum: Strength, Weight & Best Uses

Compare 6061 T6 vs 7075 aluminum easily. Discover differences in strength, weight, and applications to choose the best for your projects.

Industrialization and Application of Honeycomb Aluminum Foil

This blog explores the industrialization of honeycomb aluminum foil, focusing on the 3003 alloy production process. It covers hot rolling, continuous casting, and the continuous casting-rolling method, highlighting the benefits of process optimization in improving mechanical properties, reducing energy consumption, and lowering production costs.