Industrialization and Application of Honeycomb Aluminum Foil

14,266 Views 2025-11-25 03:22:57

Research on the Industrial Application of Honeycomb Aluminum Foil

Honeycomb sandwich composite materials are lightweight, have good compressive energy absorption, and possess high specific stiffness and specific strength.

With minimal weight increase, they can effectively improve bending stiffness and enhance the ability to withstand bending moments and pressures, making them an ideal lightweight industrial material.

Currently, with increasing interdisciplinary collaboration, honeycomb sandwich materials are attracting more and more attention from researchers.

The rapid development and maturation of production processes in recent years have led to a significant decrease in production costs, driving the application of honeycomb sandwich materials from military and aerospace fields to civilian and commercial sectors.

Currently, the most widely used honeycomb sandwich structures on the market are mostly hexagonal honeycomb structures that mimic natural honeycombs.

The most commonly used include aluminum honeycomb, Nomex honeycomb, paper honeycomb, and fiberglass honeycomb, which are widely used in the automotive, shipbuilding, construction, and packaging industries.

This paper will focus on discussing the industrial production methods, processes, and mechanical properties of aluminum honeycomb sandwich materials.

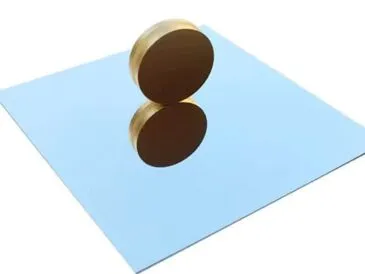

Aluminum foil honeycomb core

1. Aluminum Honeycomb Sandwich Structure

An aluminum honeycomb sandwich structure consists of a face panel, a base panel, and a thick, lightweight aluminum honeycomb core sandwiched between them.

The face panel and the core are bonded together with an adhesive to form a rigid, integrated structure.

The top and bottom panels are typically made of 3003 or 5052 alloy aluminum sheets, and can also be laminated with fireproof boards, stone, or ceramics.

Surface treatments for the face panels include fluorocarbon coating, roller coating, heat transfer printing, brushing, and oxidation. The thickness of the laminated face panels is 0.4–2.0 mm.

The frame material is 6063-T4 aluminum profile or stainless steel. The aluminum honeycomb core material is mostly made of 3003 or 5052 aluminum foil.

Due to the higher processing cost of 5052 alloy, 3003 alloy is currently the most widely used in the commercial market. The thickness of the aluminum foil in the honeycomb core ranges from 0.02 to 0.08 mm, and the side lengths of the aluminum honeycomb are available in 5 mm, 6 mm, 8 mm, 10 mm, and 12 mm.

Honeycomb cores can be categorized by shape, including square, rhomboid, circular, and regular hexagonal.

Comparing the structures and performance of various shapes, the regular hexagonal structure is simple to manufacture, uses less material, has high structural efficiency, and offers better pressure and tensile resistance, making it the most widely used type. The overall thickness of the honeycomb panel is 15-25 mm.

2. Aluminum Honeycomb Foil Blank Processing

Cold-rolled strip blanks are mainly processed using three methods: hot-rolled ingot casting, twin-roll continuous casting and rolling, and Hazlett continuous casting and rolling.

Conventional 3003 alloy honeycomb foil products utilize a melt-casting direct-cooling hot-rolling casting process.

During smelting, aluminum ingots with a content of 99.7% or higher, solid waste, and 10% to 30% electrolytic aluminum liquid are placed in a smelting furnace.

The molten aluminum is formed into ingots (large flat ingots) of 400-600 mm thickness through molds of different sizes.

The ingots need to be sawed at both ends, milled, and reheated to 480-550℃ and held for 20-25 hours before being sent to a double-coil hot rolling mill.

Through high-pressure, multi-pass rolling, hot-rolled aluminum coils of 6-8 mm thickness are produced, which are then transferred to the cold rolling process for further rolling.

Hot rolling equipment requires high investment, involves complex processes, consumes a lot of energy, has a long production cycle, and results in relatively high production costs.

It is generally used to produce can stock, automotive steel sheets, thick hard alloy plates, high-end CTP plates, and electronic aluminum foil.

Twin-roll continuous casting and rolling has three forms: top-pour, horizontal, and inclined. Their casting process is largely the same.

First, aluminum ingots with a content of 99.7% or higher, solid waste, and 20% to 60% electrolytic aluminum liquid are used as raw materials.

These are melted in a furnace to form aluminum or aluminum alloy melt. The temperature is generally below 760℃, 90 to 100℃ higher than the melting point of aluminum or aluminum alloy, using the lowest possible temperature.

Huawei 3003 aluminum foil jumbo roll

After refining and settling, the molten aluminum is transferred to a holding furnace where the temperature is controlled at 720-740℃. It then flows through a spout and a trough into a degassing device, where a grain refiner is added online.

After filtration, it flows into a front chamber where the liquid level can be controlled. It then passes through a casting nozzle made of aluminum silicate material with flow dividers, and enters the space between casting rolls that rotate in the same direction and are equipped with circulating cooling water, forming a 6-8 mm cast strip.

This strip is then coiled into a cast coil of a certain width using a coiling device. The twin-roll continuous casting and rolling process requires less investment, is highly efficient, has low energy consumption, and low production costs.

During production, the molten metal undergoes rapid cooling in the casting and rolling zone, with cooling rates reaching 102-103 °C/s. Solidification occurs through rapid, directional thermal crystallization, resulting in highly directional crystal growth, almost perpendicular to the surface of the casting rolls.

This process is characterized by the formation of numerous dendritic crystals, accompanied by some segregation. Locally, the dendritic crystals in the strip center rapidly grow into columnar crystals, forming an angle of 55°-65° with the strip center.

When producing 6-7 mm thick 3003 alloy, with a casting speed of 600-800 mm/min, the resulting microstructure exhibits segregation and locally coarse grains.

This not only increases production instability but also leads to decreased product performance stability after subsequent rolling processes.

High-throughput (Hazlett) continuous casting and rolling utilizes a melt-holding furnace, employing 80%-85% molten aluminum and 15%-20% solid material for in-furnace melting, with the melting temperature controlled at 740-760 °C.

The process employs an HD2000 refining mill, where a specific ratio of Ar and Cl₂ is injected via a high-speed rotating graphite rotor. After settling for >1 hour, the molten aluminum flows through a flow channel into the inlet of the SNIF degassing chamber.

A grain refiner is added at the inlet. The molten aluminum then flows through a filter box into a front chamber with a stable and adjustable liquid level. Under hydrostatic pressure, the molten aluminum flows into a vacuum-insulated casting nozzle tilted downwards at approximately 6°.

The nozzle is filled with circulating water, supported by magnetic support rollers, and continuously casts a 19 mm thick slab between upper and lower steel strips with a specific coating on their outer surface.

The cooling rate during casting reaches 30~80 ℃/s, falling between that of traditional hot rolling and twin-roll continuous casting. When producing 3003 aluminum foil, the grain structure is close to that of hot-rolled ingots.

The cast slab is fed directly into a three-roll mill for hot continuous rolling, producing 3003 alloy slabs with a thickness of 2.5~4.5 mm. The casting speed is 6.5~8 m/min, the rolling speed is 30~80 m/min, and the throughput is 35~50 t/h. This high-throughput continuous casting and rolling process boasts high production efficiency.

Compared to hot rolling, it eliminates sawing, milling, and homogenization processes, not only improving production efficiency and shortening the work-in-process cycle, but also saving 500 kWh/t in electricity consumption and reducing overall costs by over 600 yuan/t.

Current domestic research primarily focuses on using hot-rolled ingot casting to produce 3003 alloy honeycomb foil sandwich materials, while research on high-throughput continuous casting and rolling processes for producing 3003 alloy honeycomb foil sandwich materials is almost nonexistent.

Industrialization and application of honeycomb aluminum foil

3. Experimental Procedure

The traditional hot-rolled 6-8 mm billet rolling process is as follows: 6-8 mm billet → homogenization → cold rolling → 0.02-0.08 mm → slitting → coating → curing → honeycomb core finished product.

The high-throughput continuous casting and rolling process is: 2.5-4.5 mm billet → homogenization → cold rolling → 0.02-0.08 mm → slitting → coating → curing. This experiment refers to the national standard 3003 alloy composition, and the smelting process adopts a unified control standard.

The specific alloy composition is shown in Table 1.

| Alloy Grade | Si | Fe | Cu | Mn | Mg | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|

| National Standard | 0.60 | 0.70 | 0.02~0.20 | 1.00~1.50 | — | 0.10 | — | Remainder |

| Experimental | 0.16 | 0.47 | 0.10 | 1.14 | 0.02 | 0.05 | 0.01~0.03 | Remainder |

The homogenization process for the 3003 alloy billet is 550 ℃ for 25-35 h. After homogenization, the hot-rolled stock had a thickness of 7.0 mm, a tensile strength of 106 MPa, and an elongation of 43%.

The continuously cast and rolled billet had a thickness of 3.5 mm, a tensile strength of 117 MPa, and an elongation of 39%.

Both billets were homogenized and processed using the same method, resulting in a finished product thickness of 0.038 mm.

Samples of the finished product were cut into 30 mm × 180 mm pieces, and their mechanical properties and heat-sealing strength were tested.

The hot-rolled stock had a tensile strength of 264 MPa, an elongation of 4.5%, and a heat-sealing strength of 15 N.

The continuously cast and rolled stock had a tensile strength of 272 MPa, an elongation of 3.8%, and a heat-sealing strength of 16 N.

According to market feedback, the mechanical properties of ordinary honeycomb aluminum foil finished products require a tensile strength >260 MPa, elongation >3%, heat seal strength >14 N, and a flat and clean surface to avoid affecting downstream adhesive application.

Comparing these data, it is clear that aluminum honeycomb foil sandwich materials produced using the high-throughput continuous casting and rolling process have significant advantages, including a shorter production process, higher yield, lower energy consumption, and better product performance.

4. Conclusion

The high-throughput continuous casting and rolling process for producing 3003 alloy honeycomb foil blanks, compared to the traditional hot rolling process, can significantly shorten the process flow and improve the yield while ensuring product quality.

High-throughput continuous casting and rolling of 3003 alloy 3.5 mm and hot rolling of 7.0 mm blanks followed the same production process, resulting in virtually no difference in the mechanical properties of the finished products, both meeting the quality requirements of aluminum honeycomb foil.